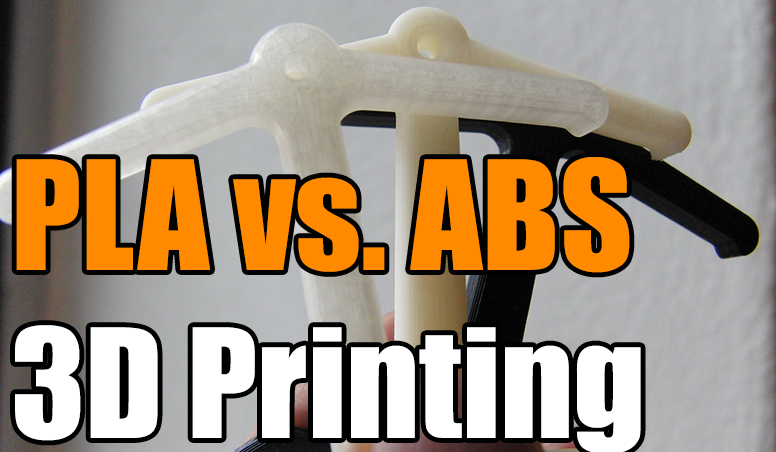

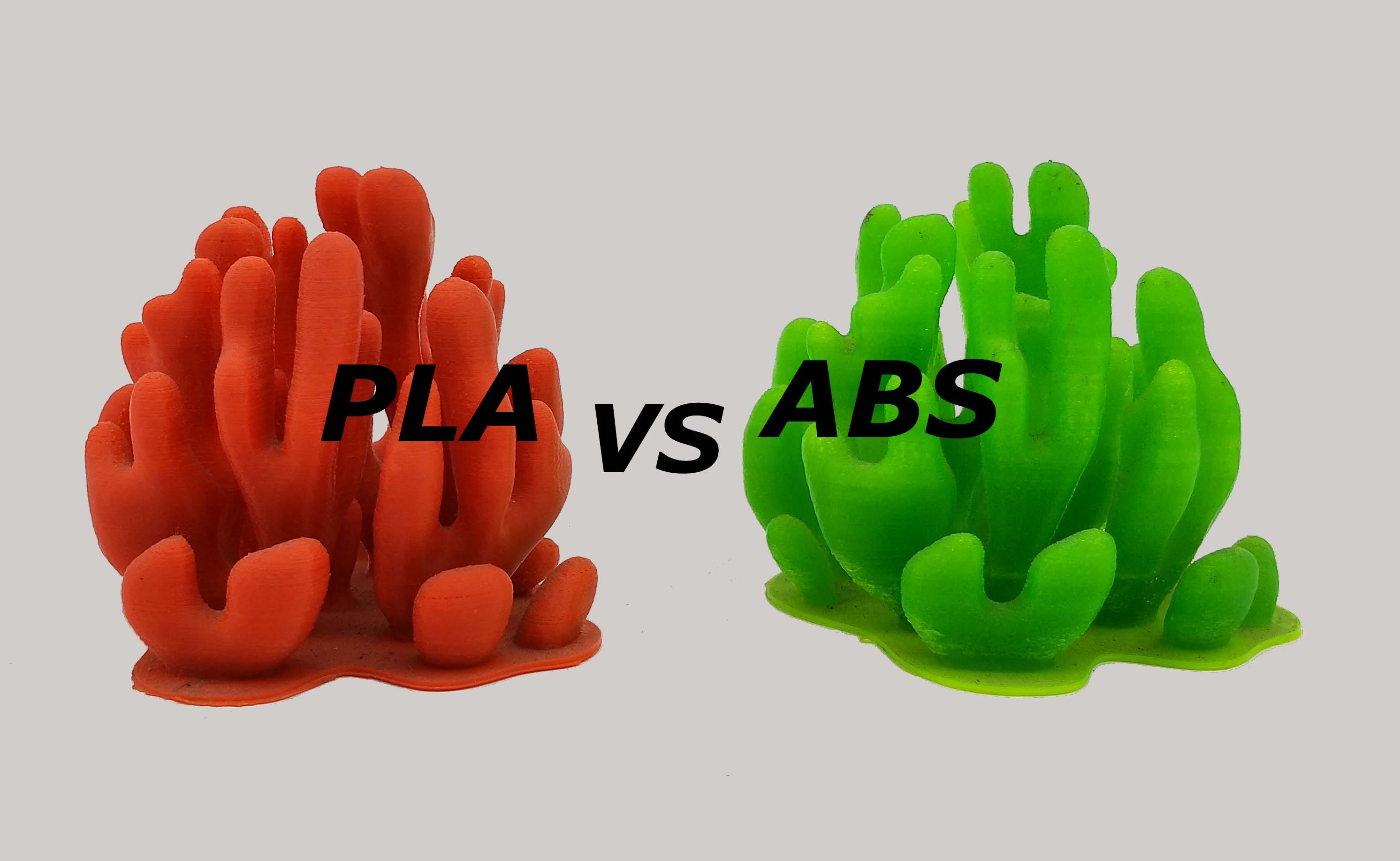

3d Printing Pla Vs Abs

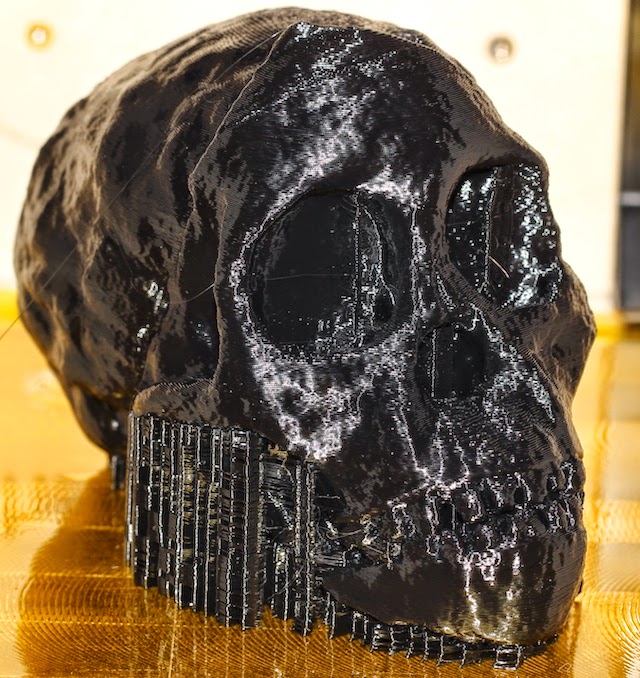

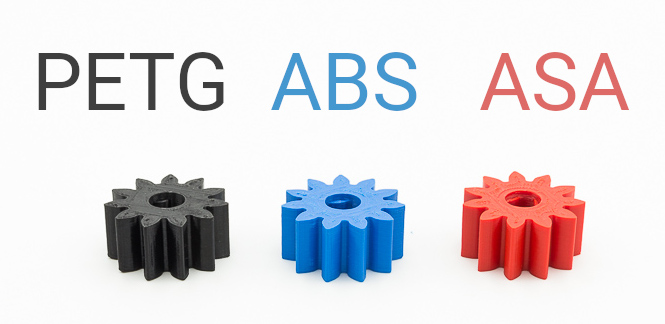

Abs is best suited for applications where strength ductility machinability and thermal stability are required.

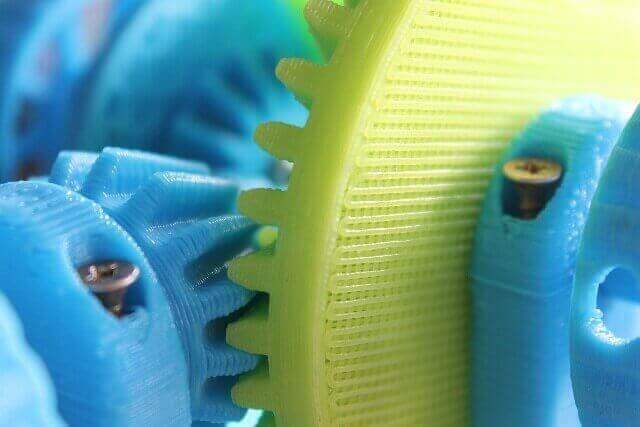

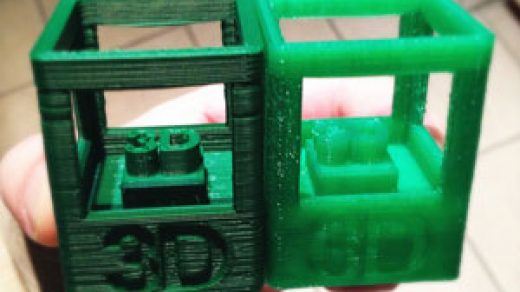

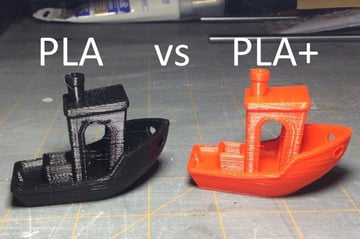

3d printing pla vs abs. However pla is preferred over abs when it comes to the sharpness of corners and features. Printing details down to 02mm and minimum features down to 12mm are possible using abs and pla filaments. Abs is ideal for printing parts and applications that need ductility high thermal stability and high strength. Pla polylactic acid is also a thermoplastic material made from corn starch.

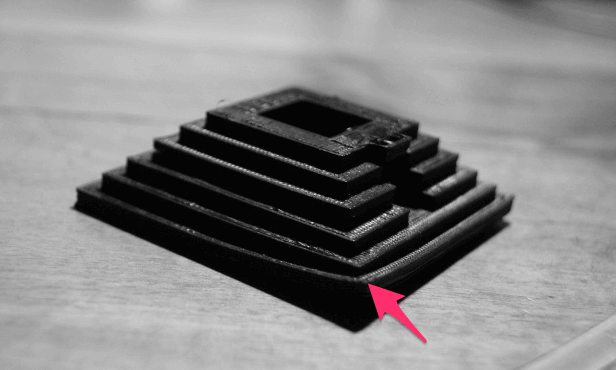

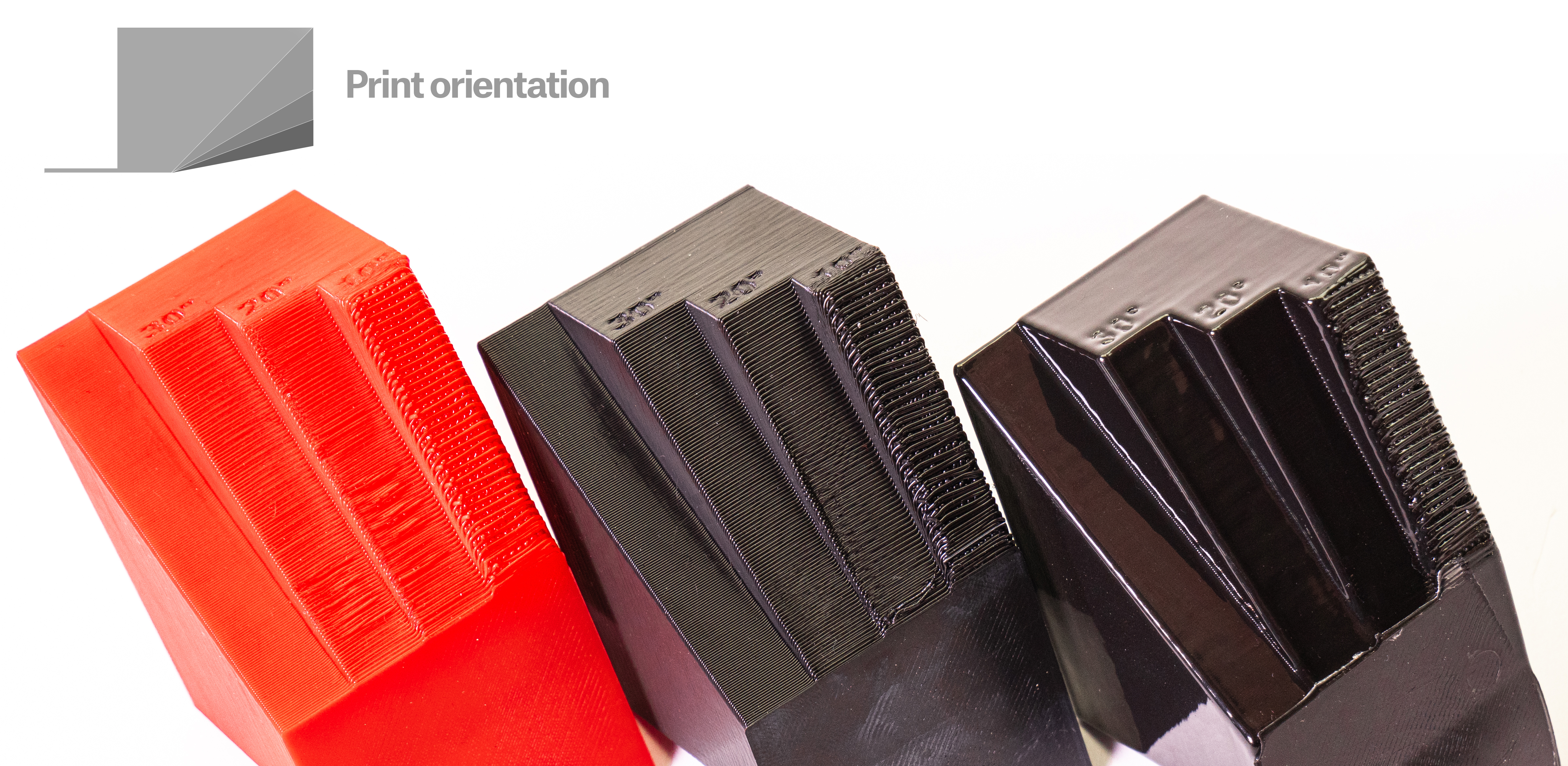

Abs is more prone to warping. A closed housing is recommended for printing with abs. Pla vs abs print accuracy both abs and pla have excellent accuracy and can be used to create dimensionally correct parts. If you print with pla your 3d printer does not necessarily need a closed printing space.

Abs has superb mechanical properties compared to pla. There are times when the answer to this comparison pla vs abs plastic depends on the object that you will be 3d printing. While both are used for making objects in 3d printing via similar processes abs and pla differ in some key ways and therefore some printers will only utilize abs or pla or both depending on. Therefore abs is a good option as 3d printing material for engineering applications.

Due to its lower printing temperature is easier to print with and therefore better suited for parts with fine details. Pla is ideal for 3d prints where aesthetics are important. Pla is a biodegradable plastic. Pla versus abs layer adhesion.

Since abs unlike pla is more susceptible to temperature changes abs prints may show cracks. Abs and pla are both desktop 3d printing materials and they are available at about the same cost. Pla has characteristics similar to polypropylene pp polyethylene pe or polystyrene ps. Abs is much harder to print than pla.

Pla at a lower printing temperature at 190 220c rather than 220 250c and warps less than abs with abs parts also prone to cracking and curling. Overall pla is easier to print. Pla and abs do not share the same strength and one of them is best used when you 3d print objects that will be subjected to wear and tear.