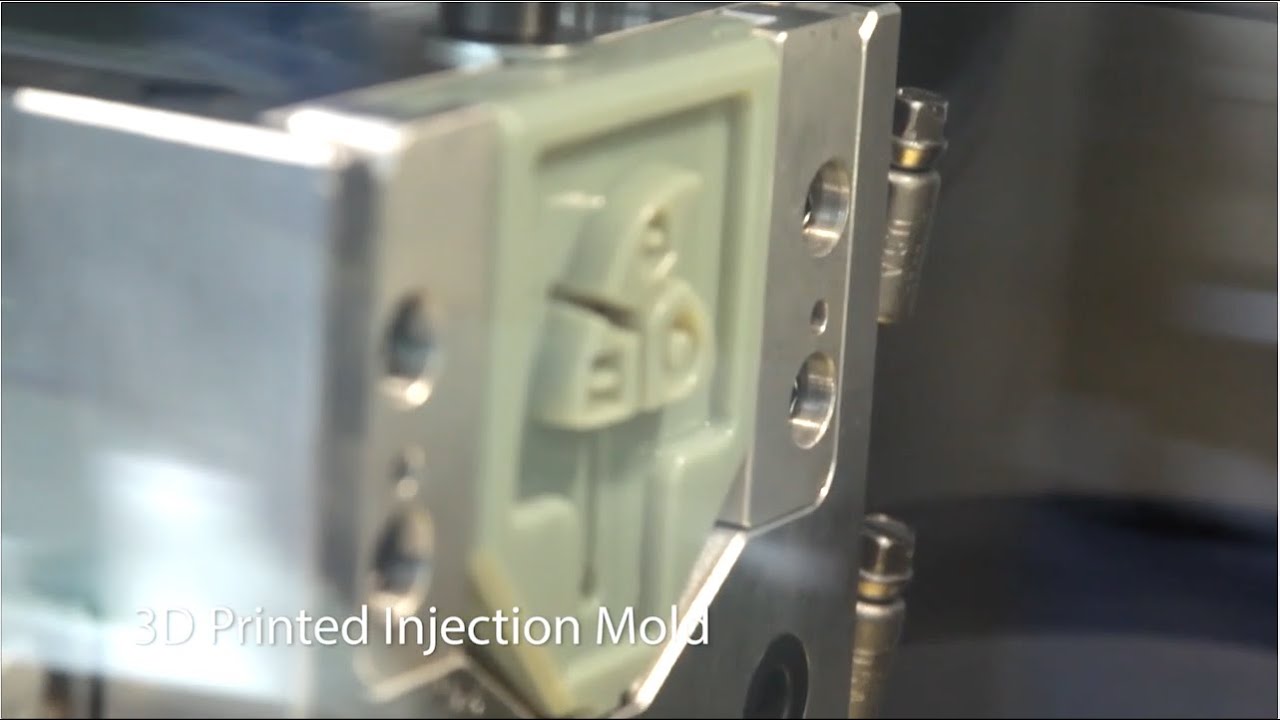

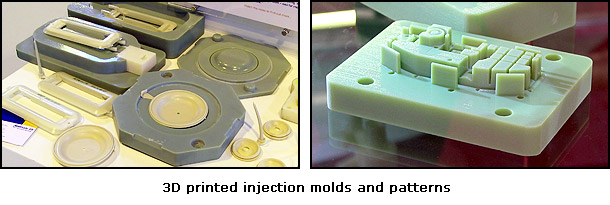

3d Printed Injection Mold Tooling

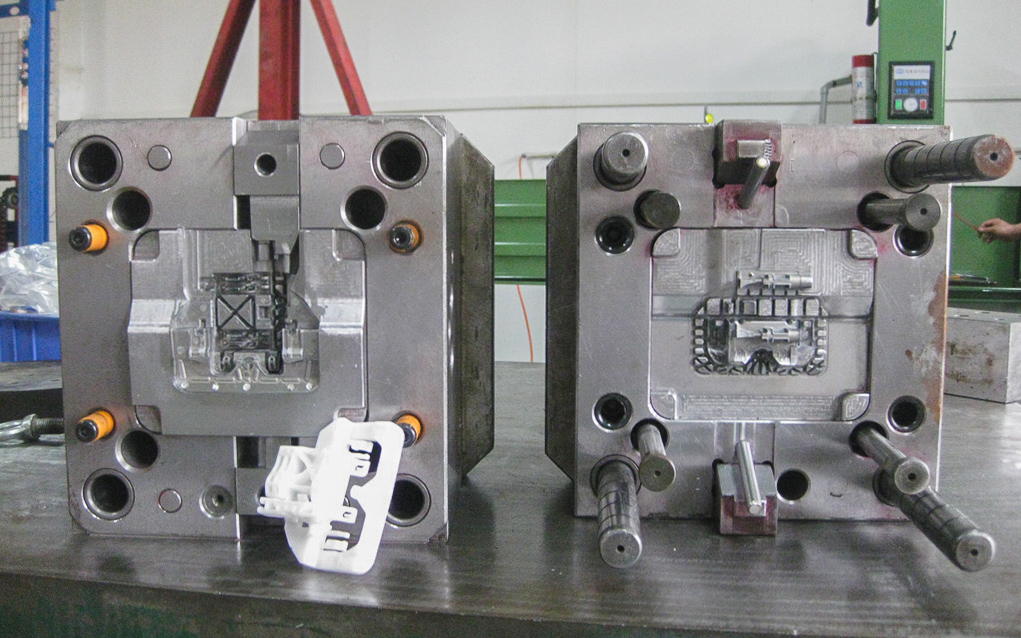

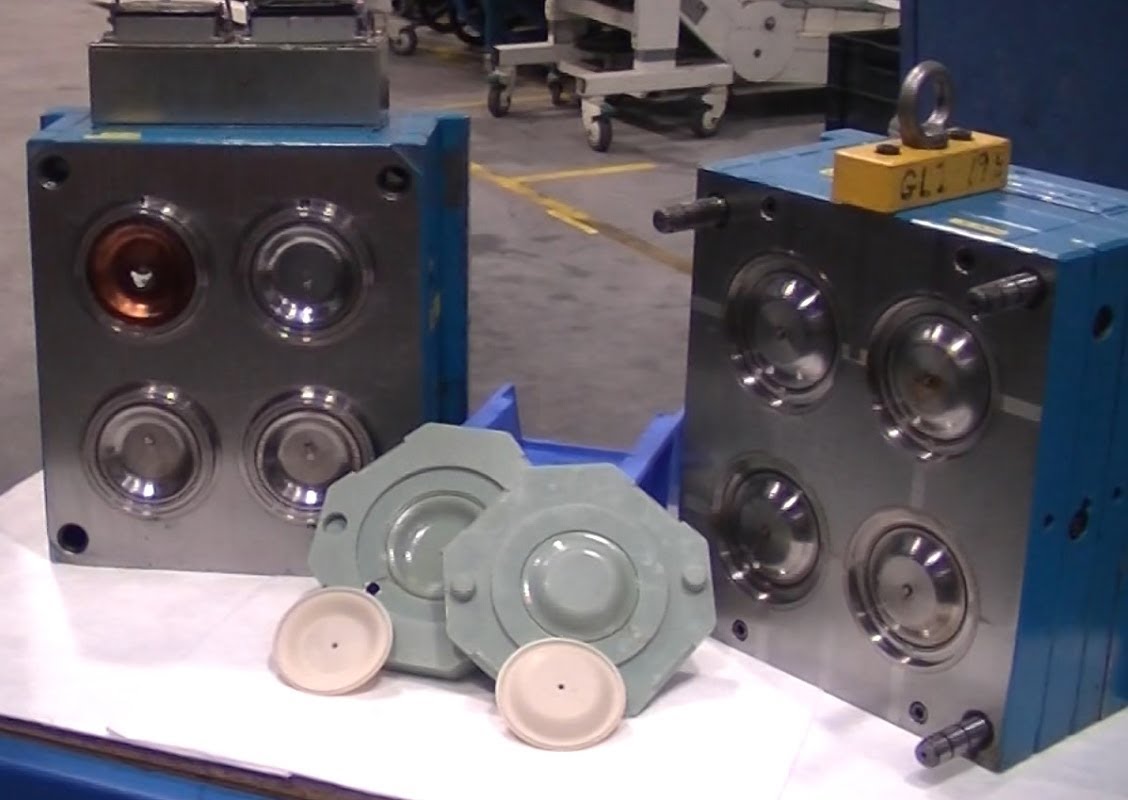

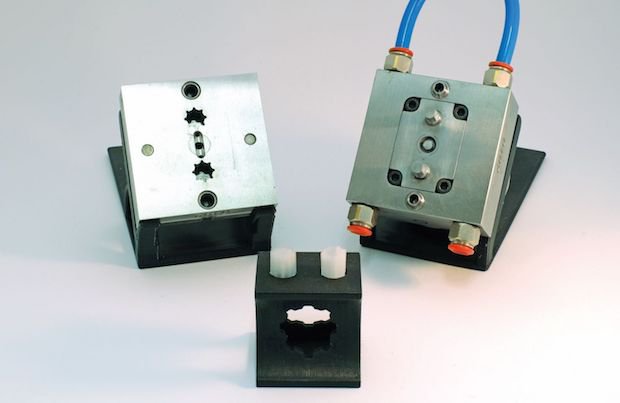

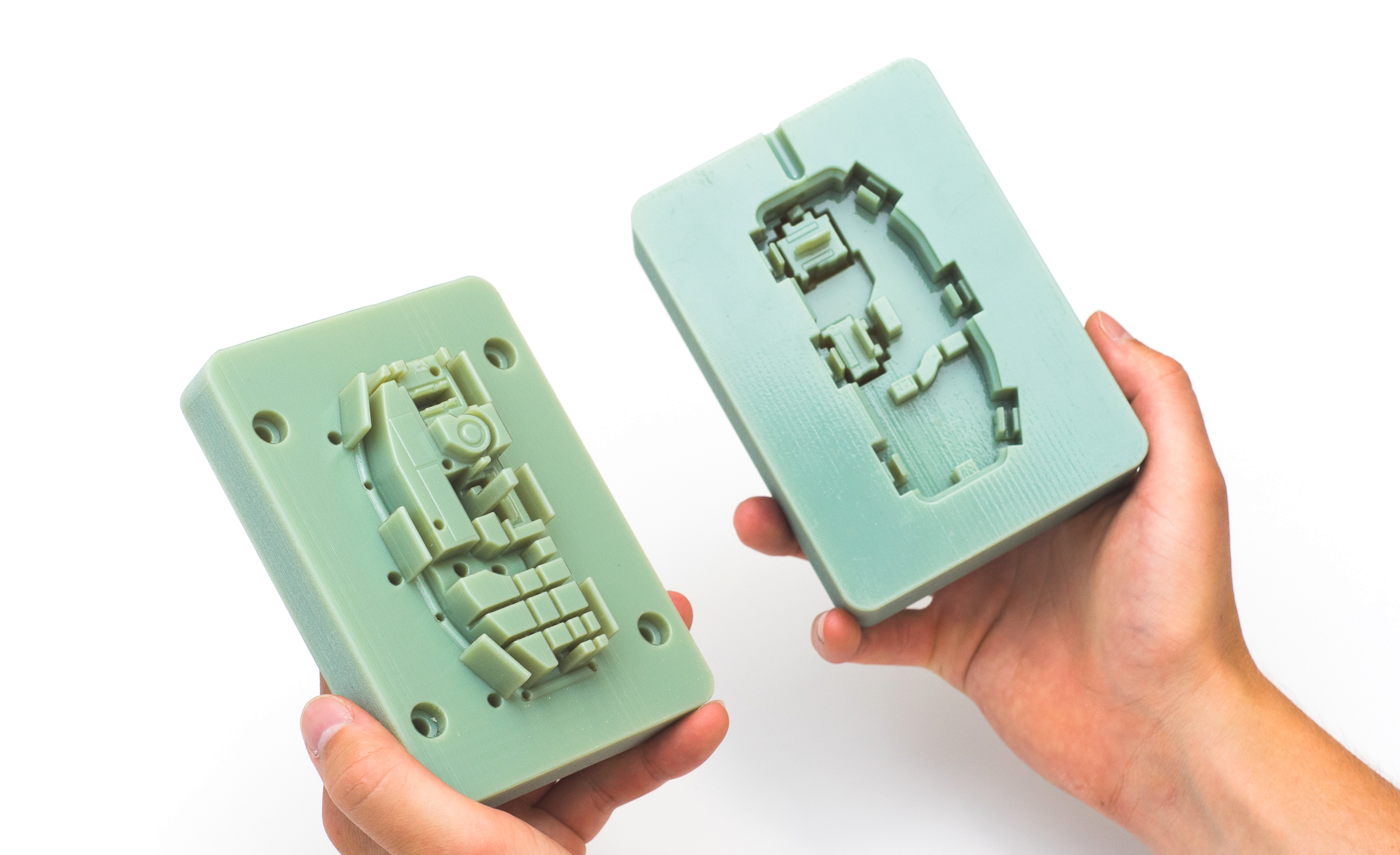

Traditional metal molds or very low run typically 3d printed plastic molds said alkaios bournias varotsis technical marketing engineer for amsterdam based 3d hubs.

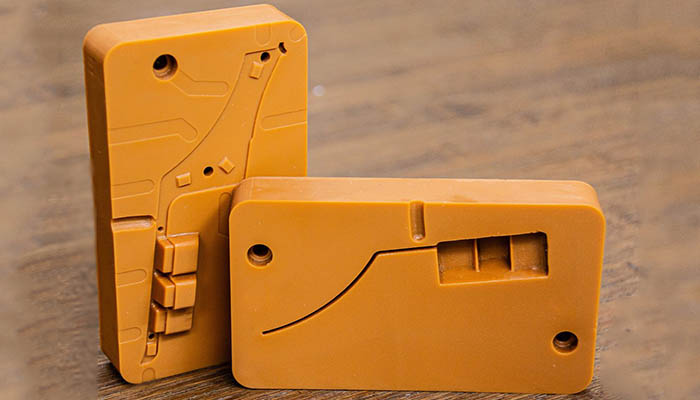

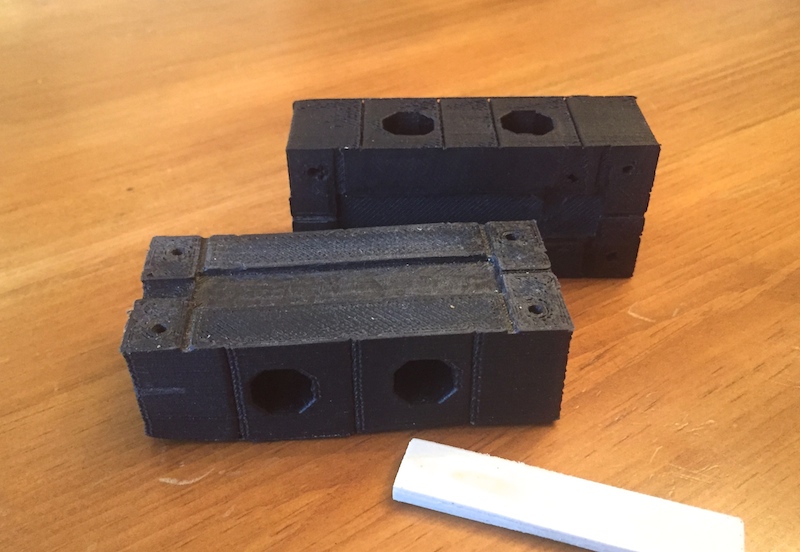

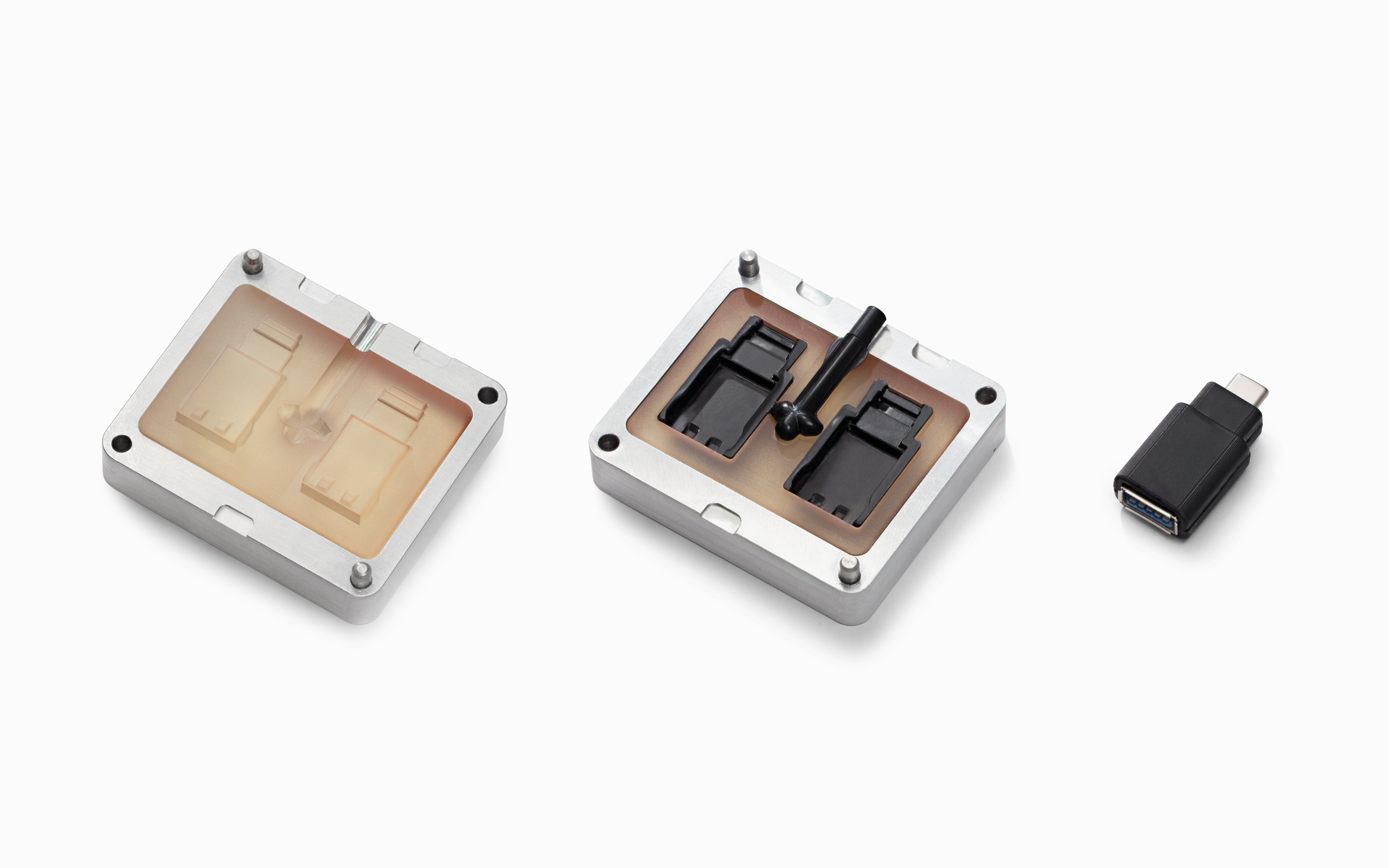

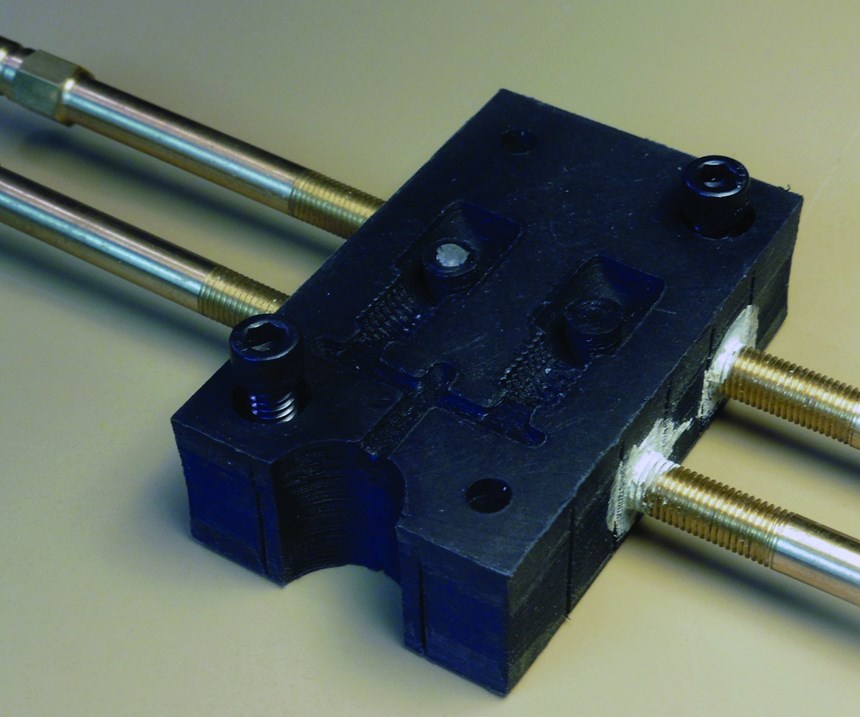

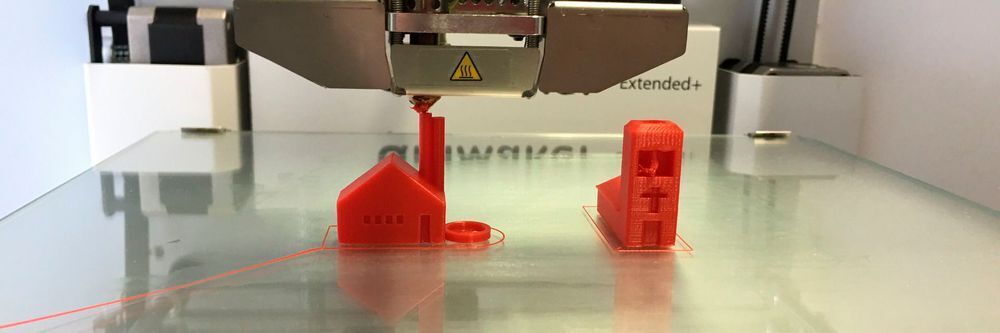

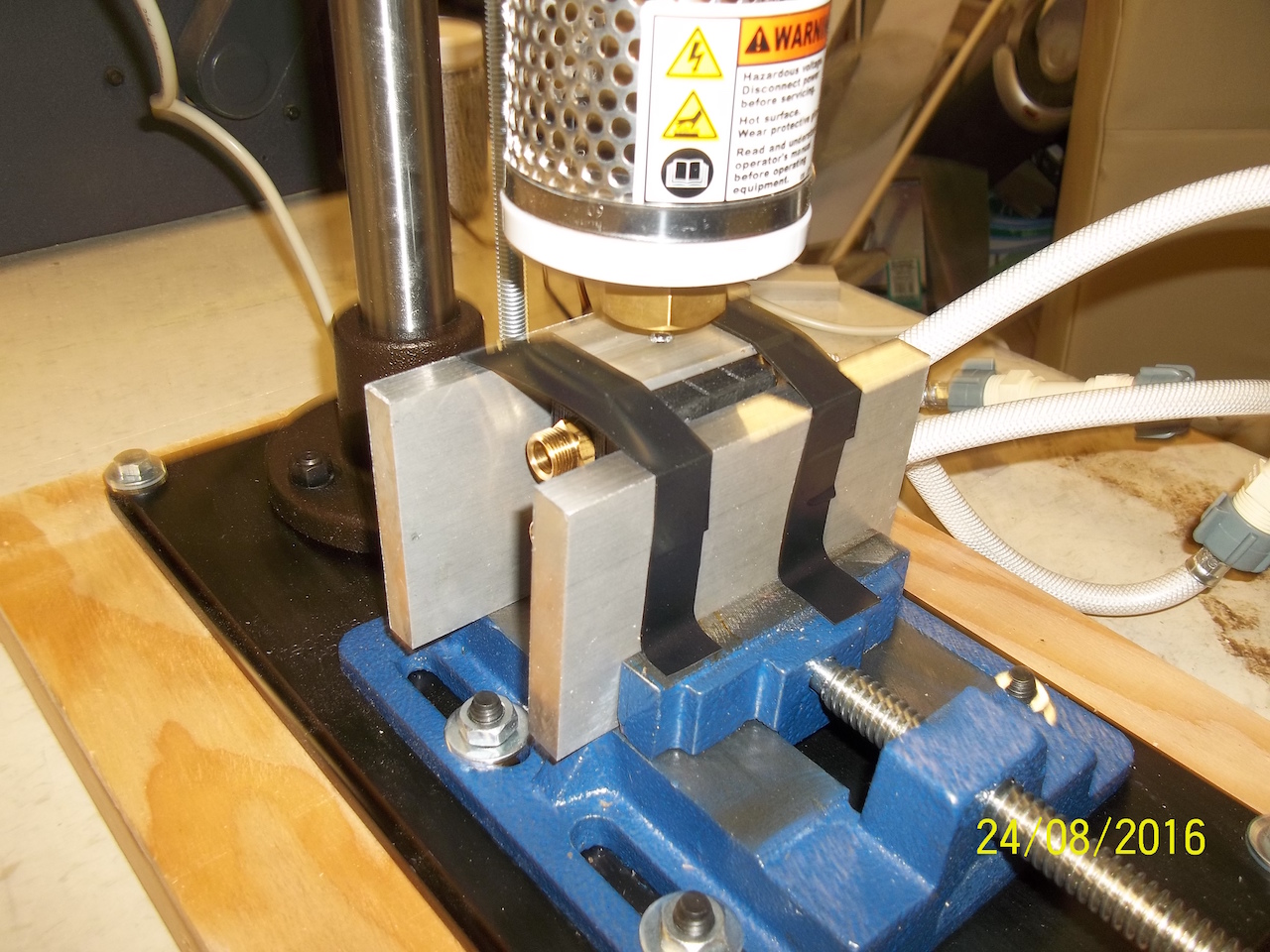

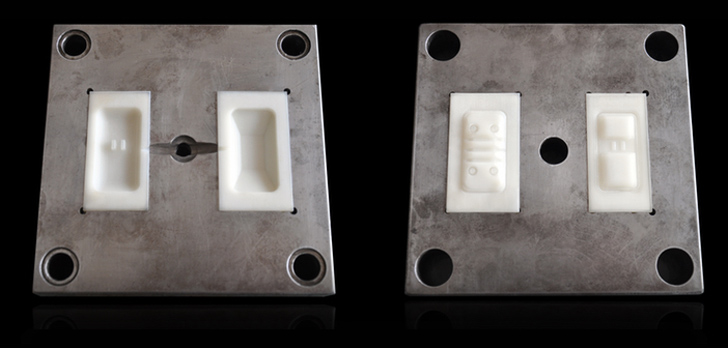

3d printed injection mold tooling. With 3d printed molds youll need to print machine assemble and test a new mold every 50 to 100 shots. This is exactly where 3d printing injection molds step up to the plate. As a rule manufacturers have two options for rapid injection mold tooling. As a rule manufacturers have two options for rapid injection mold tooling.

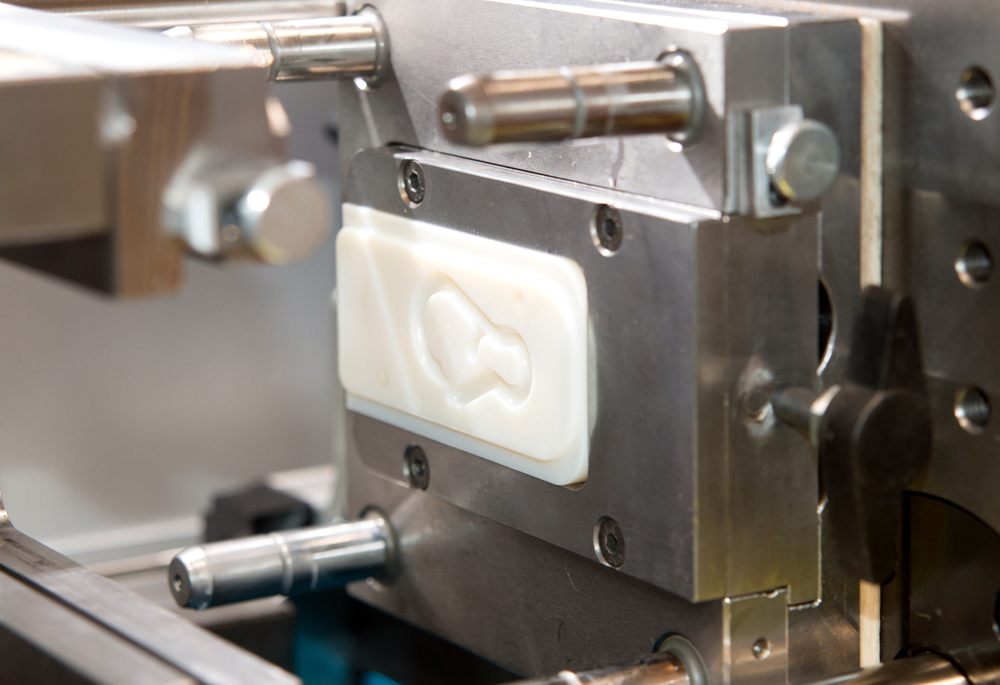

The injection molding industry has always suffered from high costs and long lead times for tool making. Since developing parts for automated laboratory testing requires a lot of trial and error speeding up the iteration process makes a significant difference. The ability to rapidly print and mold parts is game changing for part designers. 3d printed tooling exhibits faster lead times 1 2 days at a fraction of the cost of machined soft tooling making them a viable candidate for molders who are looking at the economics behind a tool that is only used for small volumes.

Aluminum tooling has no such constraints and often see service well past 10000 shots regardless of the plastic being used.