3d Printed Injection Molds Stratasys

Read on and watch how stratasys polyjet 3d printing technology helps a team at budapest university create an injection mold with pom acetal for functional testing at dramatically reduced time and cost.

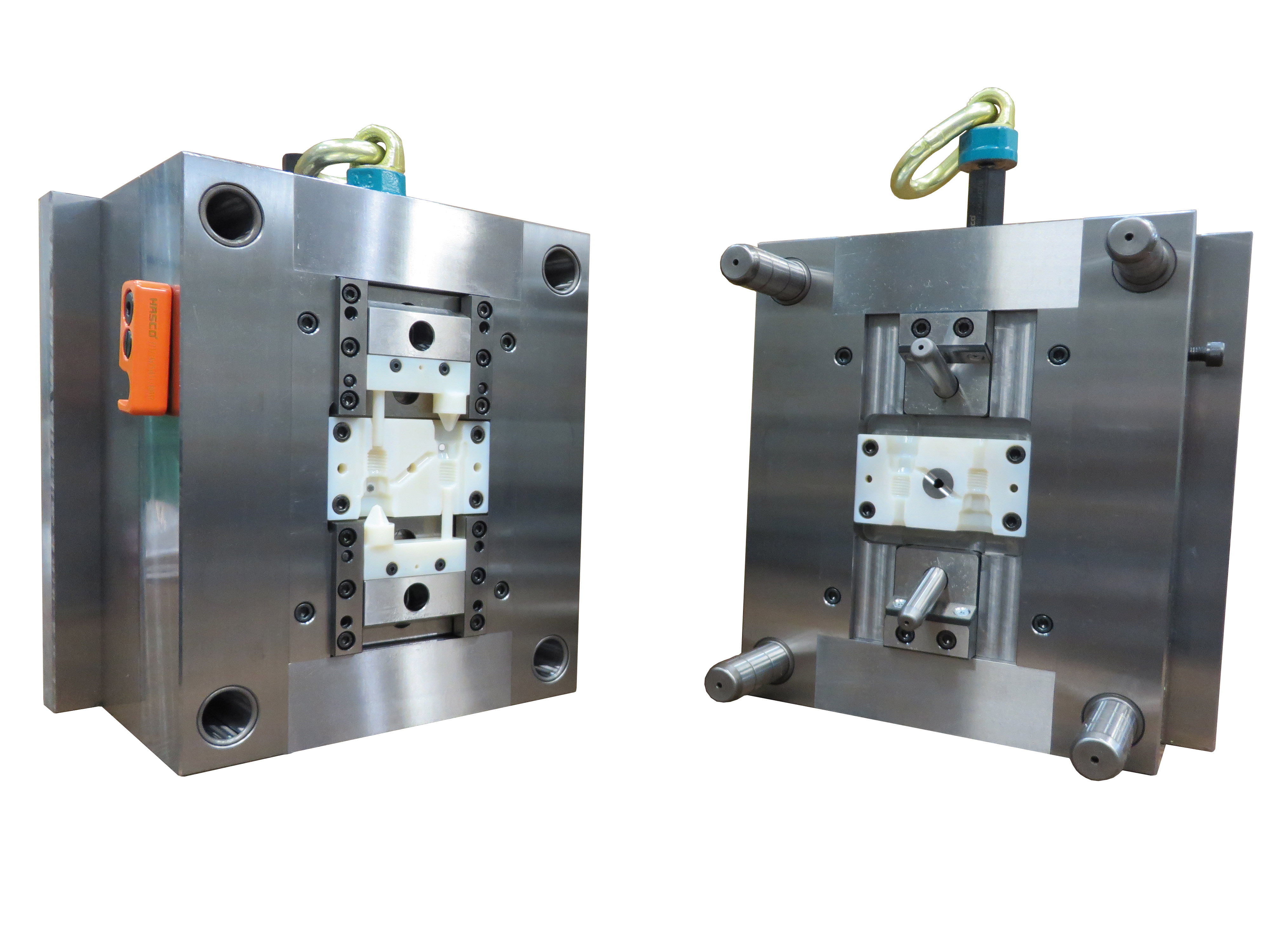

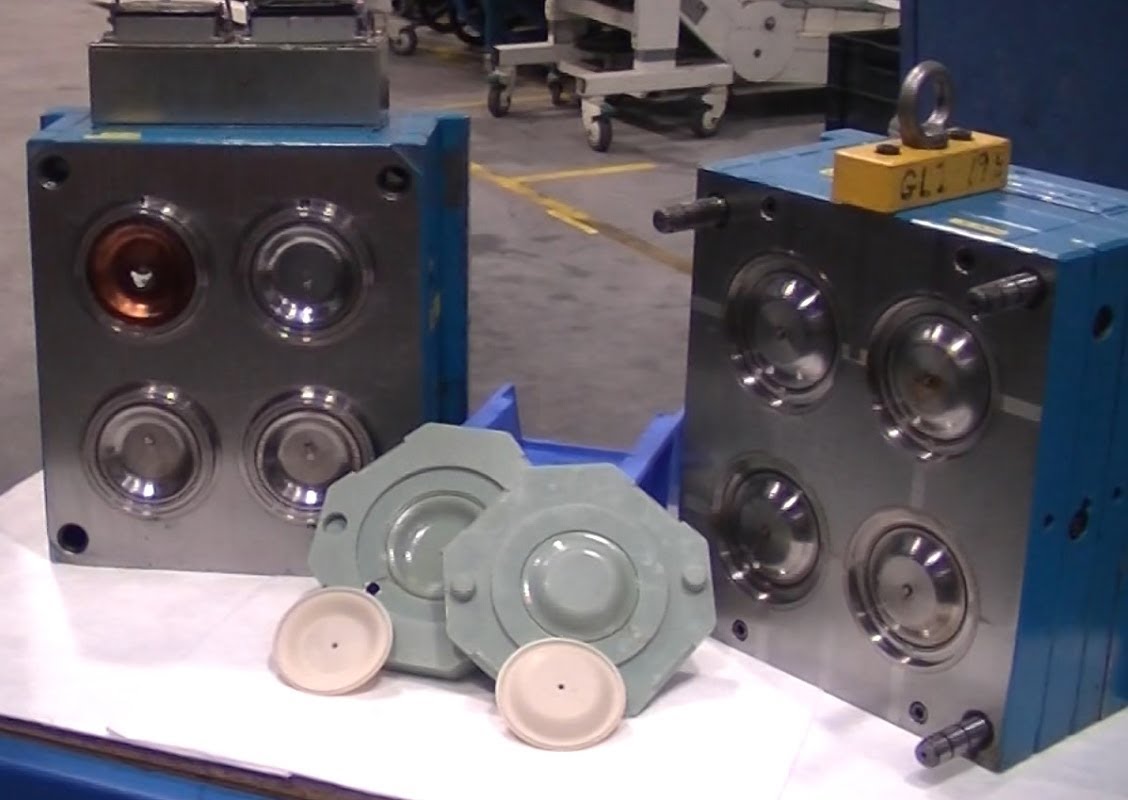

3d printed injection molds stratasys. 22 stratasys the 3d printing solutions company arad group 3d printed injection molding process injection process molded parts machine 50t arburg injection temperature 2600 c injection pressure 880 bar shot size 38 cubic cm switch over point 85 cubic cm packing pressure 200 bar. Gil robinson product manager stratasys molding applications. Stratasys 3d printing is an agile solution for designing testing and manufacturing injection molds. Learn how customers such as berker are cutting production time and costs by switching to injection molds that are 3d printed rather than traditionally manufactured.

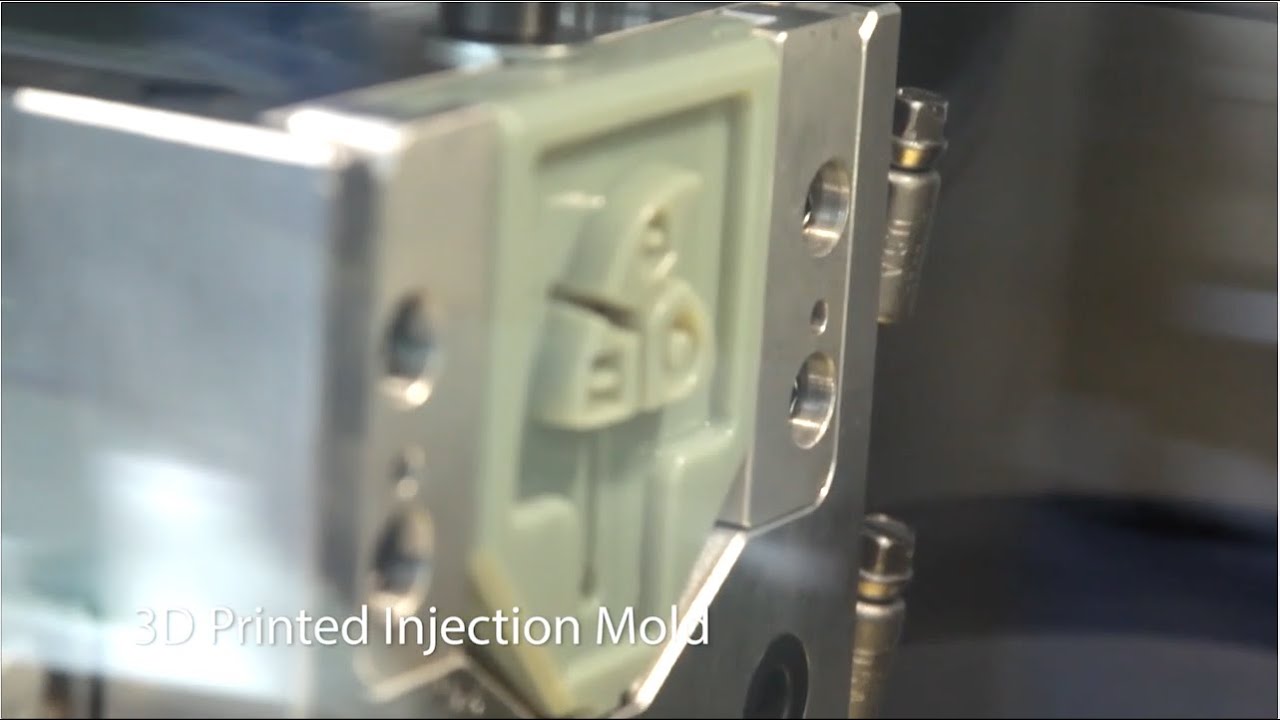

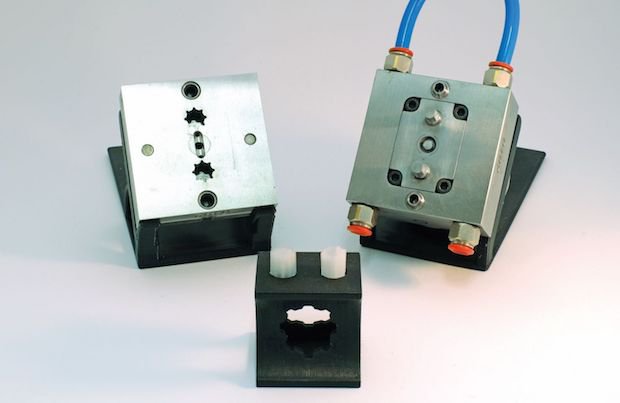

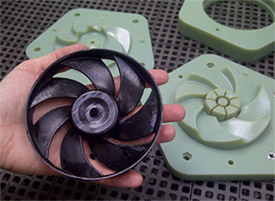

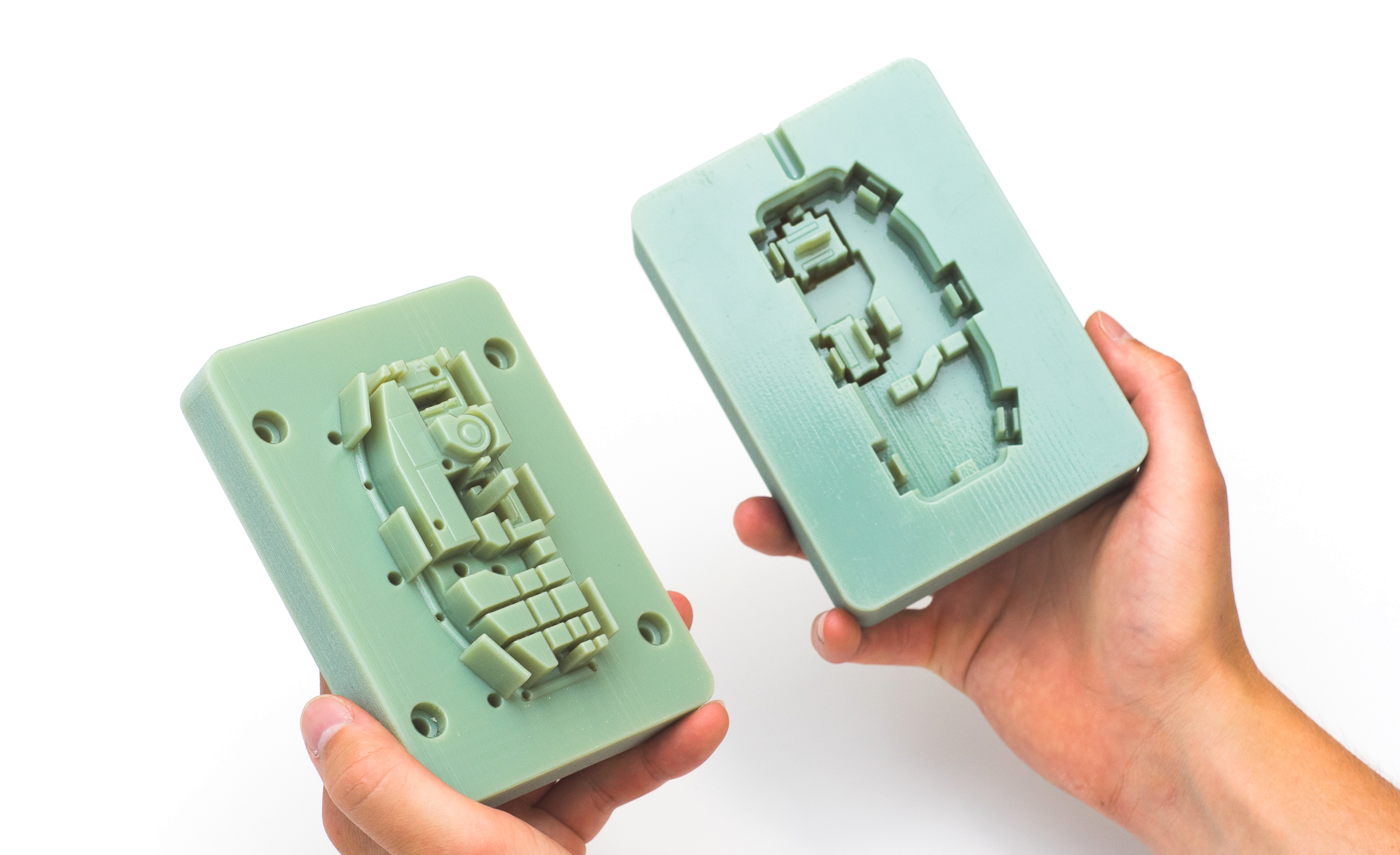

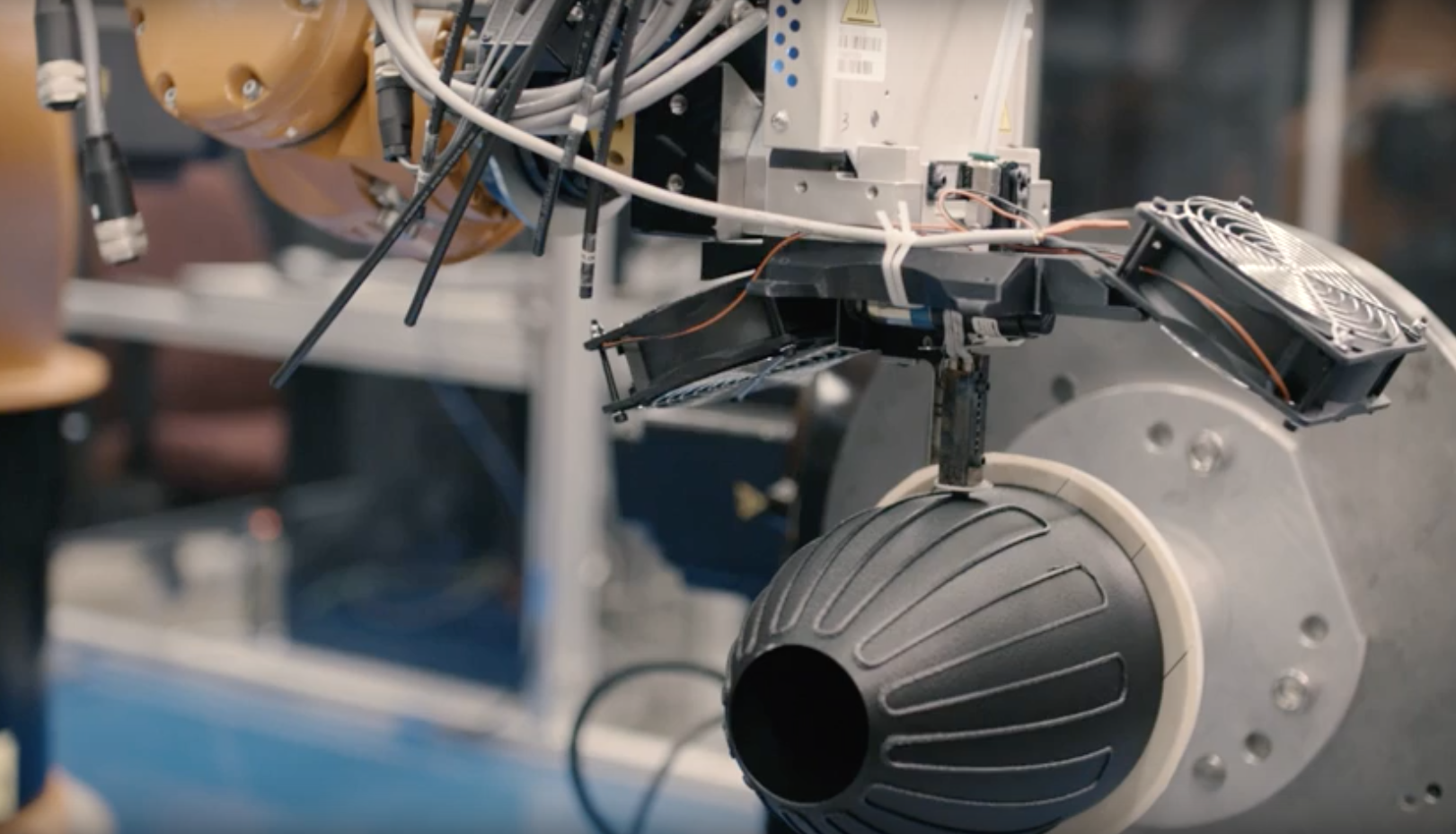

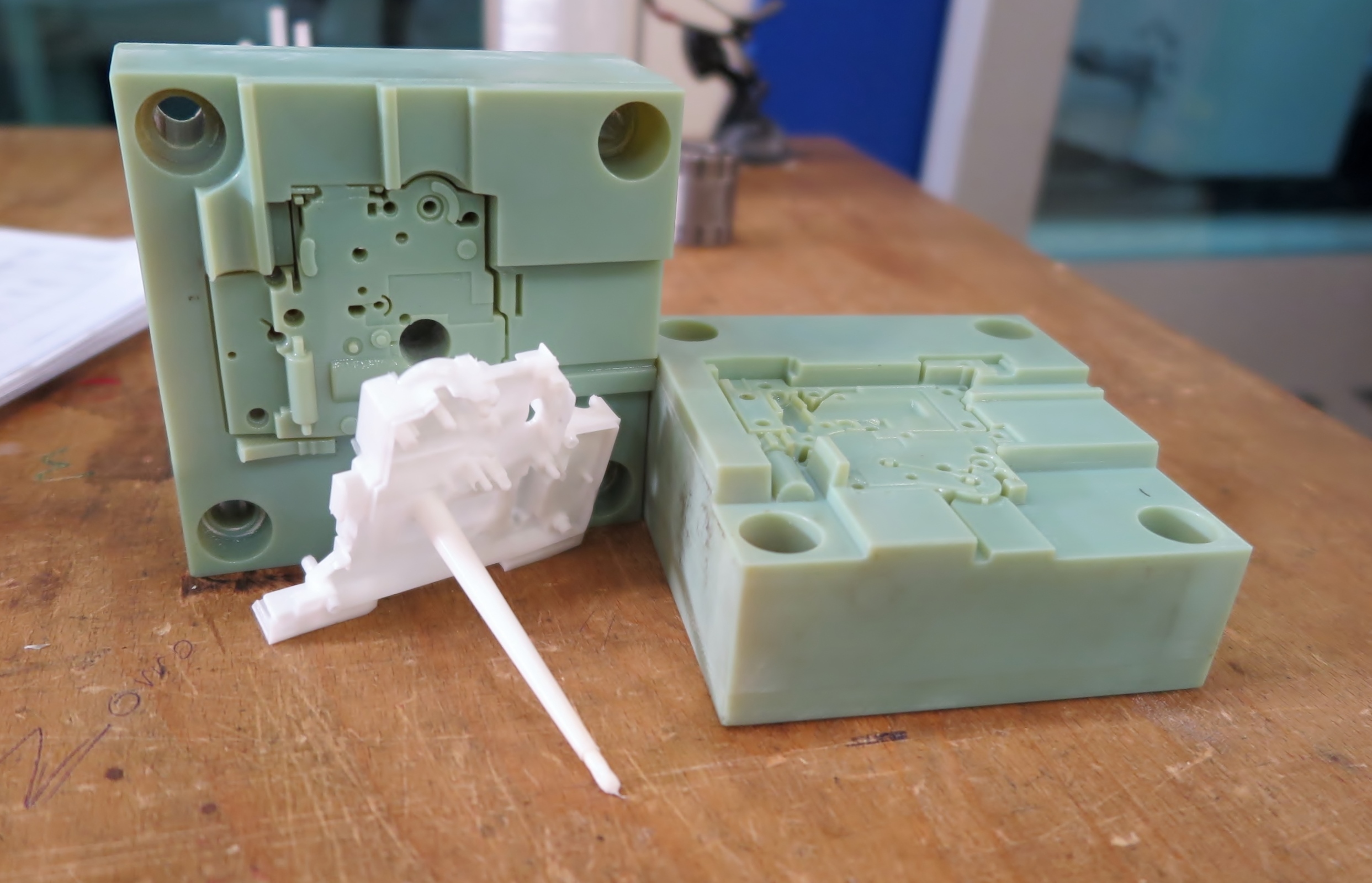

By 3d printing the injection molds with digital abs were able to achieve the high quality associated with traditional manufactured prototypes while ensuring that the high temperatures and pressures of the injection molding process. Each 3d printed mold with a different geometry was used to inject a different final part material. Streamlining injection molding with 3d printed tools milacron video. Companies such as seuffer video.

In manufacturing 3d printing has turned the production of injection molded prototypes into a quick easy and inexpensive process. Hear guidance on design expected part quantities material selection and process considerations. Milacron shifts gears to 3d printed injection molds for rapid part prototyping and whale video. In this session we will discuss printed mold tool material types of molds molded material and expected number of parts along with hints to design your printed mold.

In this free 35 minute webinar youll learn how 3d printed mold inserts can cut turnaround time and reduce costs. Stratasys polyjet 3d printed injection moldsa series part 2. Once again i want to state that stratasys pimts are not production tools however they provide a clear advantage being both cheaper and faster when a limited quantity of production parts is needed. 3d printed injection molds are fairly low cost quick turnaround method of testing mold designs and injected materials prior to mass production.

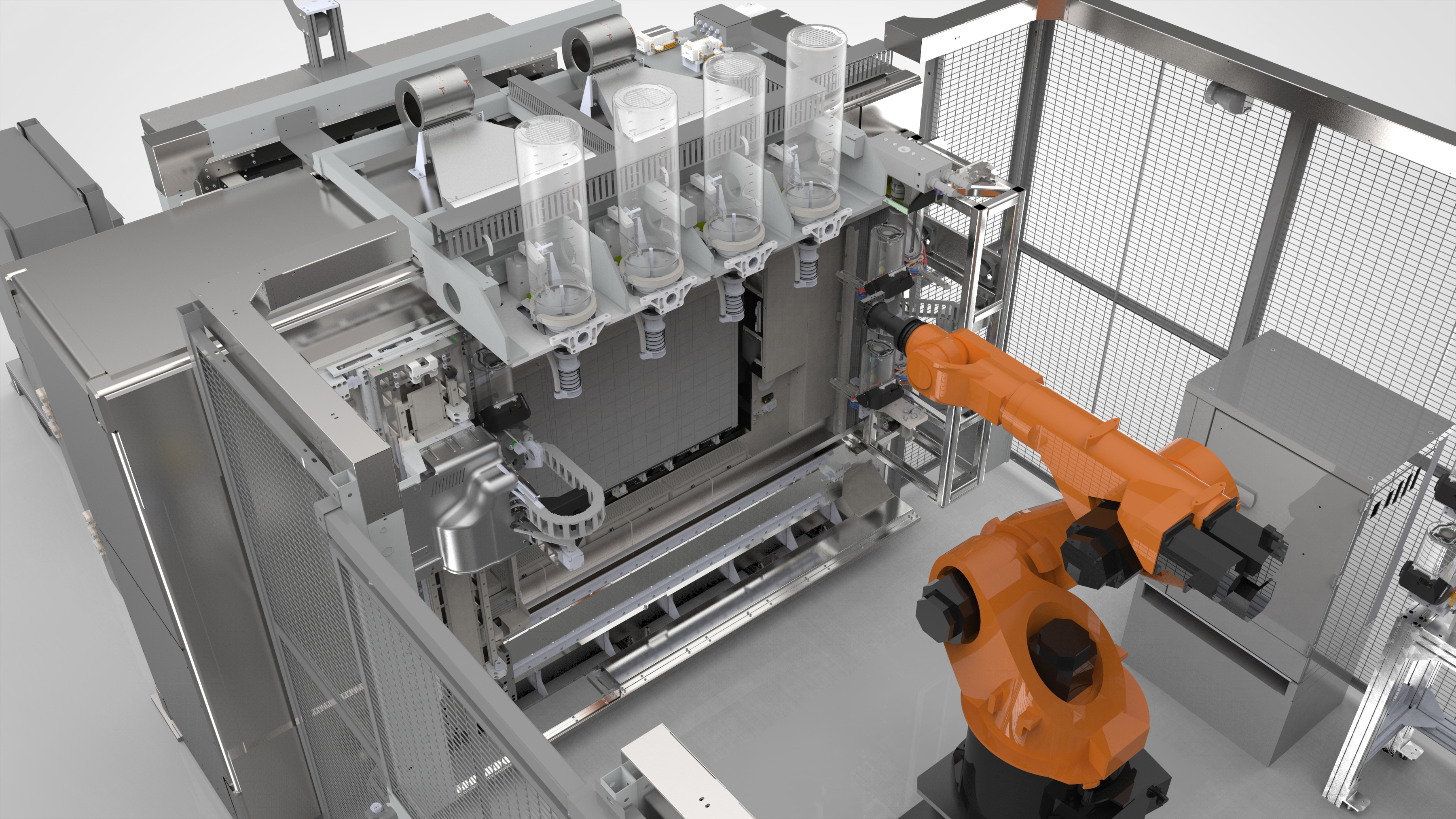

And heres a major new innovation thats further facilitating economic low volume production hascos new k3500 quick change mold system. Berker produced a series of 3d printed injection molds using stratasys polyjet technology with digital abs material. Asa pc and tpe. Decrease lead time on production parts and bring in new customers by skipping the outsourcing process and mold.

:quality(80)/images.vogel.de/vogelonline/bdb/1186000/1186053/original.jpg)