3d Printer Auto Leveling Not Working

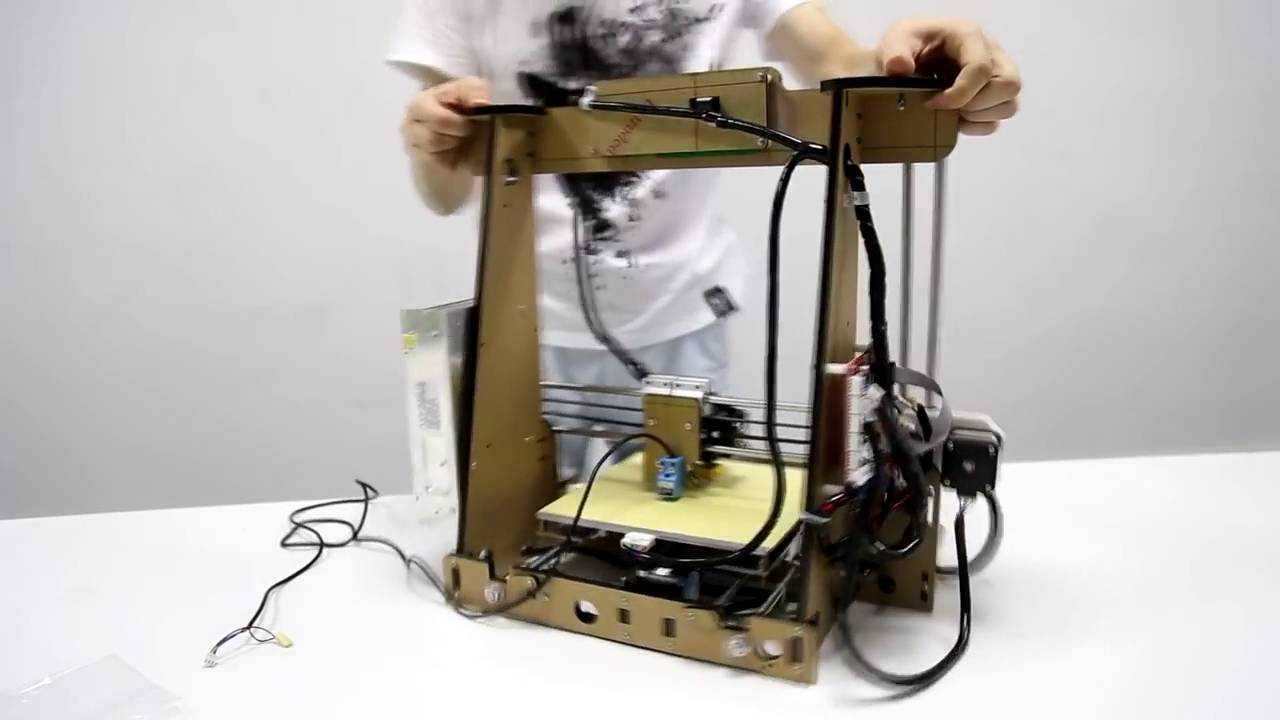

In this one we go over how to setup auto bed leveling for your 3d printer with marlin firmware.

3d printer auto leveling not working. Httpsgoogl1amxzk support the channel by cl. The noise level automatically means the r2 is not the kind of 3d printer you place near your work area. You wont need the old z stop because your sensor will be probing the bed for its z position. It needs to be in a separate room unless you do something about those noisy fans.

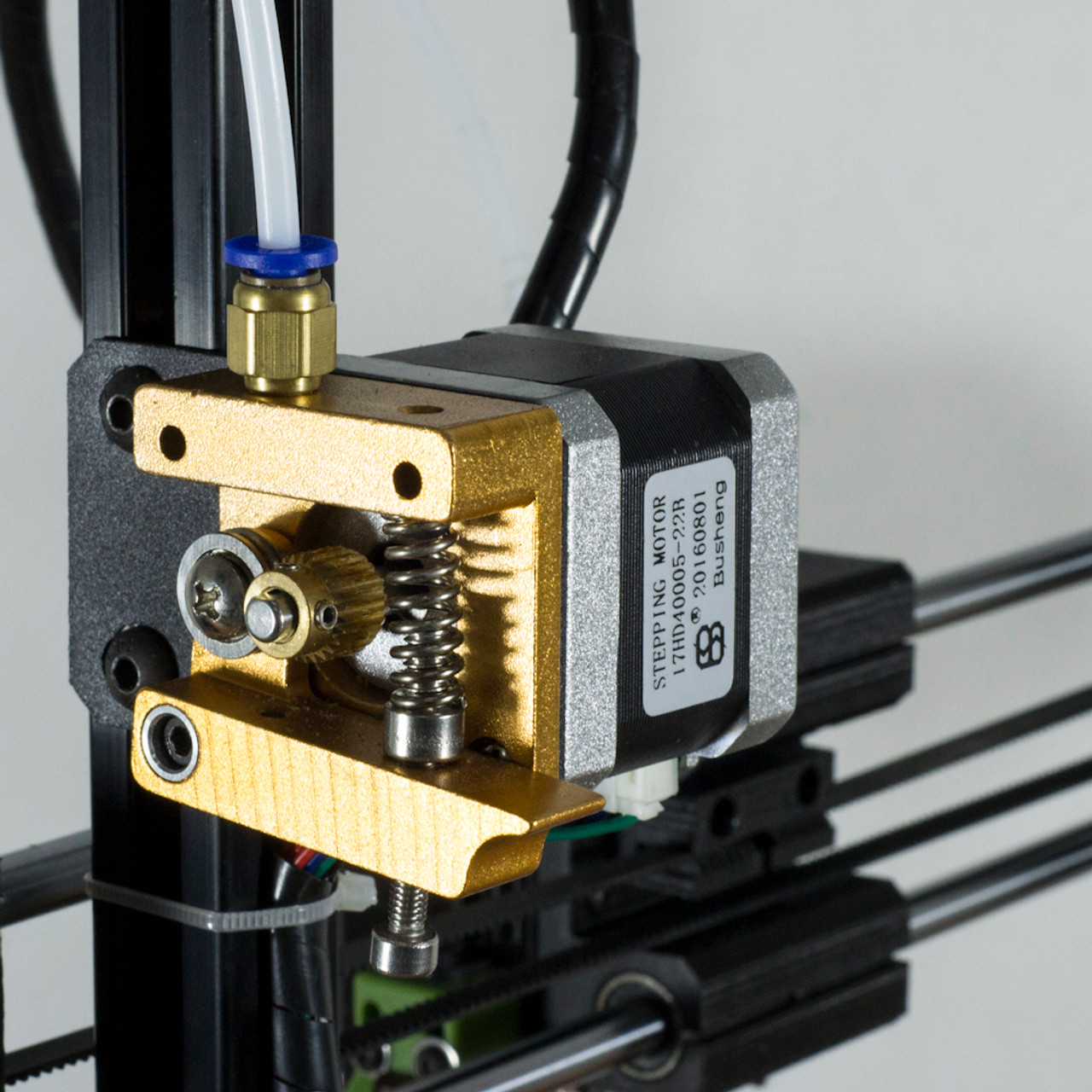

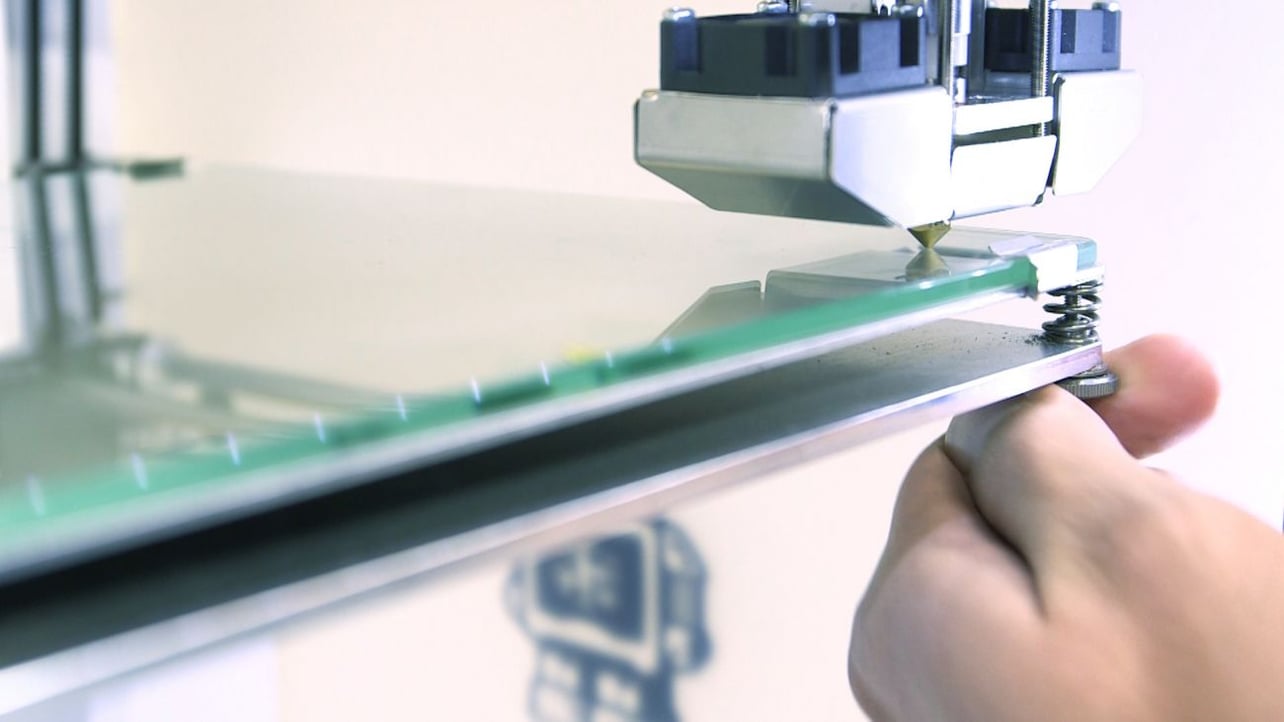

For abs use buildtak wolfbite or abs juice use baby stepping to ensure proper first layer height. Thankfully the tip is easy to clean with a dry cotton cloth. Bed leveling is meant to compensate for any anomaly on the bed and it is usually done with respect to the printers axis. Here are some things that we will need.

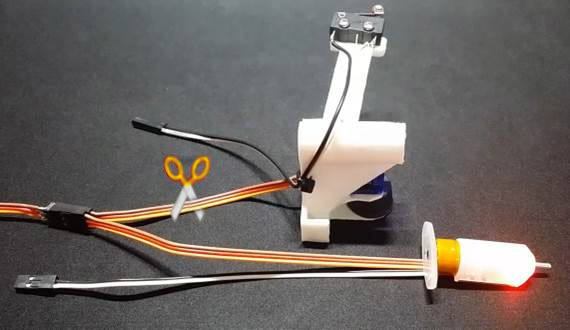

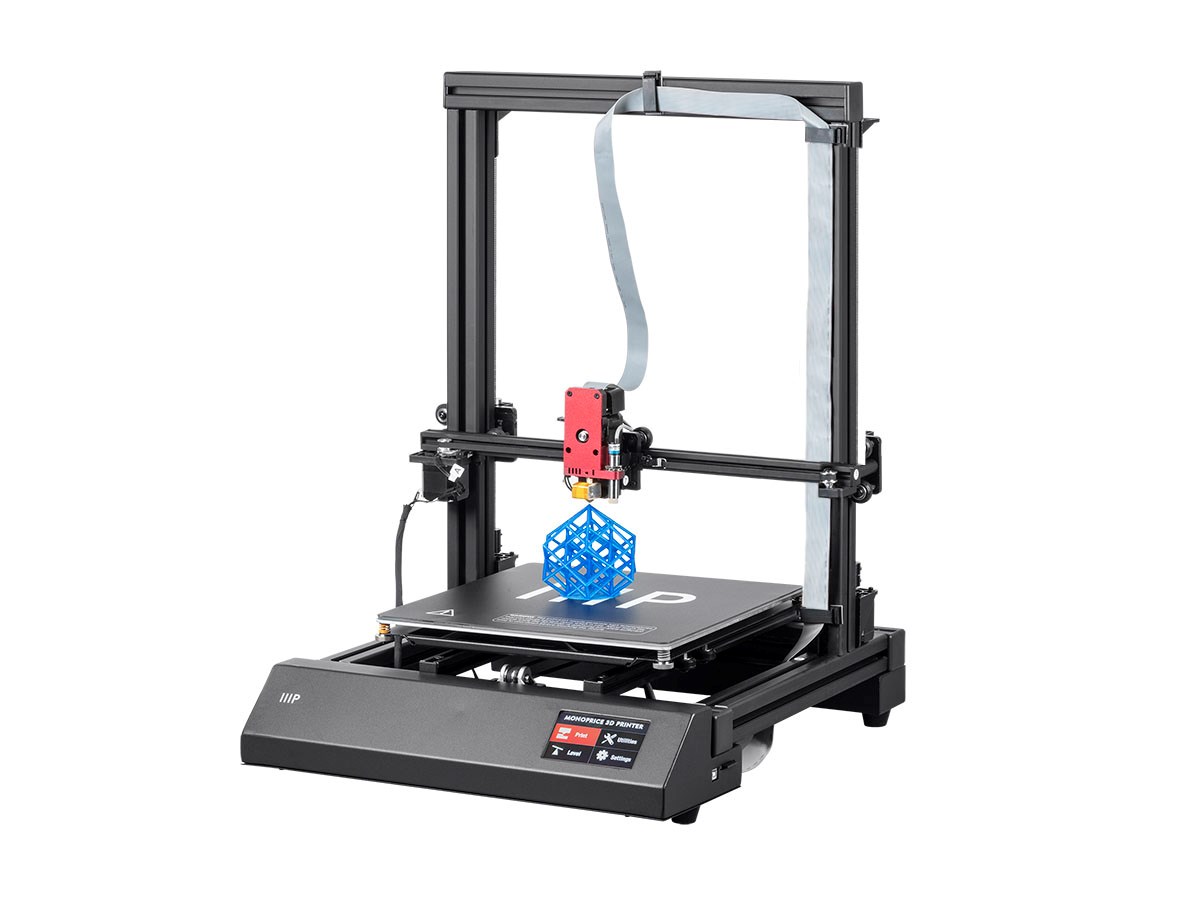

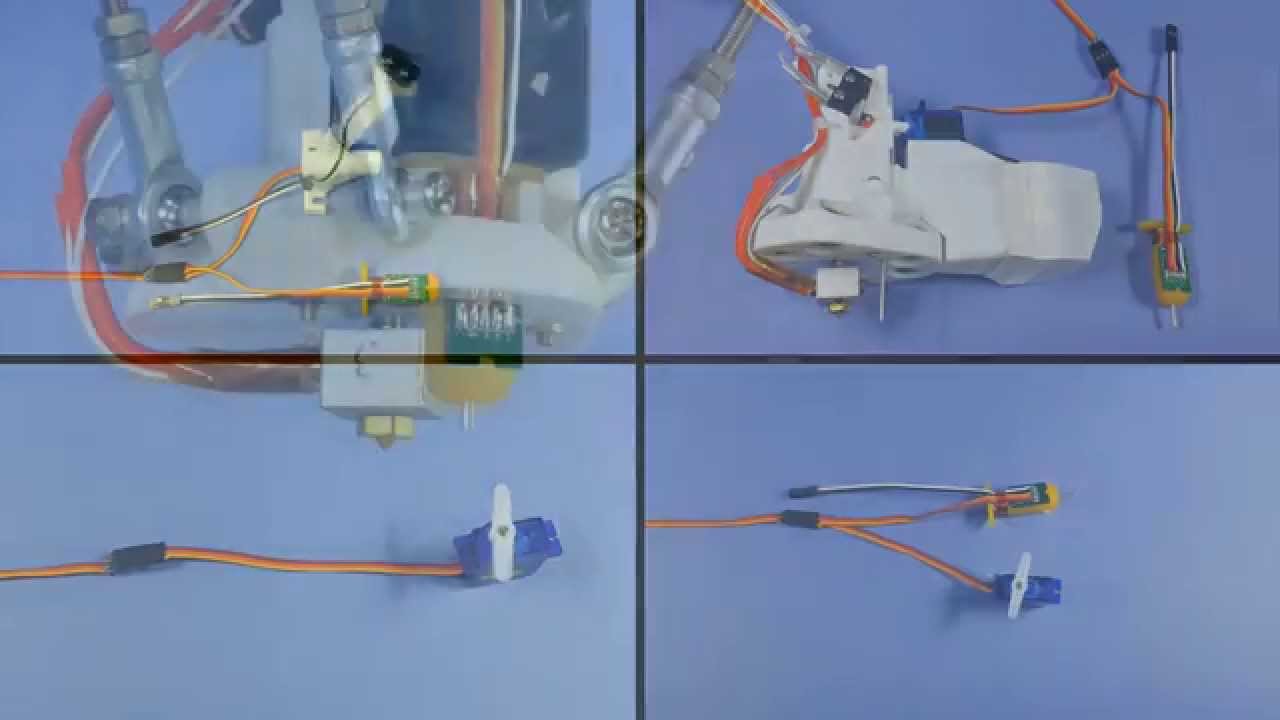

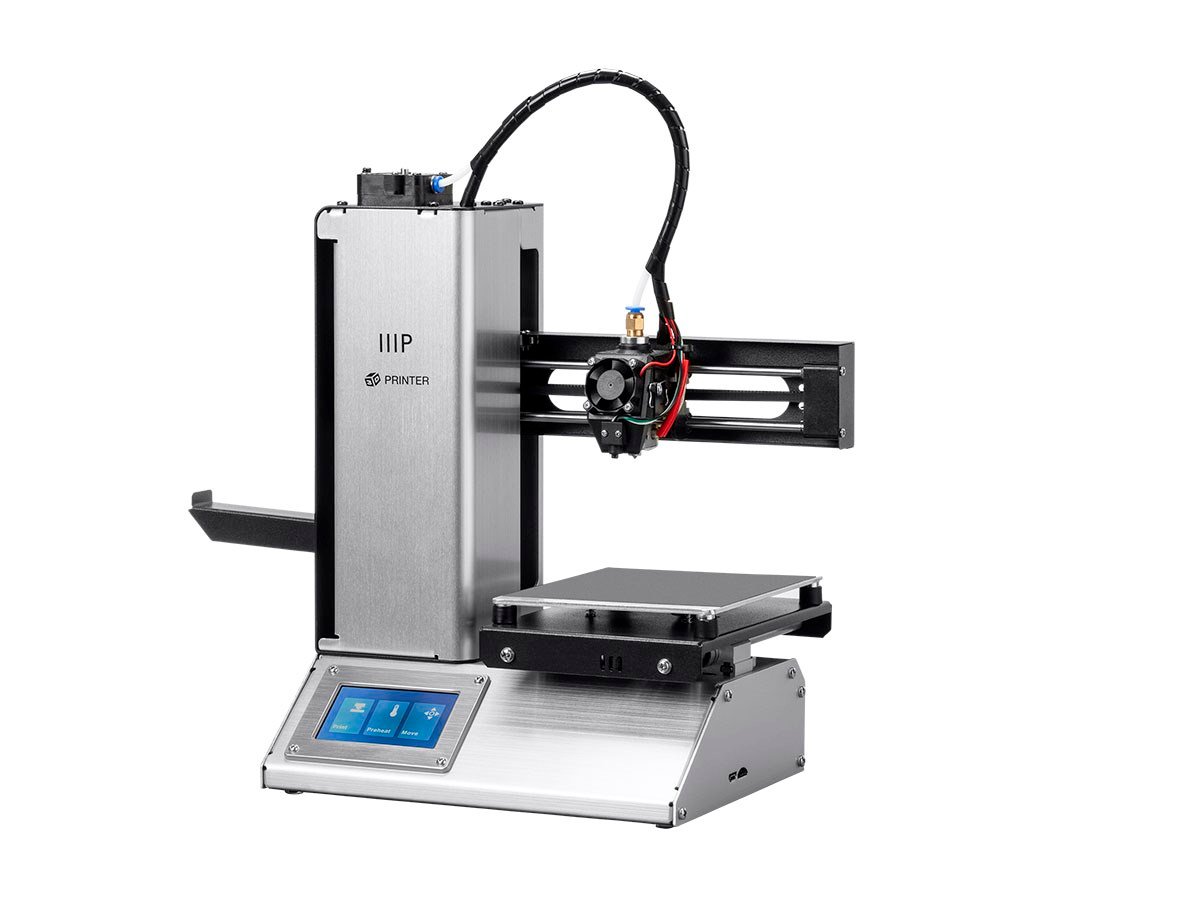

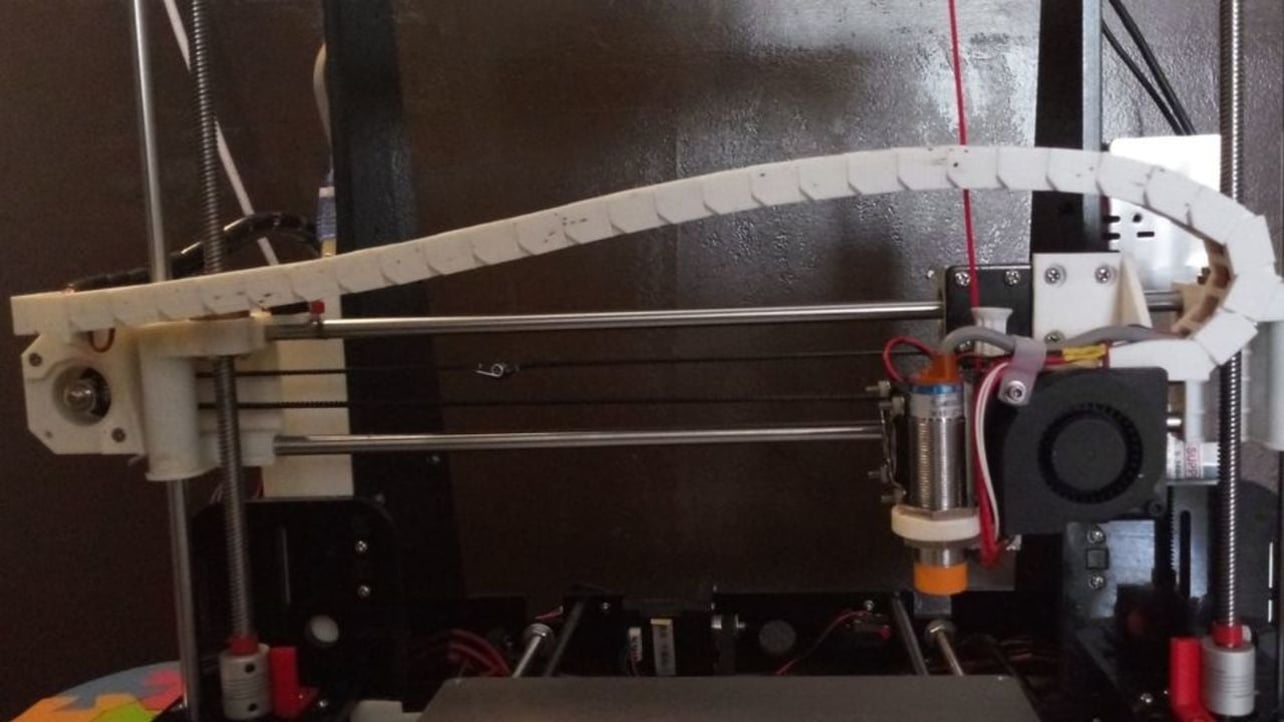

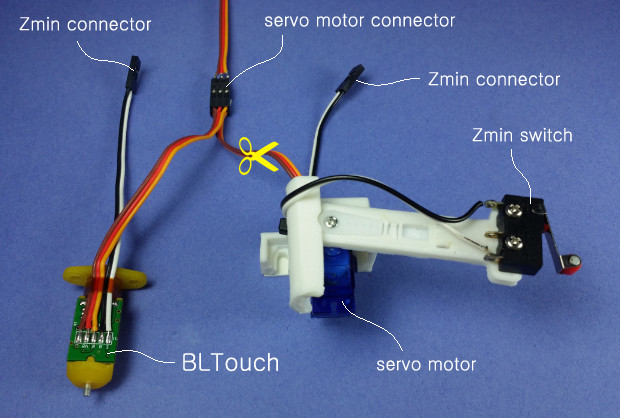

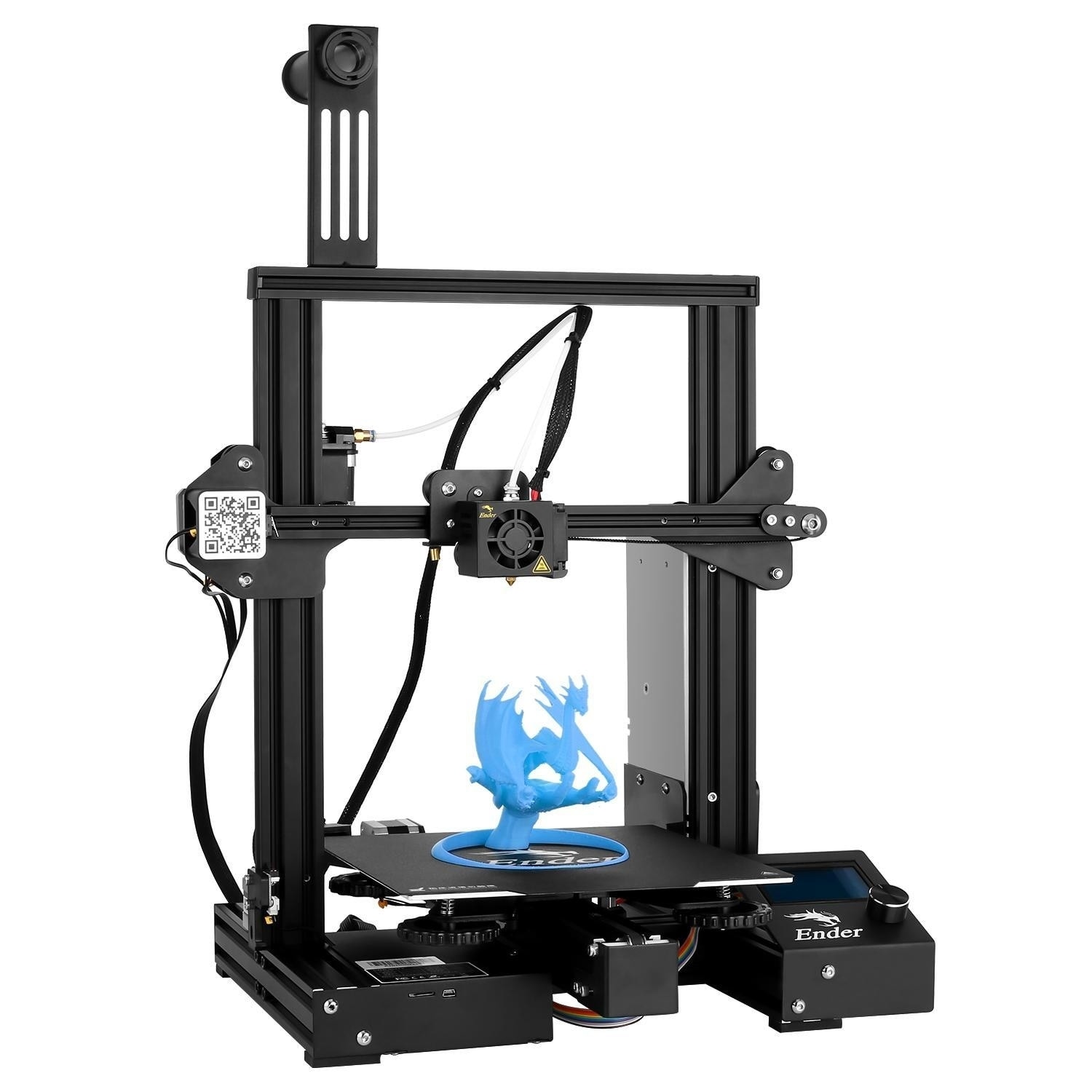

1 a already working 3d printer we will need to print a support 2 1x 9g servo motor 1x jumper computer jumpers are great. Use gluesadhesives on borosilicate glass. Heat the nozzle to the temperature the last used material was printed at and wipe off the excess plastic. Fortunately there are 3d printers that come with an automatic bed leveling feature used to confirm that the printing platform is level whenever youre preparing to print.

If you have any residual plastic on the tip of the nozzle your 3d printer bed leveling and nozzle gap adjustment will be off. Hello all i received a printer for christmas and have been working tirelessly on assembling it. I have it all together but have been having trouble trying to calibrate it. Edge near the bottom of the print or surface adjacent to the print bed is not level or flat.

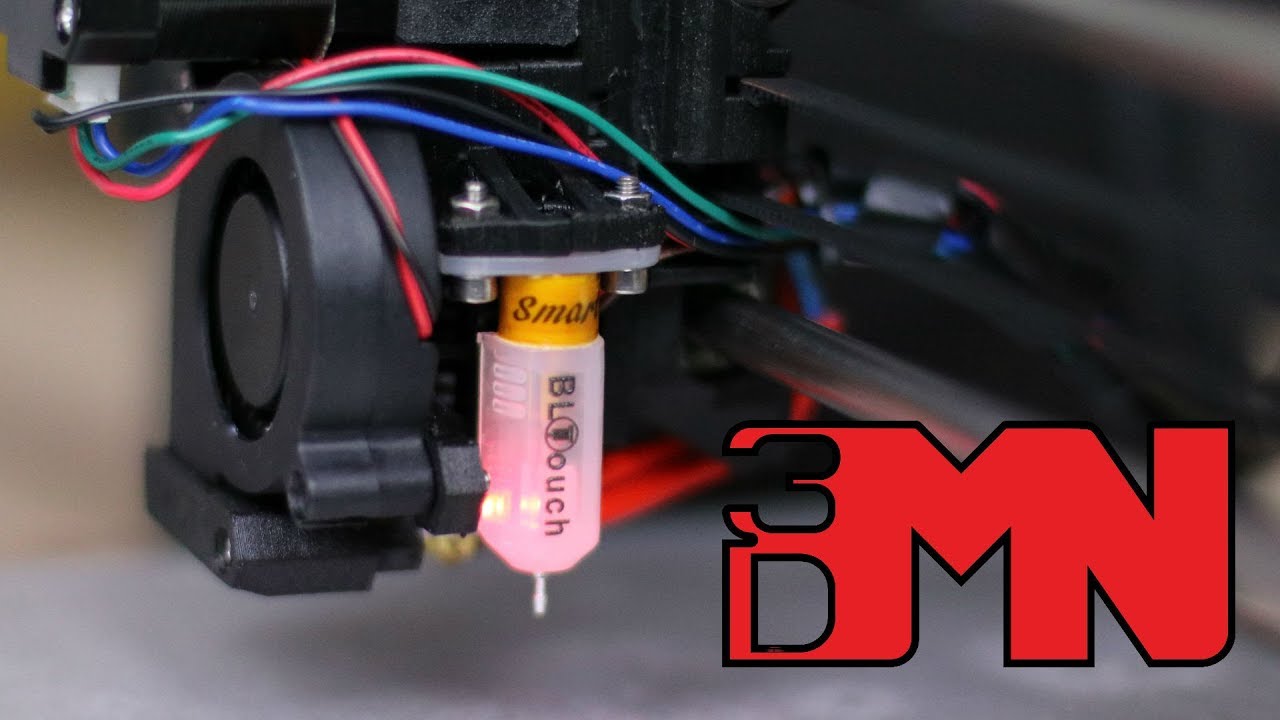

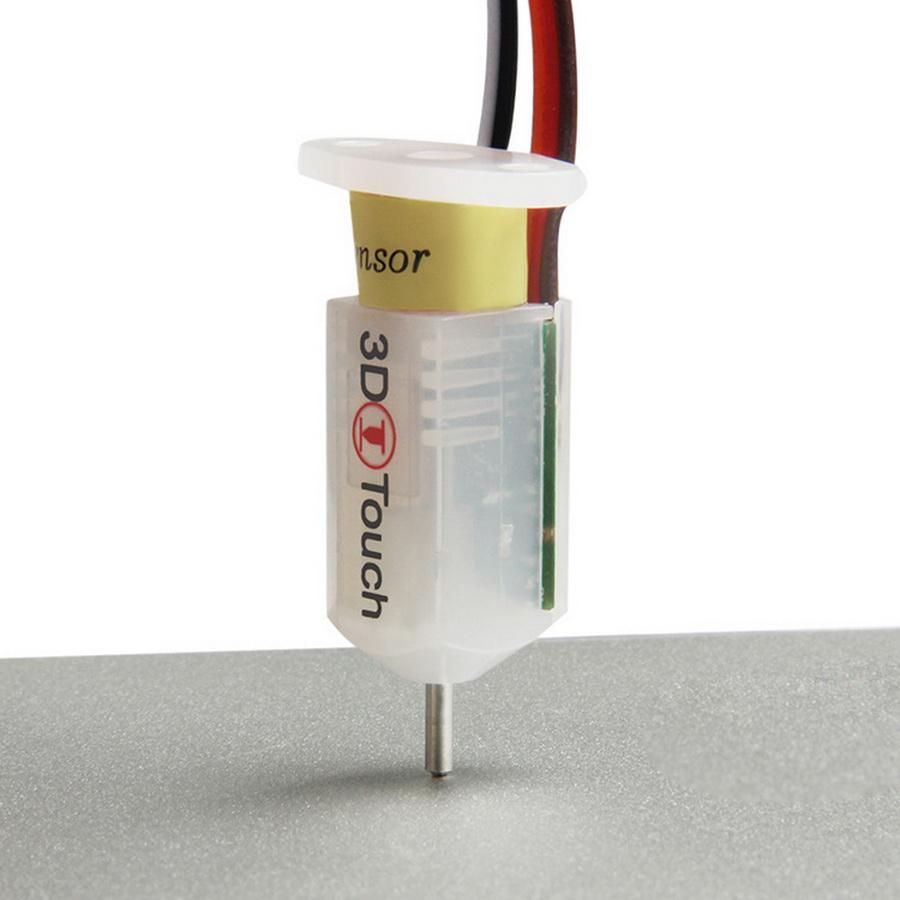

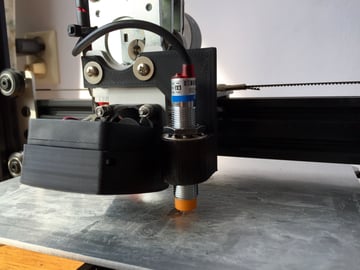

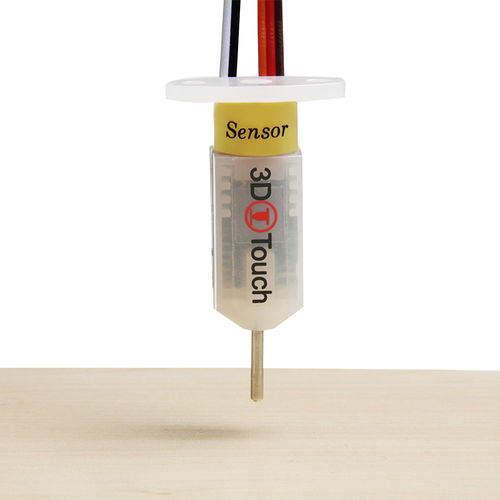

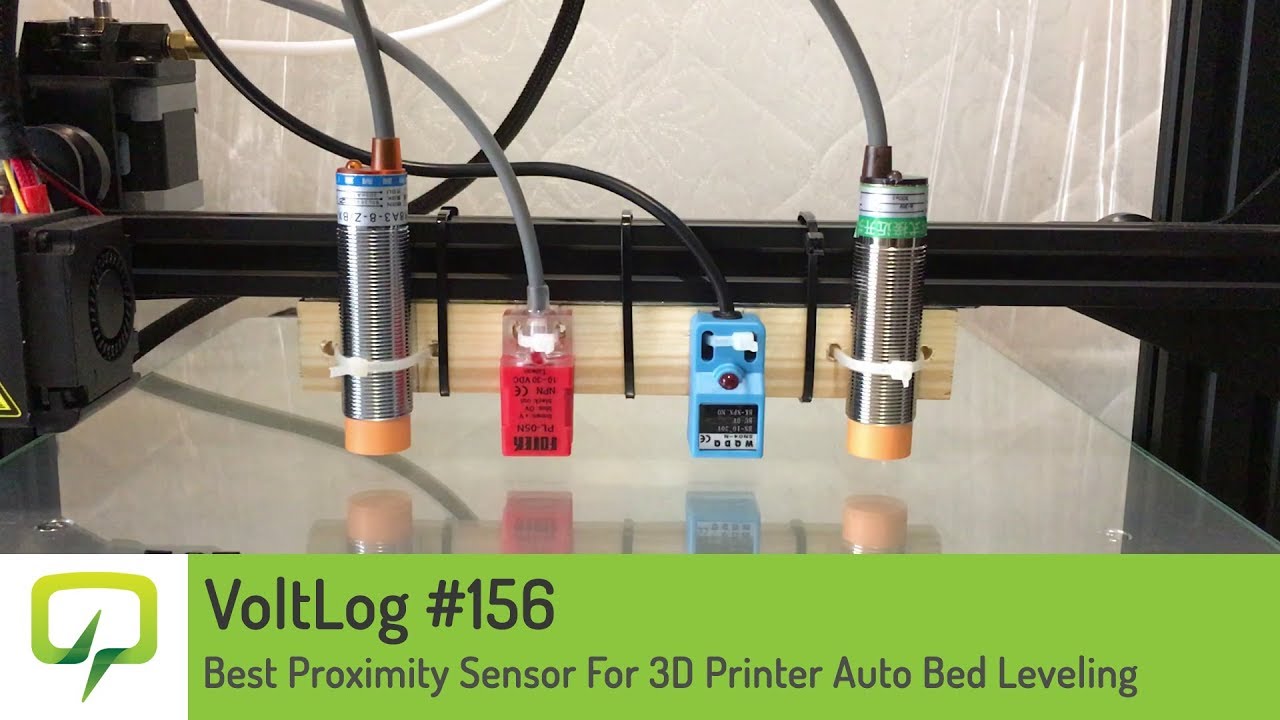

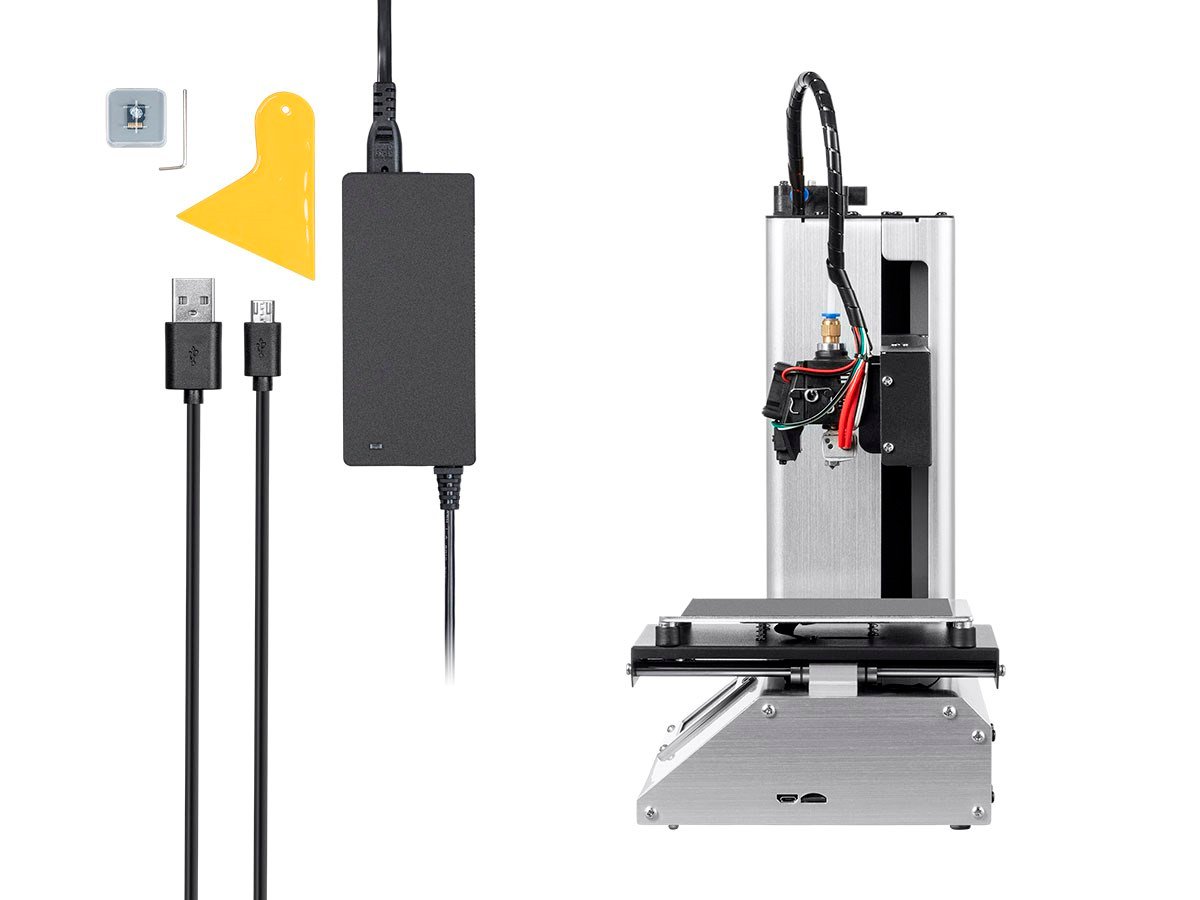

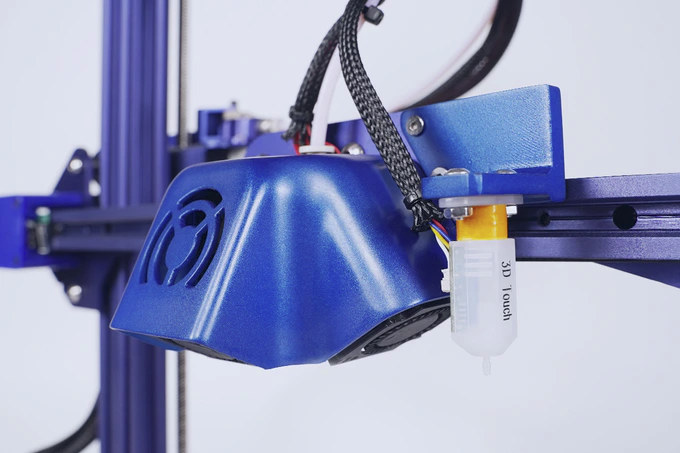

The most glaring issue with the r2 is that it can be really loud it needs a new fan right out of the box. To enable auto bed leveling we will need to edit the profile for your 3d printer. Not the laws of gravity. The auto leveling sensor will be replacing your 3d printers z end stop on your control board.

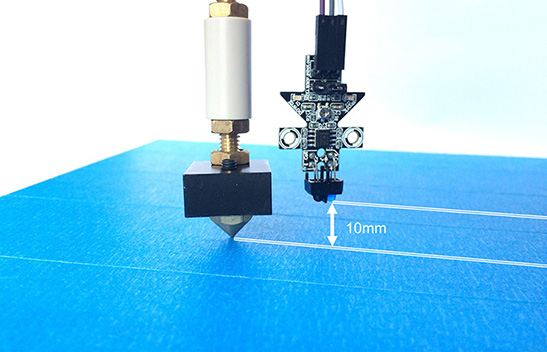

After updating your firmare make sure to keep an eye on the 3d printer things can go really bad if you mess with some setting you should not. In reality this might be lower depending on the sensing material. Abs and nylon may shrink upon cooling andor curing. Make sure your sensor has a detecting distance of at least 4mm.

If you are using a new printer for the first time you can download the stock simplify3d profile for your machine by going to help configuration assistant from within the software.

Enable Auto Leveling For Your 3d Printer With An Inductive Sensor Marlin Firmware 3 Steps With Pictures Instructables