3d Printer Carbon Fiber Composite

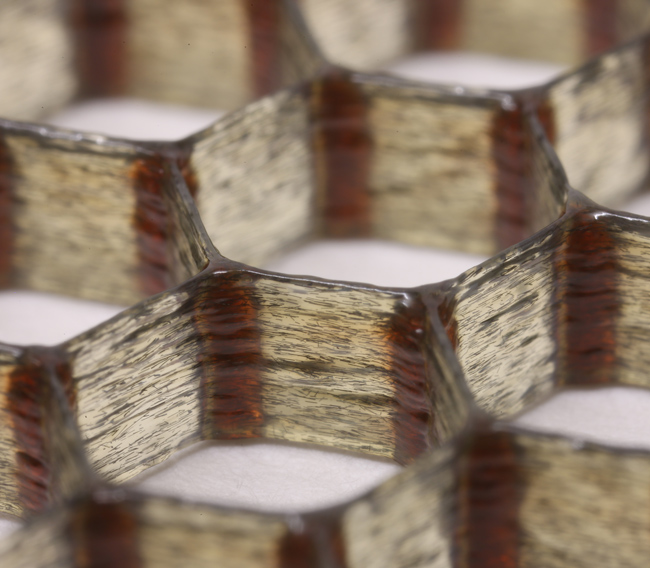

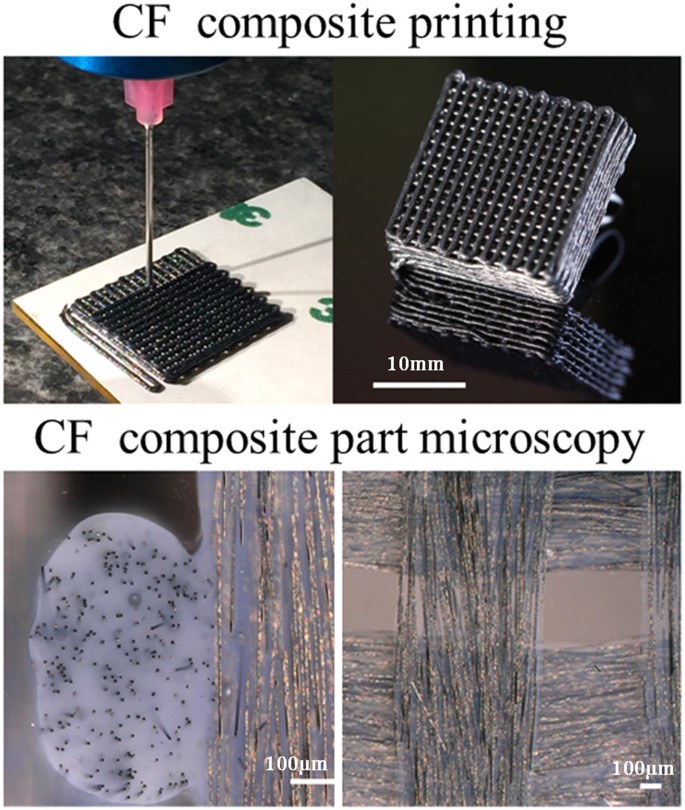

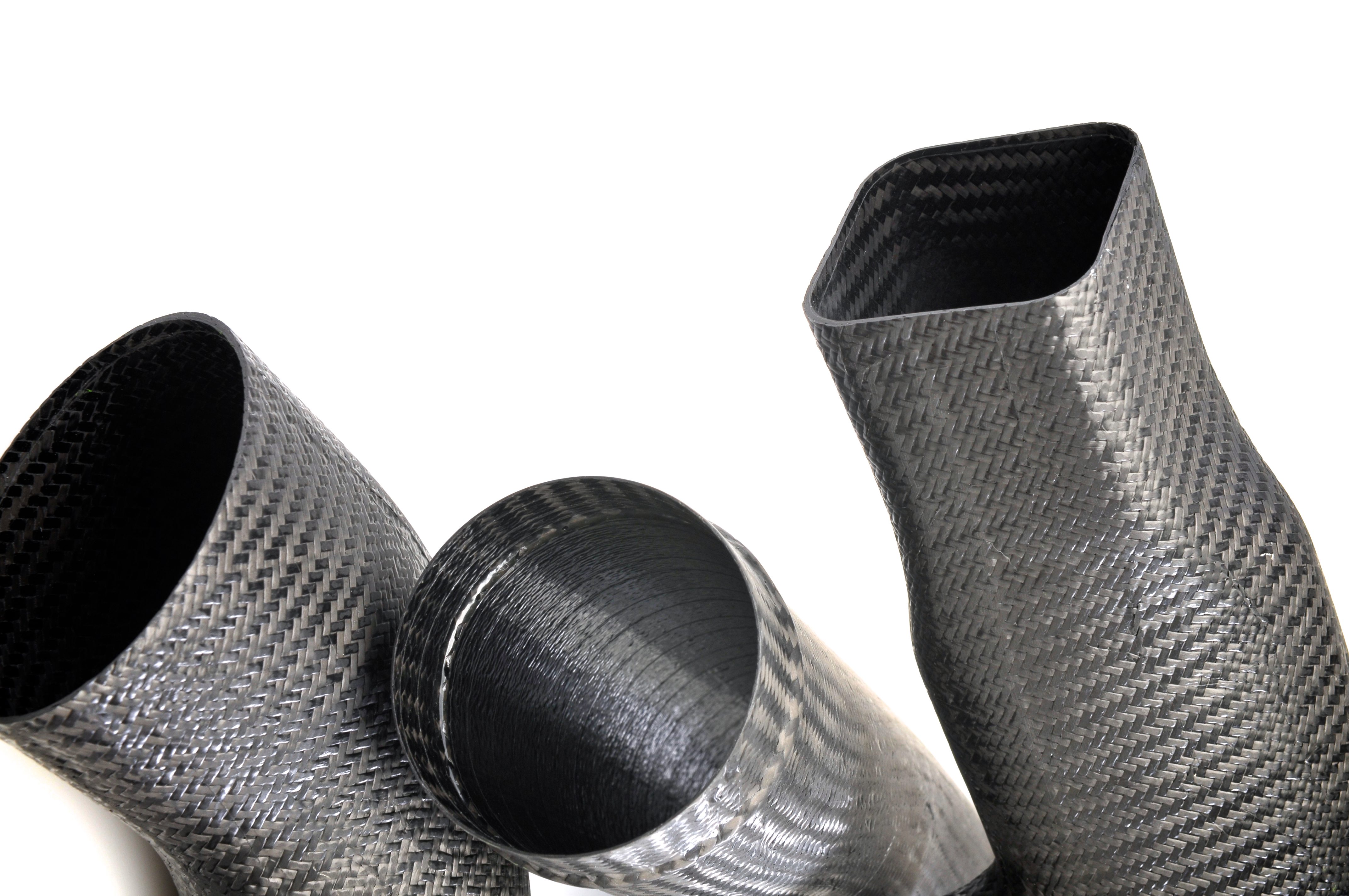

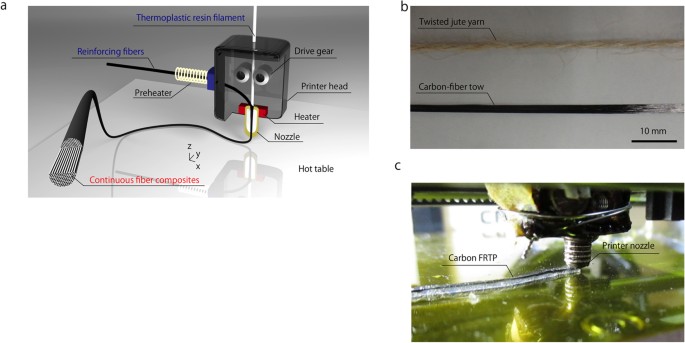

The chain is usually between 5 to 10 micrometers in diameter and varies in length according to the application.

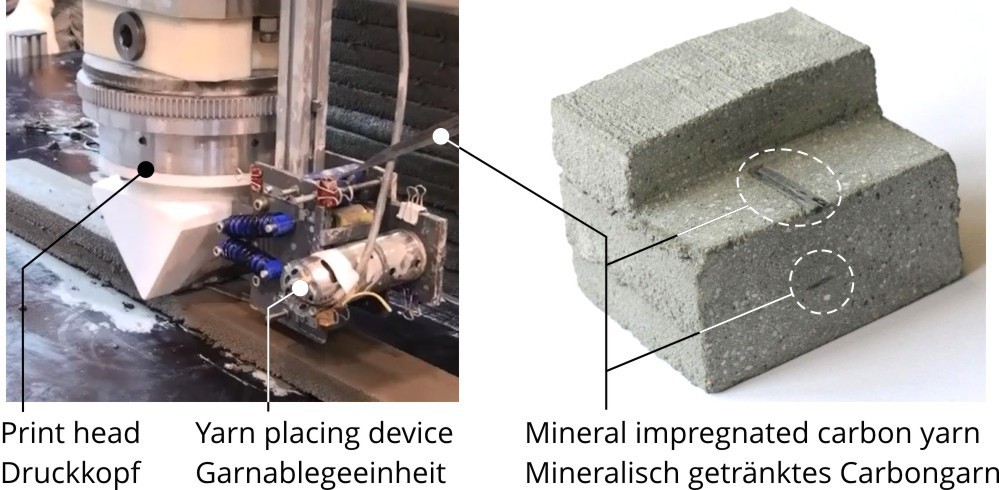

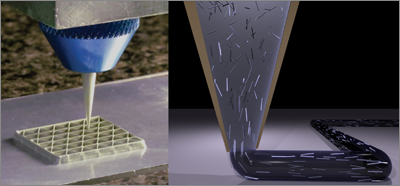

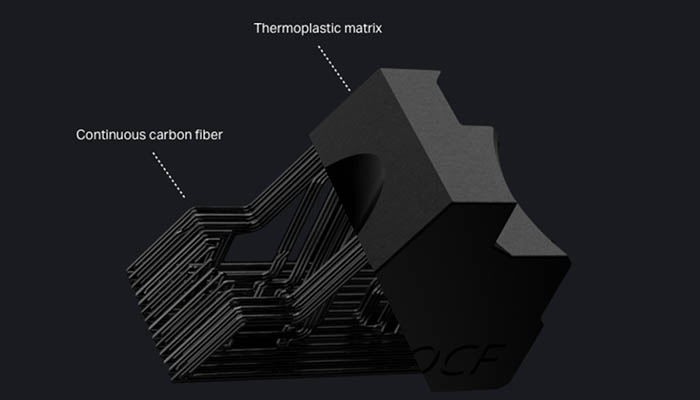

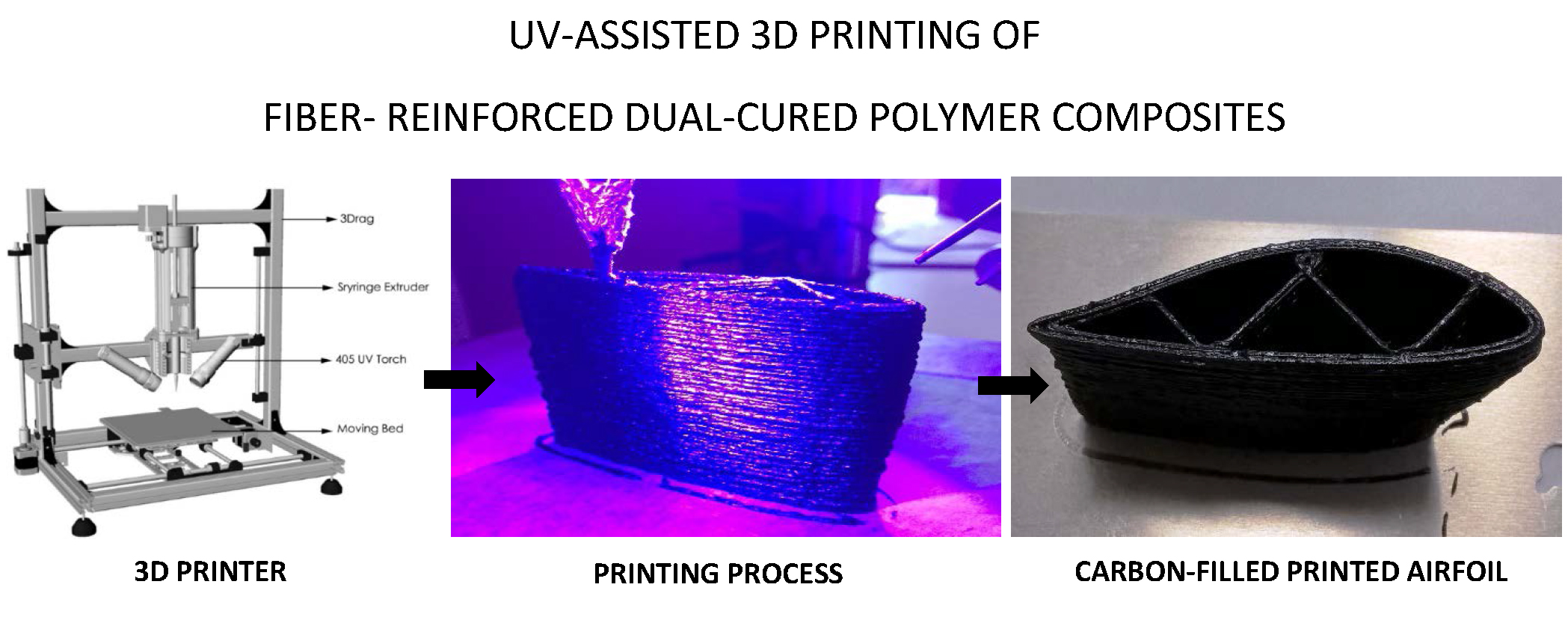

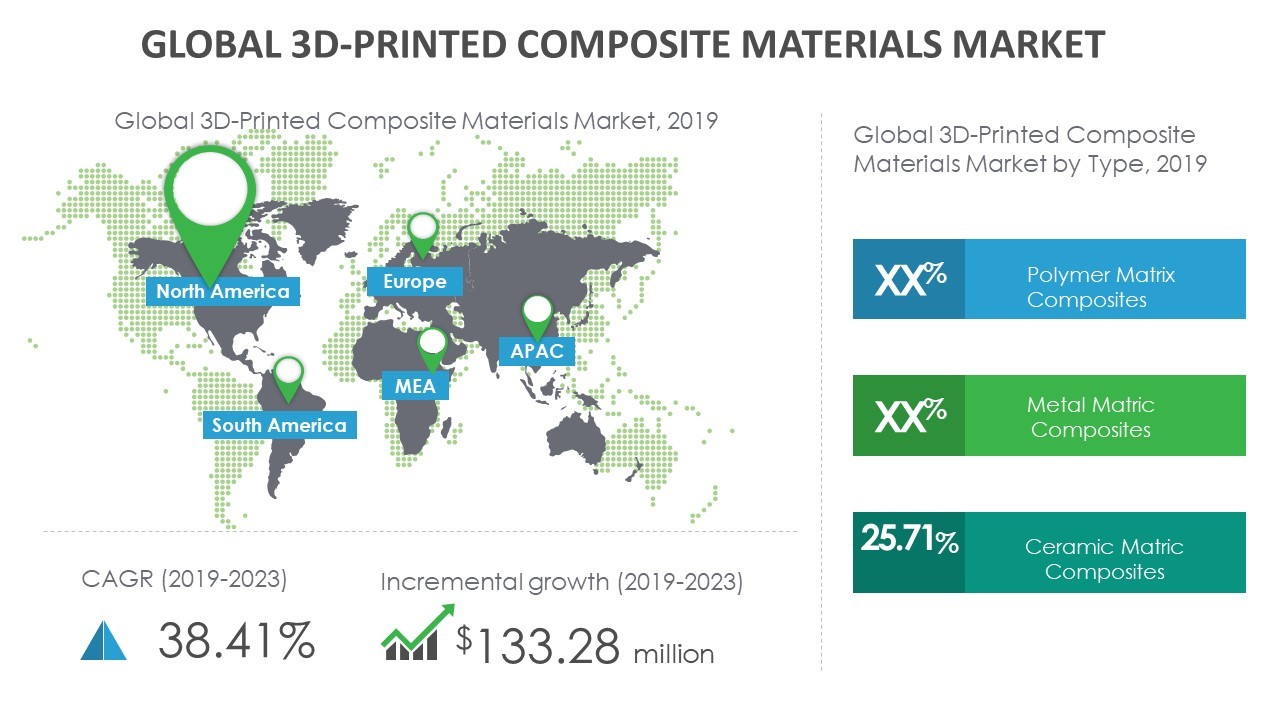

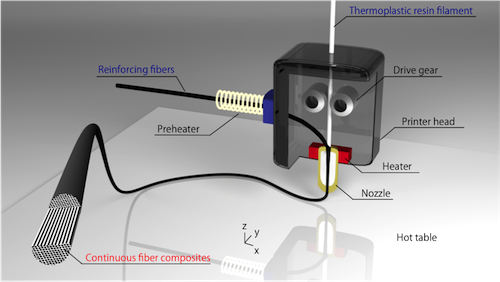

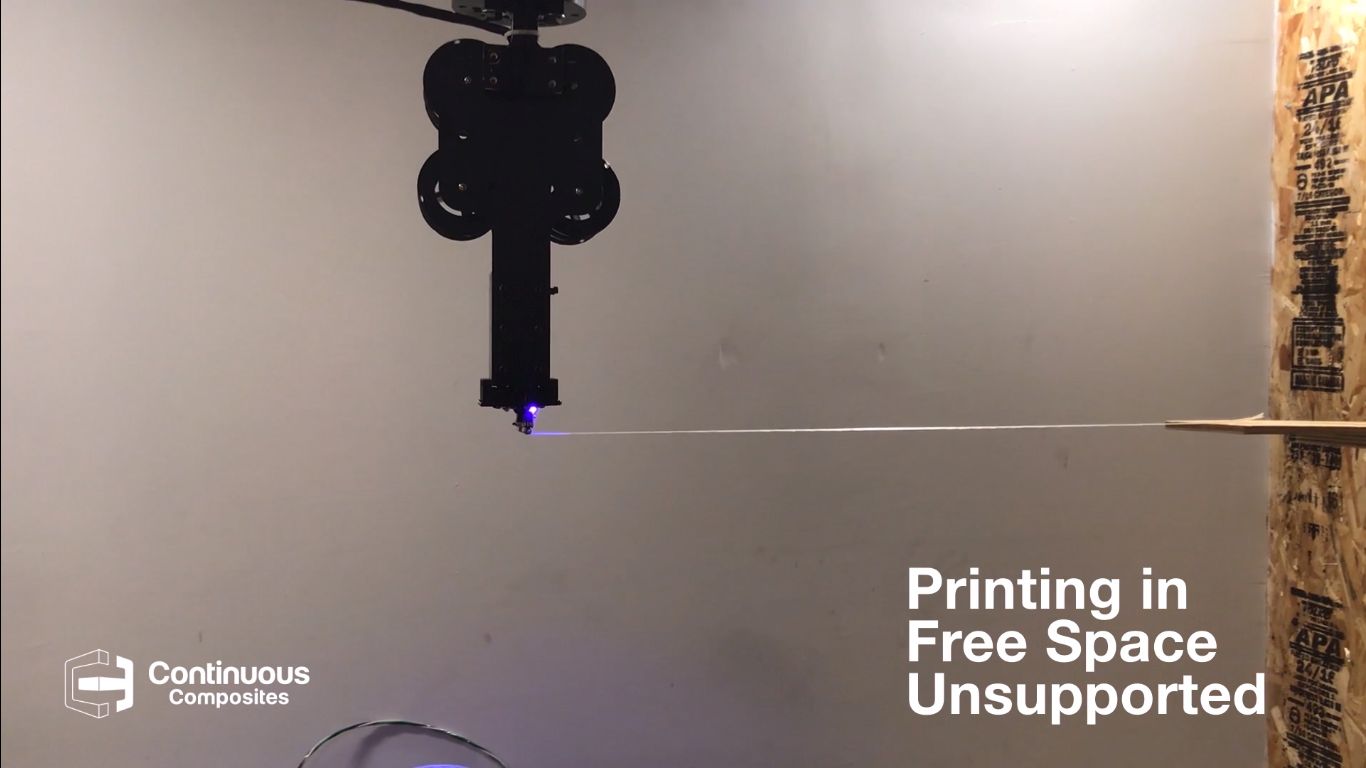

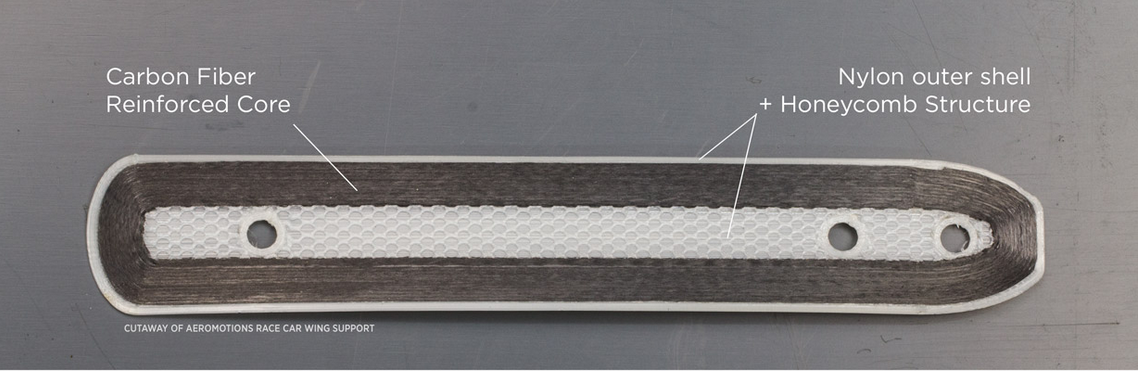

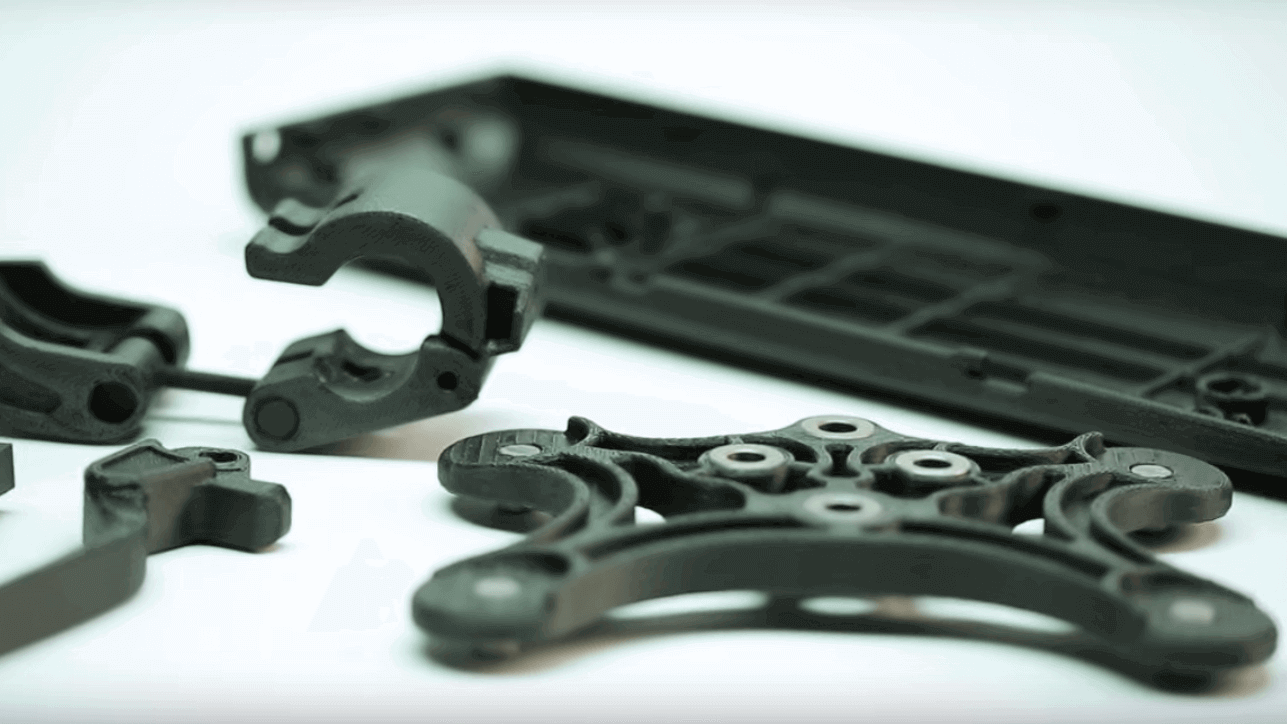

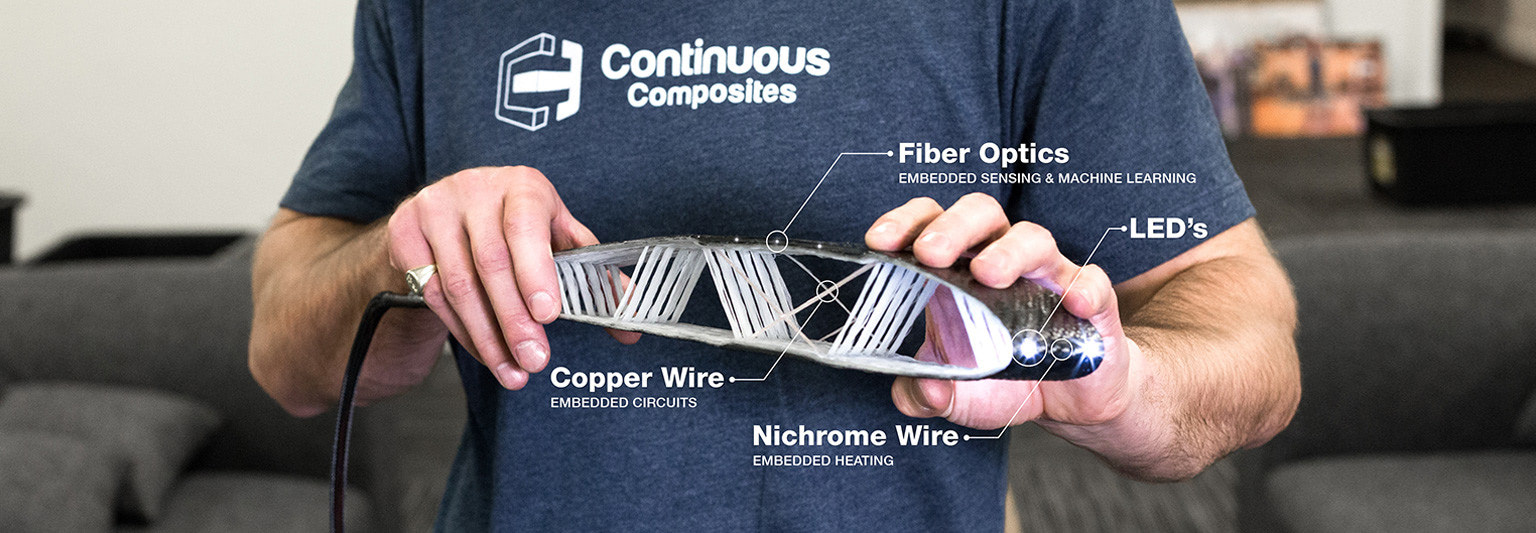

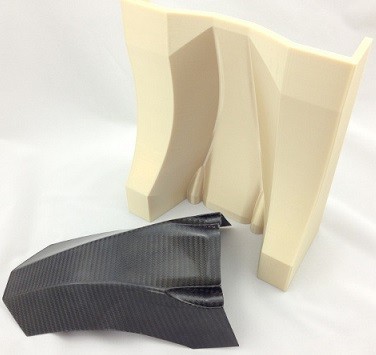

3d printer carbon fiber composite. Fiber reinforced polymer composites have many useful properties but their biggest disadvantage is that they are complex to manufacture and expensive. Over the years carbon fiber has become popular across many sectors because it offers interesting properties including high stiffness high tensile strength low weight high chemical resistance high. 3d printing with carbon fiber composites is economical and efficient. Its strength and stiffness make it the perfect material to replace metals like aluminum for lighter parts and tools.

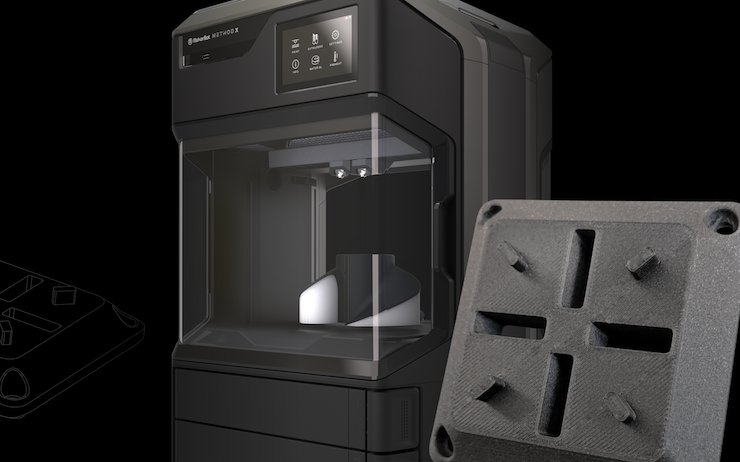

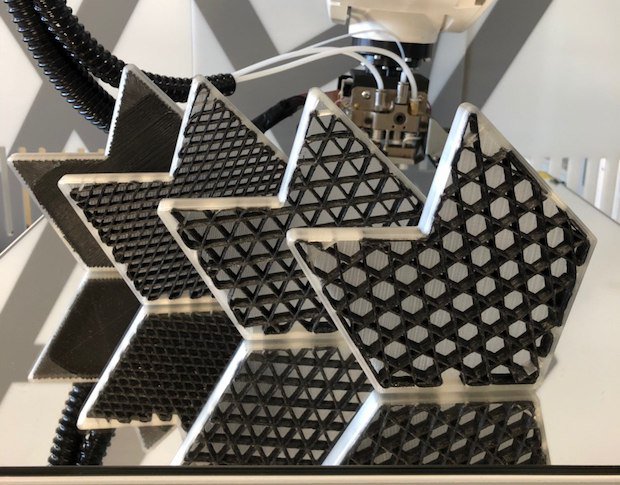

The onyx pro prints composite parts that are 10x the strength of plastic by reinforcing chopped carbon nylon with continuous strands of fiberglass. Produced for the first time by joseph swan in 1860 carbon fiber is made of a long chain of carbon atoms bonded together. Widely recognized as one of the premier carbon fiber 3d printers on the professional market the markforged mark two gen 2 is a workhorse machine that is compatible with a range of composite materials including carbon fiber high temperature glass fiber hsht fiberglass and kevlar. Our carbon fiber composite 3d printing material nylon 12 carbon fiber consists of chopped fiber combined with nylon 12 to deliver the strength and stiffness you need for rigid tools prototypes and production parts.