3d Printer Heated Bed Temperature

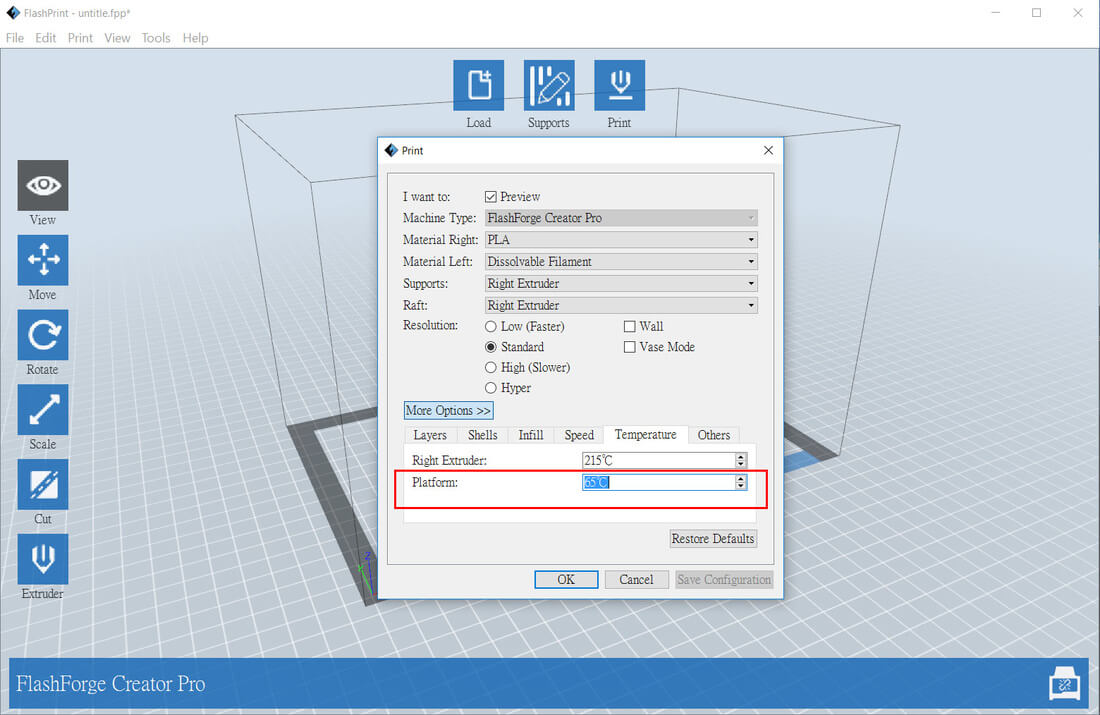

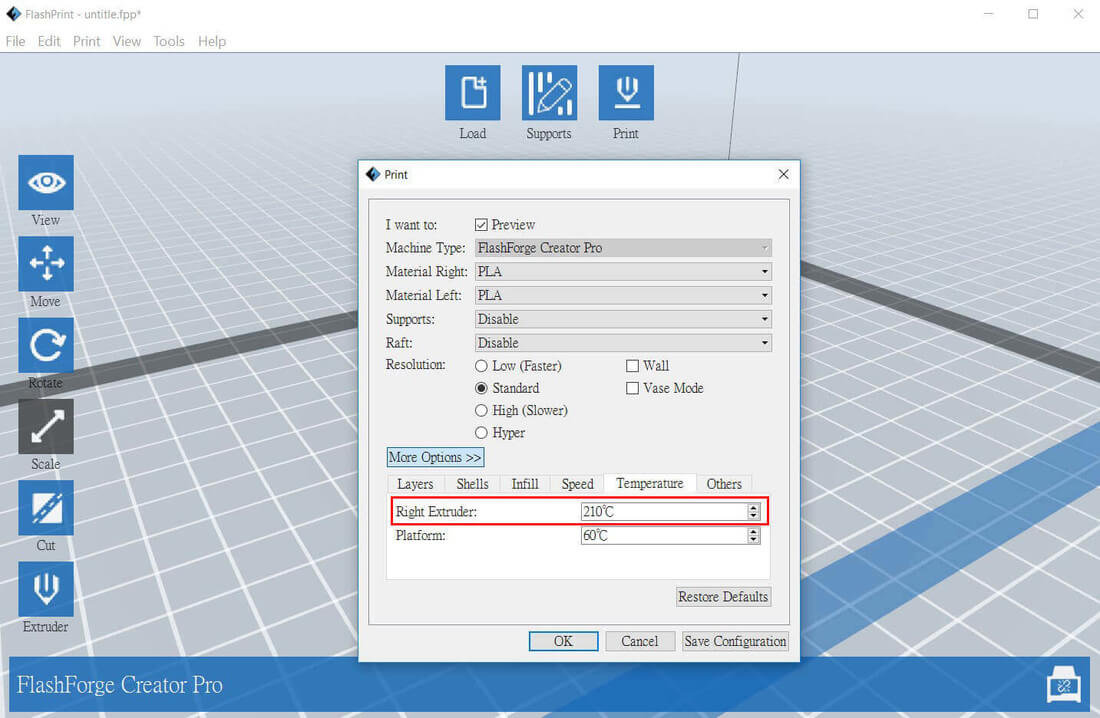

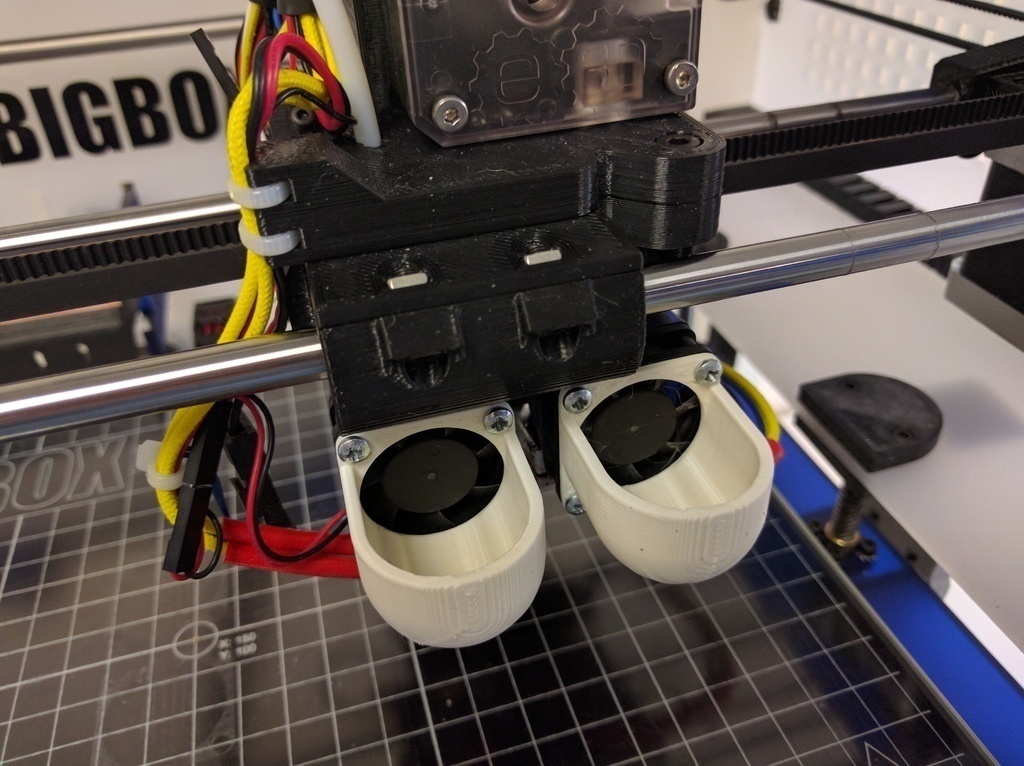

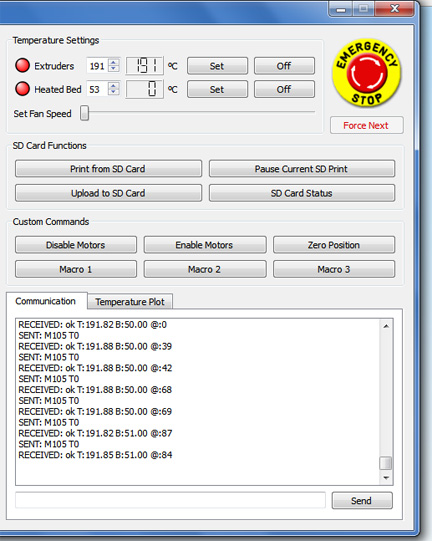

I have only one extruder so i will set it to 0.

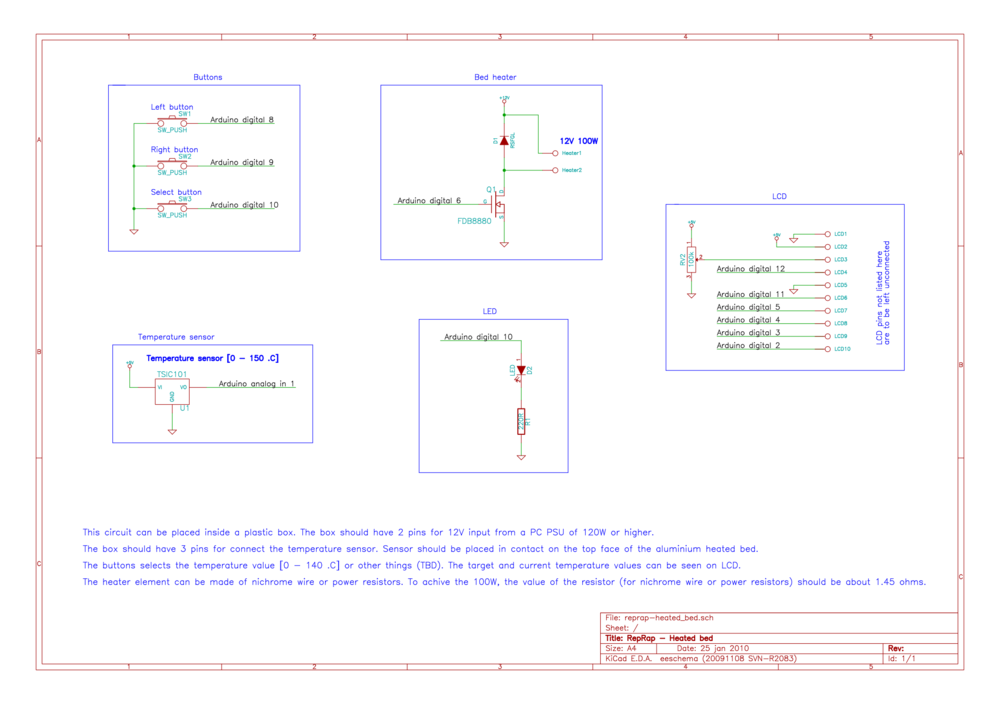

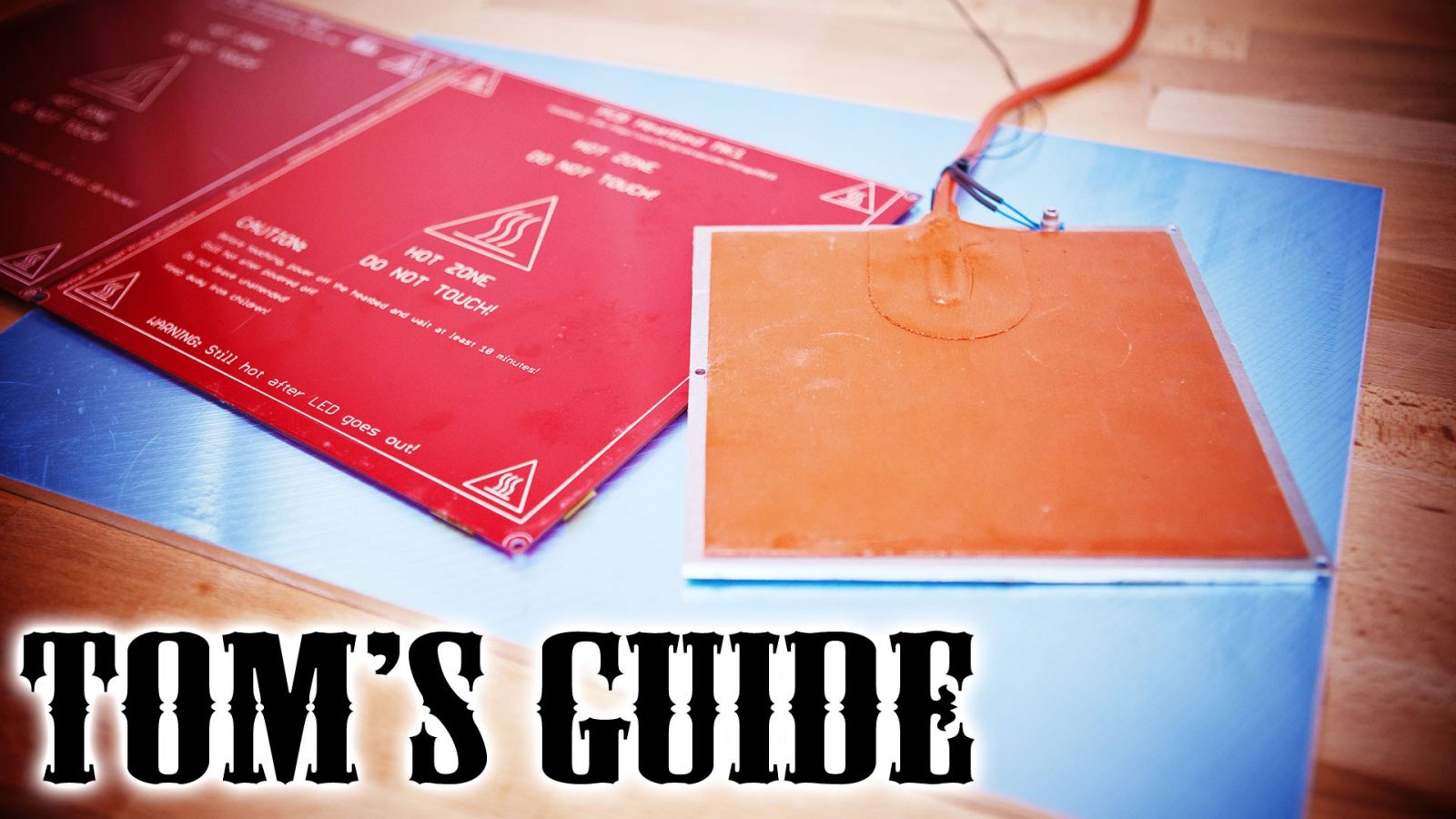

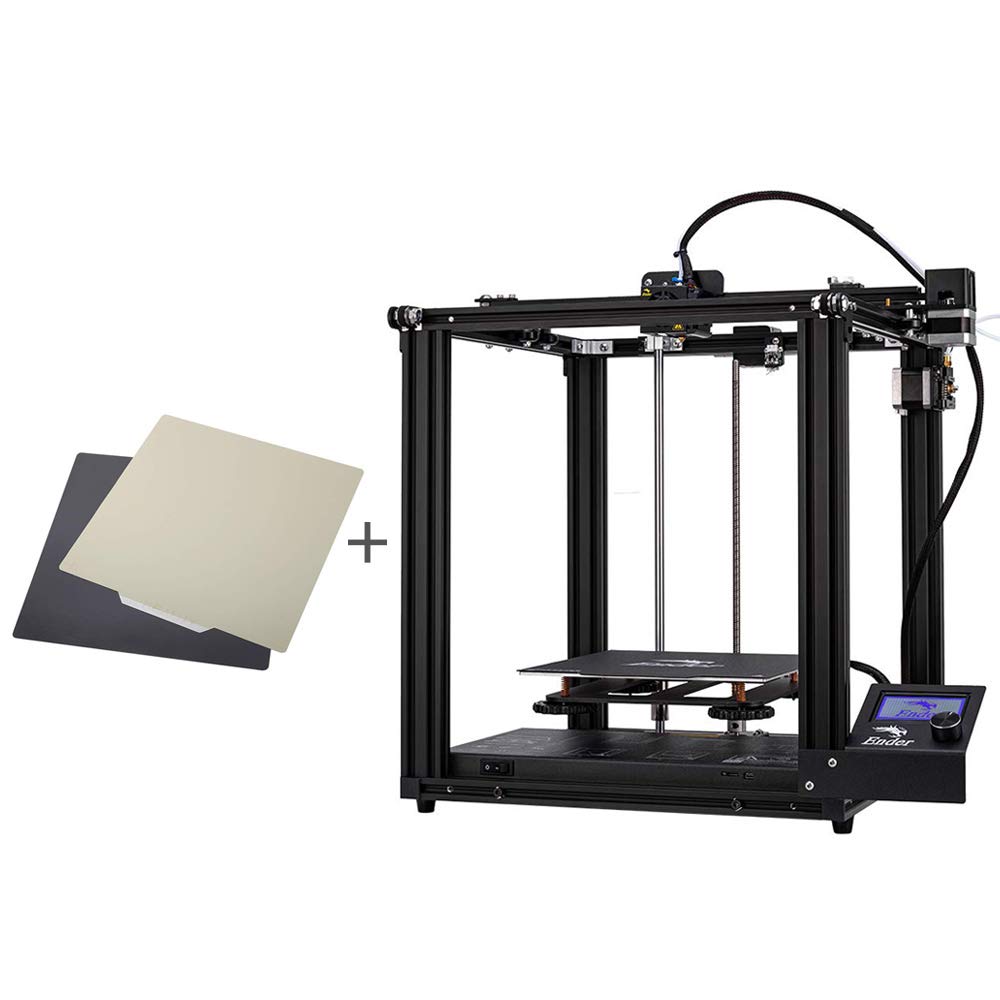

3d printer heated bed temperature. You will learn a bit more about how the heated bed works. A hotter first layer gives the plastic more time to spread into the blue tape and adhere to itself. These heat beds are used by many 3d printers and our own rostock v10 due to their great performance and affordabilitythis particular heat bed has 2 integrated leds and an integrated resistor which makes it rather plug and play when compared to other solutions. This article is part of the diy 3d printer from scratch.

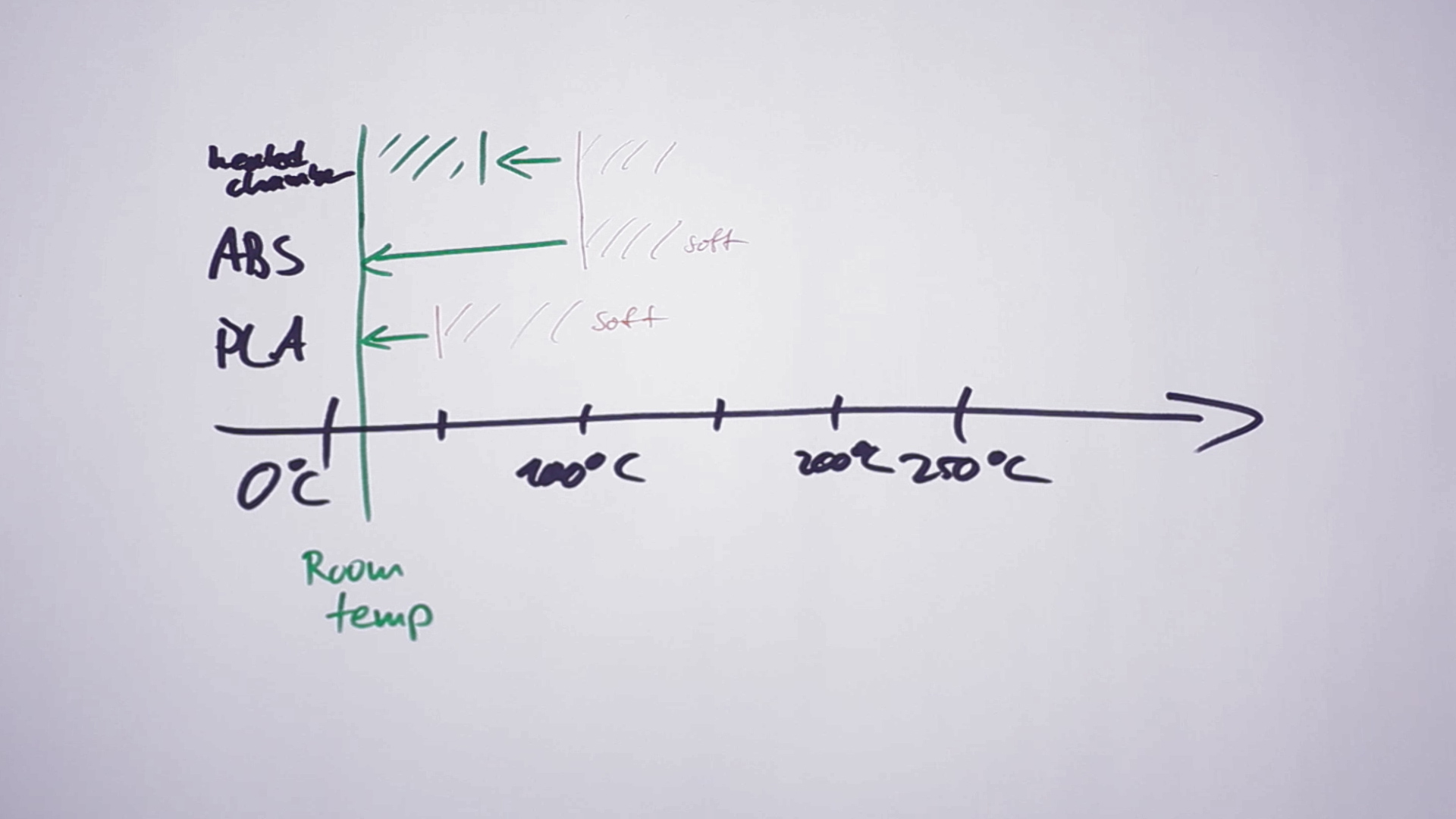

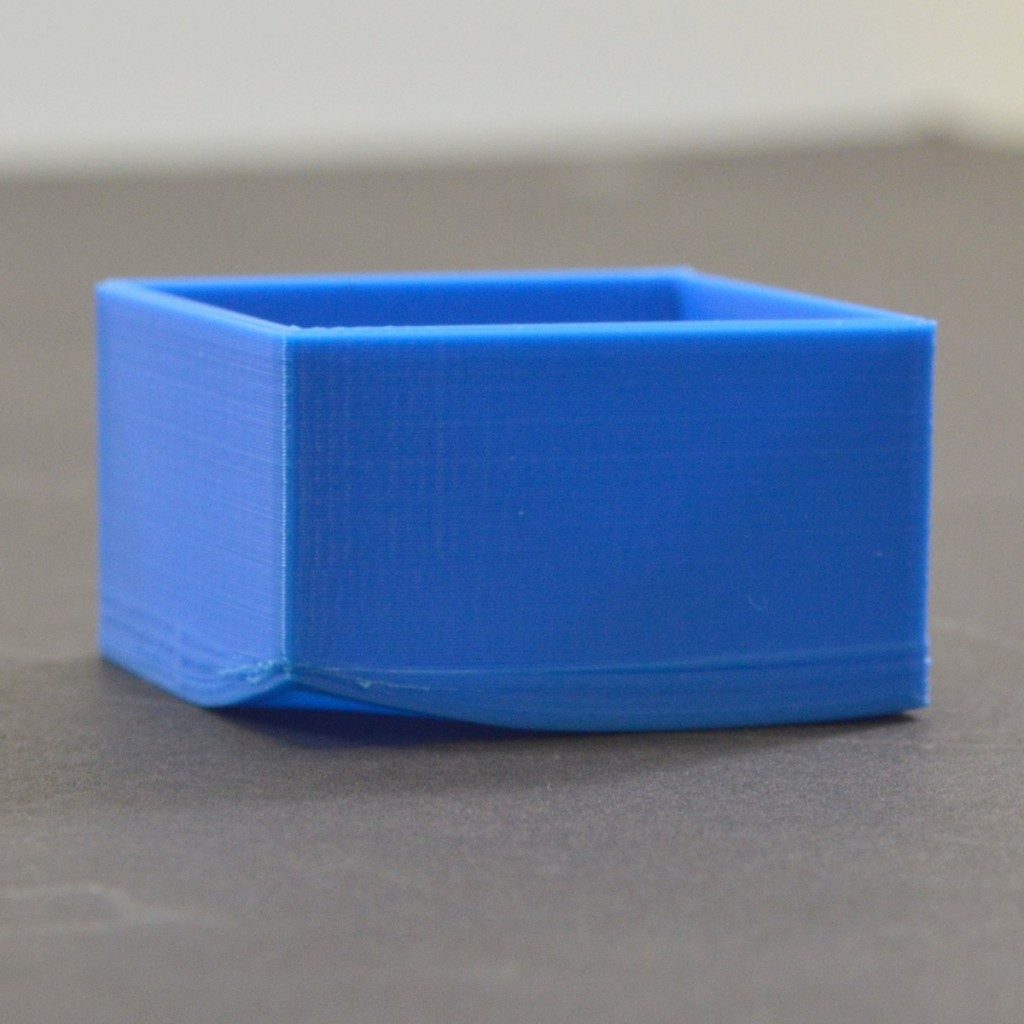

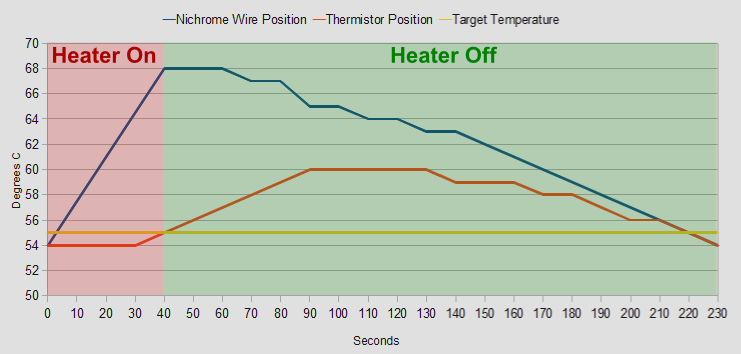

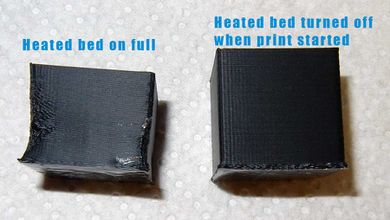

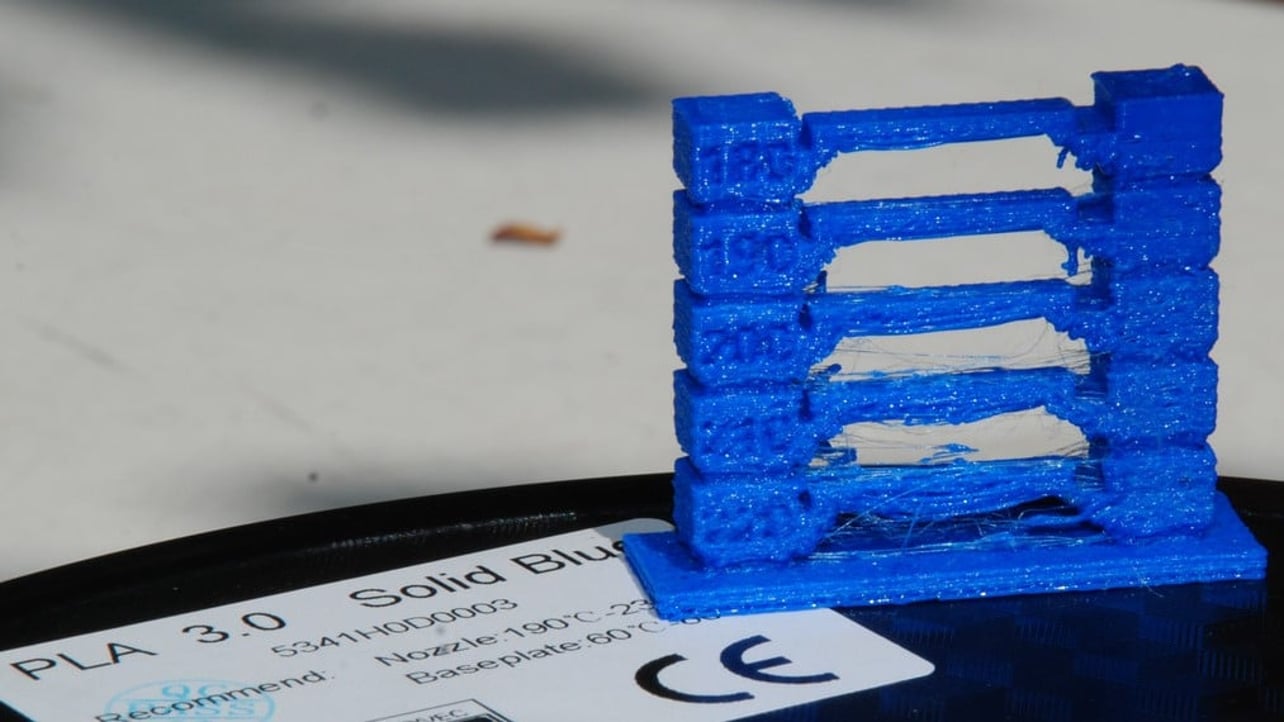

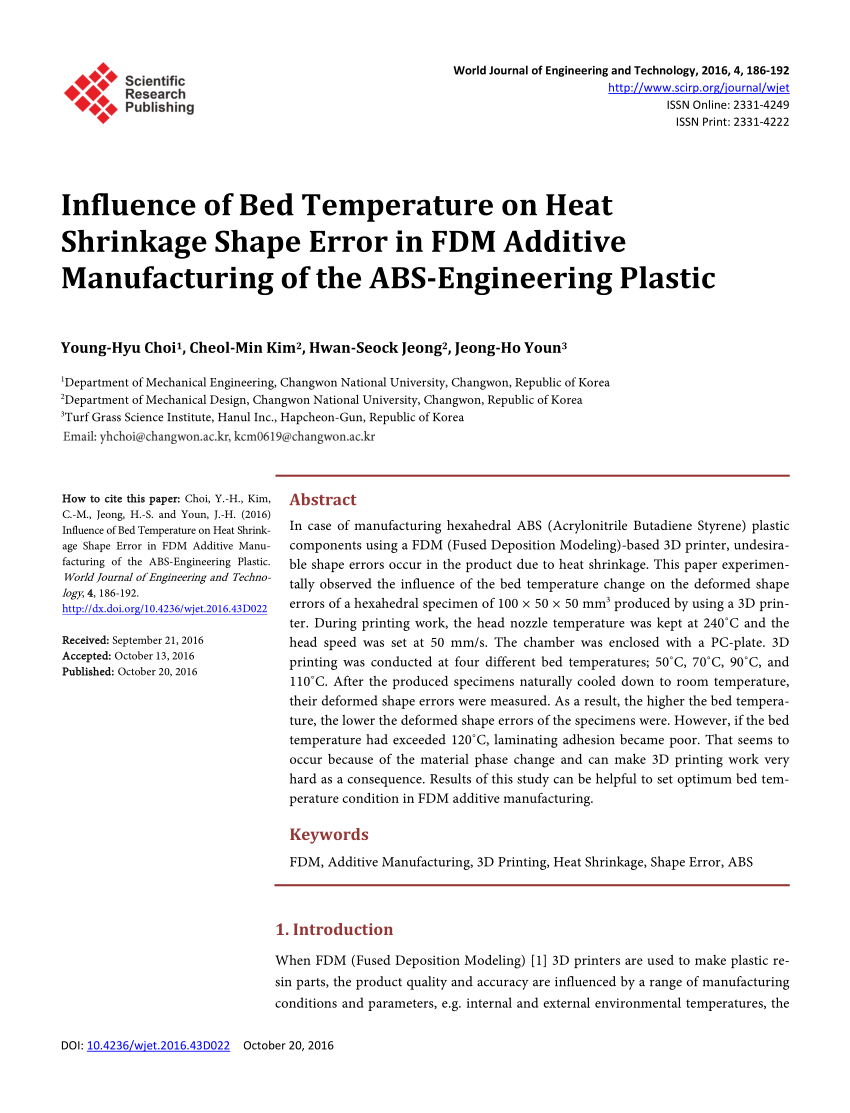

M303 this command initiates a process of heating and cooling to determine the proper pid values for the specified hotend or the heated bed. Thats because when abs cools it shrinks and if a print cools too fast it will warp. You can also deliberately make your print bed stickier by the application of adhesion enhancers which is a time honored practice in the field of 3d printing. The extreme case of this would be a heated chamber which keeps your abs print at 60 to 800c so youd end up with the same 300 temperature difference.

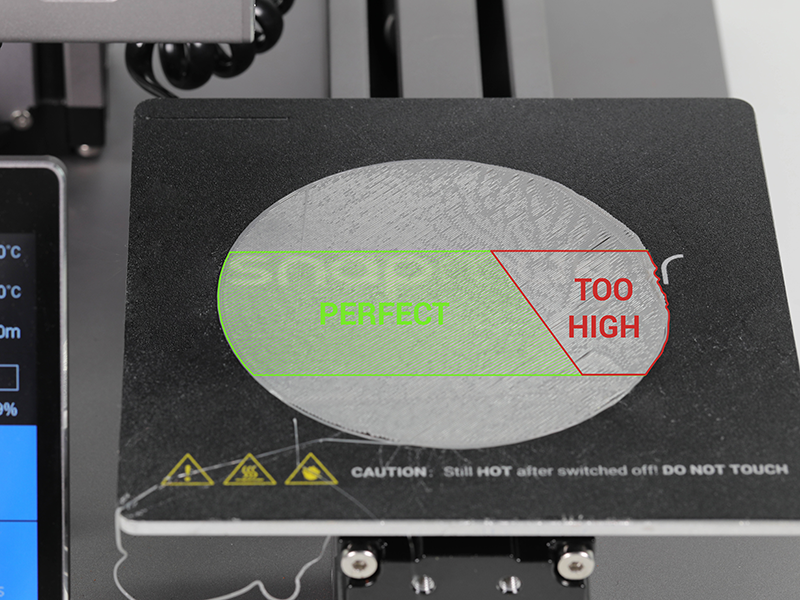

Too little contact with the bed. The heated bed is a device that should provide a warm surface to the plastic stick. Weve found for example that the best range is between 550c and 700c. Set your print bed temperature to approximately 600c 700c.

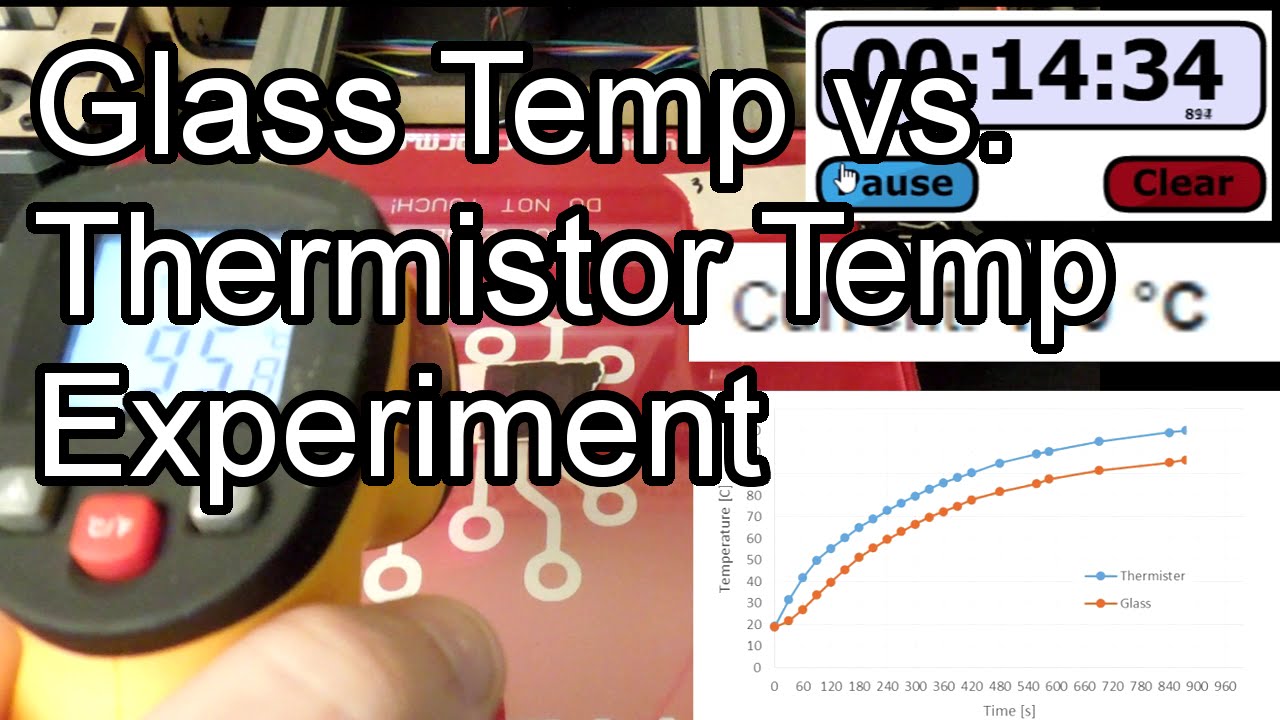

A nozzle temperature of 210 to 250 0c is best and a heated bed around 80 to 110 0c is necessary. Although not all printers have them the ones that do always need to be set to a certain temperature. That really depends on your material but a good rule of thumb is your first layer should be at the glass transition temperature and then you should print the rest about 10 20 0c colder than that. The easiest solution to bed adhesion problems is to orient your design such that it has the most contact with the bed upon printing.

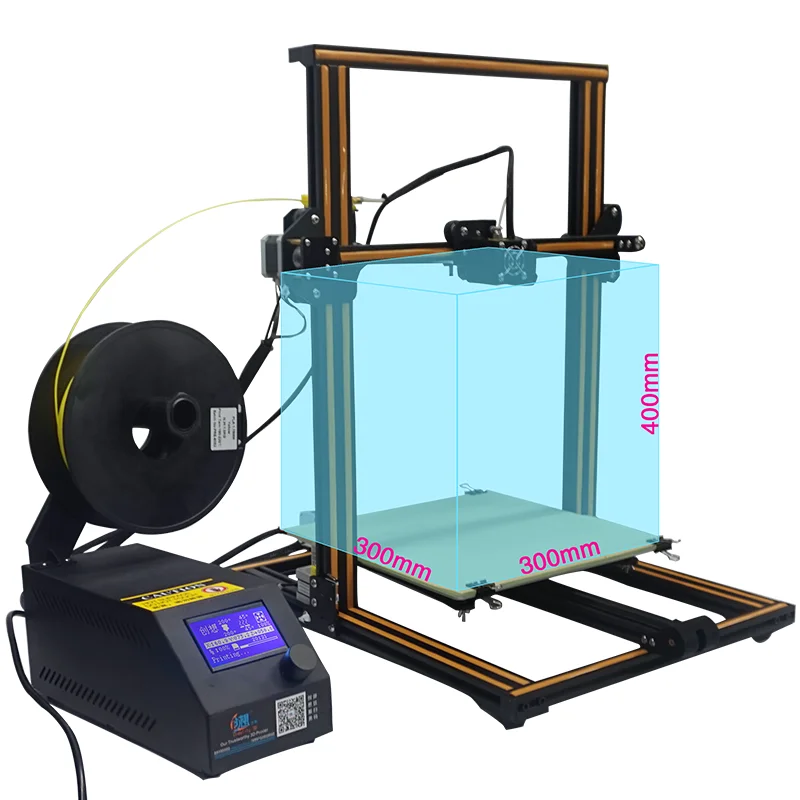

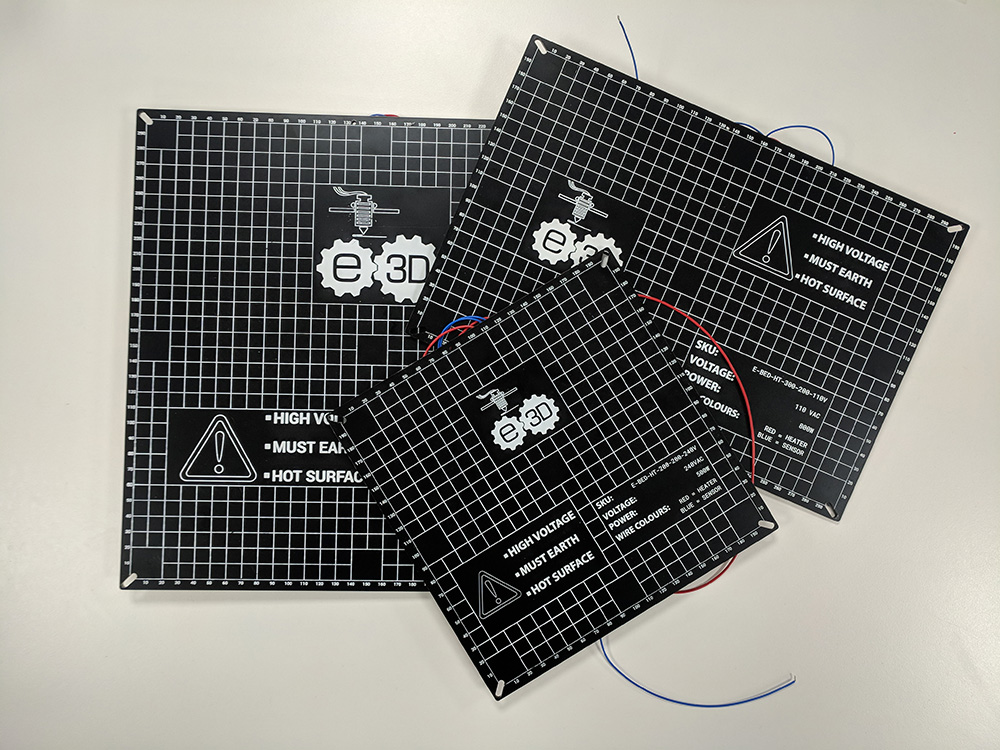

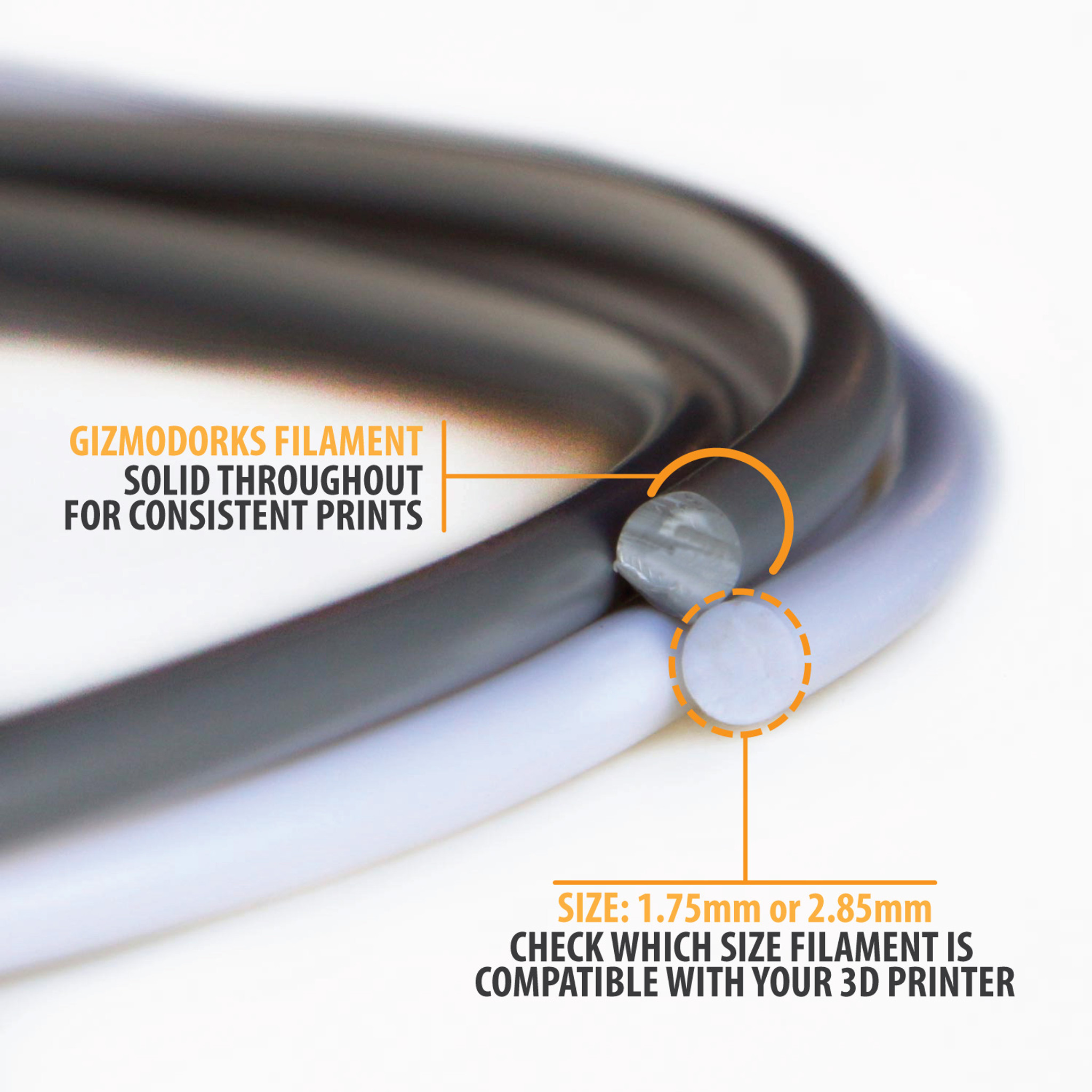

For the 175mm the recommended printing temperature is 1850c 2000c with a heated print bed or 2000c 2300c without a. In addition to this abs needs to be printed in an enclosed 3d printer so that it cools very slowly. The mk2a heat bed 200mm x 200mm is a good example of a pcb heat bed. E0 this argument selects the extruder we want to calibrate.

Even though the recommended pla print temperature is 700c this doesnt always work. Heated chambers or at least enclosed printers are extremely nice for the high temp plastics but thats an entirely different topic. For the 300mm the recommended printing temperature range is 2000c 2300c. The recommended printing speed is 40.

Heated beds have a huge advantage against warping and other adhesion issues when compared to cold beds.