3d Printer Hot End Design

As you design.

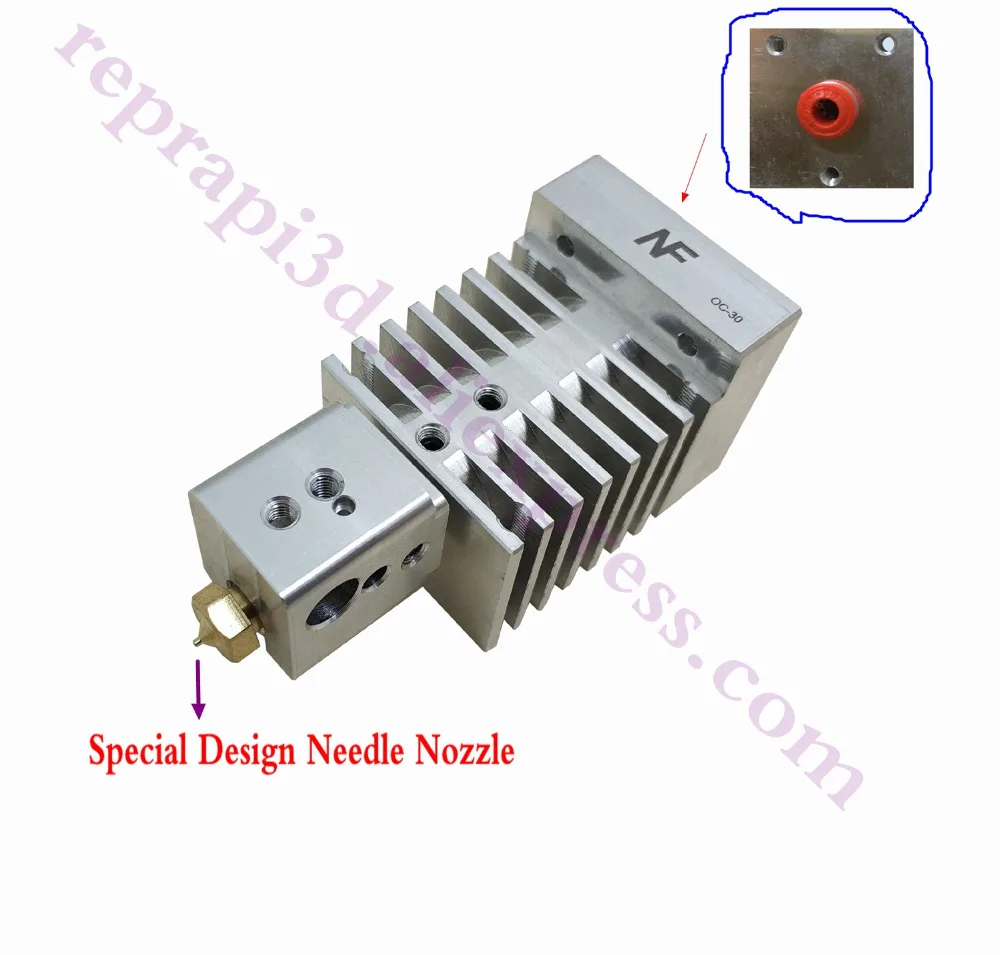

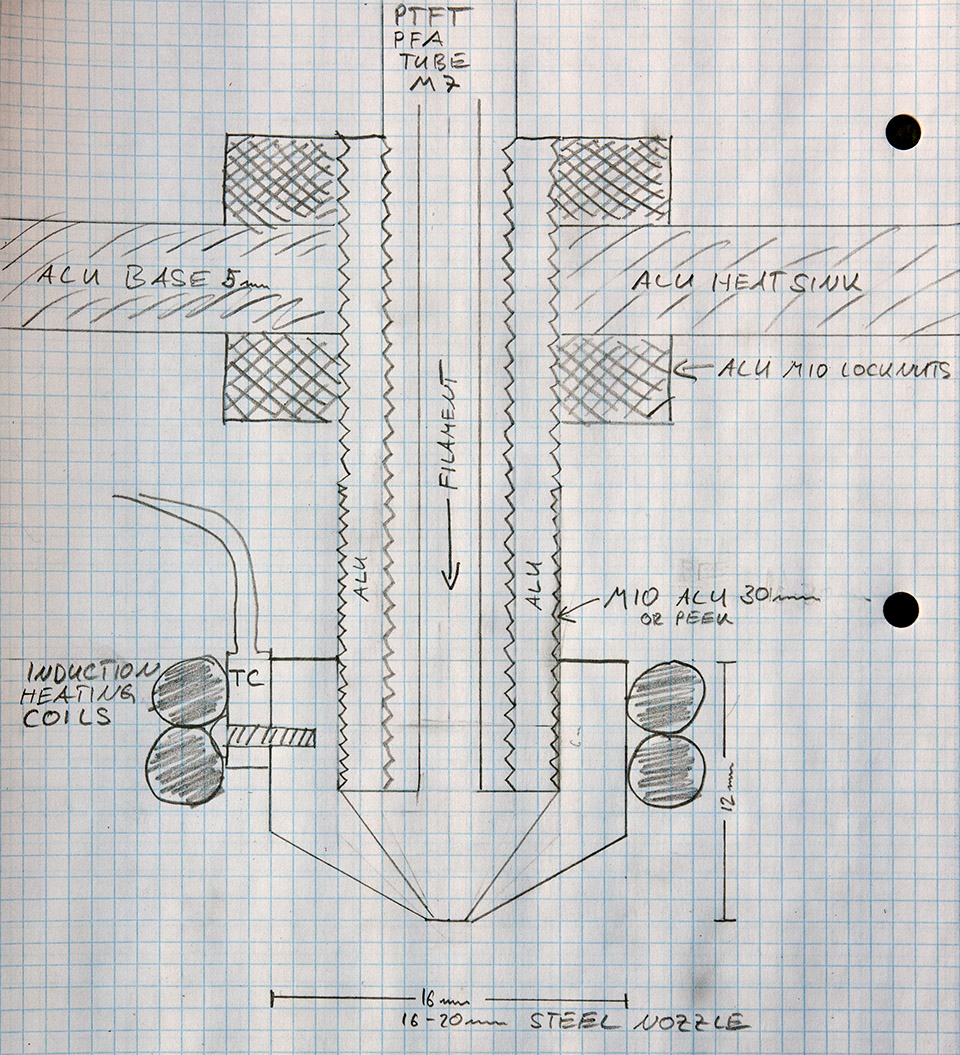

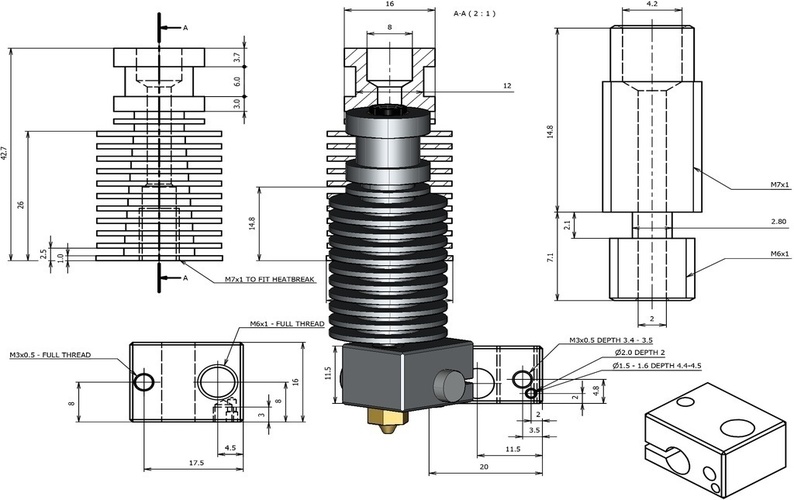

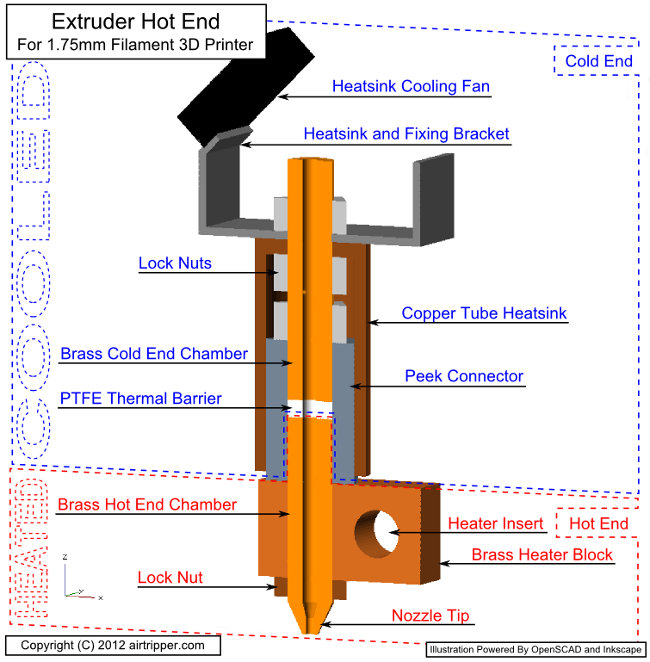

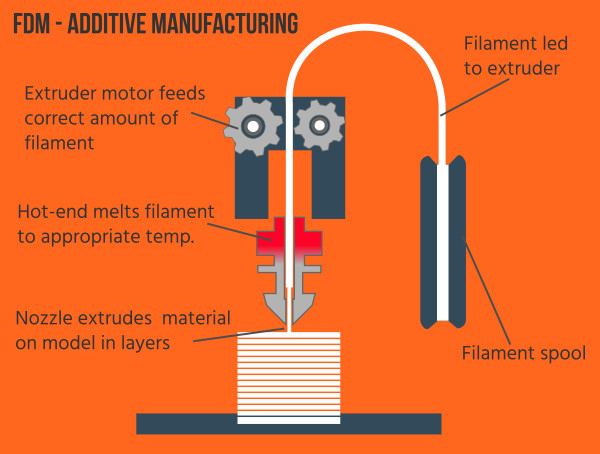

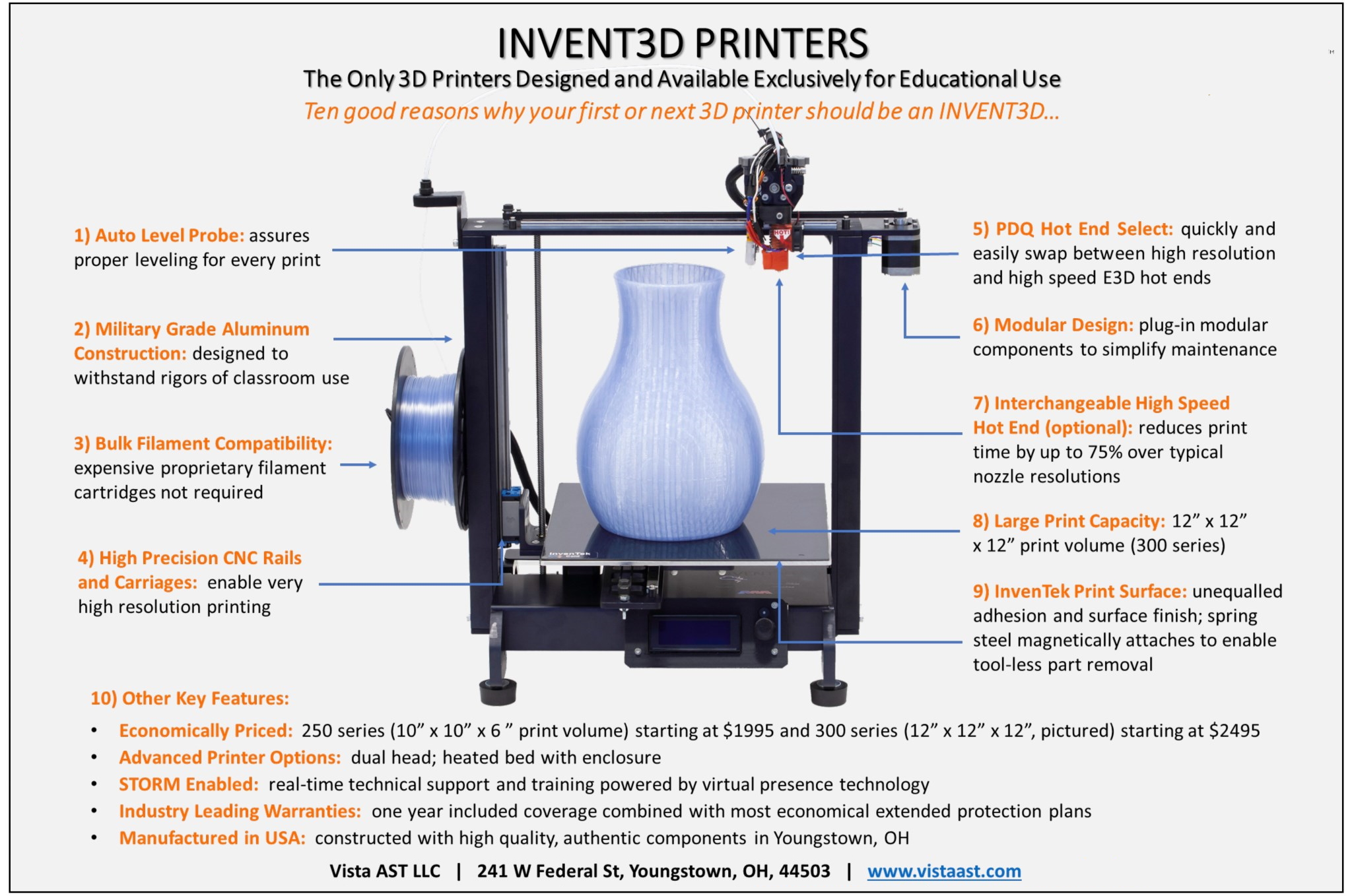

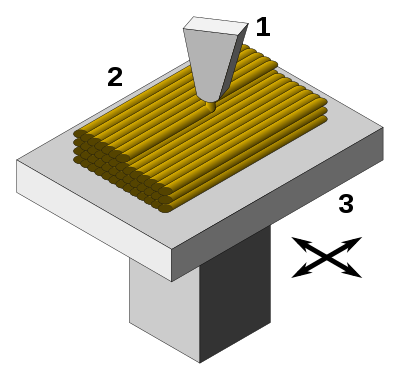

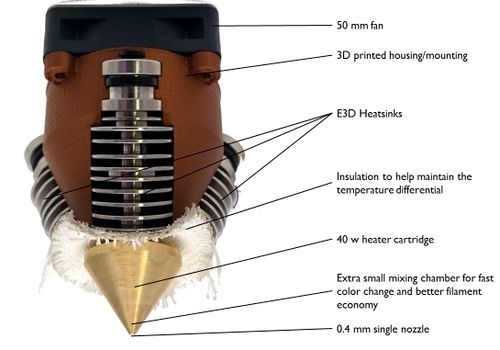

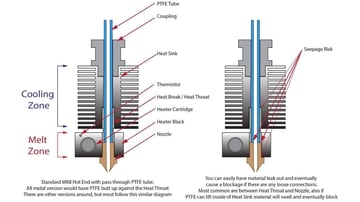

3d printer hot end design. To understand what makes an all metal hot end so special we need to go back to the design of a standard hot end the type that probably came with your 3d printer. This is the part that actually melts the filament and extruders it onto the print bed. Find the best hotend upgrade for your 3d printer from our wide selection of top brands like e3d slice engineering micro swiss and more. The hot end is one of the most important parts of a 3d printer.

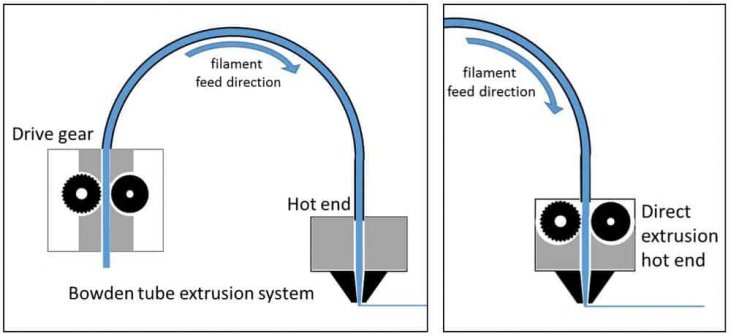

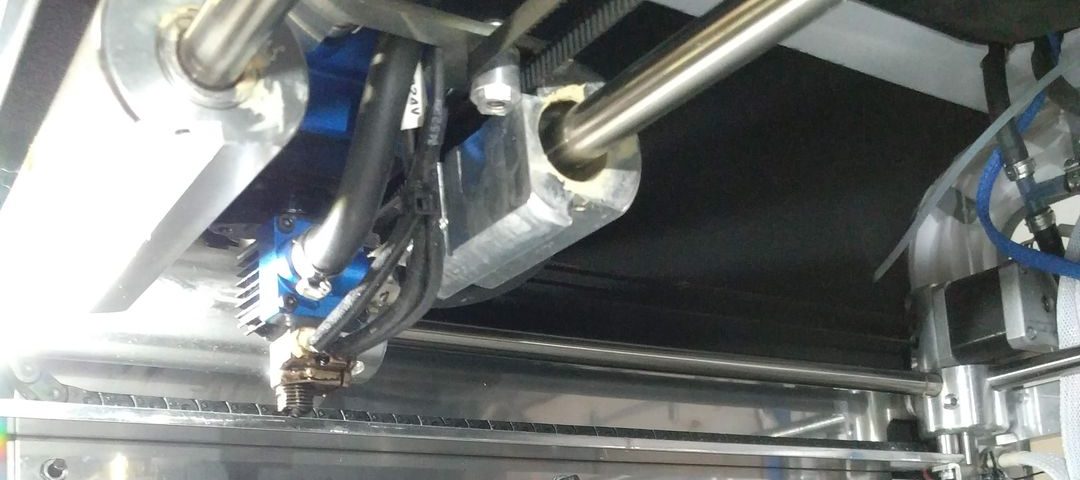

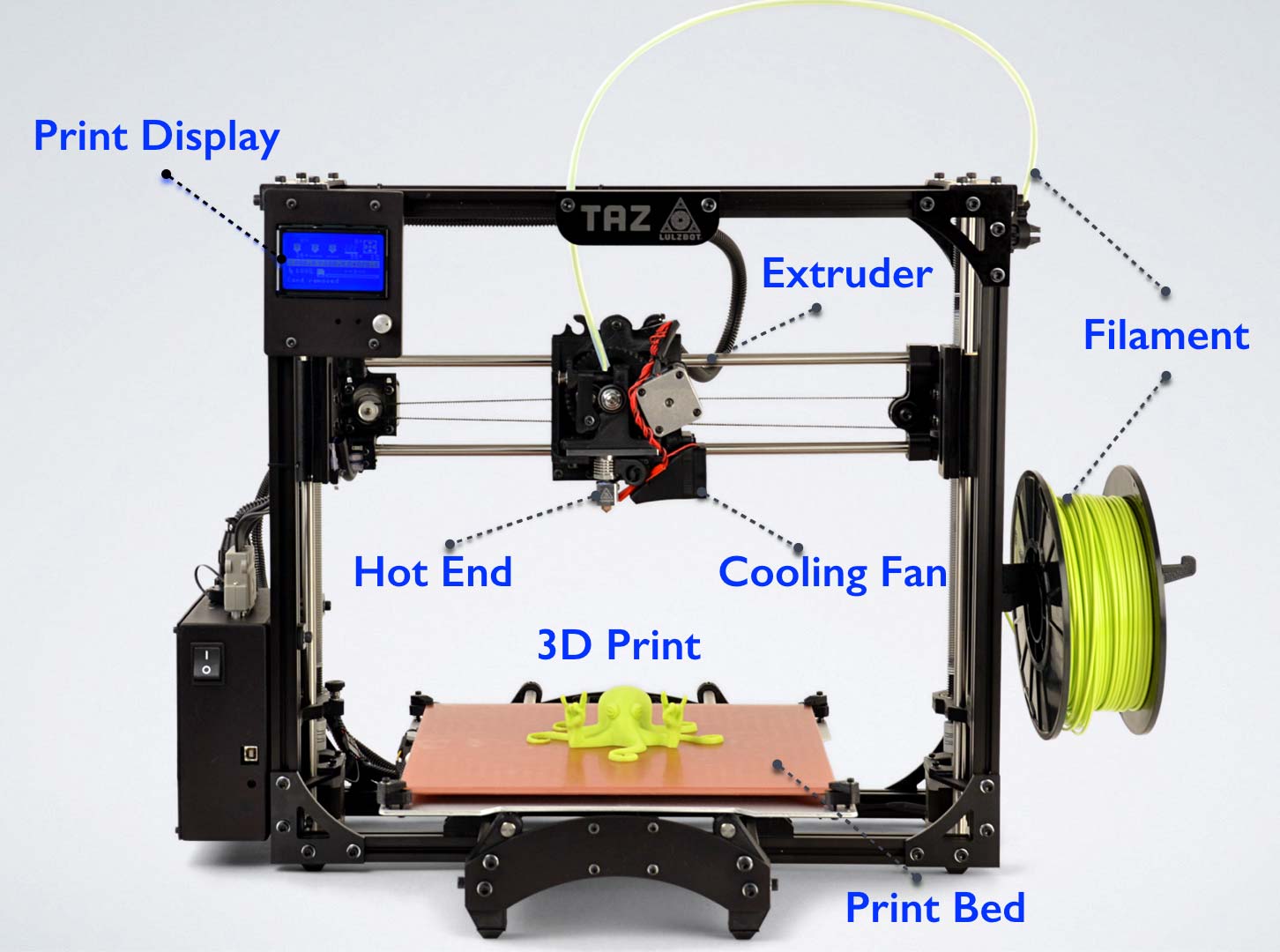

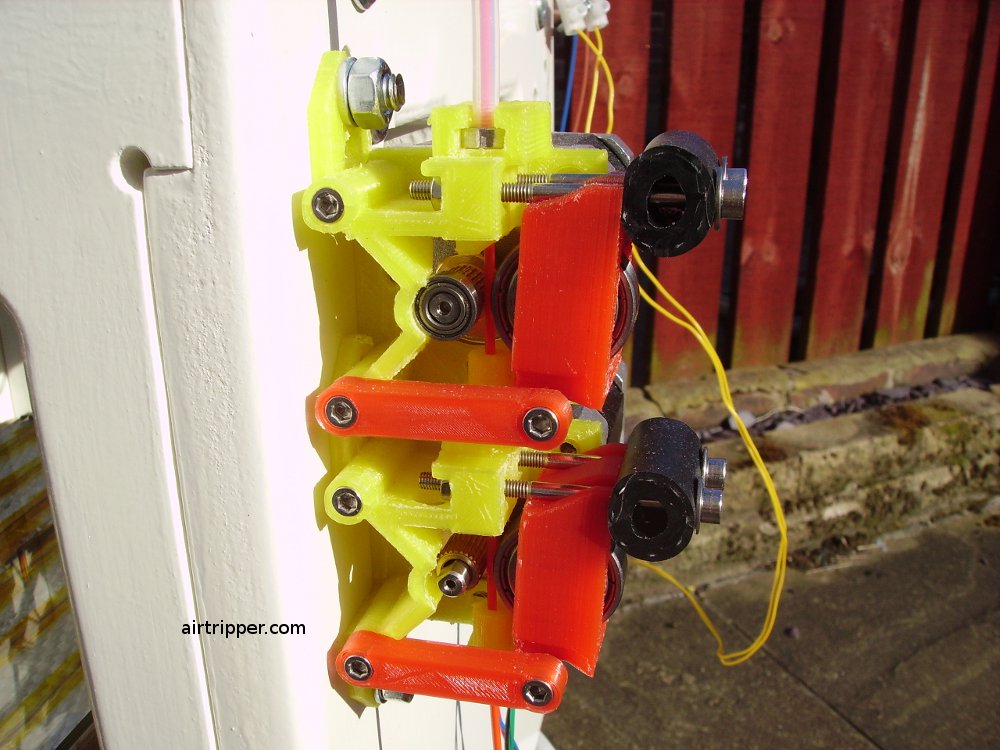

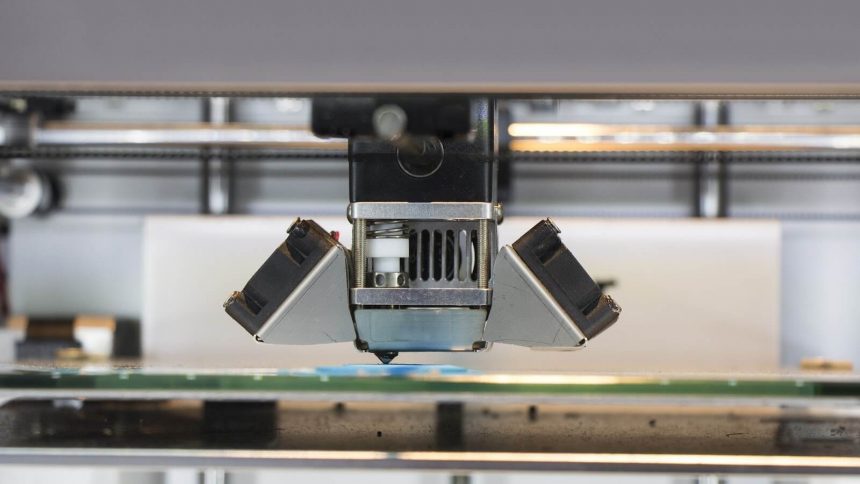

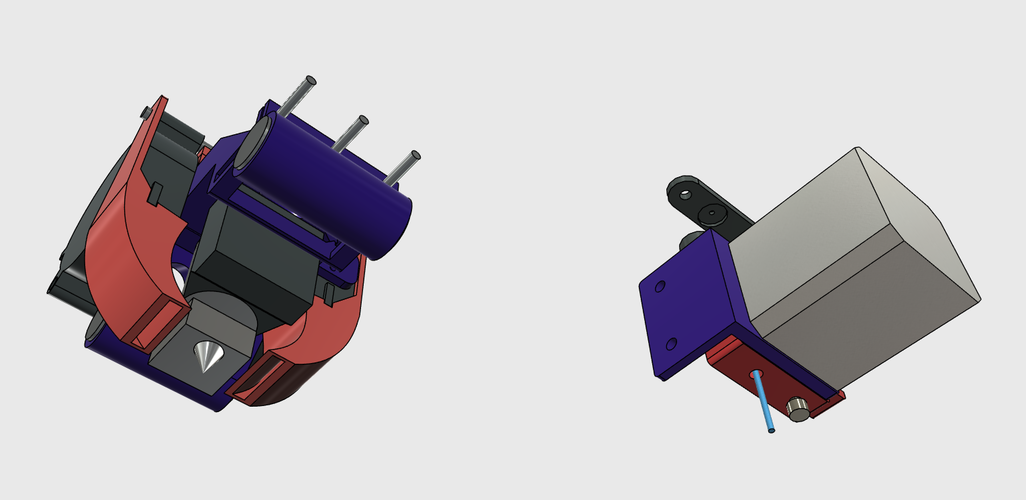

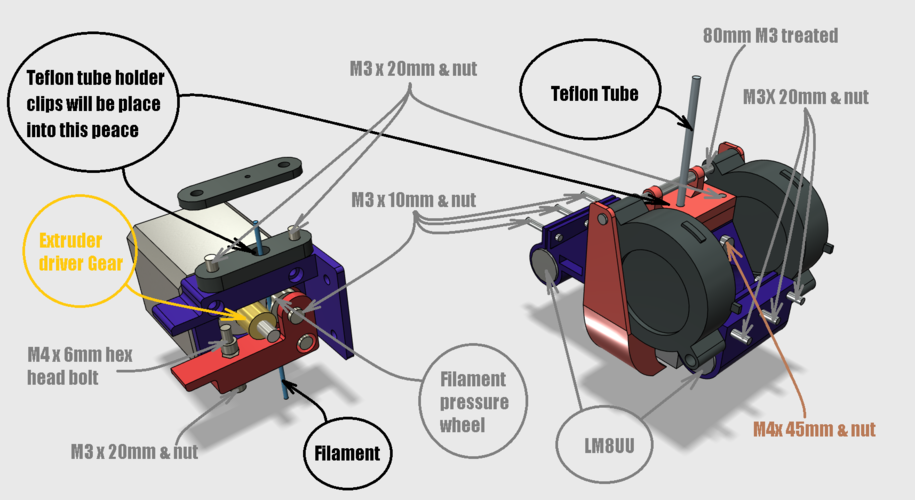

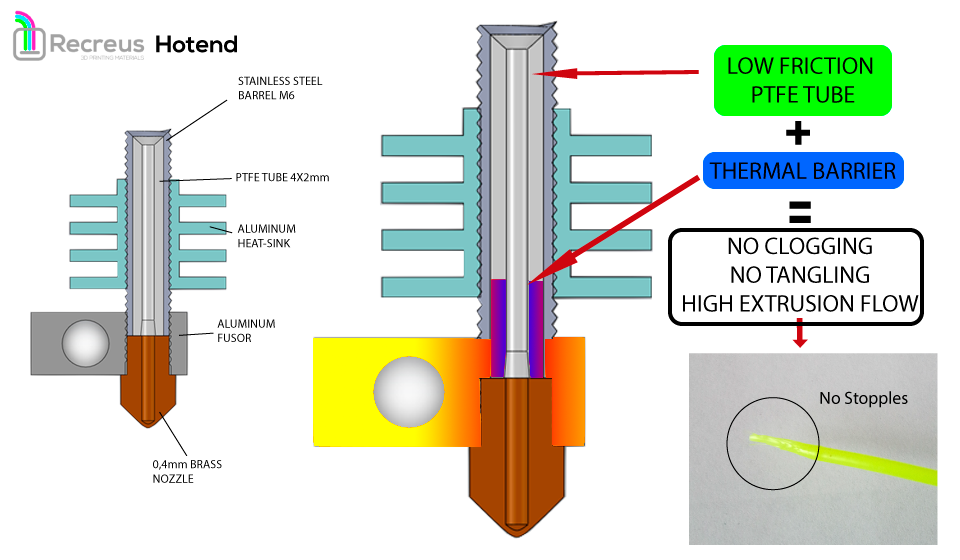

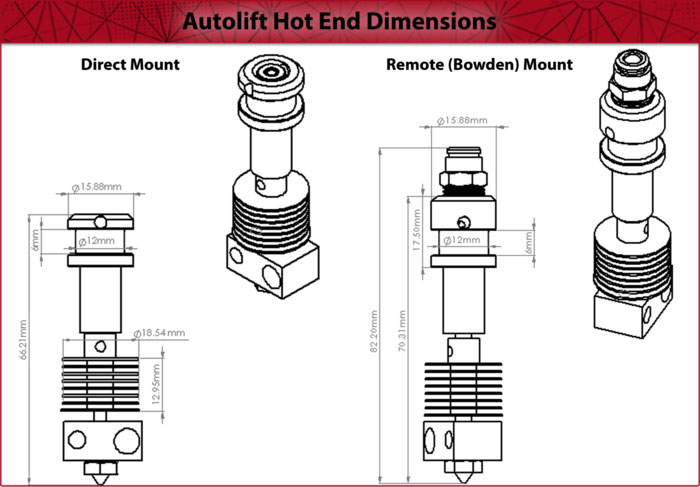

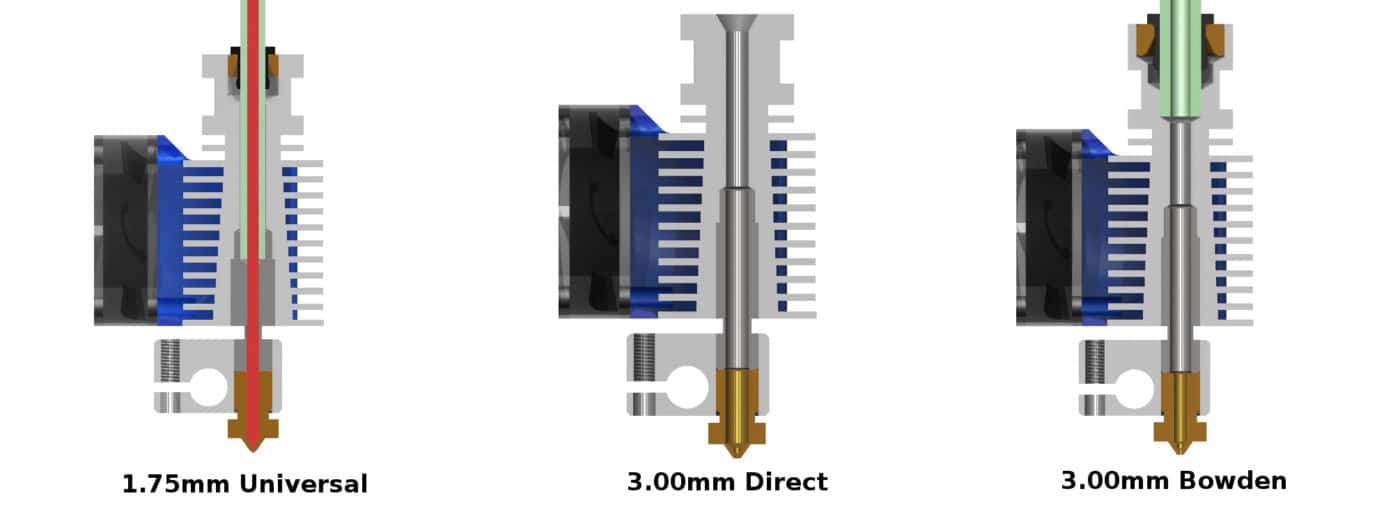

All hot ends have a melting zone where the filament undergoes melting via heating. In a bowden setup the hotend is separate from the cold end which is mounted somewhere on the frame. A good quality hot end makes prints less likely to fail enables you to print with more materials and improves print quality. In a direct drive setup the hotend is positioned directly below the cold end.

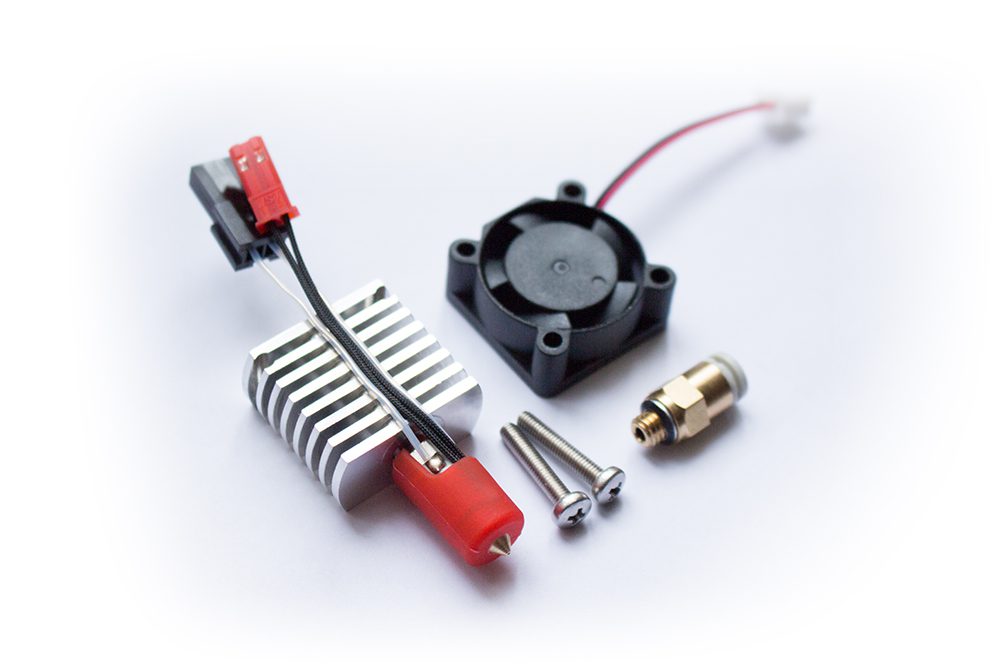

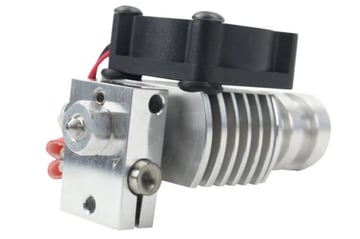

The titan aero takes e3ds titan extruder design and attaches a heatsink directly to it depicted above eliminating the need for an external heatsink. To understand the design features of hot ends you must have a basic knowledge of the thermal properties of thermoplastics specifically the way they behave at their glass transition temperature tg. It controls the maximum print temperature the nozzle size and the cooling of the filament to ensure your prints come out perfect every time. A hybrid of their popular e3d v6 hot end and titan extruder the titan aero is designed to be a compact high performance assembly for direct drive 3d printers.

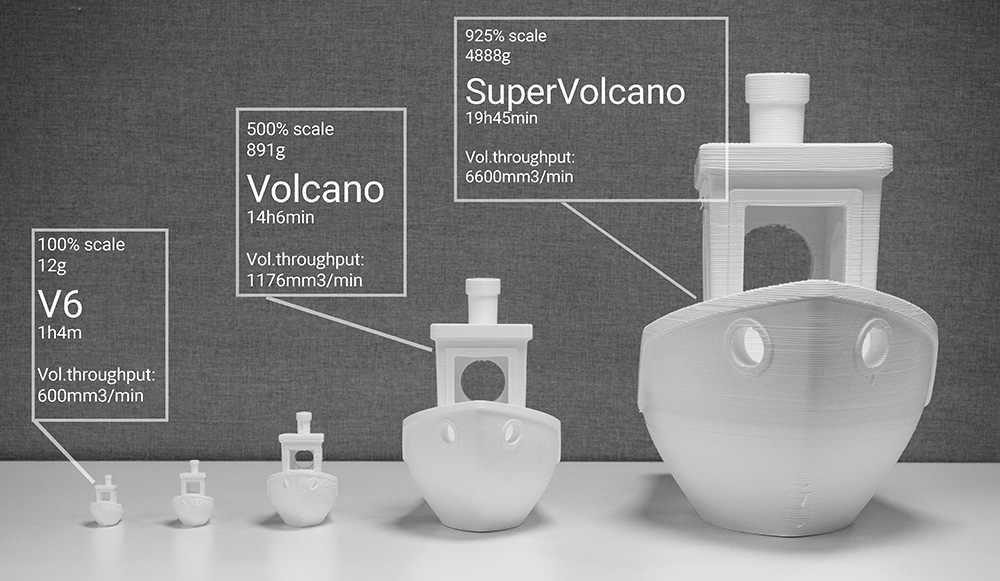

Lets rewind back to 2014 almost a lifetime ago in 3d printing years back to when we introduced the volcano to the e3d ecosystem. The hot end is capable of extruding 175mm pla at temperatures up to 230 degrees c without changing the glass transition of the plastic in the cold end. 3d printed parts intended for practical use need to be designed for both the application and the printing process youre using. The hotend counts for one half of the print head or extruder with the cold end being the other half.

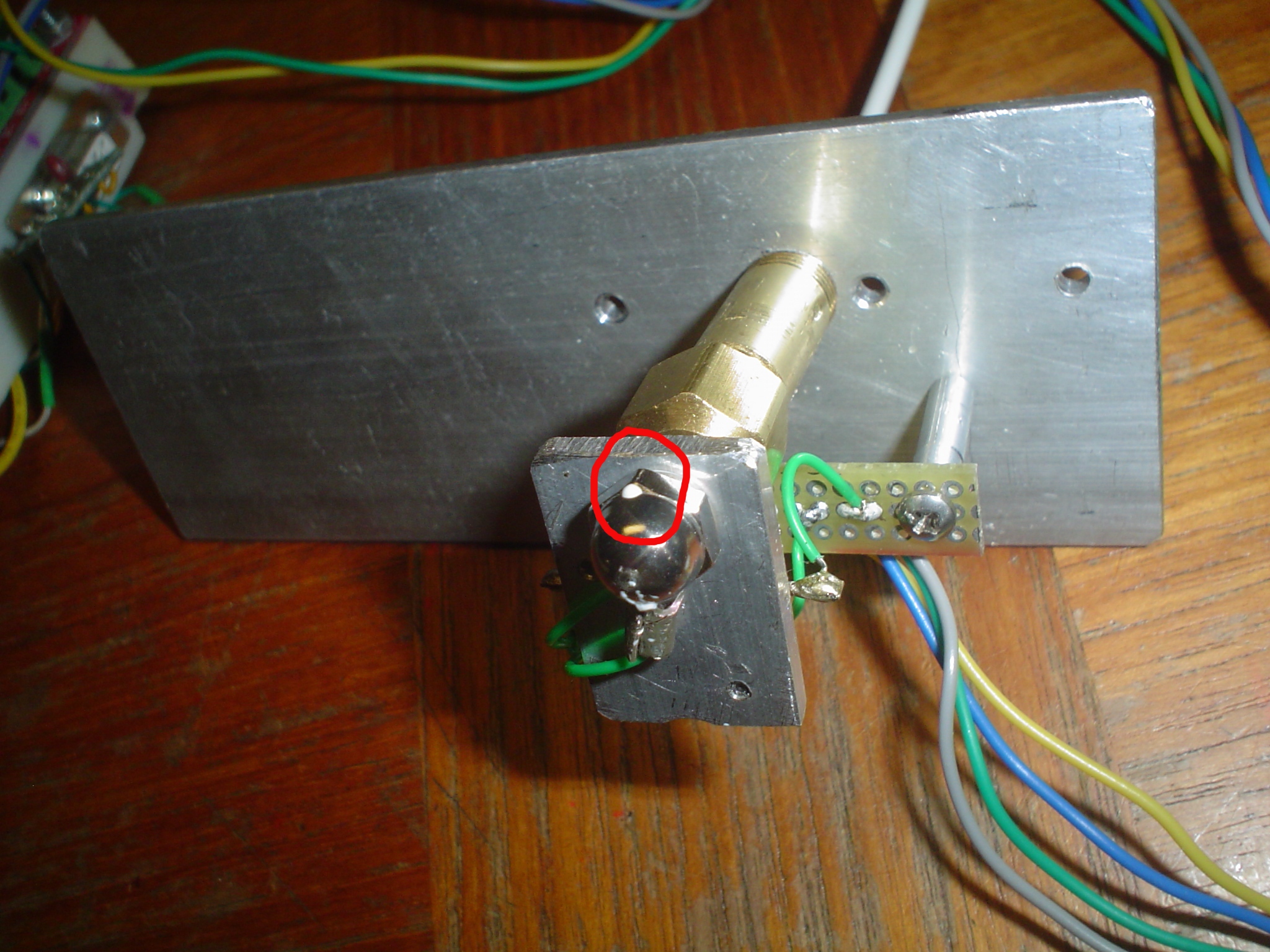

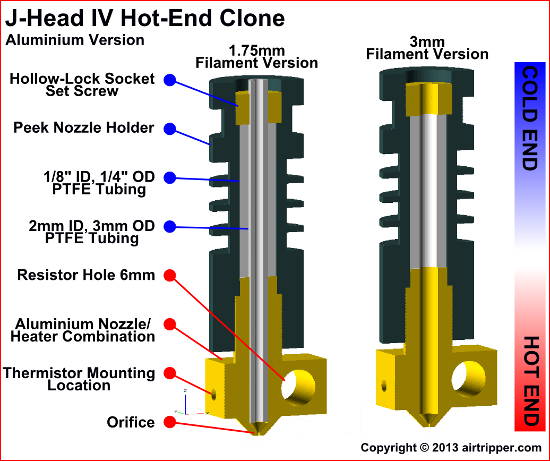

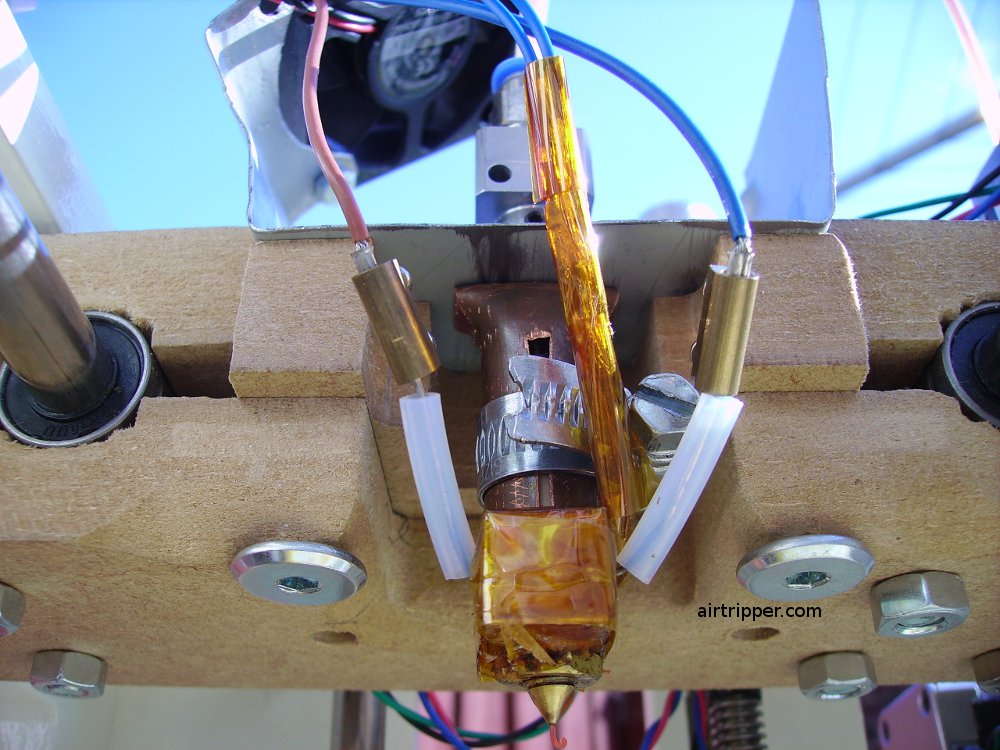

3d printer nozzle tube parts with ptfe tube seperator. You also look at what materials are appropriate to use for this bracket and similar objects. The hotend is the component of a 3d printer that melts the filament for extrusion and helps maintain a consistent and accurate temperature for successful prints. Here you look at the design aspects and print settings of an example spool mounting bracket.

In short a 3d printer wont be able to do its core function without it.

Opam One Piece All Metal Water Cooled Hot End Launches On Indiegogo 3dprint Com The Voice Of 3d Printing Additive Manufacturing