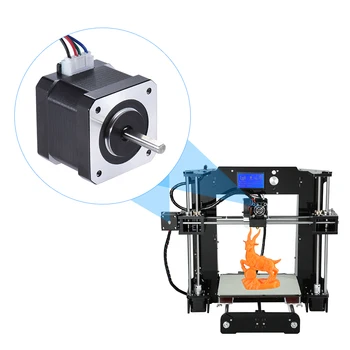

3d Printer Stepper Motor

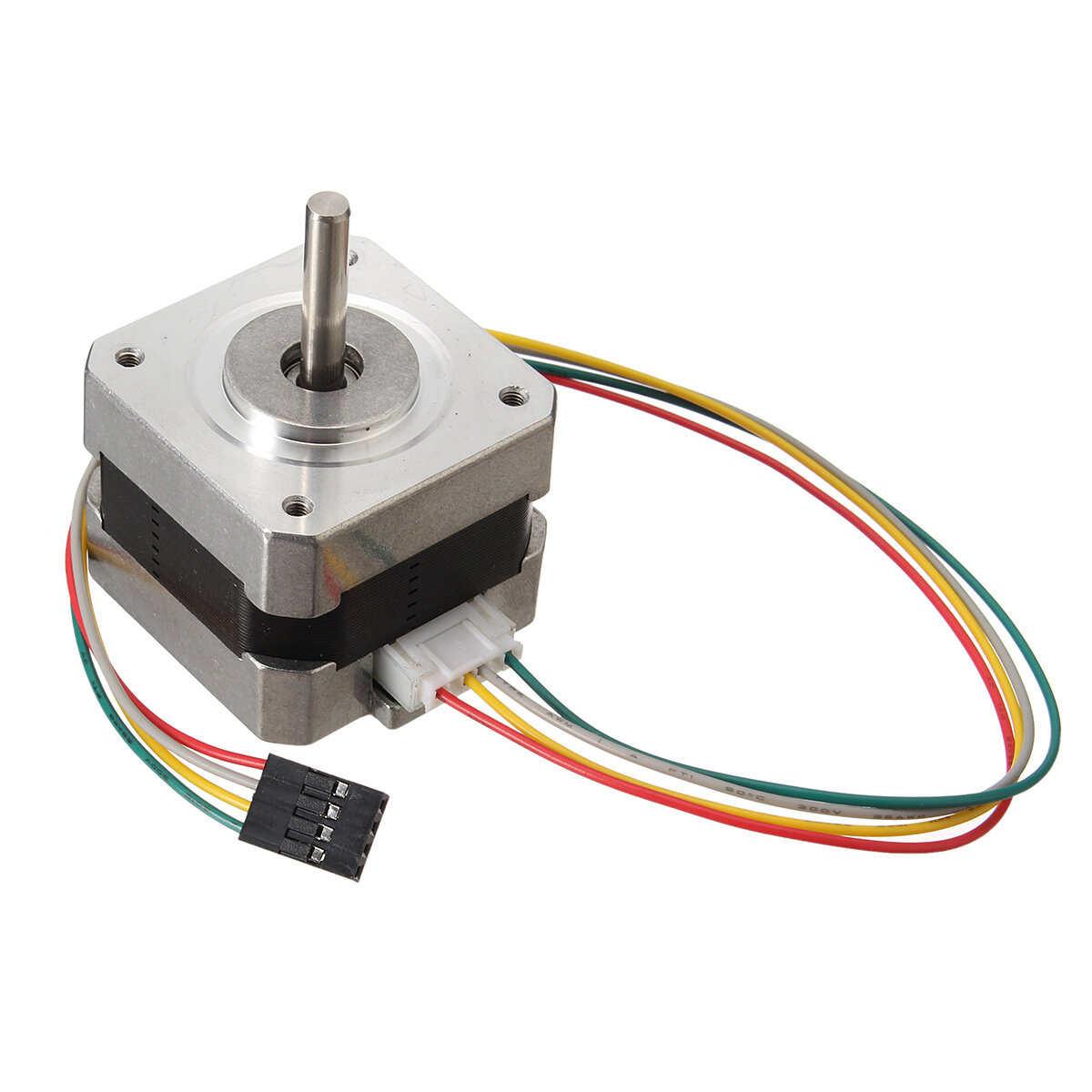

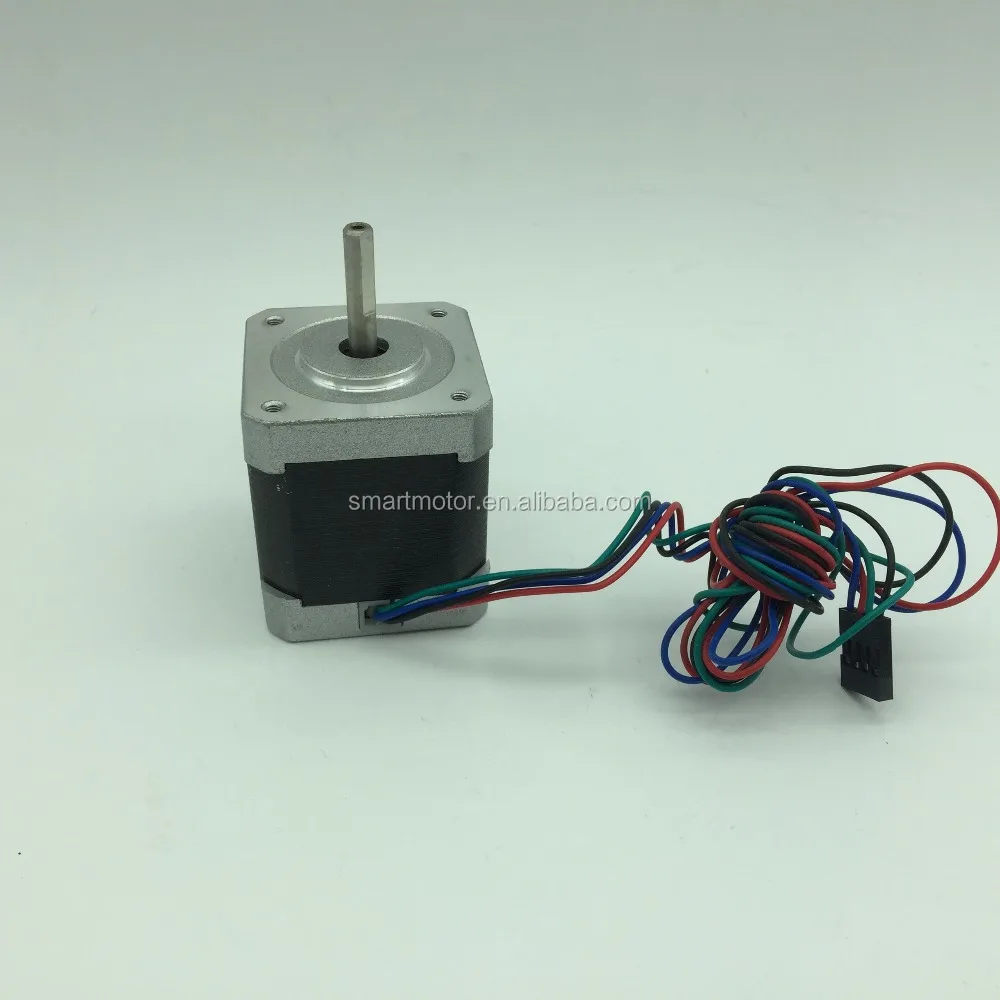

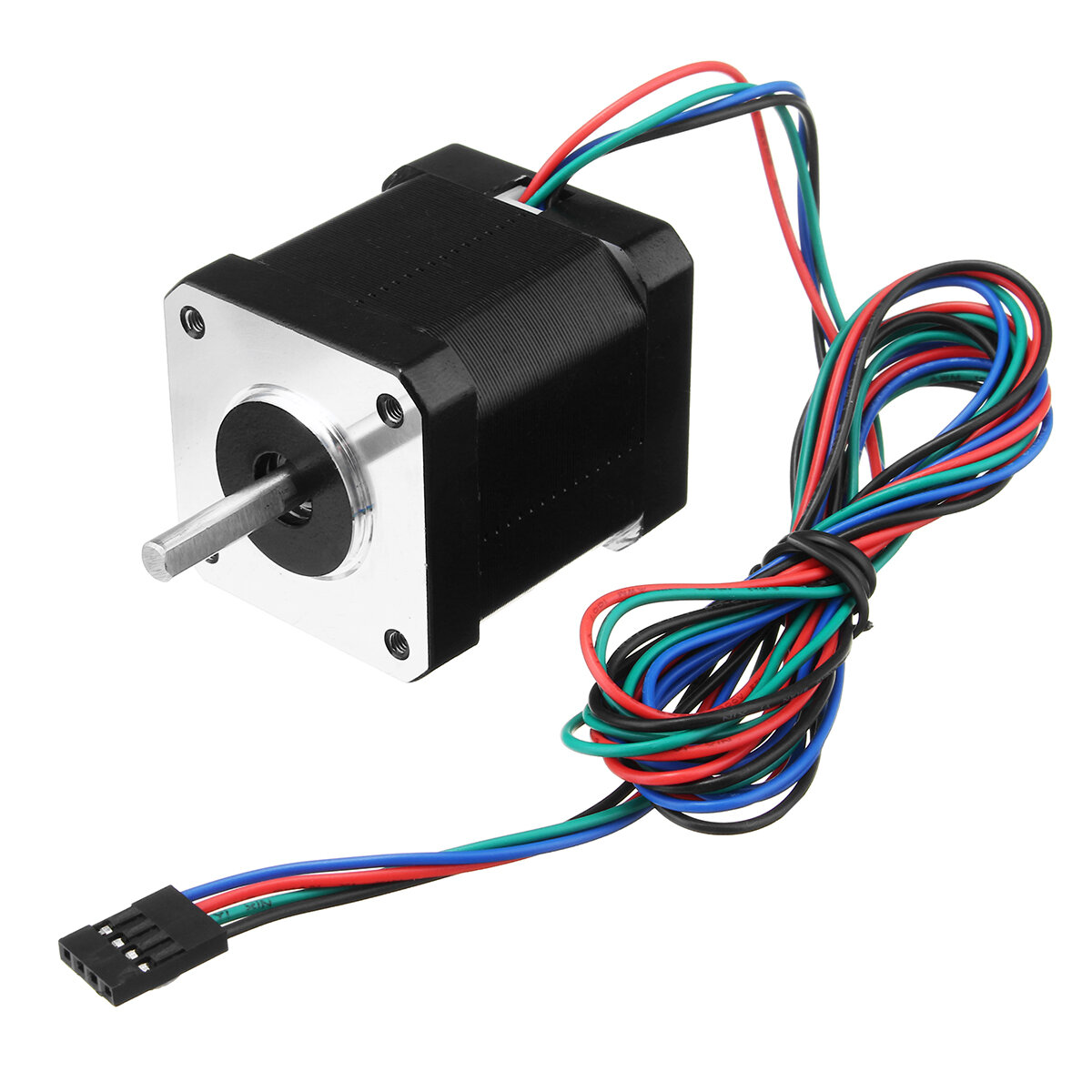

Anet 42 stepper motor for 3d printer diy cnc robot 18 degree 09a 04nm 42mm stepper stepping motor drive with 90cm lead cable for 3d printer black 1pcs 46 out of 5 stars 10 13491349 get it as soon as tue feb 11.

3d printer stepper motor. The motors are responsible for accuracy in terms of degrees. One of the very first things you should do with a new 3d printer is to calibrate your extruder and x y z steppers. The controller sends pulses to the stepper motor to cause it to turn exactly the amount to raise the platform accordingly. These coils are activated when you want to spin the motor.

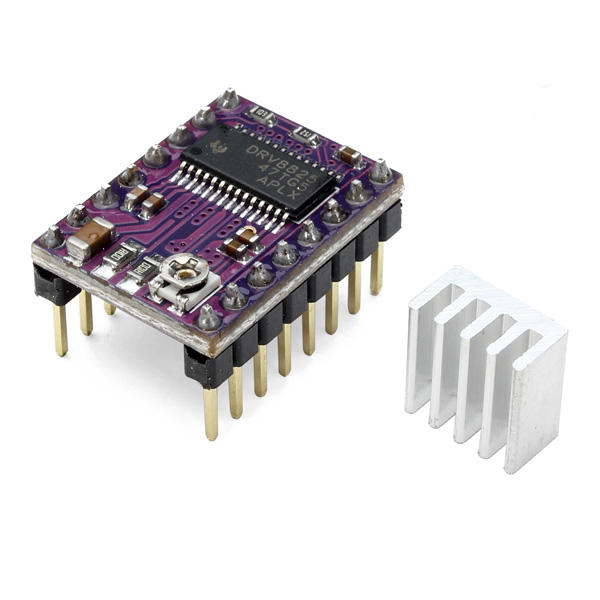

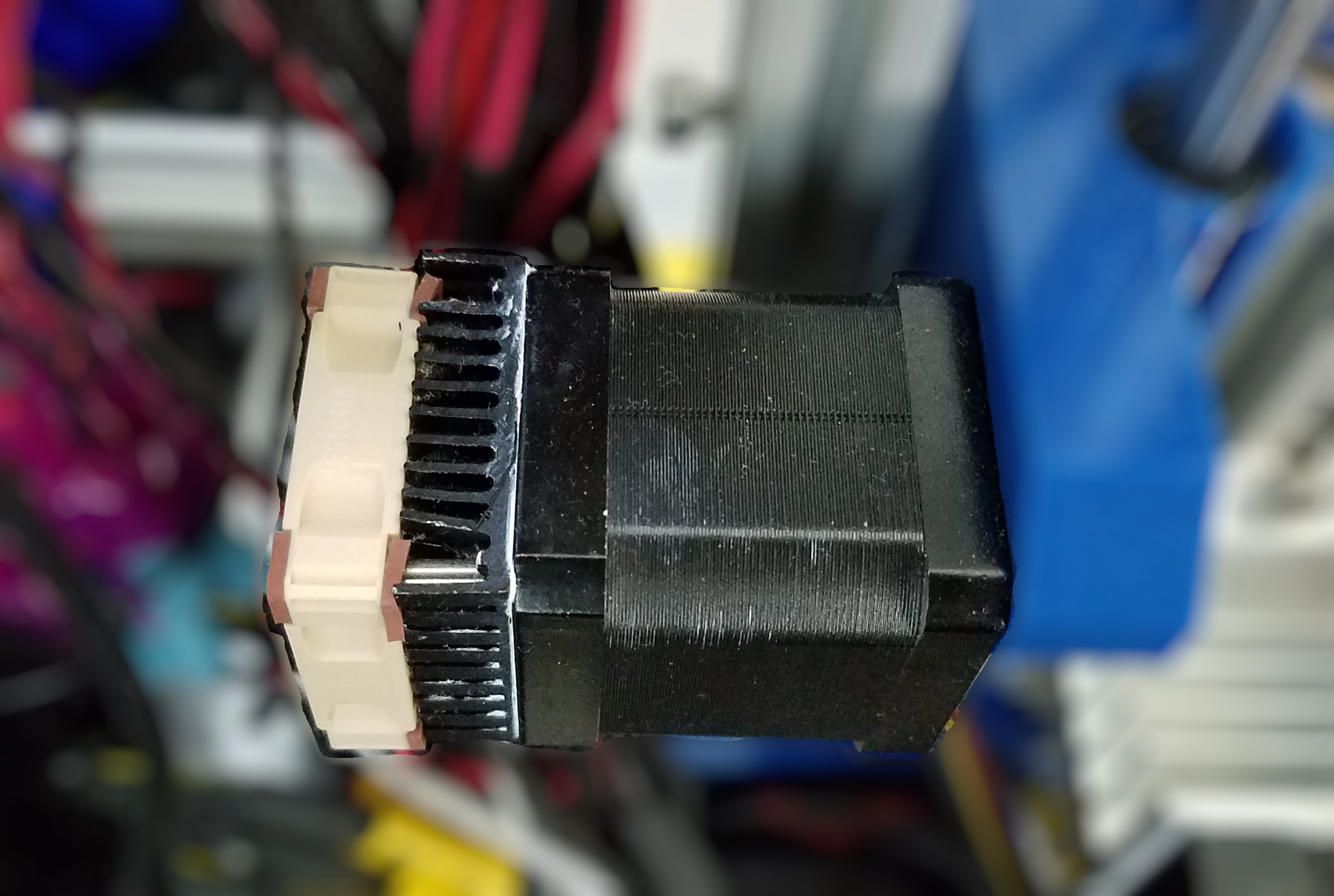

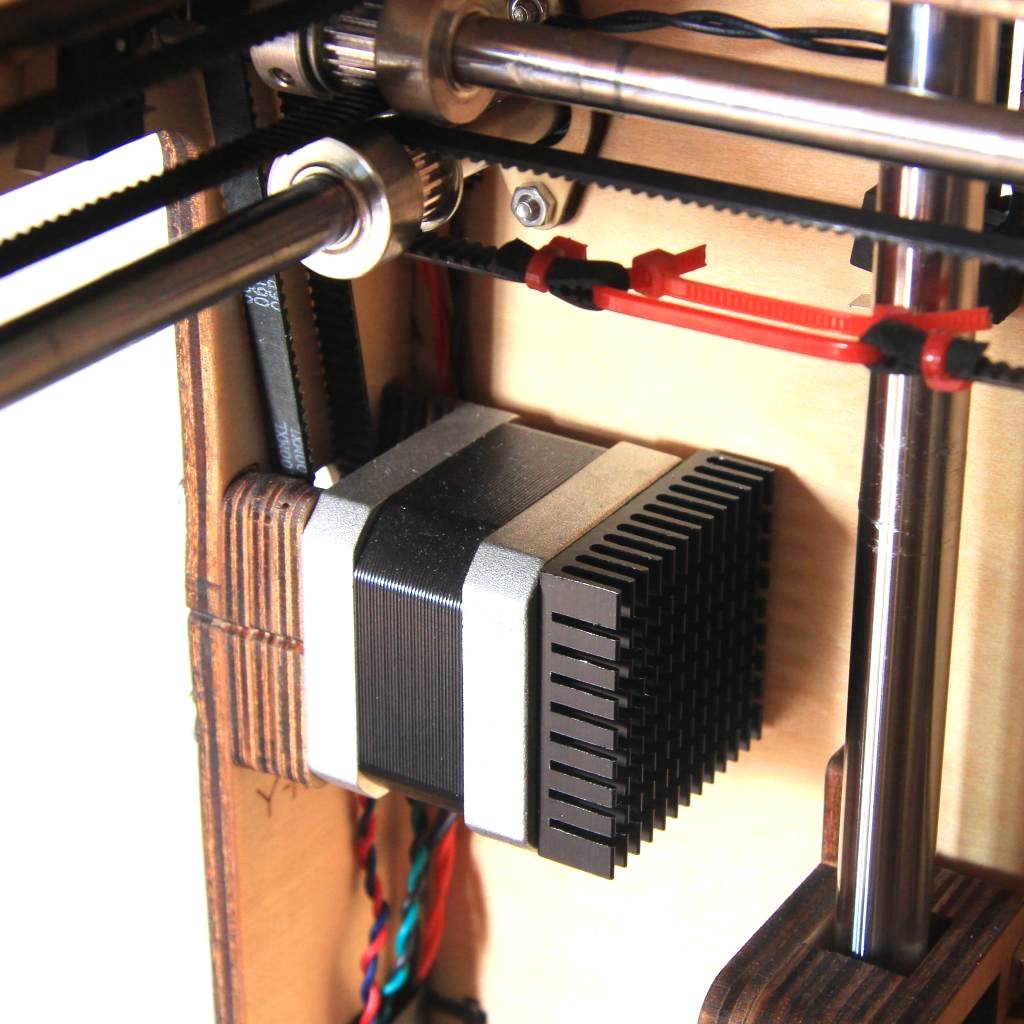

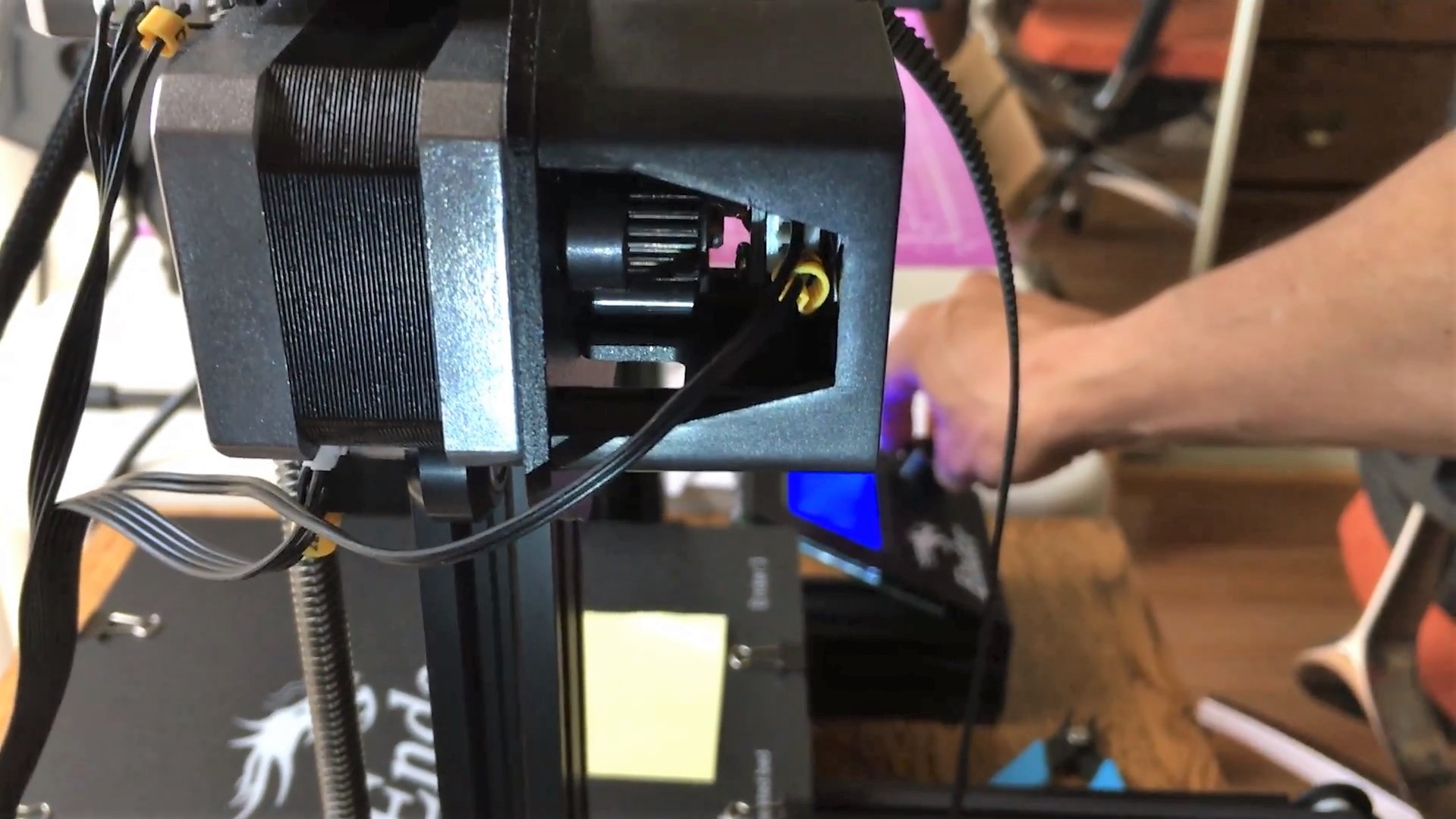

Stepper drivers are an important part of any 3d printer. The nema specification is what allows stepper motors to be identified and references the size of the faceplate of the motor. Myhomefab drv8825 adjust stepper current goes into the adjustment of the reference voltage for the commonly used drv8825 which is an alternative to the popular a4988. Without stepper motors we wouldnt be appreciating 3d printers as much as we do because they wouldnt have the same charm.

3d printers are precise machines that rely on precise movements thats why stepper calibration is important. The position of the motor can be ordered to move and hold at certain steps and used at your desired torque and speed. Pololu a4988 stepper motor driver carrier with voltage regulators this is a very common stepper driver. A series of electromagnetic coils are activated in a specific sequence to spin a motor shaft a precise number of degrees.

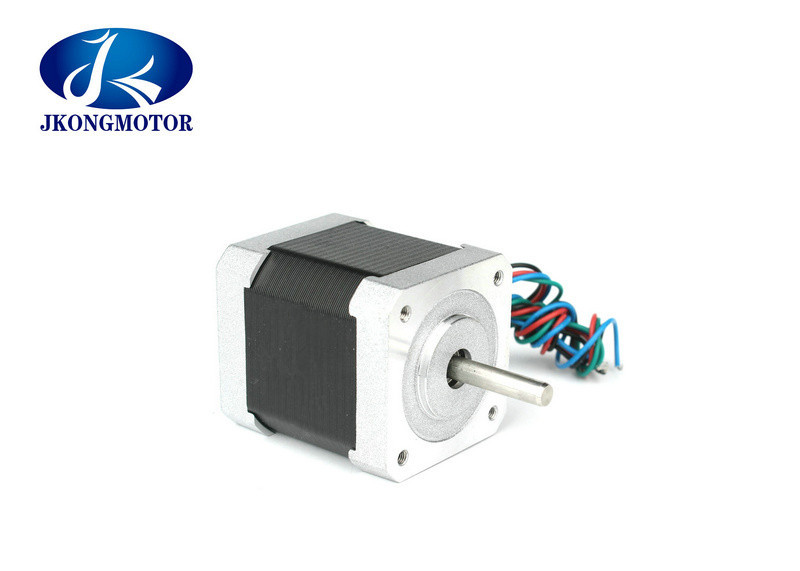

Most 3d printers utilize nema 17 stepper motors. The proper definition of a stepper motor is a brushless dc electric motor that divides a full rotation into an equal number of steps. How do we know the printer is moving a millimeter. An un calibrated 3d printer can cause all kinds of issues.

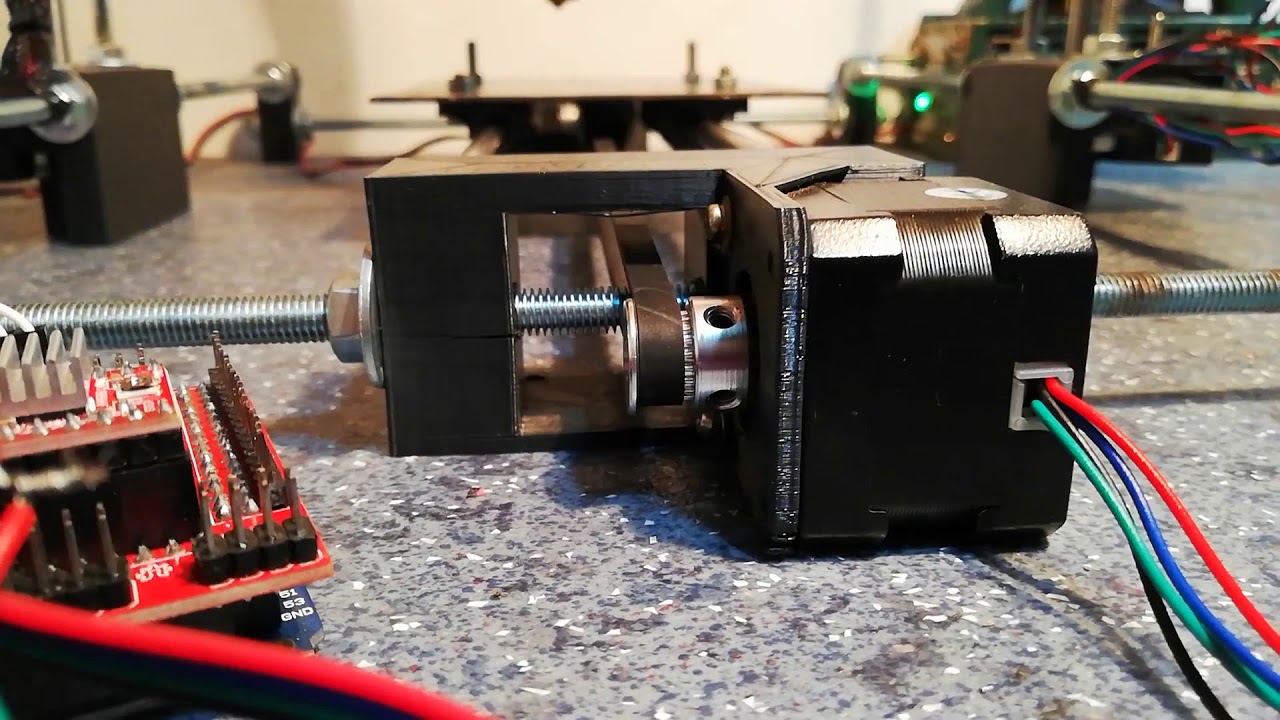

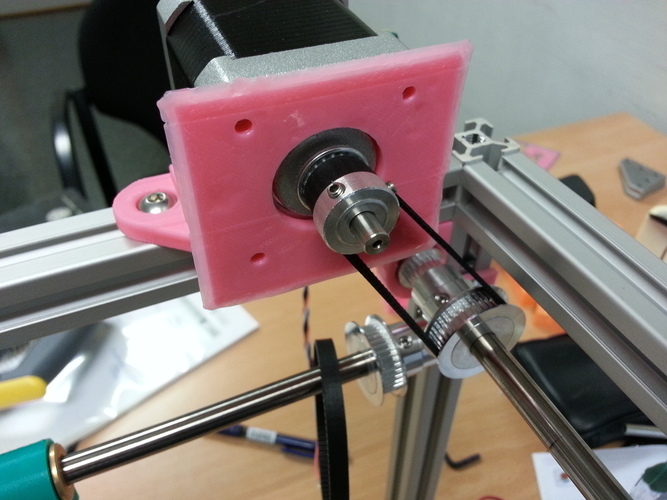

There is however an application for geared stepper motors in 3d printing. This is a specialized motor that can turn in discrete steps. Weve covered a little about how your printer works. Under the hood of every 3d printer out there youll find a stepper motor.

You feed it instructions in a language called gcode which basically says up z axis increase y axis decrease x axis extrude 1mm there is a small problem with this though. Geared stepper motors usually sacrifice speed for increased torque and for this reason are not used on the linear axes of 3d printers where rapid movements are needed. Stepper motors are relatively simple mechanisms.

/i/716351/products/2020-02-22T07%3A17%3A47.769Z-3.jpg)