3d Printing Flexible Materials

Diran 410mf07 is a durable nylon based thermoplastic demonstrating exceptional toughness and resistance while maintaining a smooth surface quality.

3d printing flexible materials. There are several types of tpe with thermoplastic polyurethane tpu being the most commonly used among 3d printing filaments. Flexible material filaments are now beginning to hit the market and theres so much work to be done. Tango resin photopolymer sls. A print made in the tough pla offered by makerbot.

The pros and cons of each type. Polylactic acid pla is a. A graphic representation of the basic mechanics of stereolithography 3d printing. Sla 3d printers use light reactive thermoset materials called resin when sla resins are exposed to certain wavelengths of light short molecular chains join together polymerizing monomers and oligomers into solidified rigid or flexible geometries.

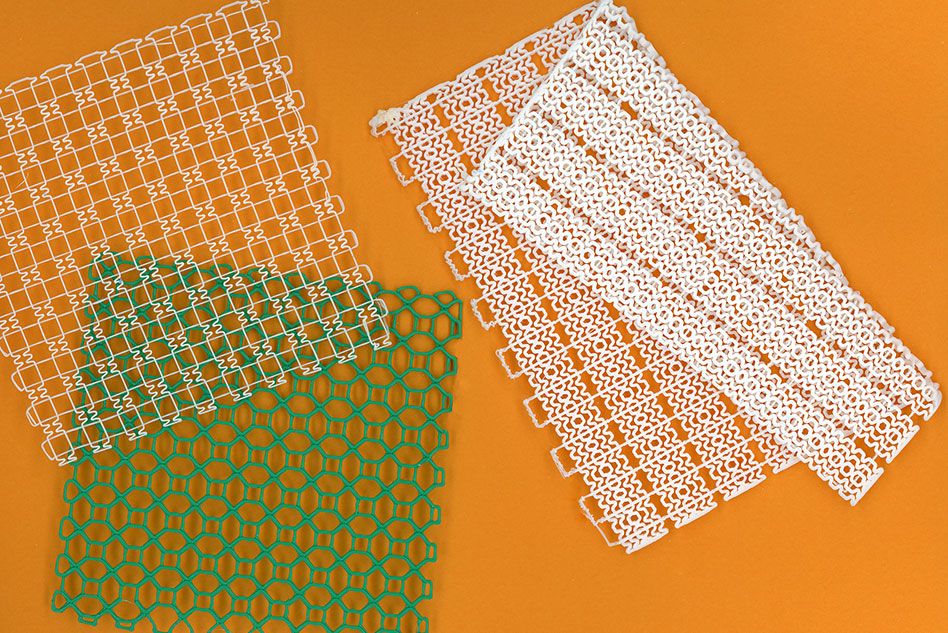

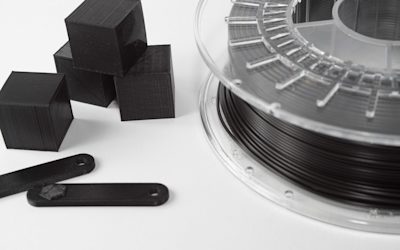

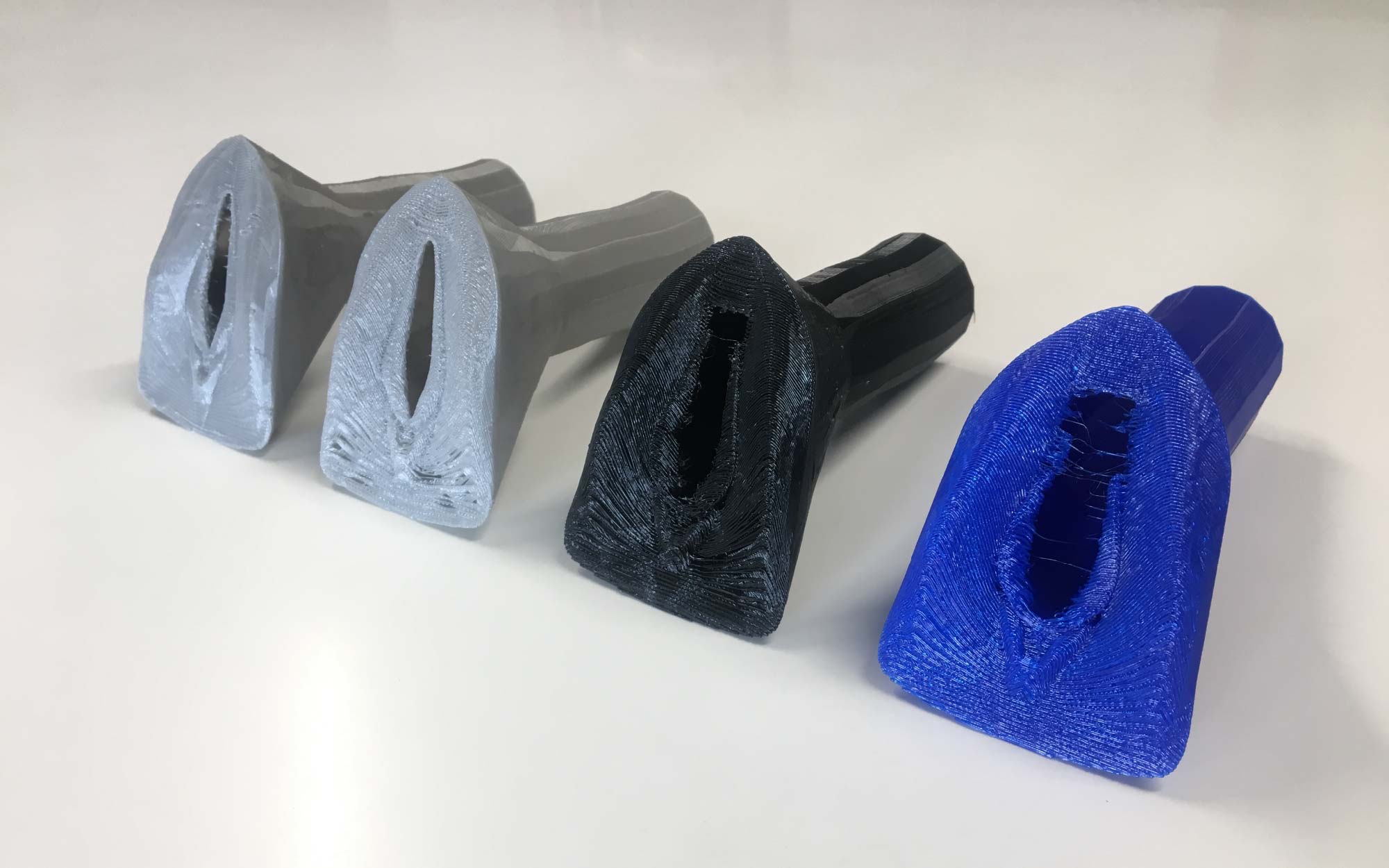

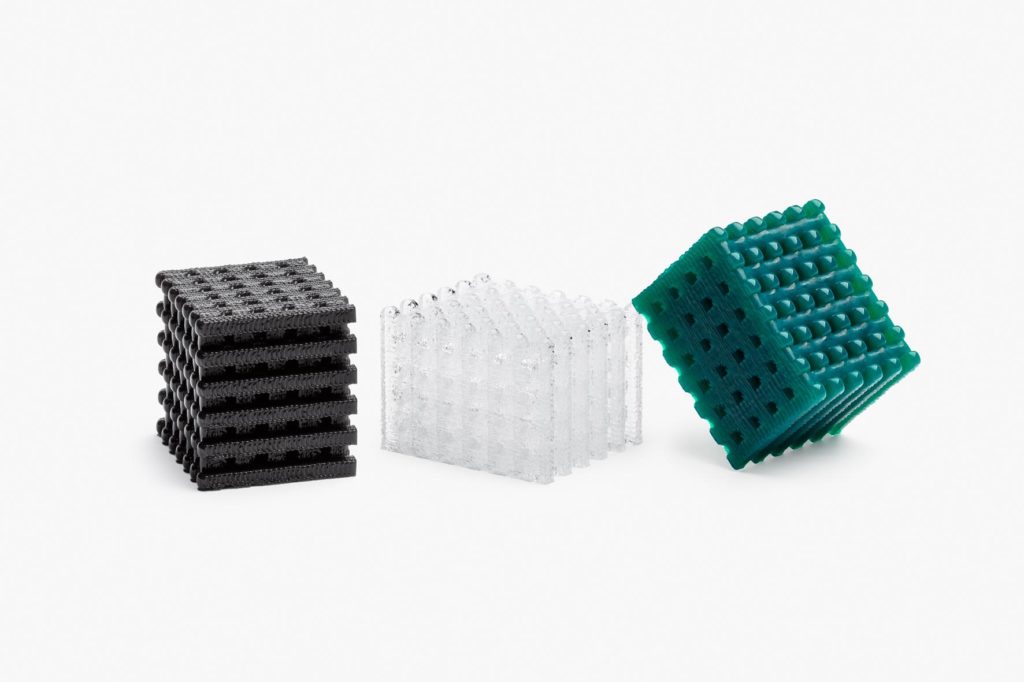

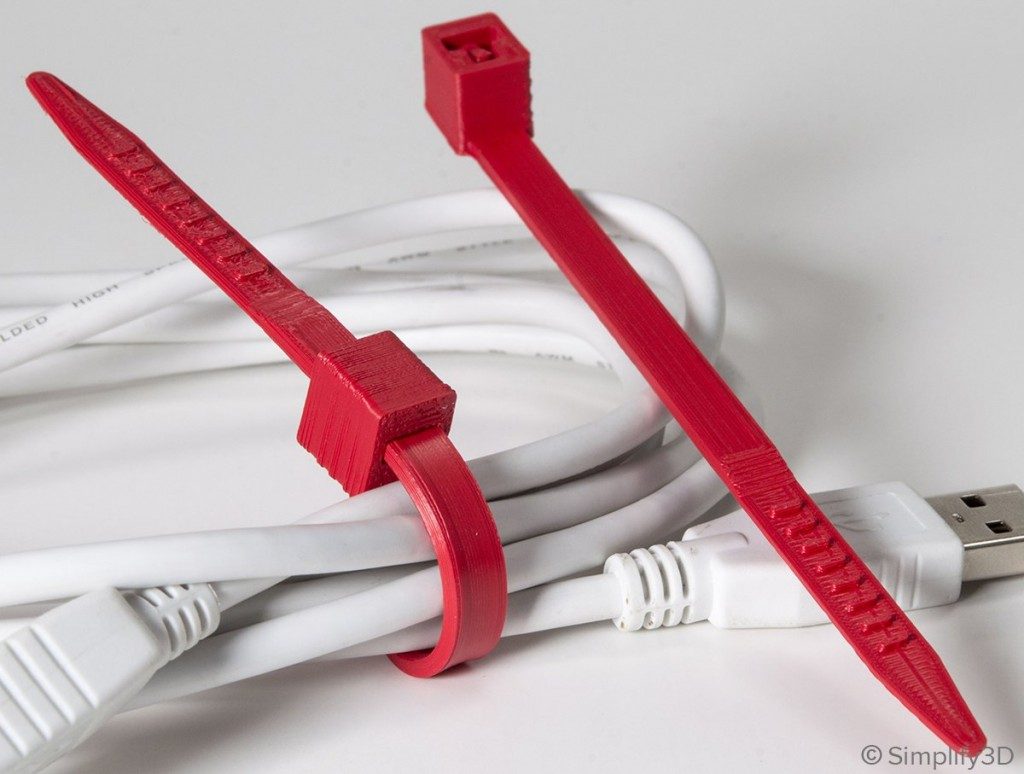

In many cases these terms are used interchangeably along with popular brand names such as ninjaflex. Flexible filaments are still very elastic their elasticity depending on the type of filament used mixing plastic polymers and rubber to create hybrid materials. Flexible filaments are made of thermoplastic elastomers tpe which are a blend of hard plastic and rubber. Abs filament is the most commonly used 3d printing plastics.

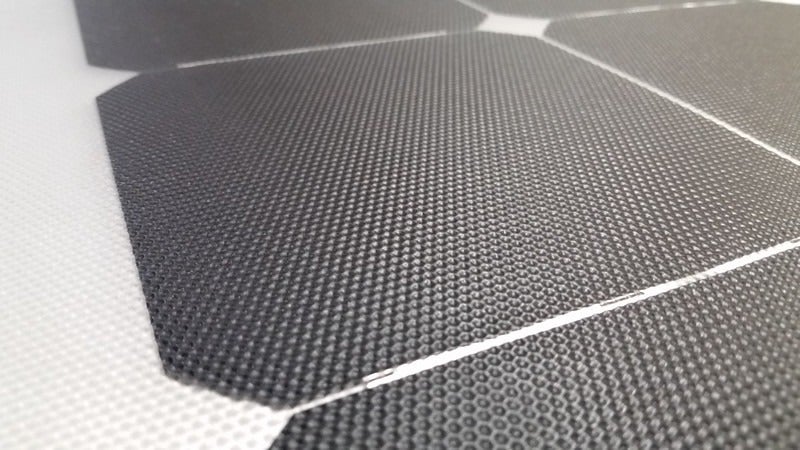

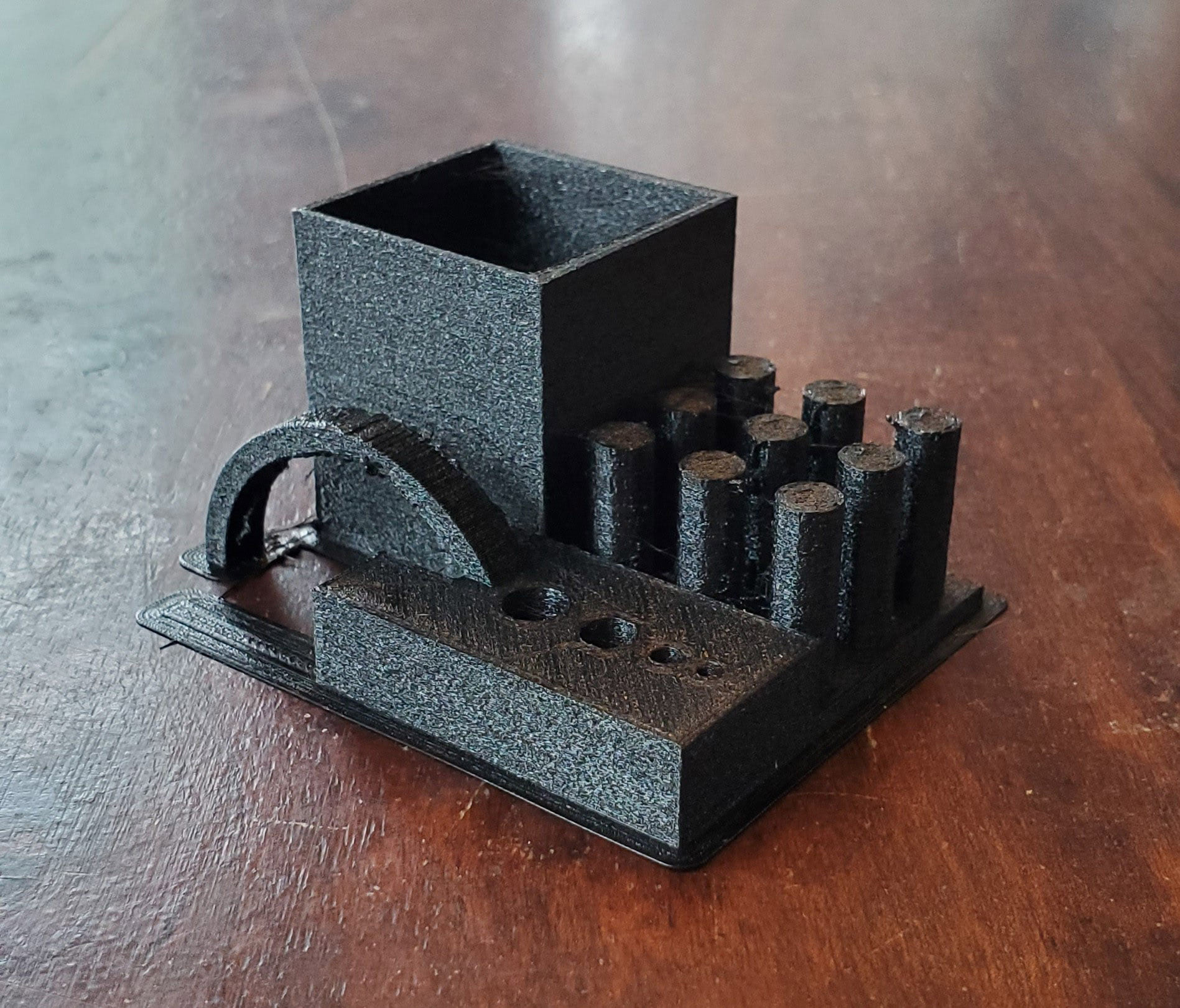

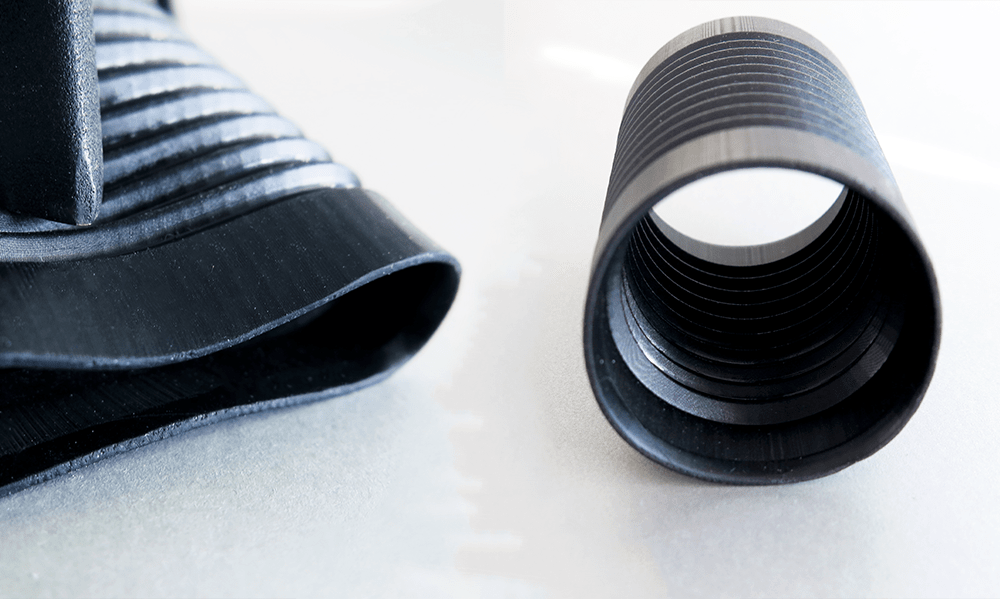

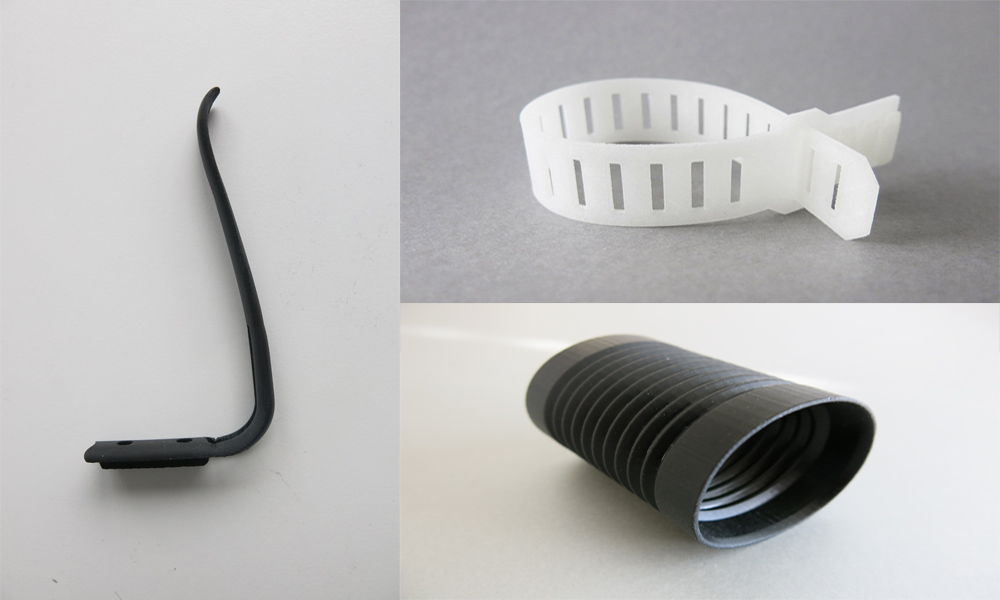

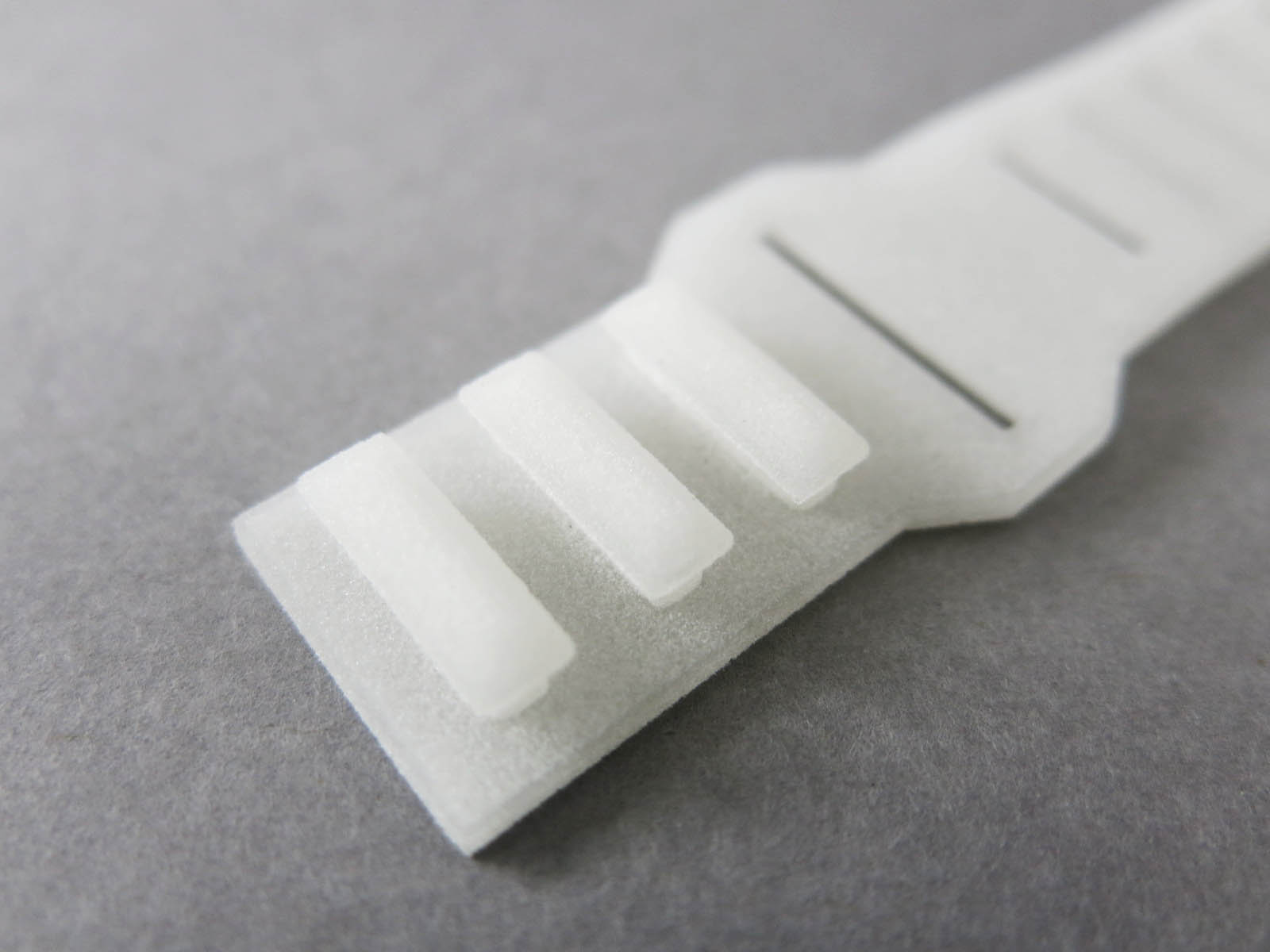

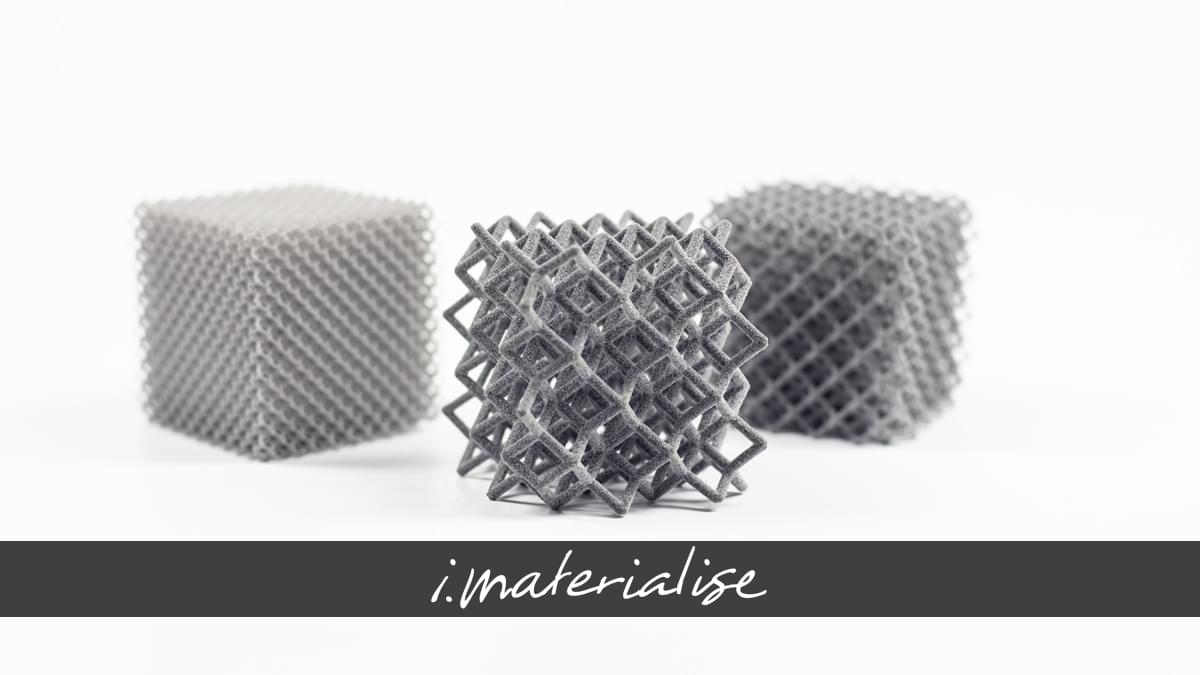

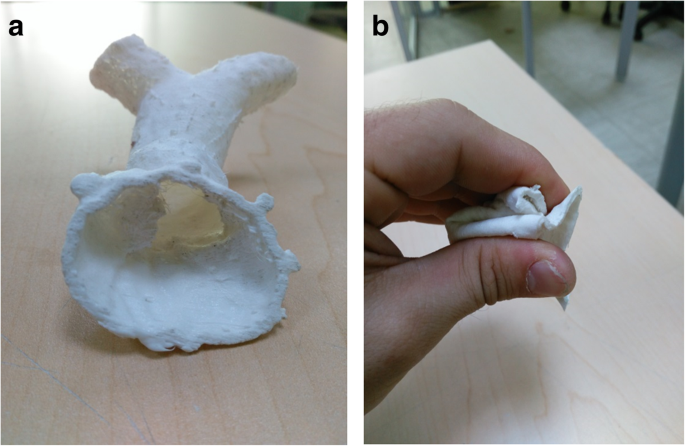

The surface of this material is somewhat sandy and granular. 3d print tough parts ideal for design verification and functional performance testing with digital abs plus. Each image highlights a sample project that was printed with that material. Acrylonitrile butadiene styrene abs is the same plastic used in legos.

It is used in the bodywork of cars appliances and mobile phone cases. As 3d printing rubber is not possible flexible filaments are the next best alternative for stretchy elastic parts. Whether youre new to 3d printing or an advanced user looking to experiment with a new material this guide has everything you need to make the most of your next project. A print made with abs filament by the m3d micro printer.

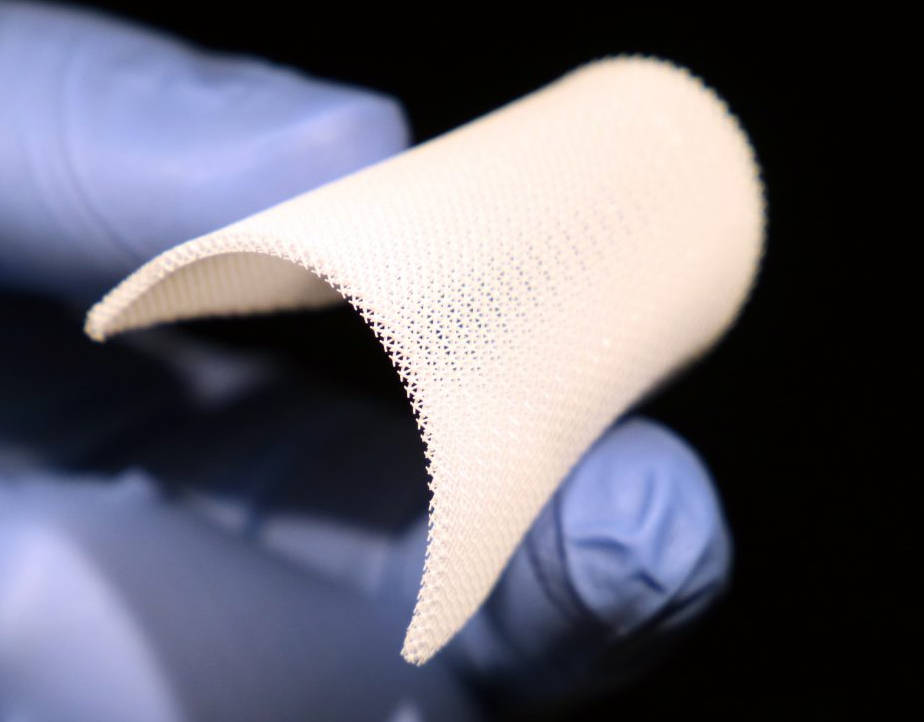

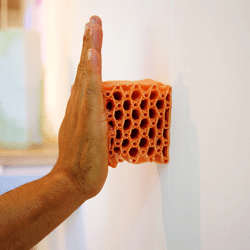

3d printing with flexible materials the standard for 3d print filaments at present is hard inflexible processed plastic but imagine the possibilities with more textures and feels going forward. Peba and also pa12 which is slightly flexible clip. As the name suggests this material is elastic in nature allowing the plastic to be stretched and flexed easily. 3d prints in rubber like are built layer by layer from an off white very fine granular powder.

It is a thermoplastic which contains a base of elastomers based on polybutadiene making it more flexible and resistant to shocks. Its technical name is tpu 92a 1 a thermoplastic polyurethane. Select one of the materials below to get started.

_1.gif)