3d Printing Support Material

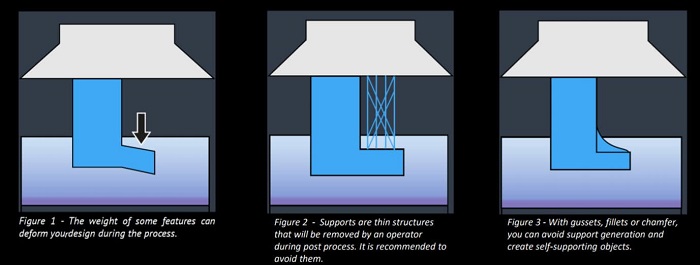

Gravity is a crucial consideration for the success of any 3d printed part.

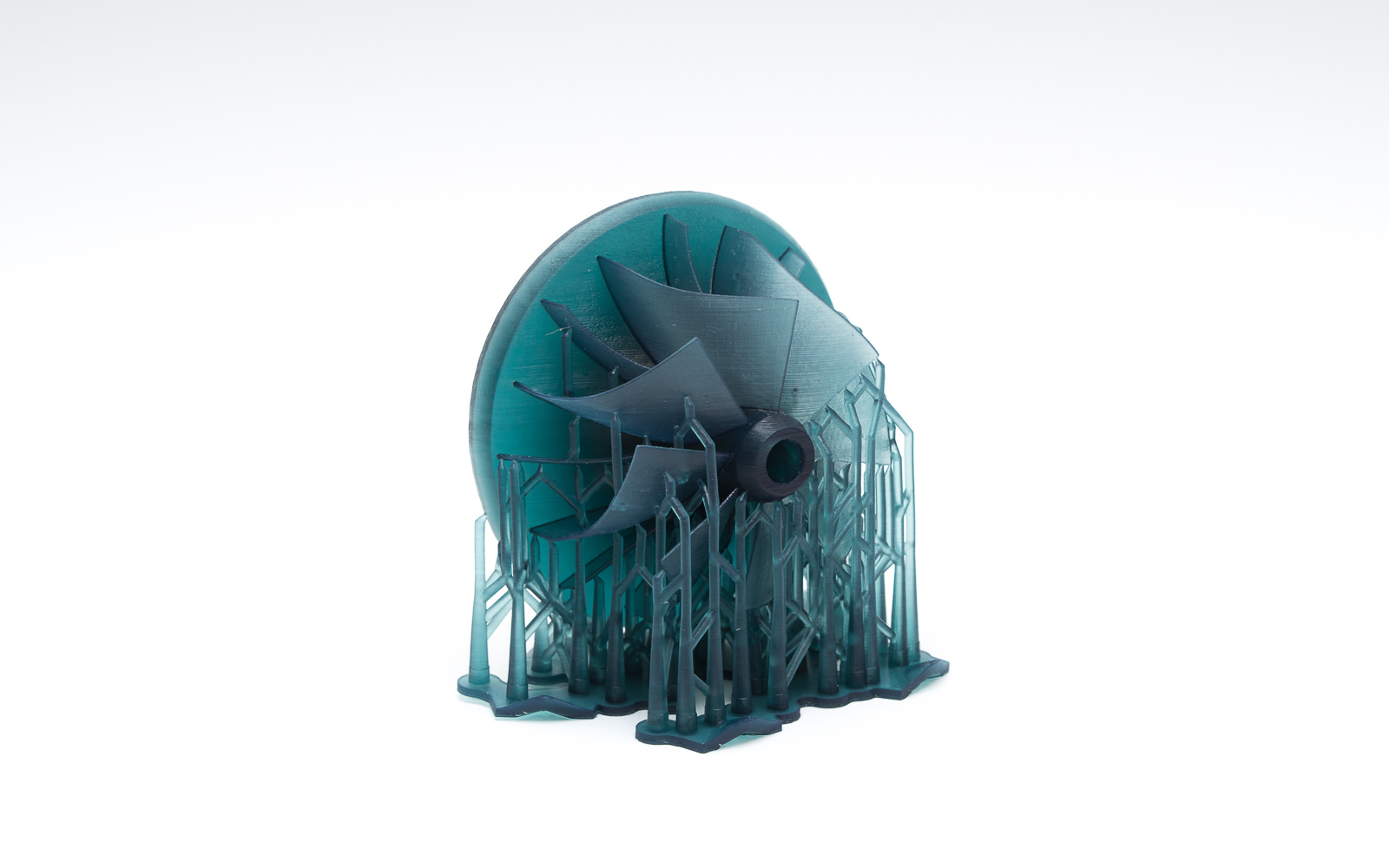

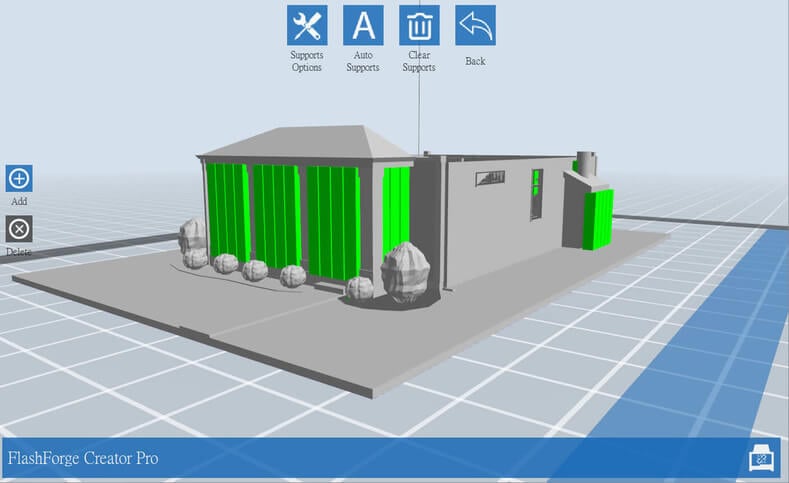

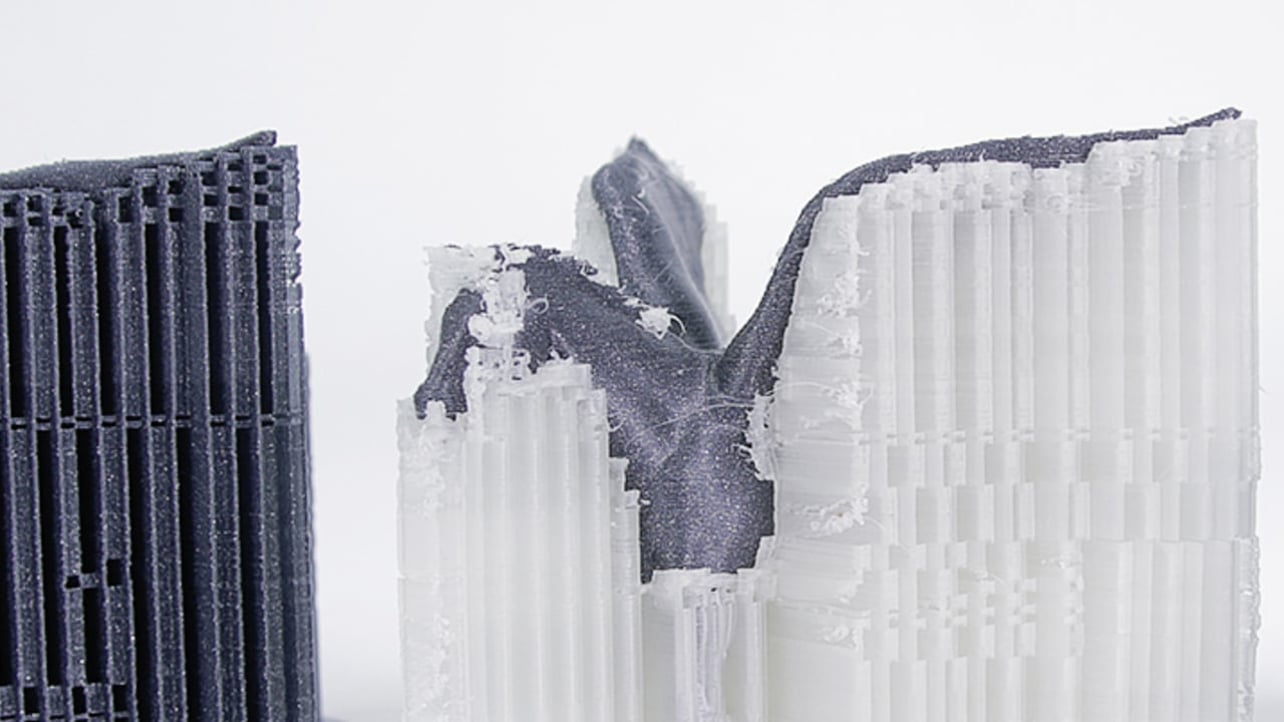

3d printing support material. Because it dissolves away when submerged in water it gives you almost complete design freedom. If your 3d printer can print more than one material then it is also possible to combine your build material with a separate support material that is easier to remove. Material jetting stratasys polyjet and 3d systems multijet modeling technologies are similar to inkjet printing but instead of jetting drops of ink onto paper these 3d printers jet layers of liquid photopolymer onto a build tray and cure them instantly using uv light. Click on any settings gear and check to show experimental tree support.

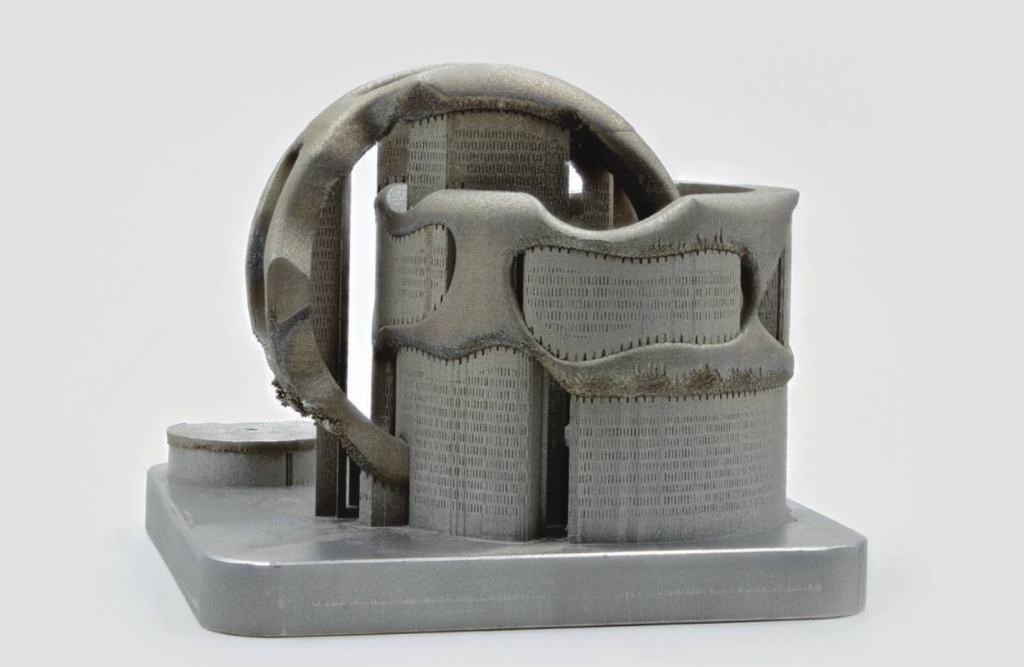

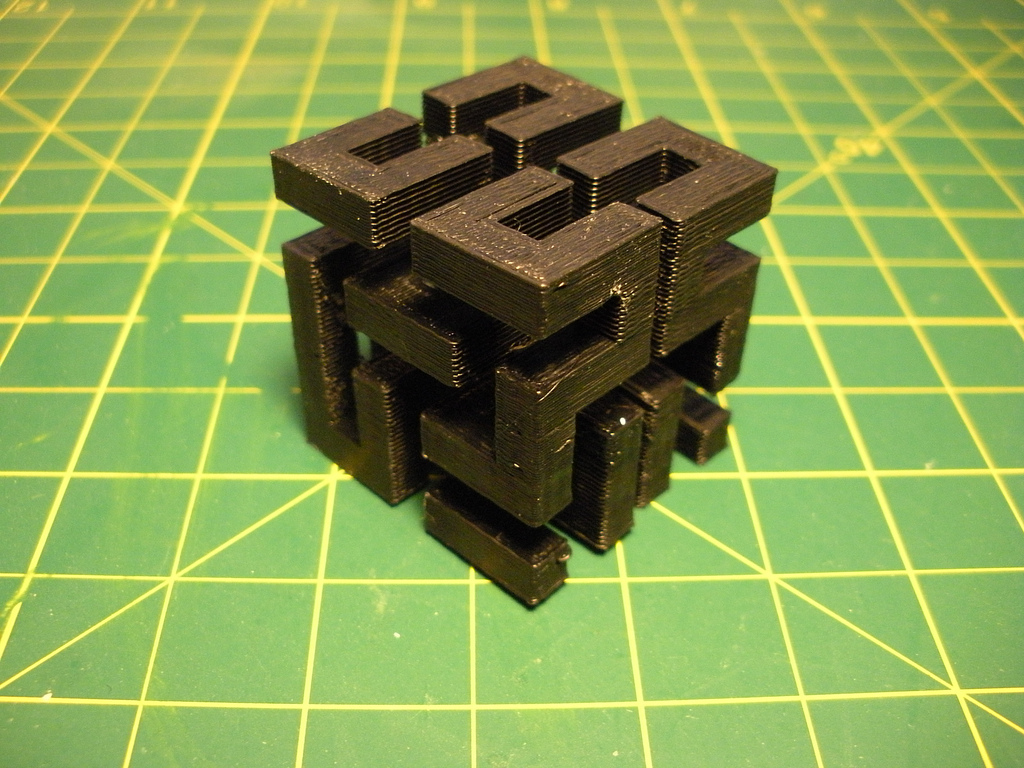

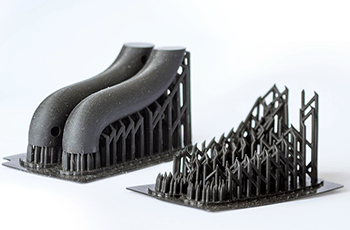

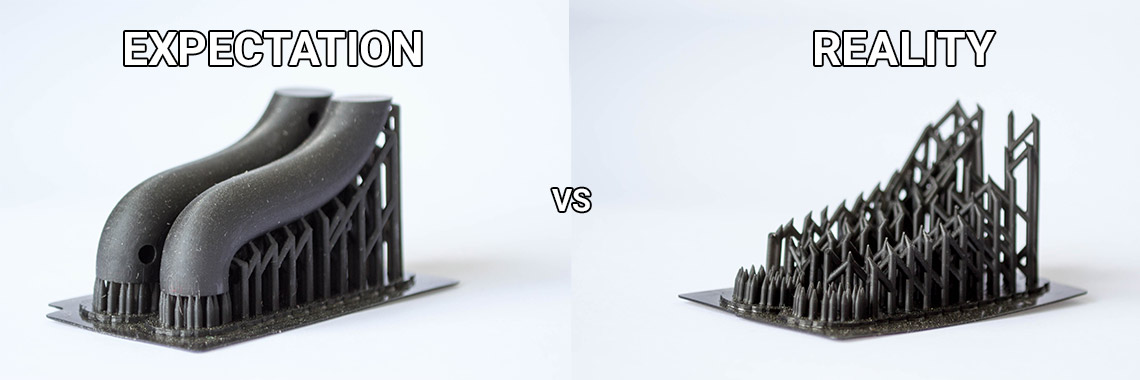

So every bit of 3d printing support structure that you use add to the cost of the model. Support structures consume material and this material is later removed and discarded. It has very high heat and impact resistance making it an ideal choice for tough environments. Polycarbonate is known for its strength and durability.

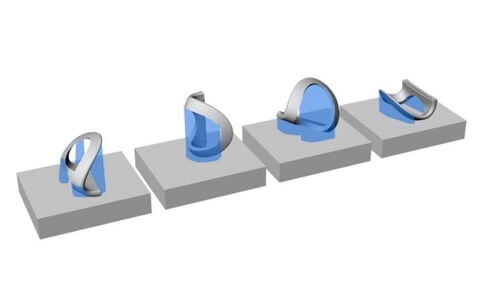

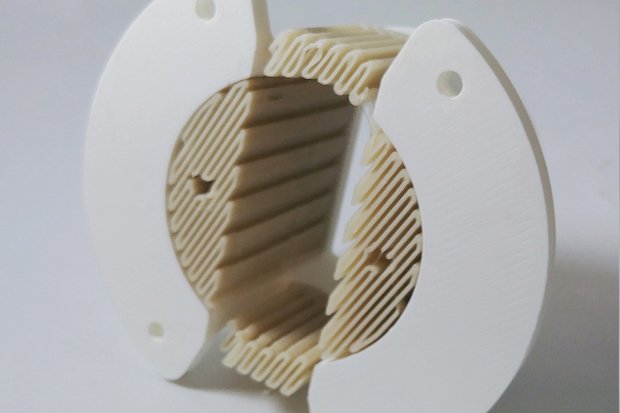

Material jetting support structures. Support materials and structures ensure that extruded filament remains in its intended shape and form during the build and cooling process. Interface distance from the object. Mp select mini 3d.

3d printing with nylon and nylon composites. 3d printing support structures obviously add to the cost of the model. 3d printing these supports can save on material and print time. Between 1800c 3560f and 1900c 3740f interface support on.

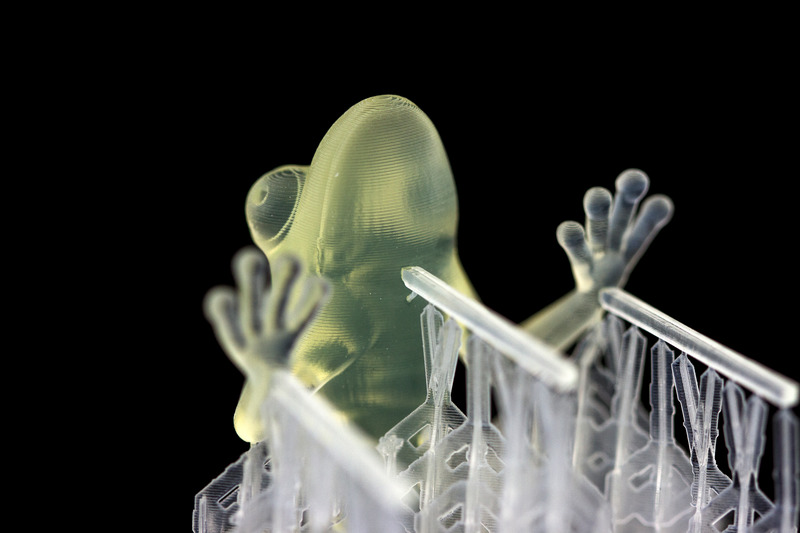

Polypropylene is great for high cycle low strength applications due to its fatigue resistance semi flexible and lightweight characteristics. Use for organic shapes humans animals. When is support needed in material jetting. Rigid and soluble support materials make it possible to build 3d printed parts with intricate shapes and interior cavities.

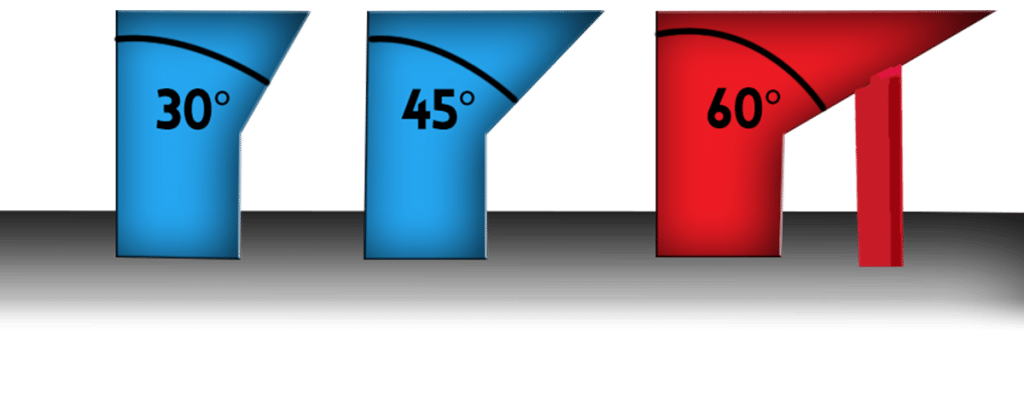

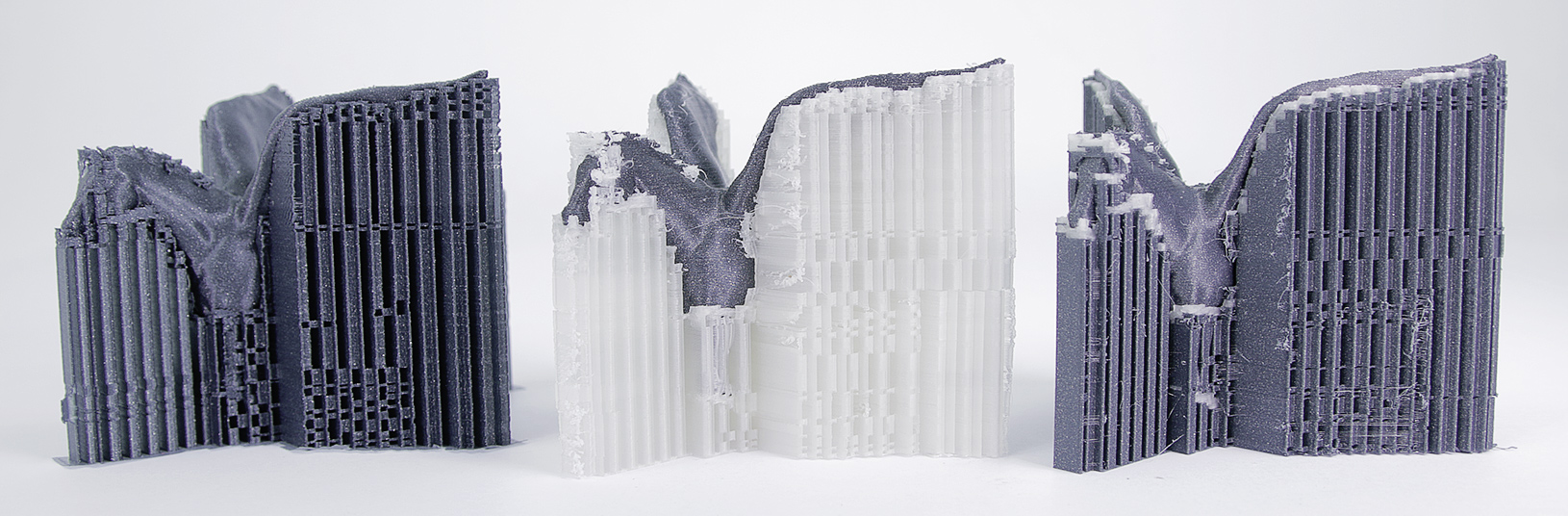

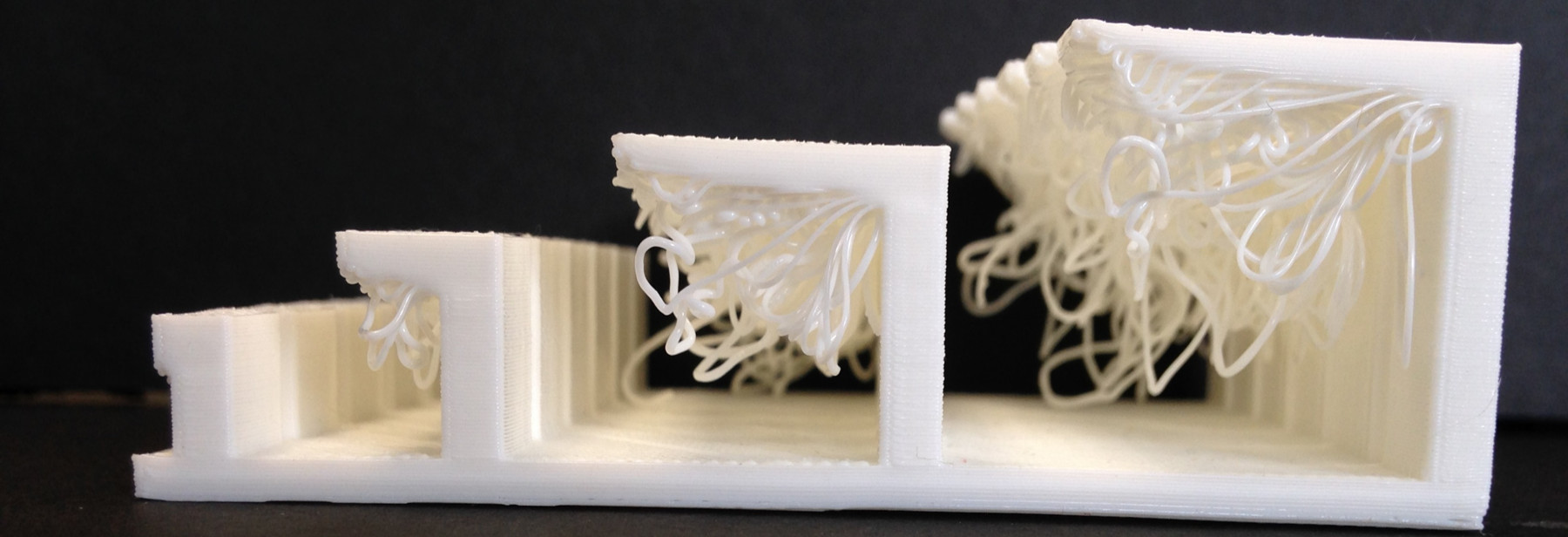

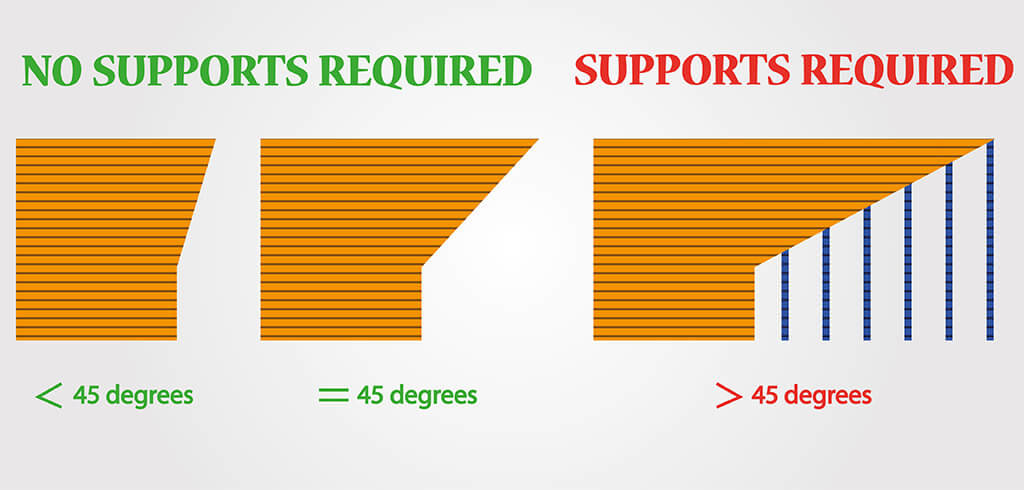

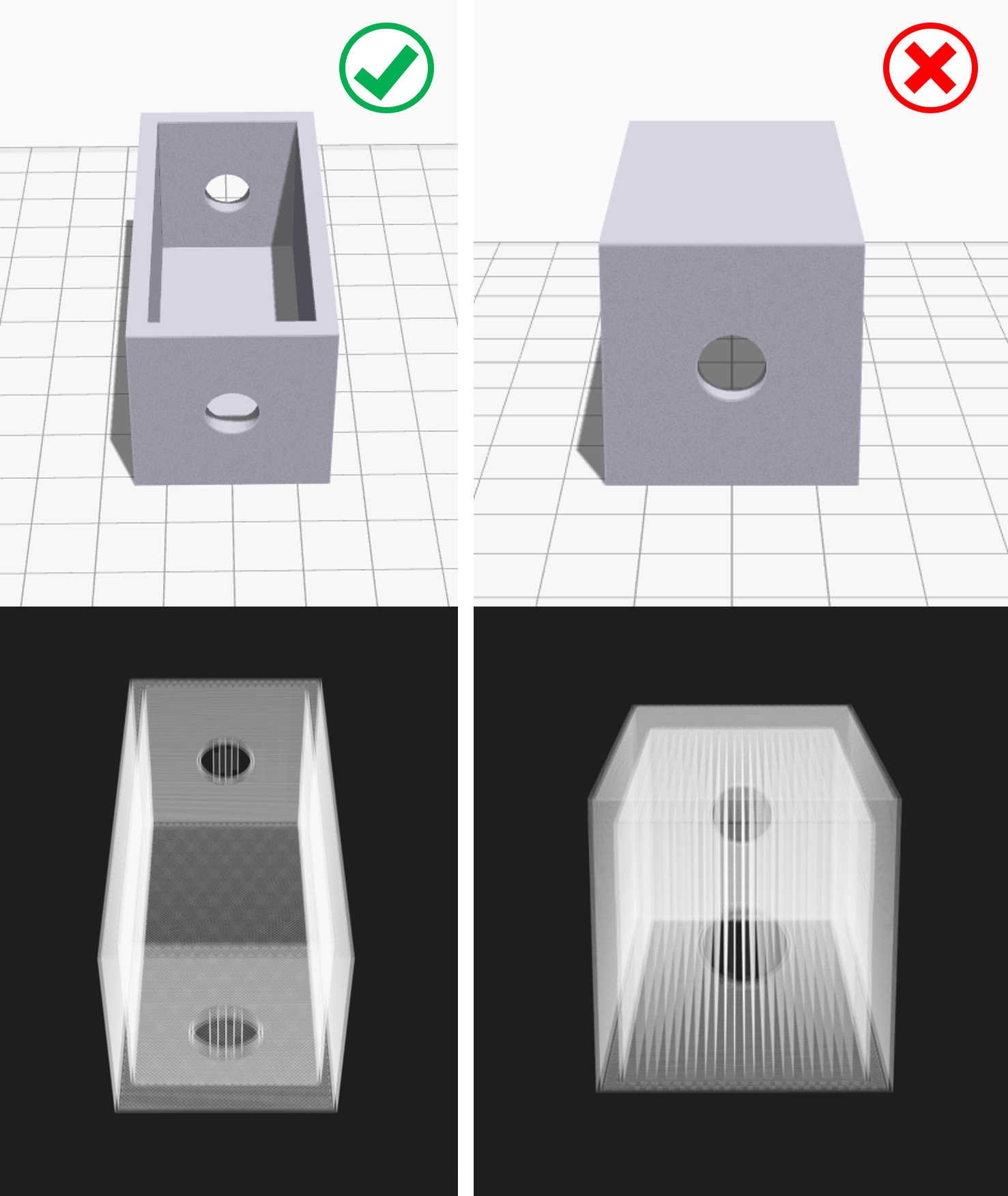

With fdm 3d printing support materials enable structures with an overhang of over 450 degrees. The same easy to print material with new advanced properties. They start from a couple of trunks near the base of your print and branch out to support overhangs in your model as height increases.

/Removing-Support-569fbe123df78cafda9e120b-f5965d604204464aa58ac16e1f230121.jpg)