3d Printing With Nylon

Nylon has an enduring popularity within the 3d printing industry.

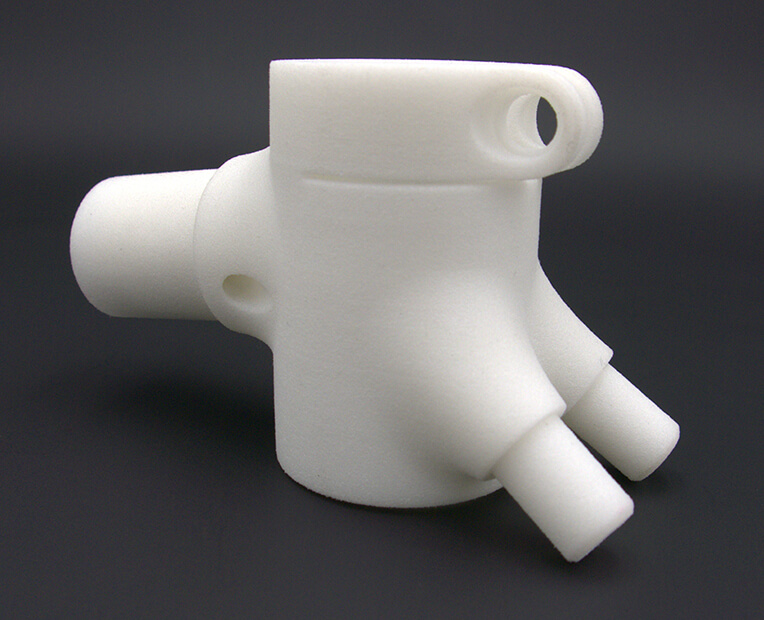

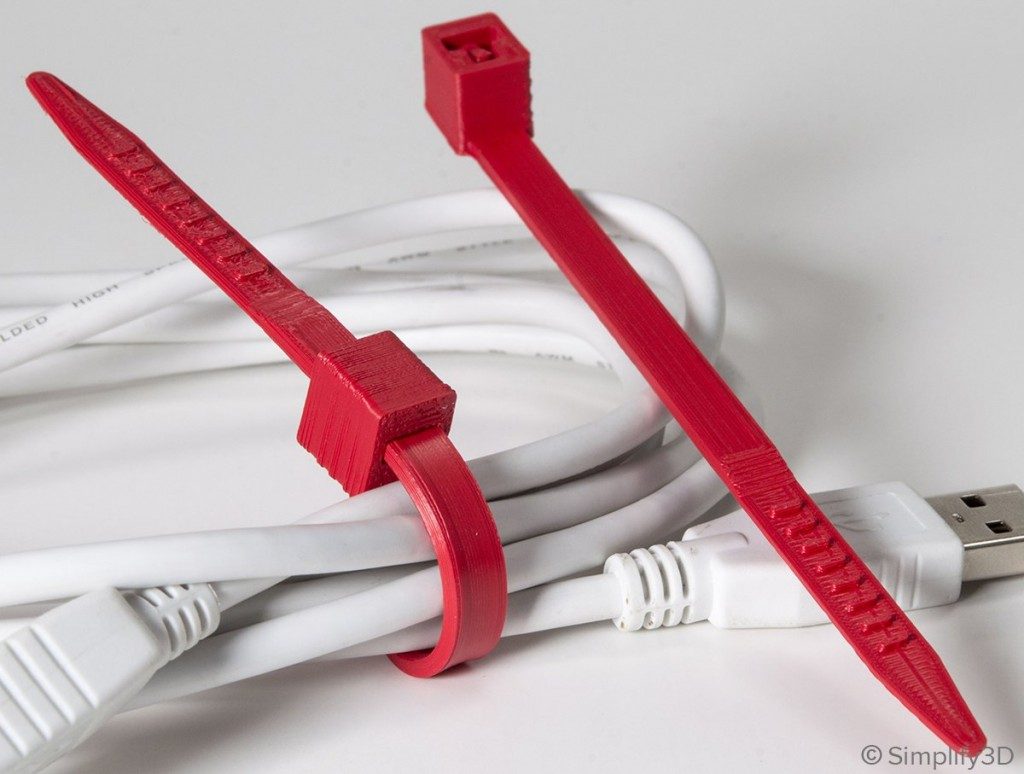

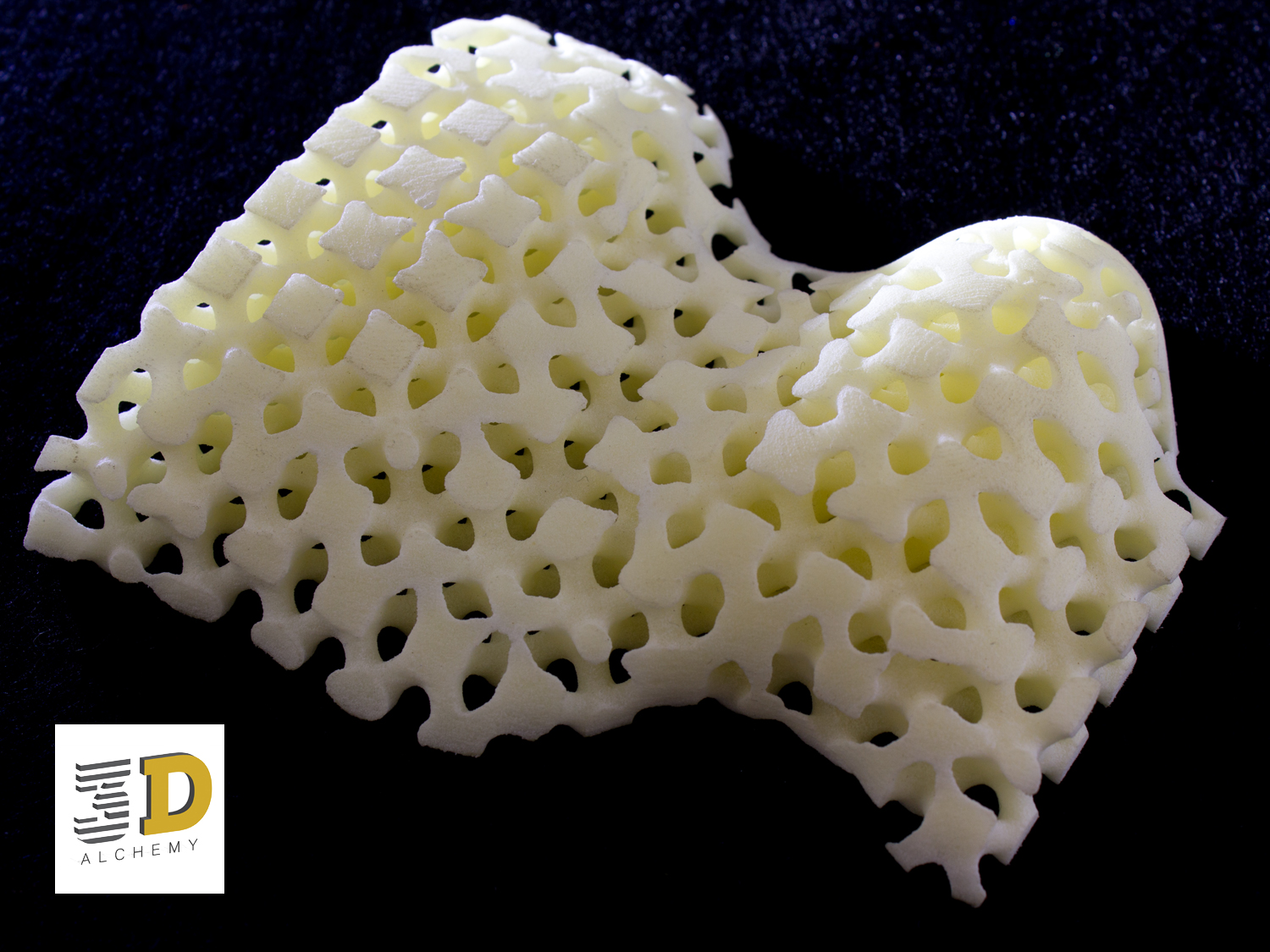

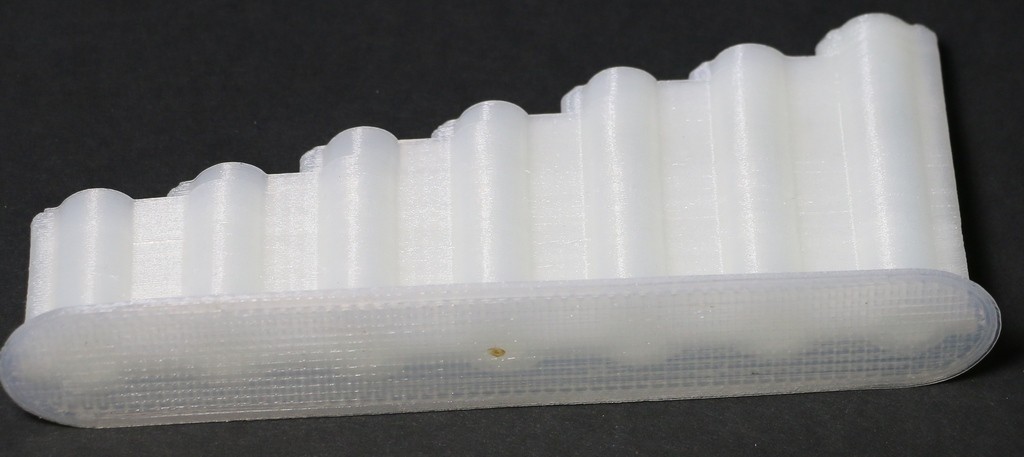

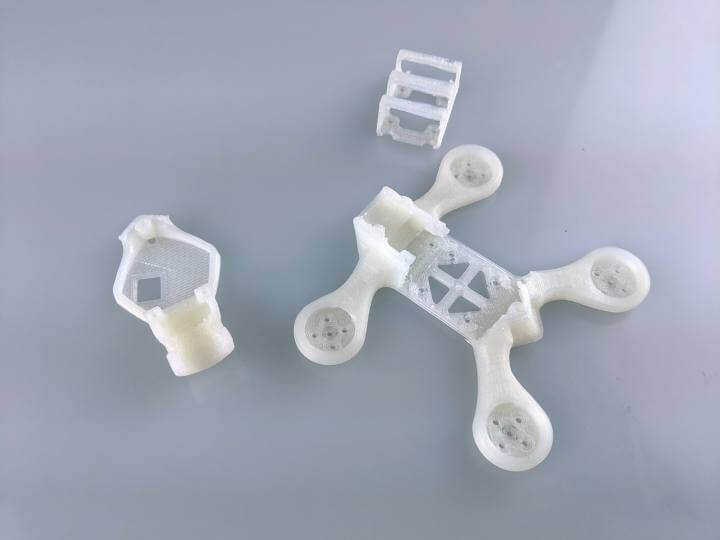

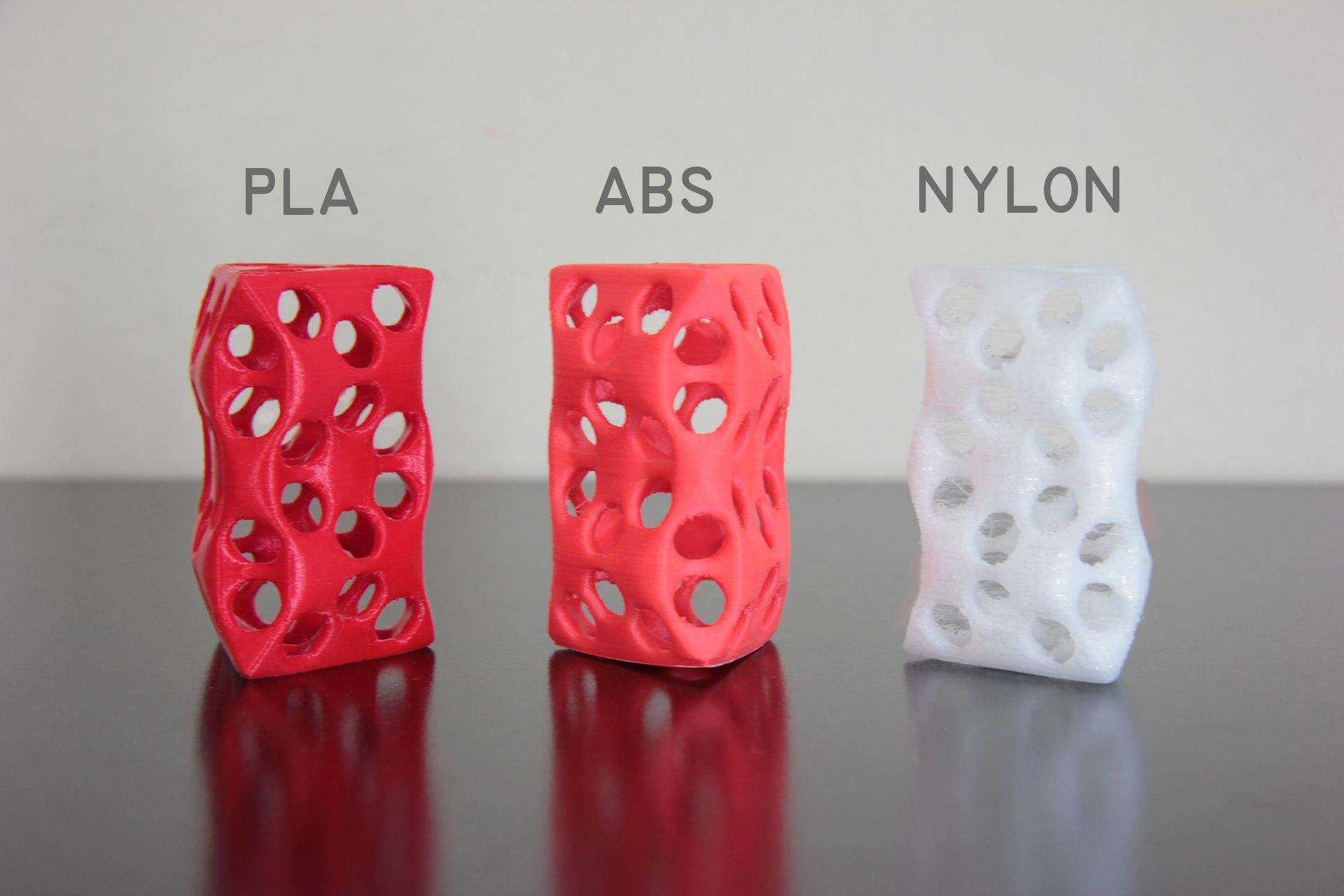

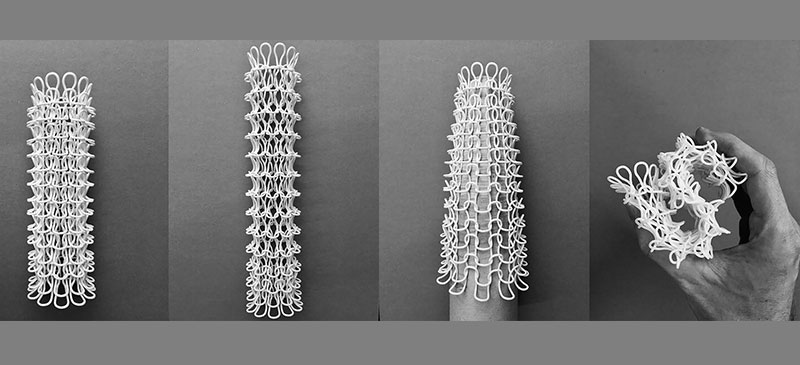

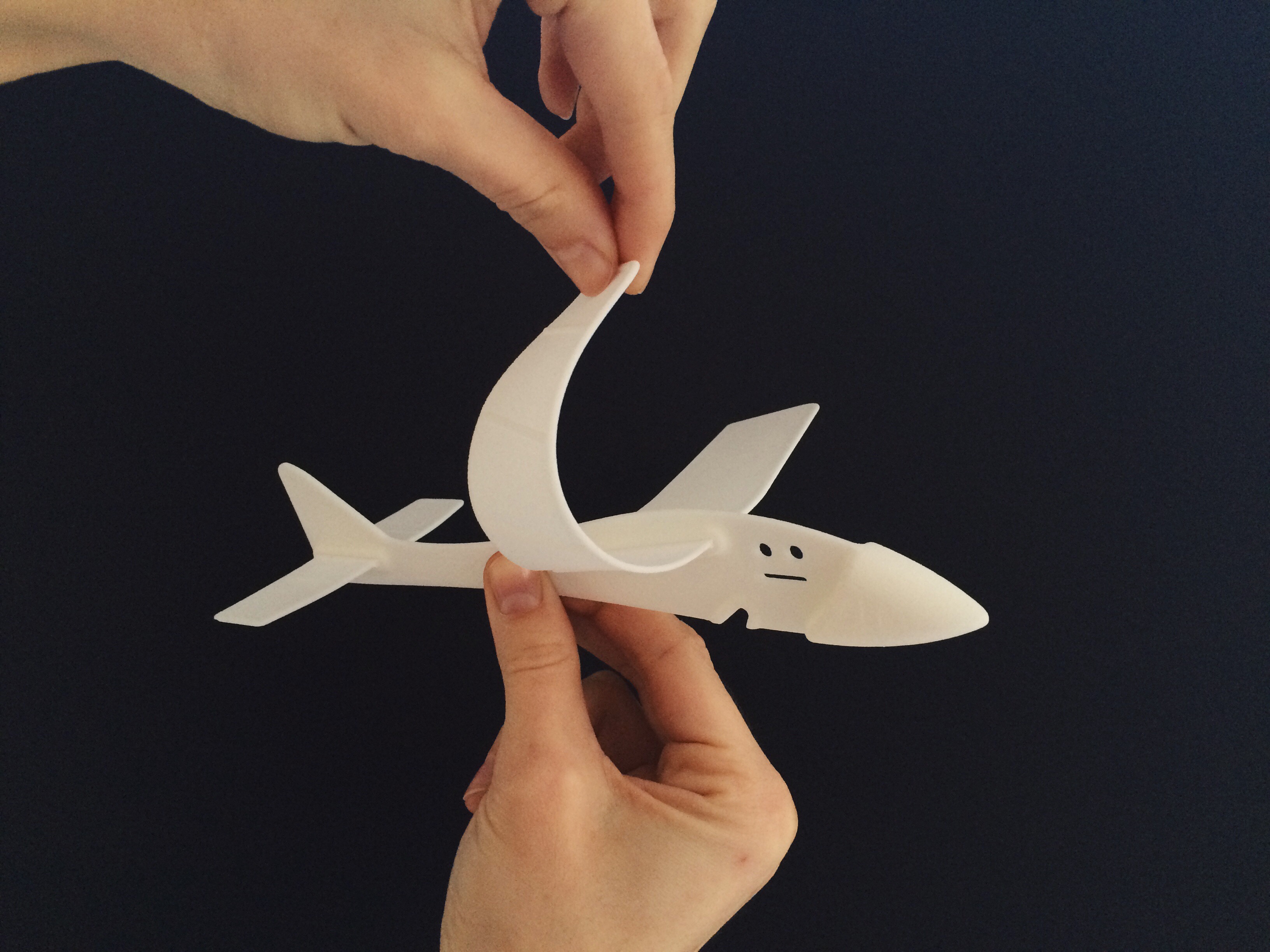

3d printing with nylon. Its resilient strong durable and a tad bit flexible. 3d printable nylon mostly exists as pa 11 and pa 12 or as composite materials like carbon fiber filled and glass filled nylon. When printed in thick parts with higher density infill and wider wall thicknesses it produces a very strong part that can handle significant shock and has excellent impact resistance. Admittedly there was a learning curve to getting a successful print.

Nylon pa 11 is more flexible than pa 12 whereas the latter has great all round mechanical properties ideal for functional prototypes. Sls is the most suitable technology for 3d printing nylon. It is applicable to both material extrusion and powder bed fusion 3d printing technologies. You typically wont find it snapping like brittle materials.

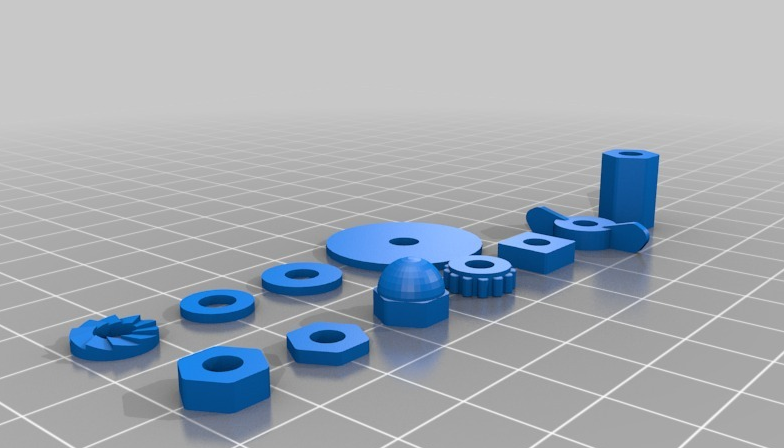

Ultimaker s5 is a phenomenal best in class 3d printer overall but it also works with nylon filament out of the box. Start printing at 250 0 c and adjust in increments of 50c until you find the right temperature that produces a strong. 2400c 260 0 cstart printing at 250 0 c and adjust in increments of 50c until you find the right. Before 3d printing with nylon make sure your 3d printer meets the hardware requirements listed below to ensure the best print quality.

Nylon is a synthetic polymer which is based on polyamides. Recommended nylon 3d print settings. The right temperature. 3 d printing with nylon seems to be one of those things that the 3d printing community doesnt talk about much.

It can be difficult to print on a desktop 3d printer so weve gathered a few tips and tricks.