Carbon Fiber 3d Printer Resin

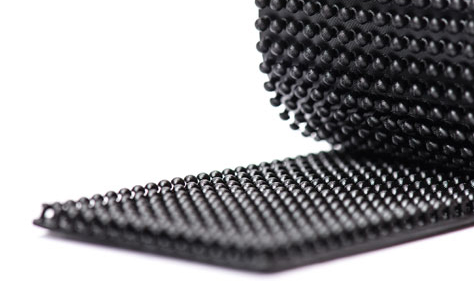

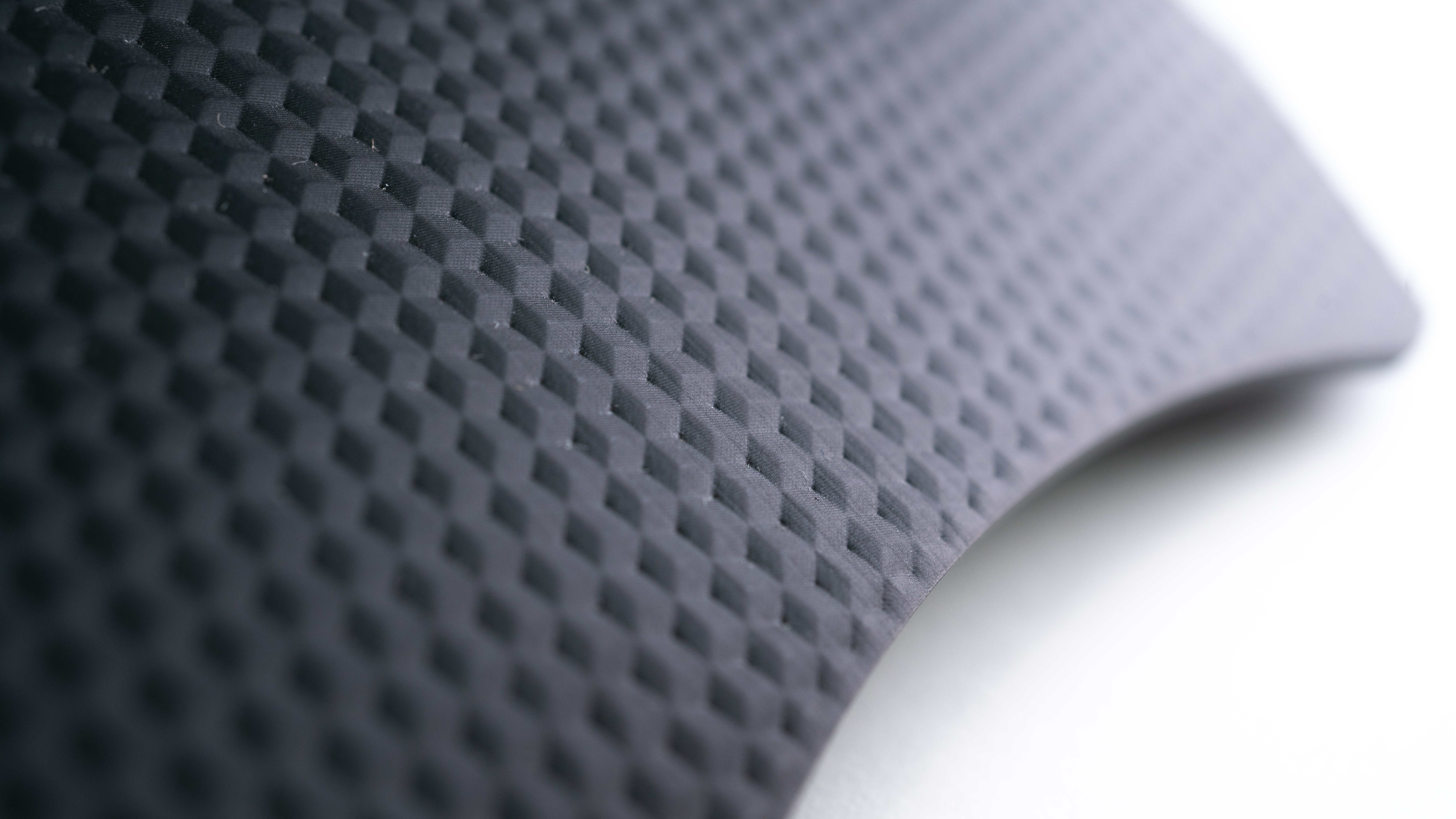

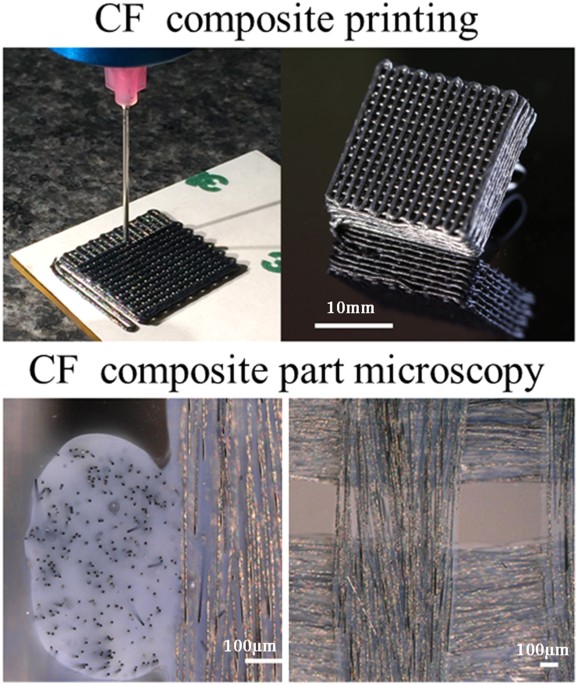

By necessity the lengths of the chopped carbon fiber must be far less than the diameter of the extrusion nozzle typically 04mm wide.

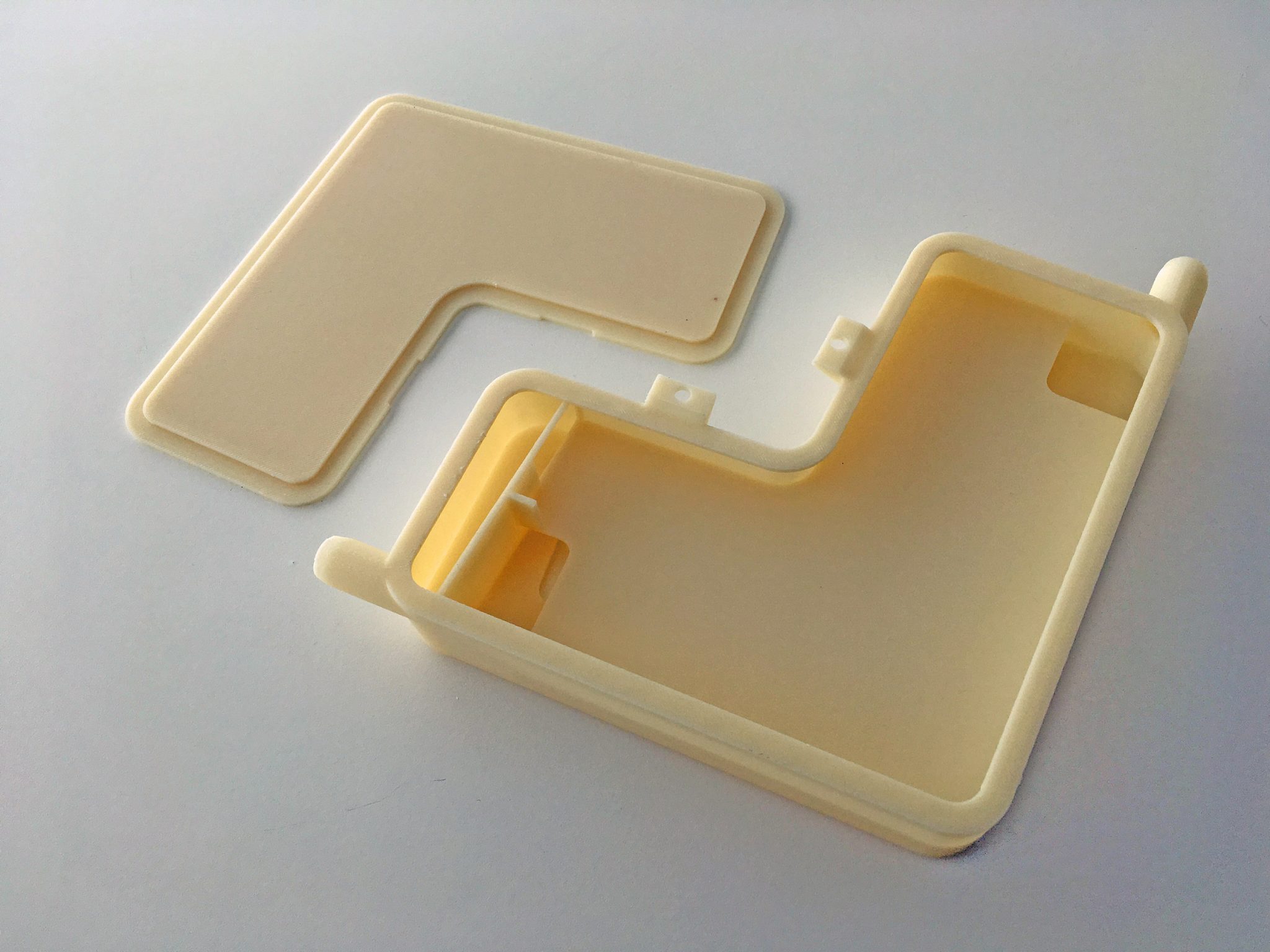

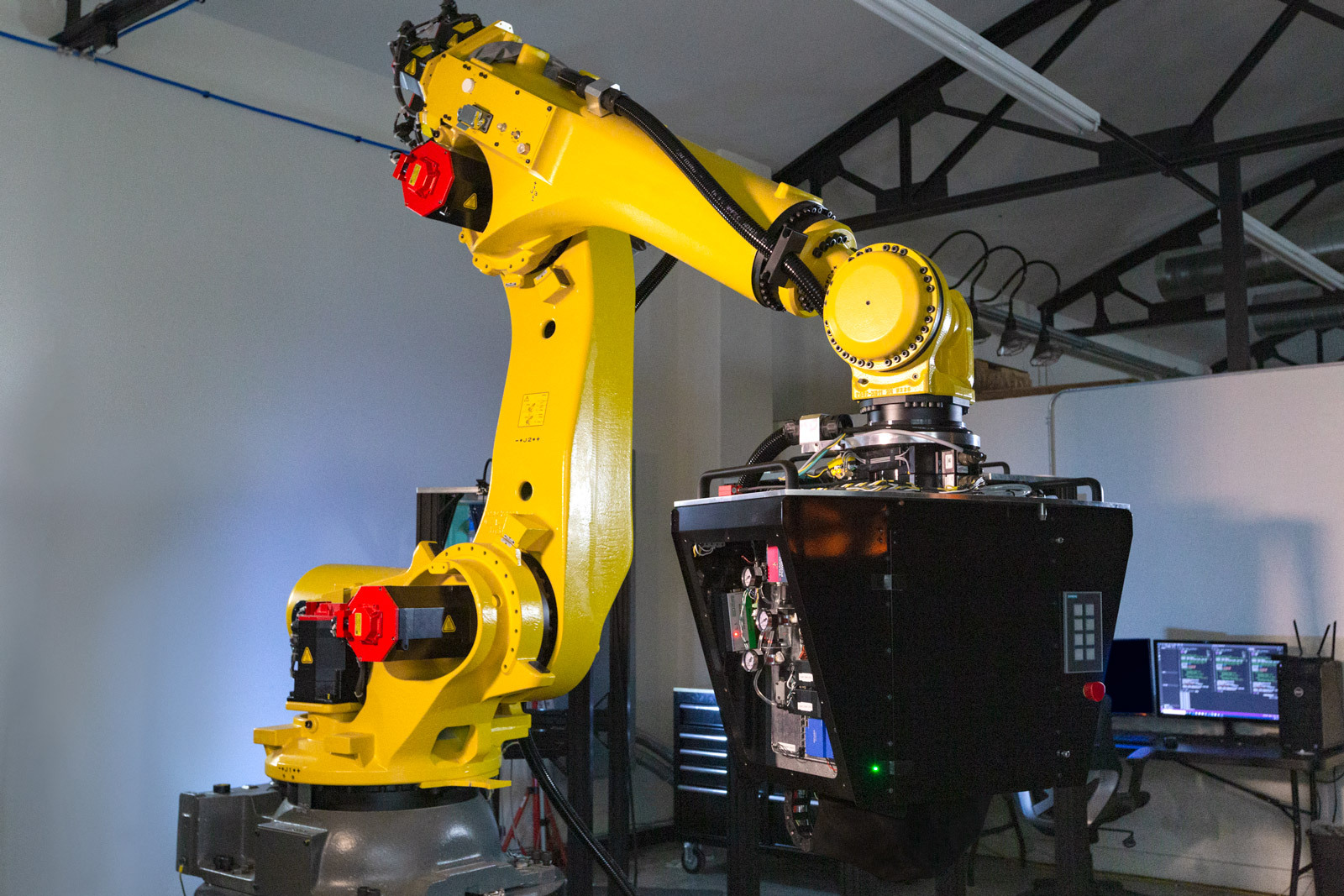

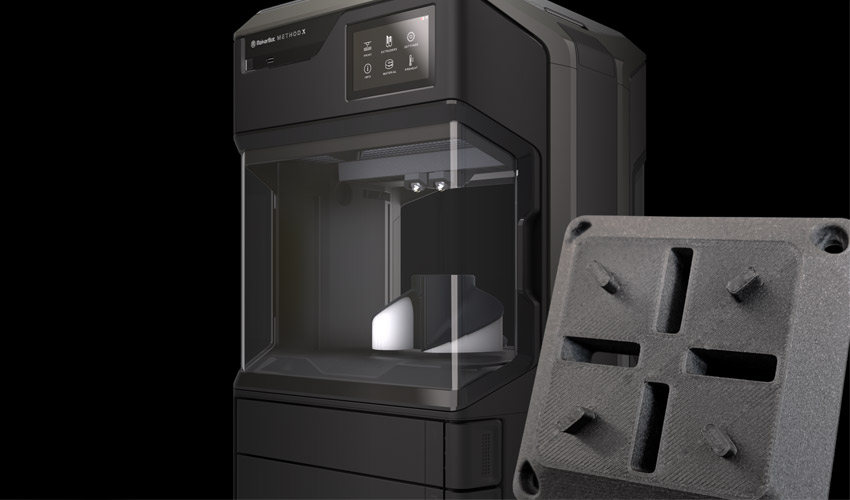

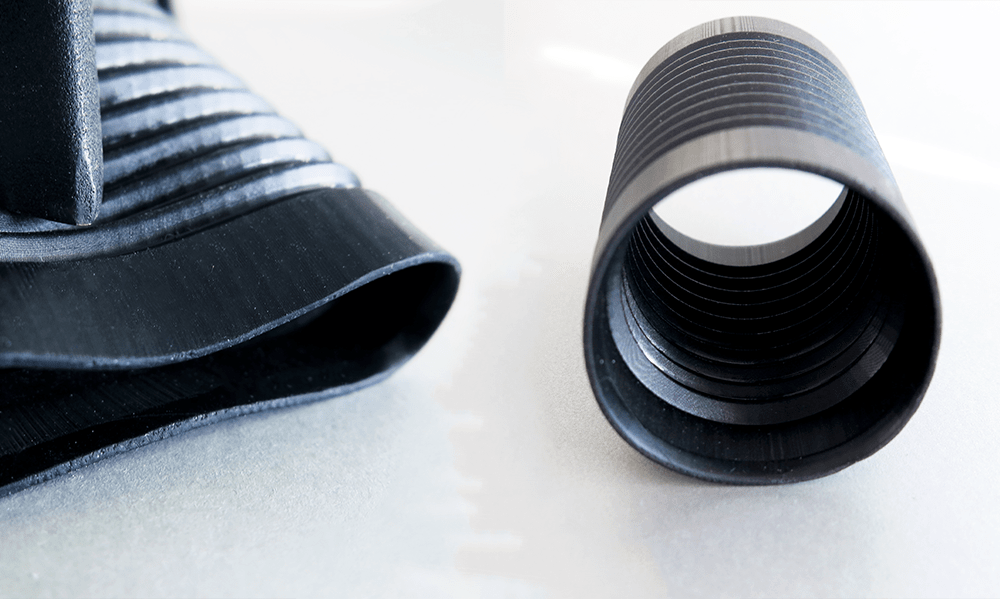

Carbon fiber 3d printer resin. Compare all carbon materials 3d printed parts without compromise. Chopped fiber filled plastics are the most common type of composite 3d printed plastics. With markforged industrial 3d printers you can economically print with advanced materials including nylon chopped carbon fiber reinforced continuous fiber and metal. These materials uniquely combine excellent mechanical characteristics high resolution and exceptional surface quality into isotropic parts ready for real world products.

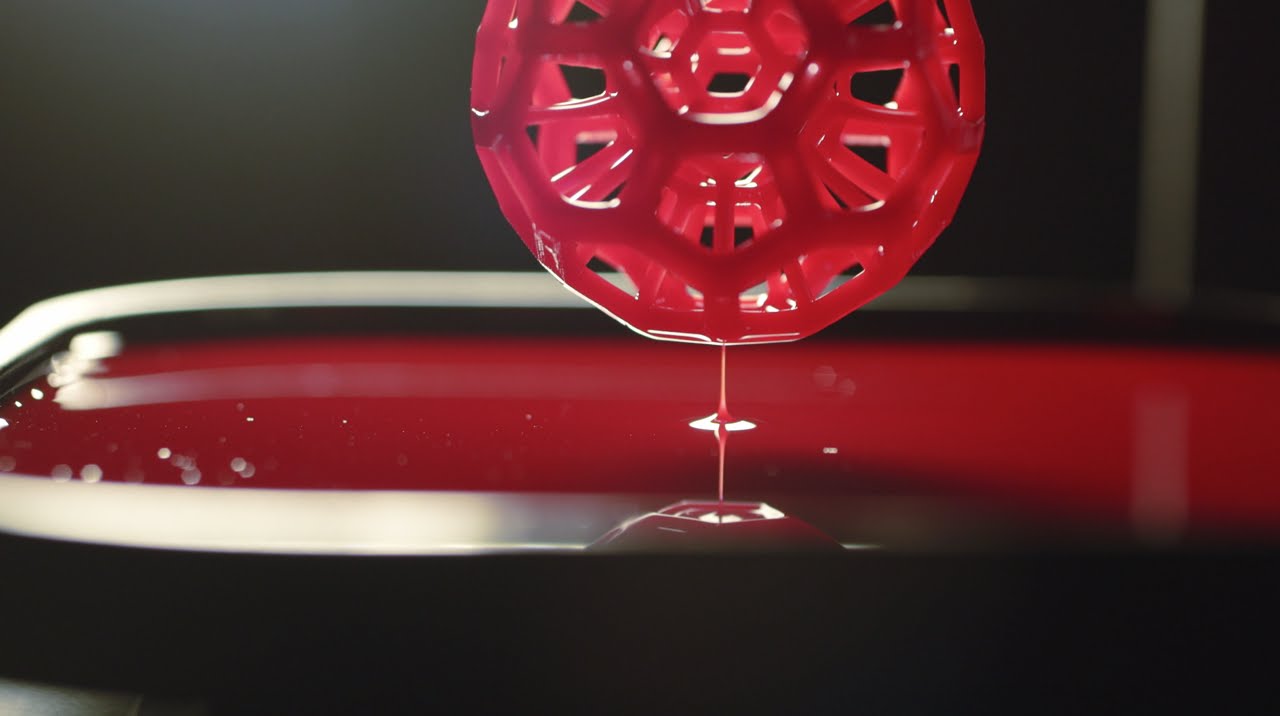

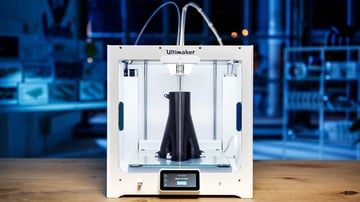

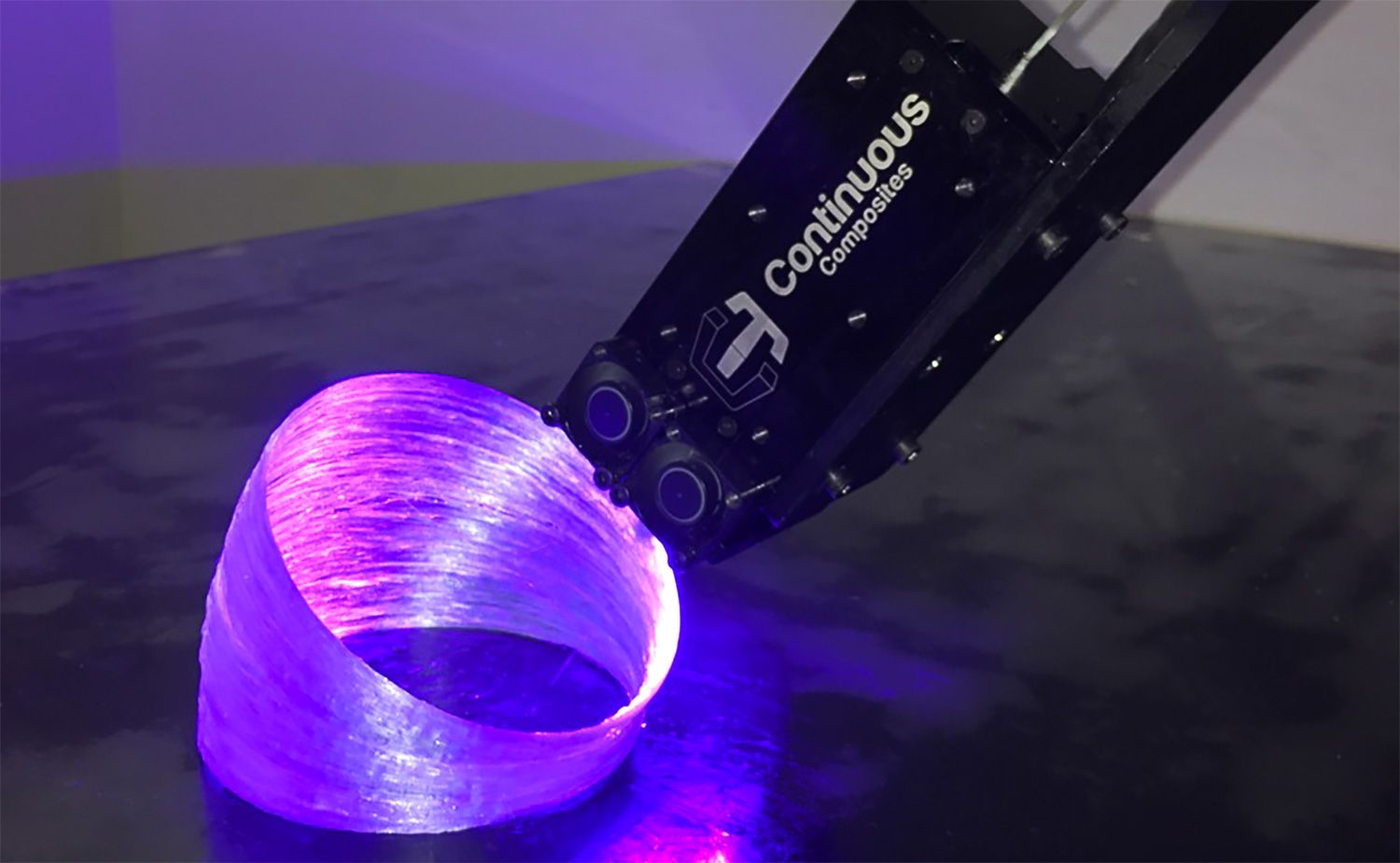

Widely recognized as one of the premier carbon fiber 3d printers on the professional market the markforged mark two gen 2 is a workhorse machine that is compatible with a range of composite materials including carbon fiber high temperature glass fiber hsht fiberglass and kevlar. Featuring closed loop heat control the uafp head constructs a high density continuous fiber reinforcement while the fff printhead enables a high resolution exterior shell. Carbon offers best in class 3d printable materials for prototyping and producing real functional parts. We put the elegoo mars.

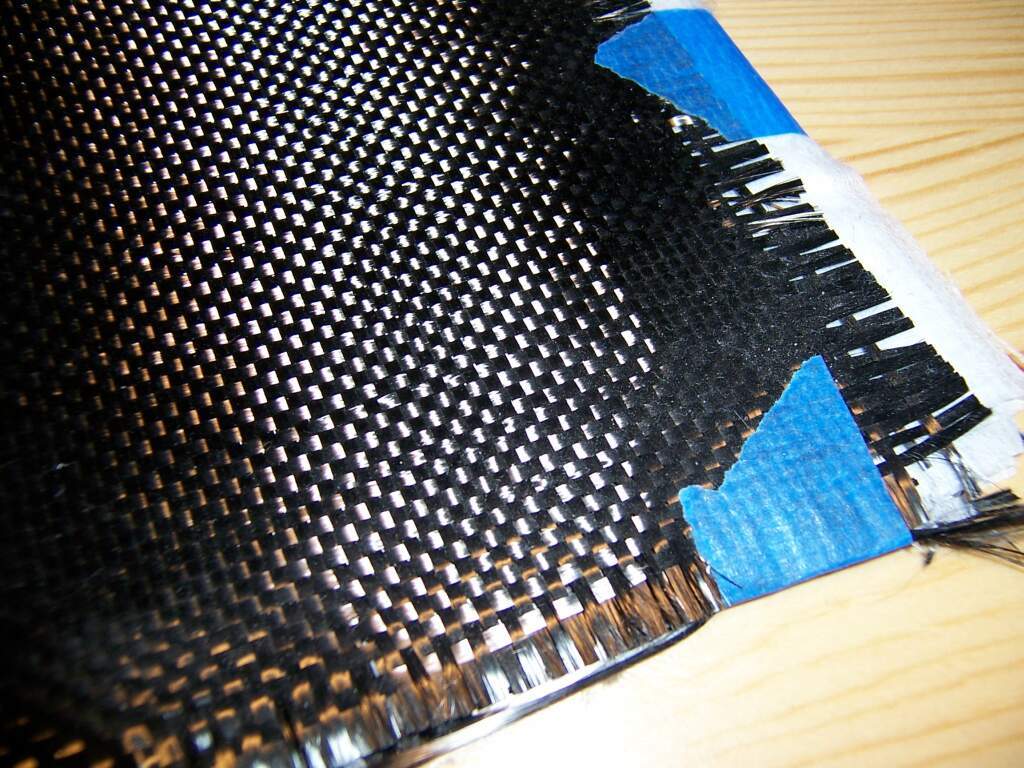

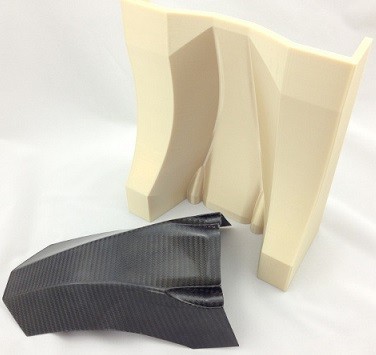

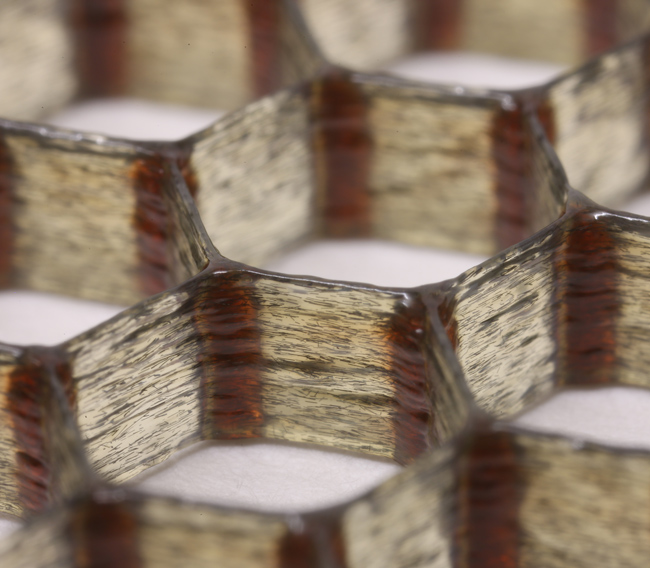

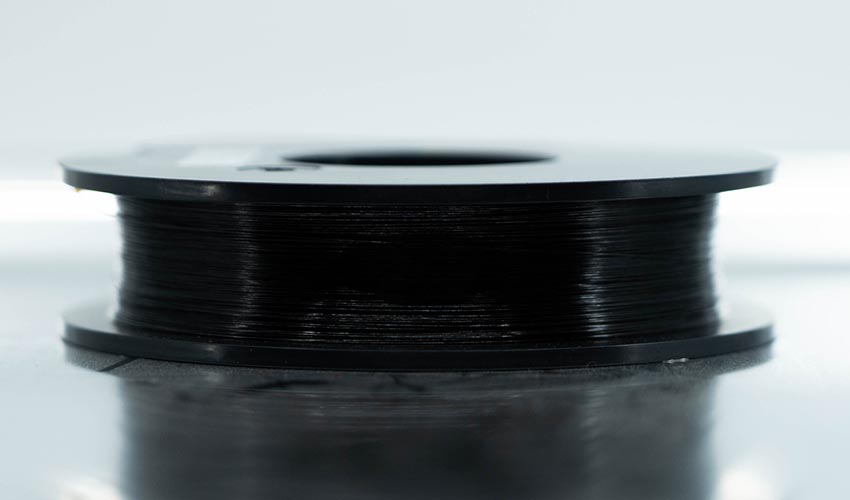

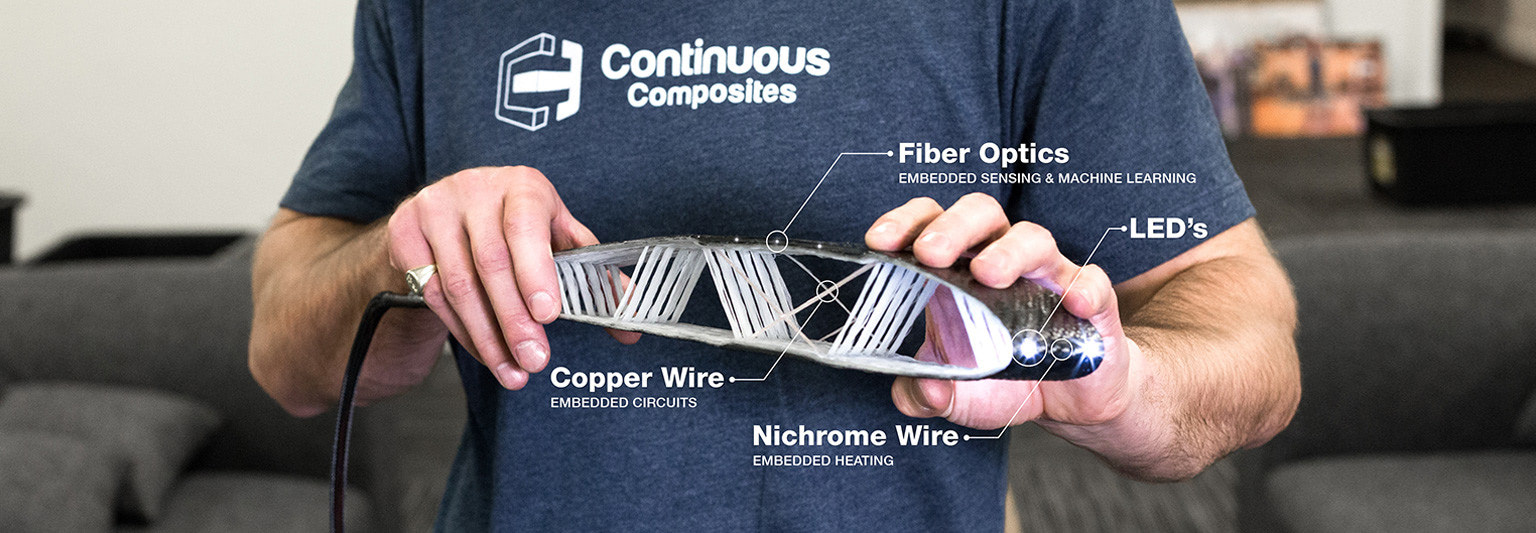

In fact continuous carbon fiber 3d printing is strong enough to replace aluminium at half the weight. Several popular filaments can be bought with carbon fiber fill including pla petg nylon abs and polycarbonate. From rapid prototyping and low volume production to custom end use parts carbon digital light synthesis technology is the promise of 3d printing fulfilled. Carbon fibers were chopped into very short lengths and then mixed in with standard 3d printer plastic resin then extruded into filaments and wound out spools.

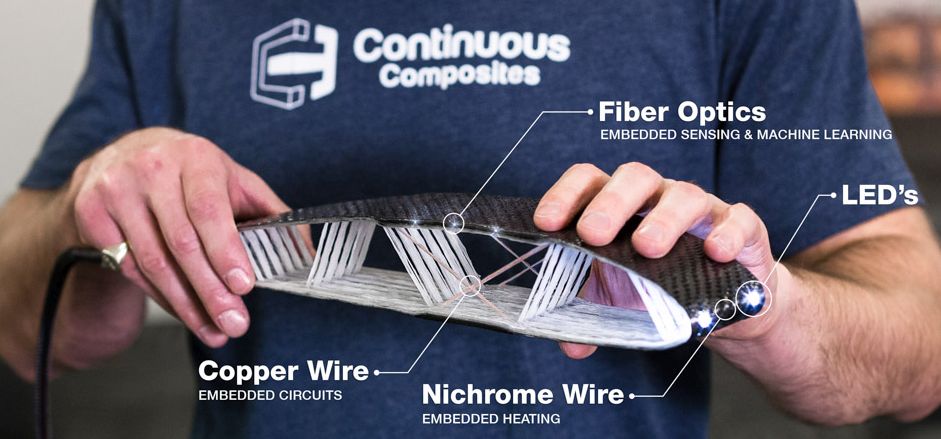

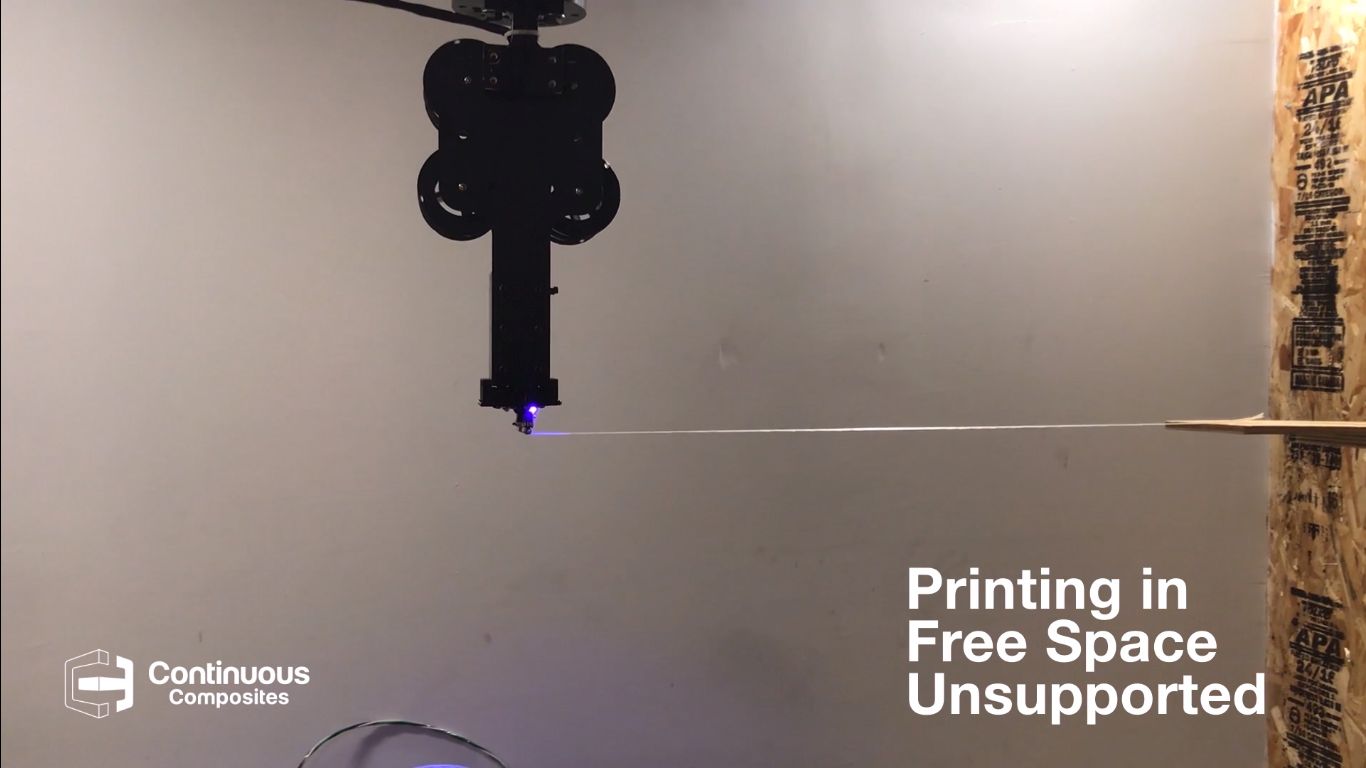

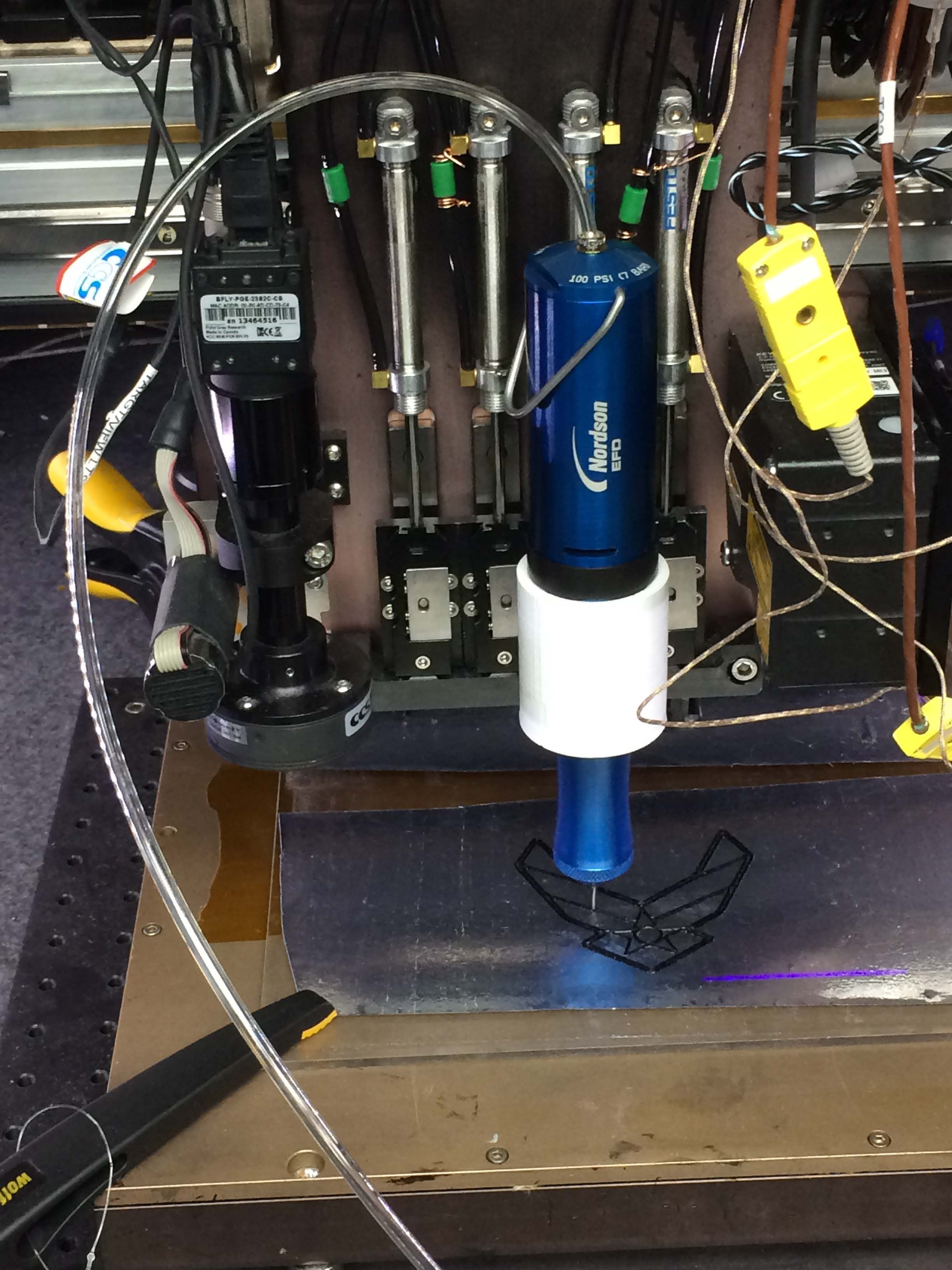

Fiber is the only composite 3d printer to use micro automated fiber placement mafpunlocking exceptional part strength for a desktop printer. In addition to the wood fiber and metallic filaments you can print carbon fiber nylon abs plastic flexible plastics and more. Since the carbon fiber is not chopped up into smaller pieces it retains much more of its strength. Adding this filling to thermoplastics is a material booster pack.

This also means that the 3d printed parts will be much lighter and more dimensionally stable as the fibers will help prevent shrinking of the part as it cools. The most widely used chopped composite 3d printing material is chopped carbon fiber where carbon fiber pieces are mixed with traditional 3d printing plastics like nylon abs or pla.

Amazon Com Qidi Tech 3d Printer Large Size X Plus Intelligent Industrial Grade 3d Printing With Nylon Carbon Fiber Pc High Precision Printing 10 6x7 9x7 9 Inch Electronics