Continuous Carbon Fiber 3d Printer

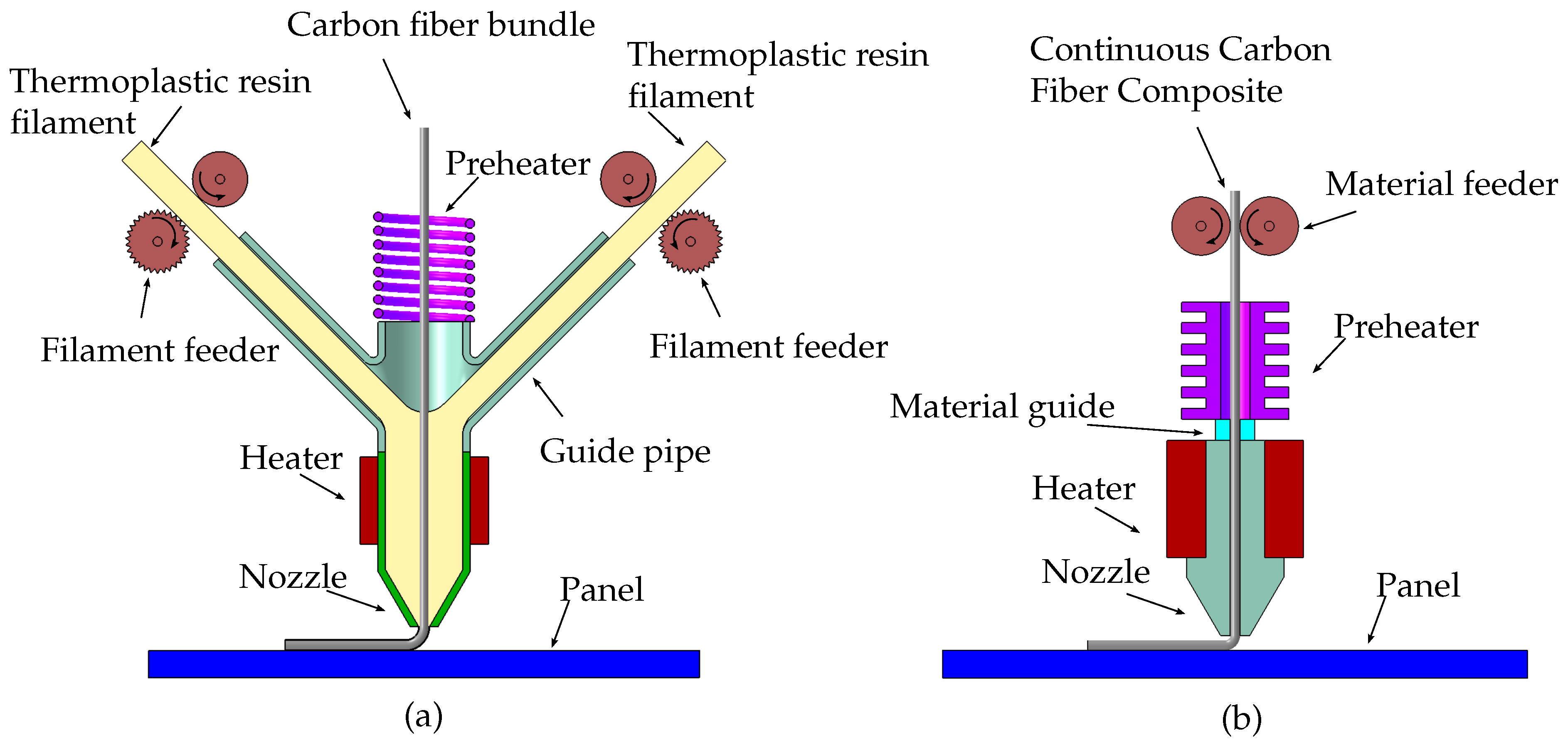

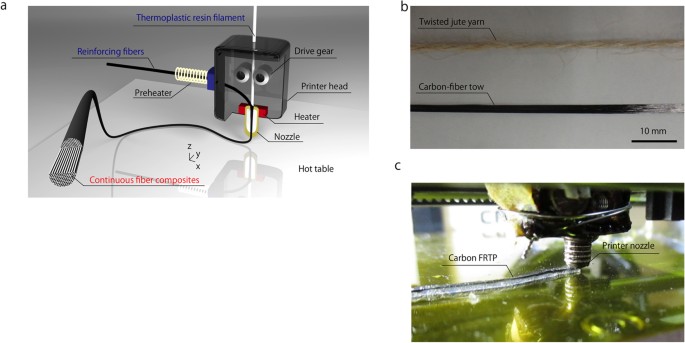

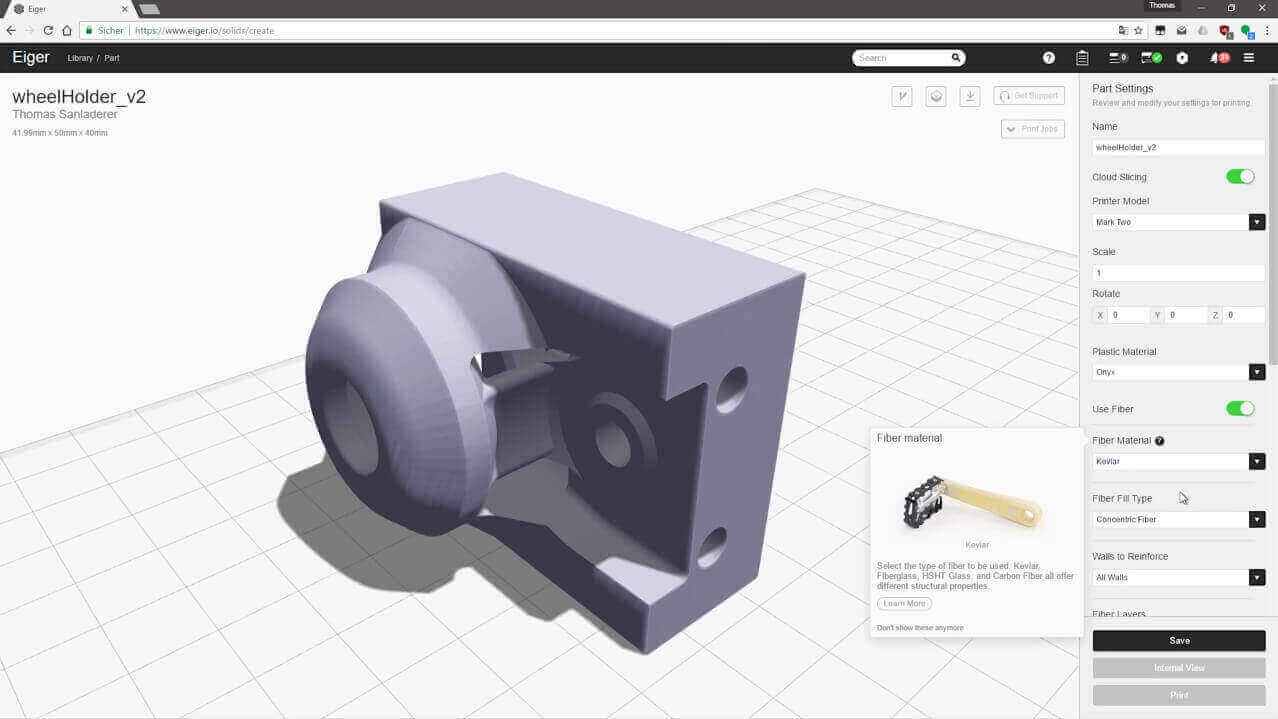

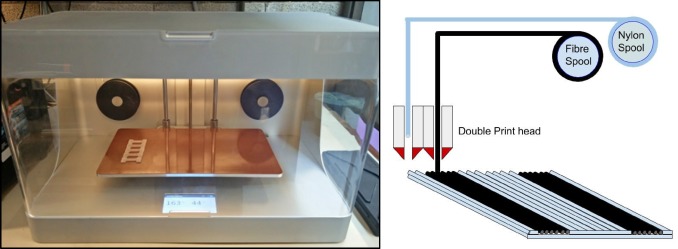

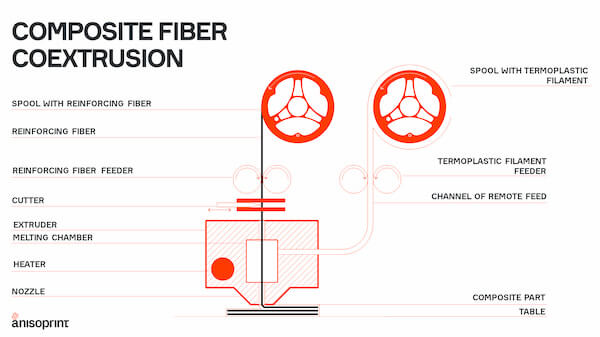

Cff uses two print nozzles to produce parts with continuous.

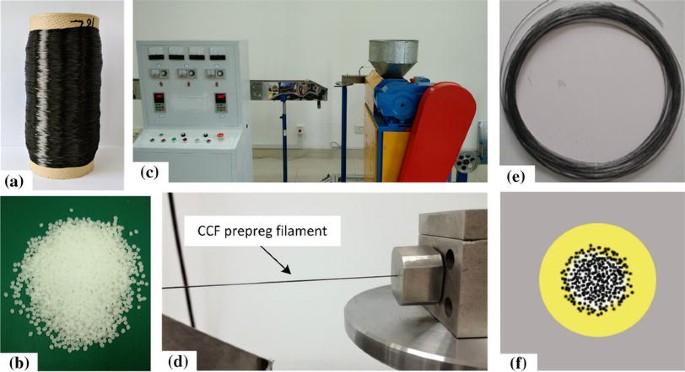

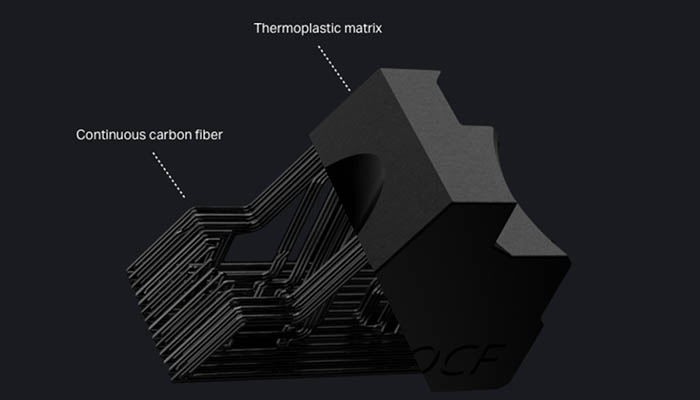

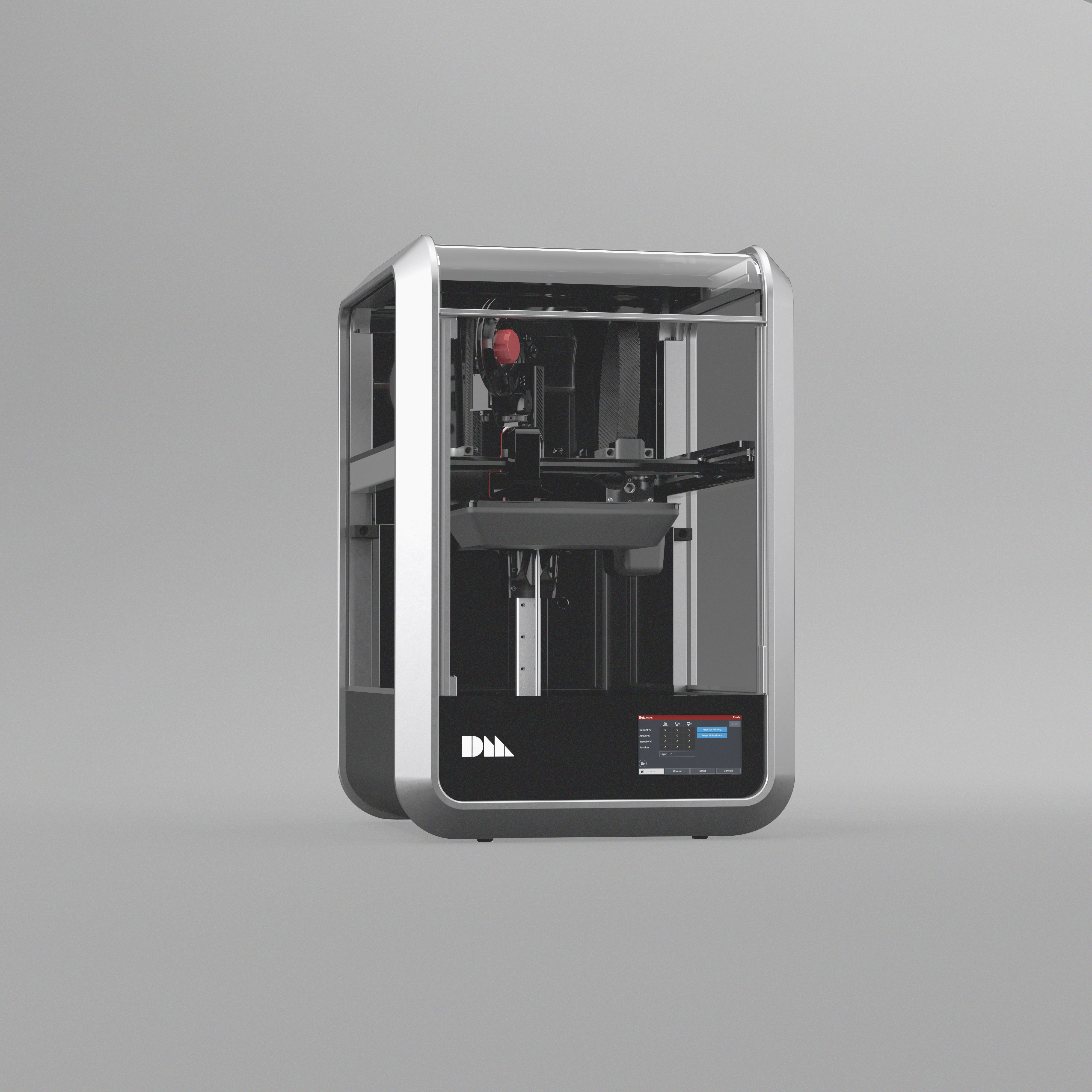

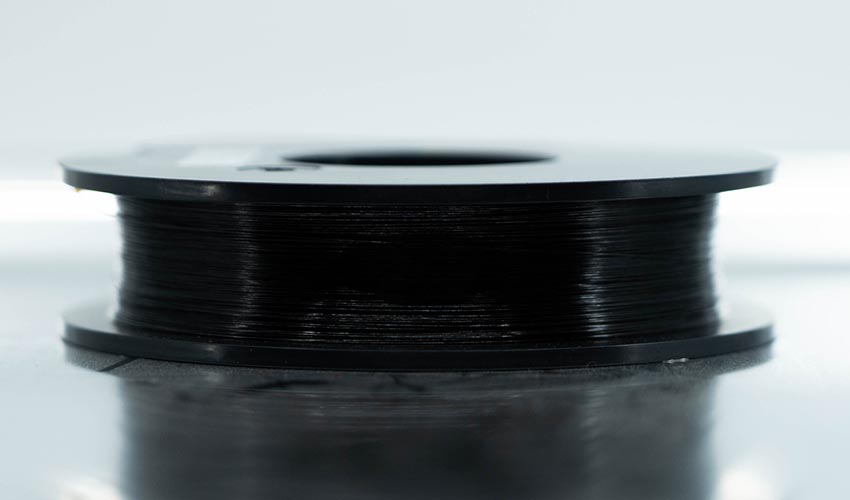

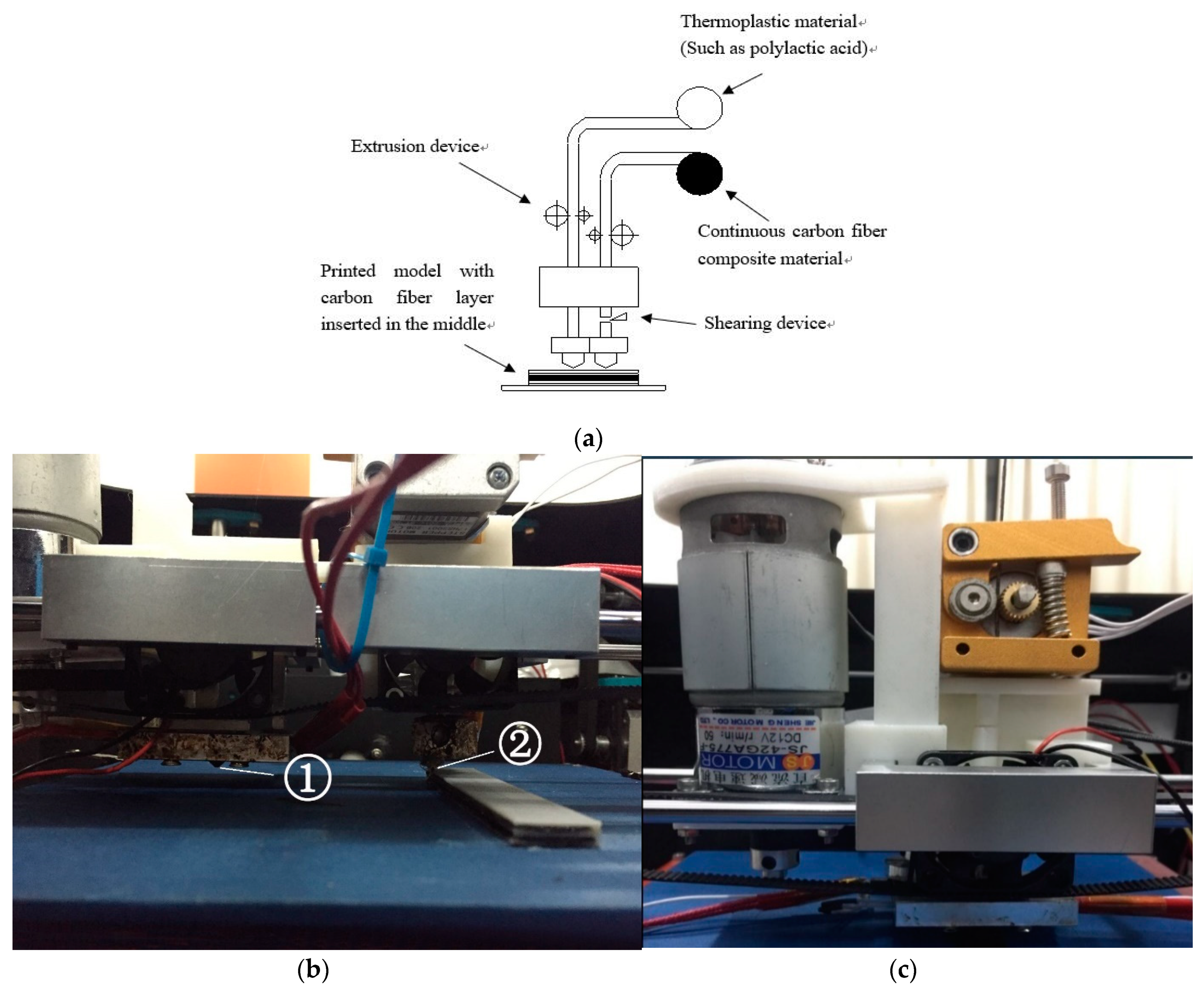

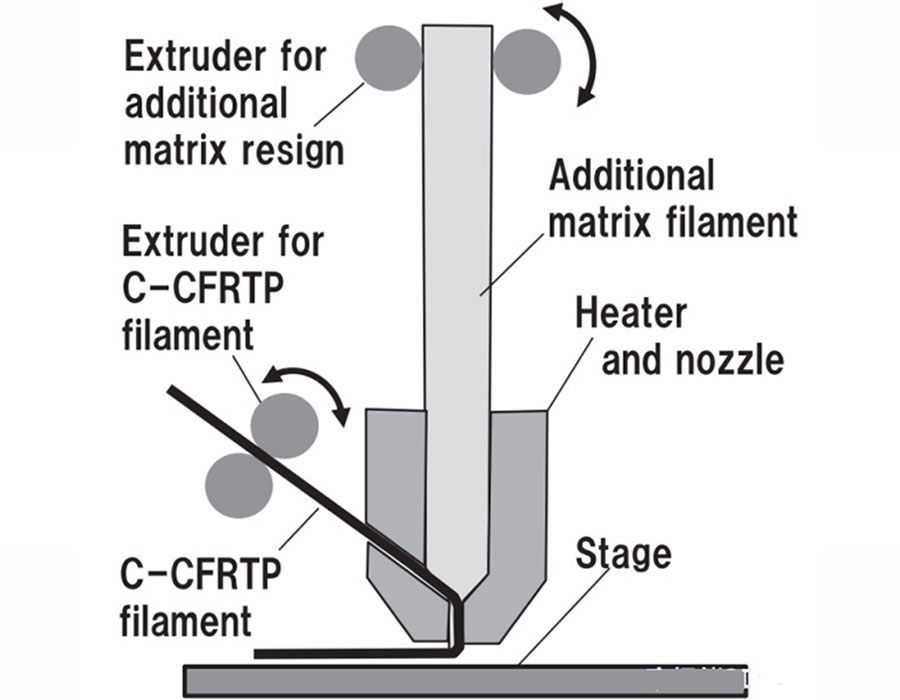

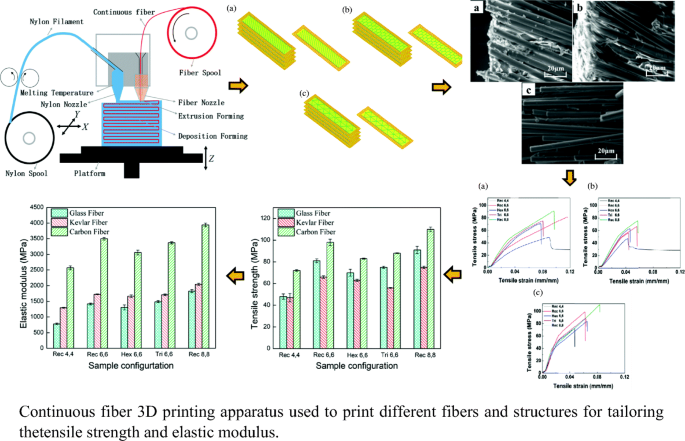

Continuous carbon fiber 3d printer. Cf3d combines the power of composite materials with rapid curing resins to create a moldless out of autoclave ooa manufacturing process. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. The result is an am printer that can produce parts made with continuous carbon fiber in a thermoplastic resin. Carbon fiber is mixed into another material which can be virtually any thermoplastic ranging from pla to peek.

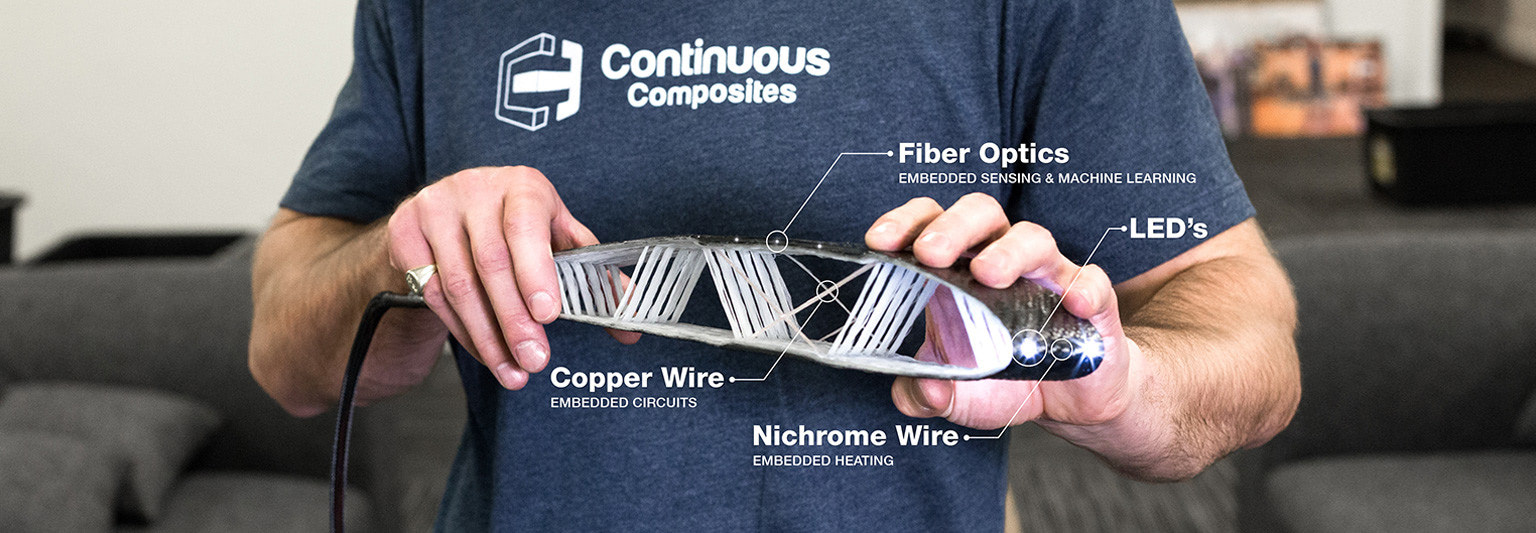

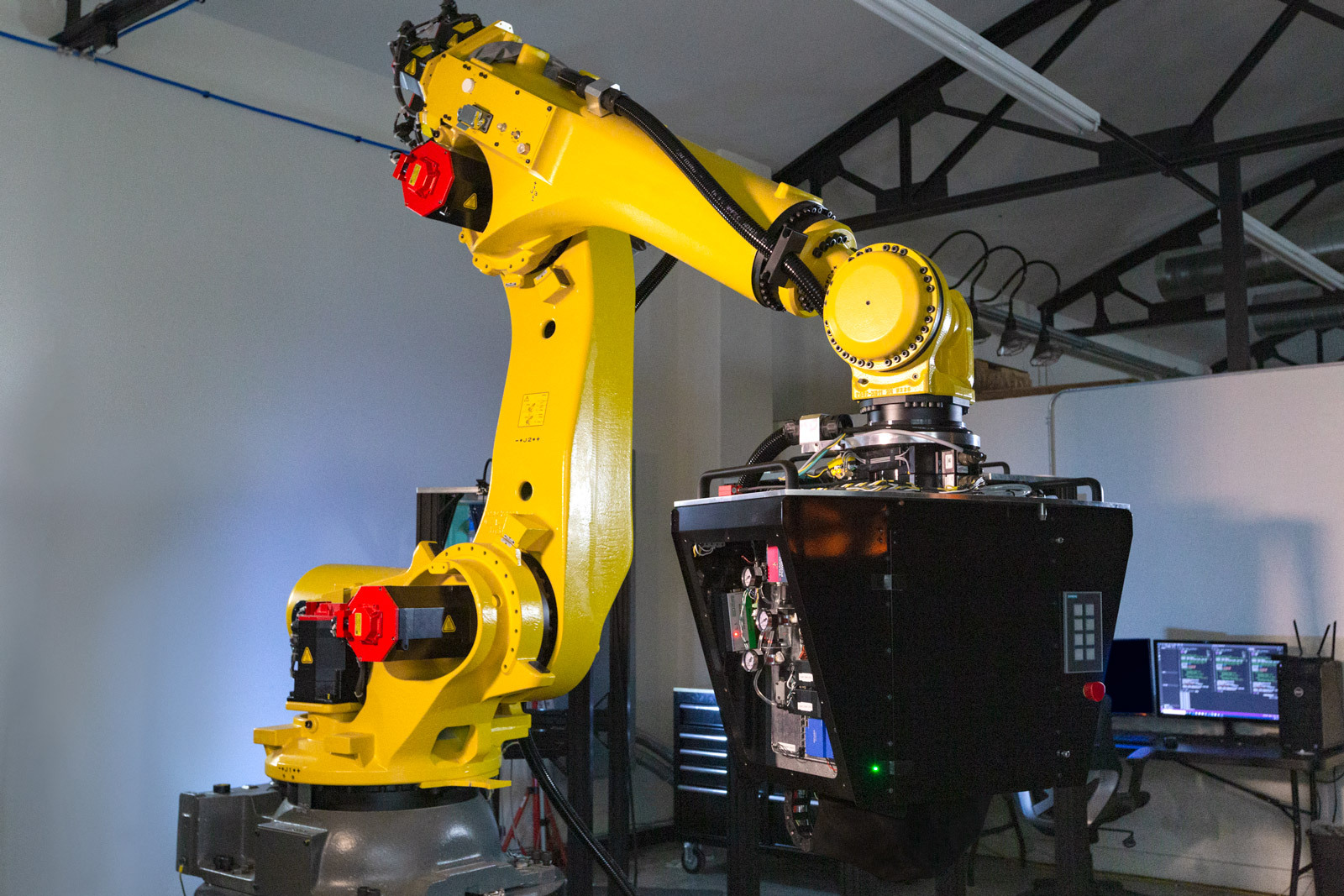

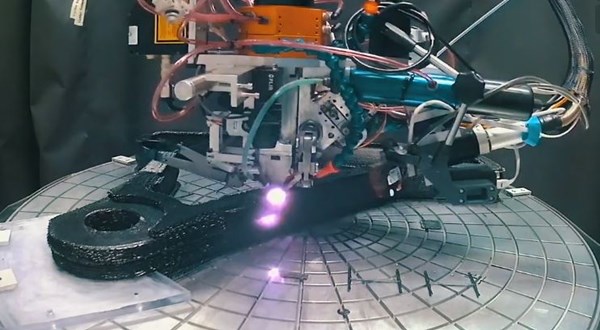

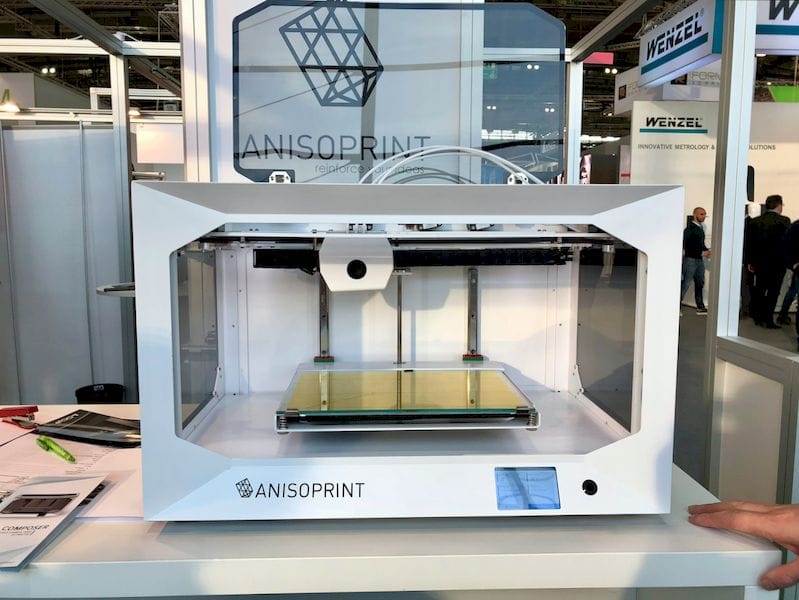

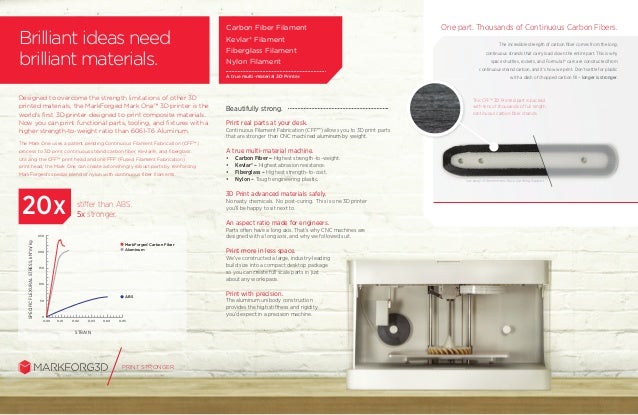

To address these criteria cead developed continuous fiber additive manufacturing cfam which is capable of 3d printing parts up to 4m x 2m x 15m in size at a rate of 15kg per hour. Continuous fiber fabrication cff is a process developed and coined by markforged a massachusetts based producer of 3d printers. See how we do this. To make those components strong enough the company turned to composites specifically glass and carbon fiber reinforcement materials.

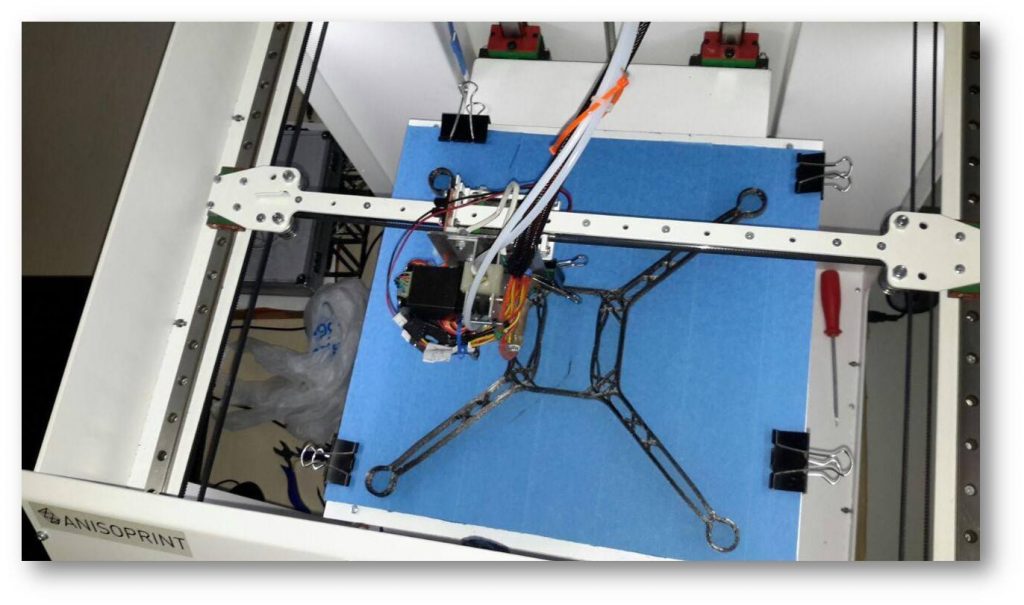

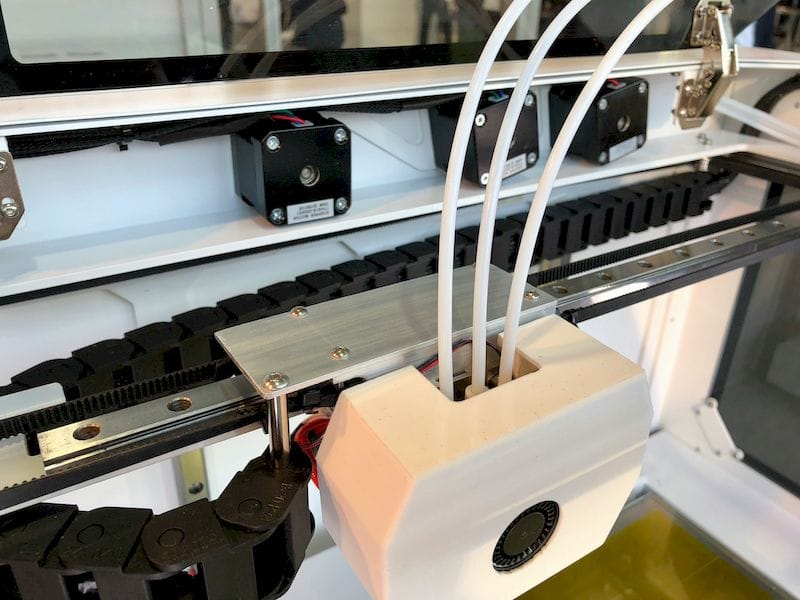

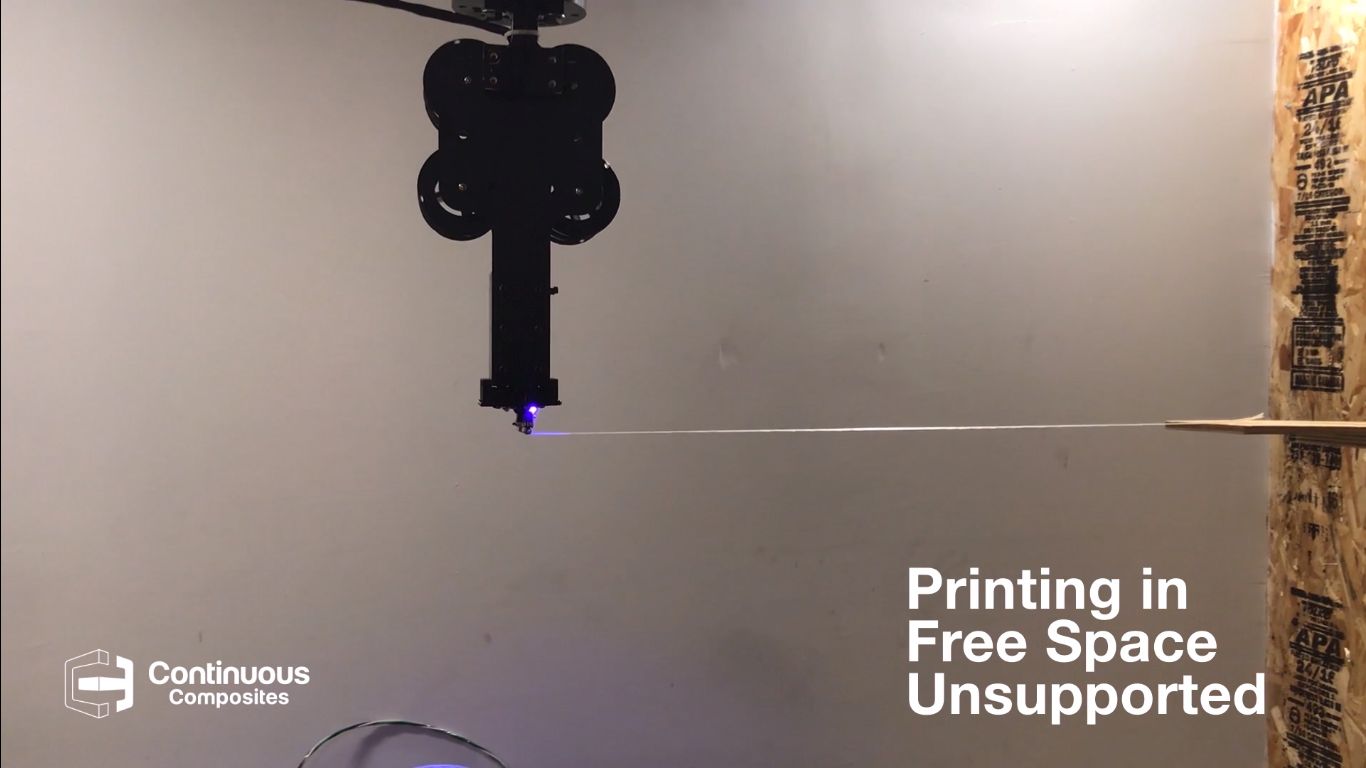

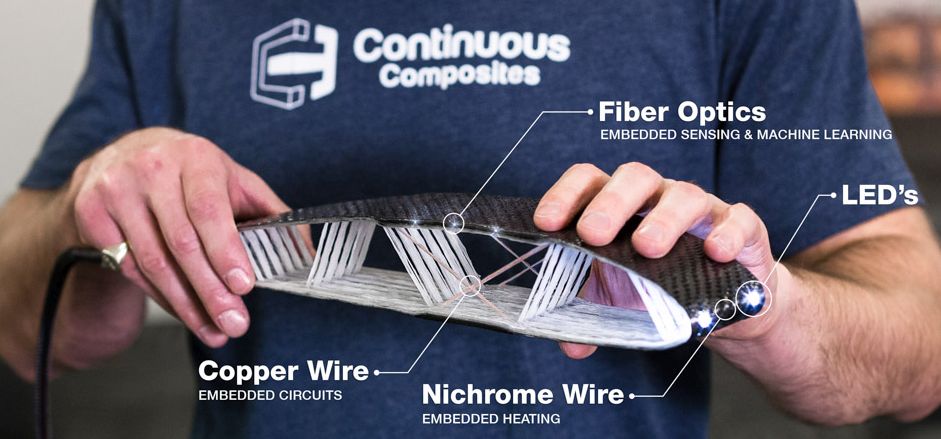

Rd was initially based on open source 3 d printers which the company refined iteratively to create a more robust and reliable process. With the ability to print both structural and functional fibers into free space continuous composites dares to redefine manufacturing. It has a modest 320 x 132 x 154 mm build volume and is capable of achieving a layer resolution of 100 microns. Reinforced with continuous carbon fiber filament material the arm is stiff and lightweight enough for the robot to have a precision of 50 microns about 0002.

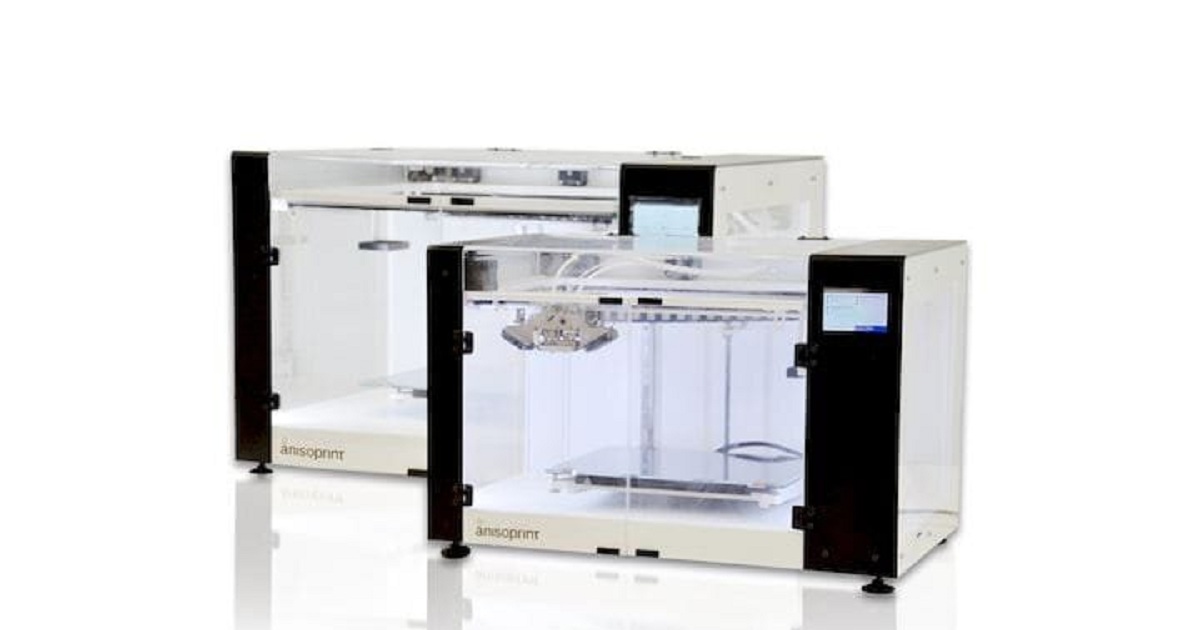

A complicated 3d product can be printed using continuous cfrtp. Application spotlight haddington dynamics is a company that developed dexter a 3d printed robotic arm made almost entirely out of markforged parts. Currently machine with markforged industrial 3d printers you can economically print with advanced materials including nylon chopped carbon fiber reinforced continuous fiber and metal. This 3d printer uses a continuous carbon fiber reinforcement process to produce end use parts with high strength and versatility.

3d printer manufacturers claim that it can replace metal 3d printing for some applications the main advantage being it is cheaper than metal. This guide covers continuous carbon fiber printers the advantages and limits of 3d printing carbon fiber alternatives and more. The filament is usually less than 05 mm in diameter and may bend when large curves and sharp corners are printed.

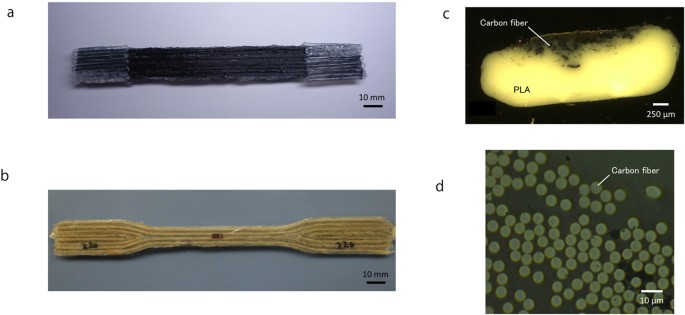

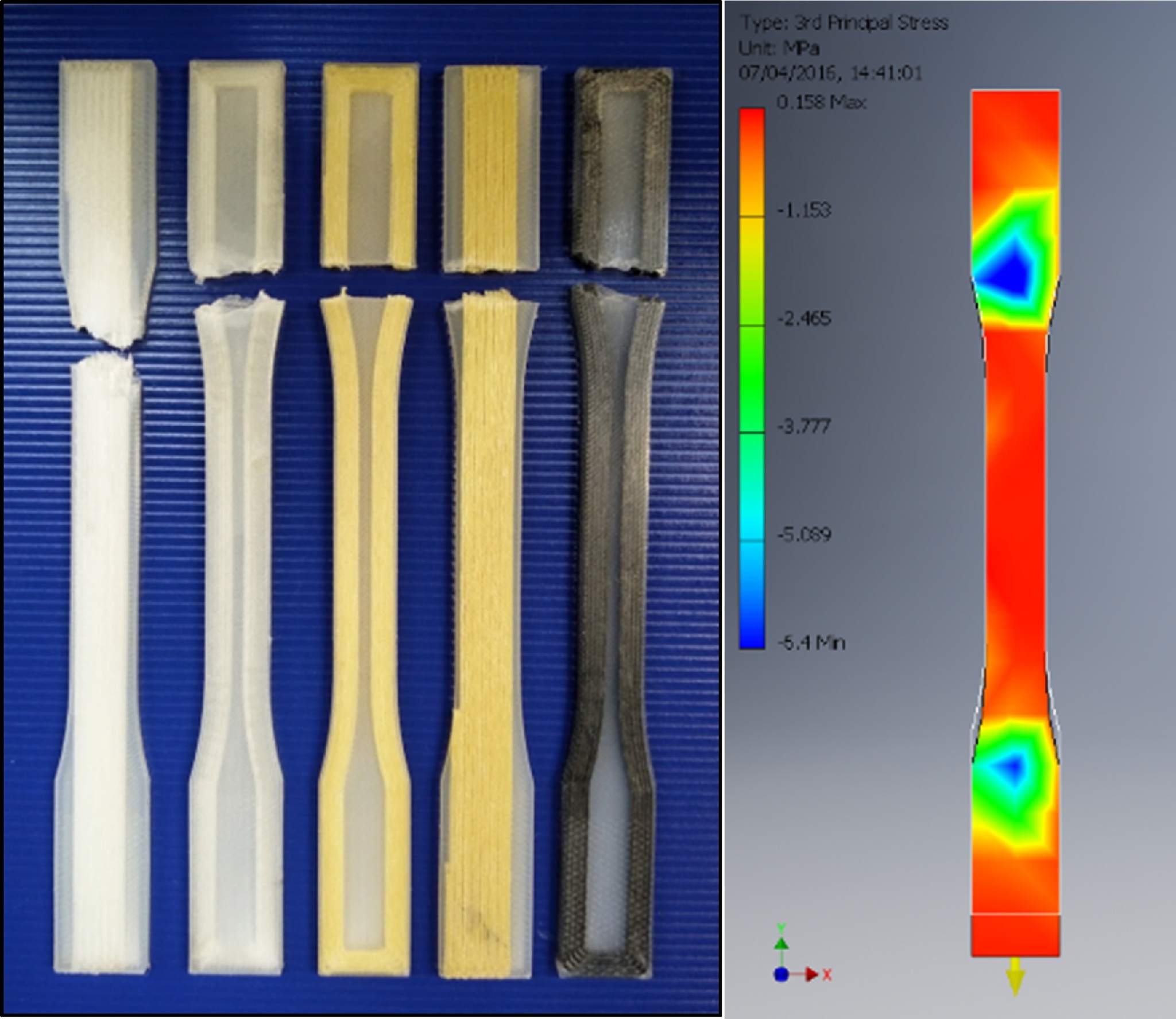

Recycling And Remanufacturing Of 3d Printed Continuous Carbon Fiber Reinforced Pla Composites Sciencedirect

Mechanical Characterization Of Fdm 3d Printing Of Continuous Carbon Fiber Reinforced Pla Composites Sciencedirect