Filament Metal Composite 3d Printer

Being one of the most widely used 3d printing filaments most 3d printing hobbyists and professionals already have a deep understanding of how to get good results with pla.

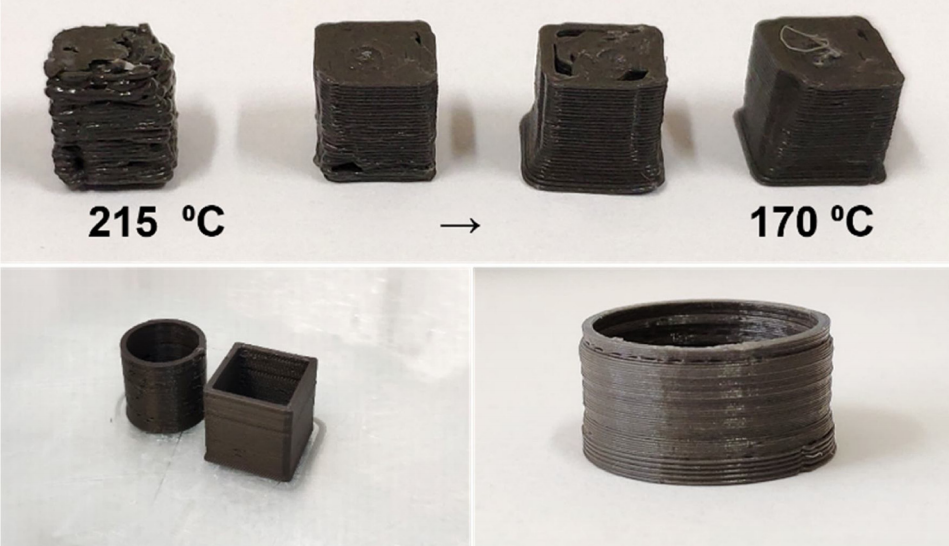

Filament metal composite 3d printer. Sometimes composite filaments dont flow as easily as their un filled counterparts. That just changed you can now print copper and bronze on any 3d printer. Composite filaments are typically more brittle than standard ones in filament form so be careful not to push too hard. This also allows composite filaments to be printed at relatively low temperatures.

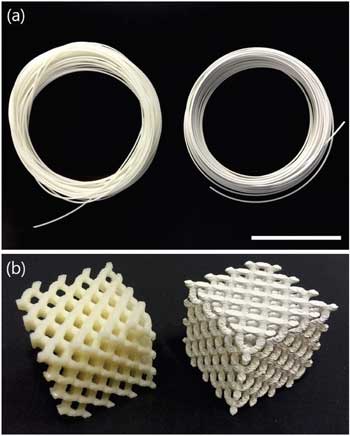

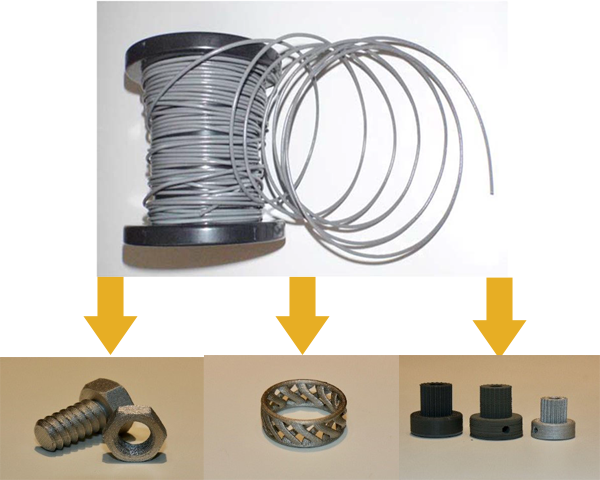

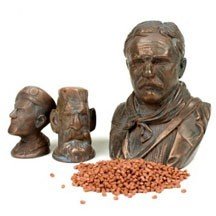

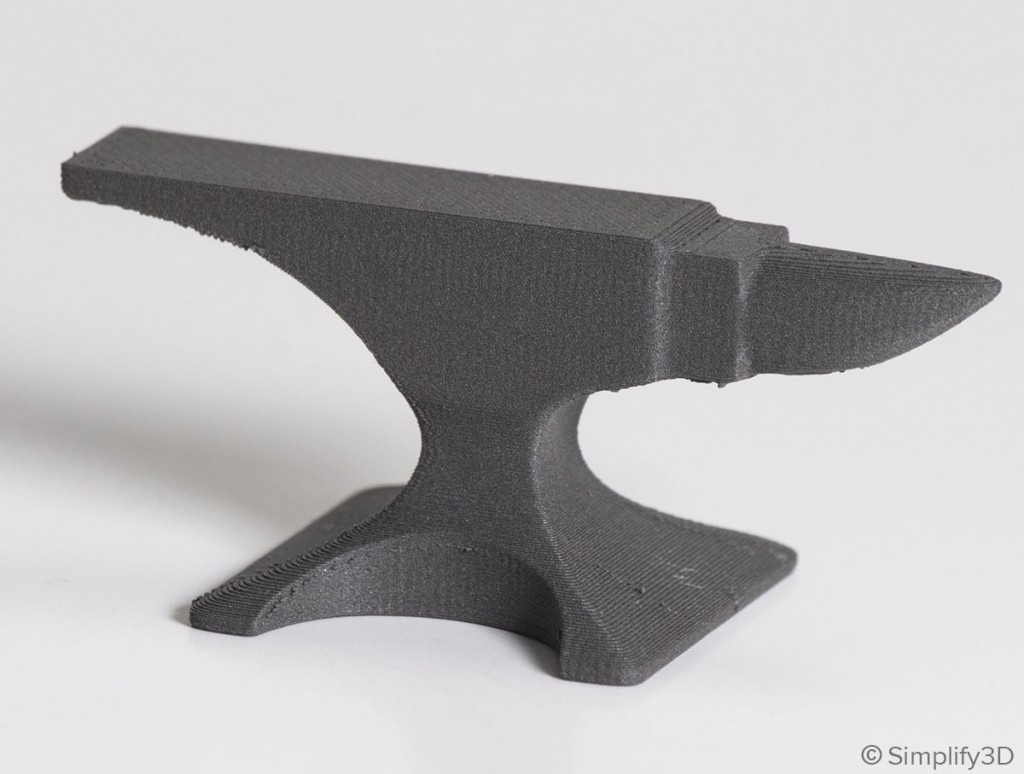

Basf ultrafuse 316l metal 3d printing filament is an industrial material designed for digital fabrication on virtually any desktop 3d printer. Another aspect to consider while upgrading is the nozzle size. Proto pasta offers the following five metal 3d printing filaments. All filaments are made with 70 80 of metal powder by weight approximately 30 40 by volume and can work with almost any fdm printer.

Full metal 3d printing is a well established industry with companies like eos and stratasys leading the way. The dutch company formfutura has a new metal 3d printing filament that they have increased their ratio up to 85 percent metal powder and 15 percent pla for more of a metal feel. The composite material does not possess. If you do plan to try some of these metal 3d printing filaments you may want to upgrade your 3d printer nozzle depending on your 3d printers quality.

We are of course talking about metal printing that can be done at home using your desktop 3d printers and composite metal filaments. When debound and sintered users are left with a 3d printed part made of nearly 100 solid 316 stainless steel. 3d printing with metal composite filaments cost. Copper brass and bronze filled htpla heat treatable pla as well as steel and iron filled composite pla.

You should be able to see the new material coming out and verify flow of the new material. There is a reason metal filled plastics are not used in manufacturing. This new filament from the wisconsin based company could literally be a game changer disrupting the current course of 3d. Check your filament diameter.

Upgrading to a wear resistant nozzle will help reduce the wear significantly. The limitation of full metal 3d printing as you would expect is the prohibitively high costs associated with it. Since metals can be abrasive in general brass nozzles can easily wear out when used with metal filled filaments. Us based proto pasta is one of the early players in the metal 3d printer filament market.