How To Smooth Out 3d Prints

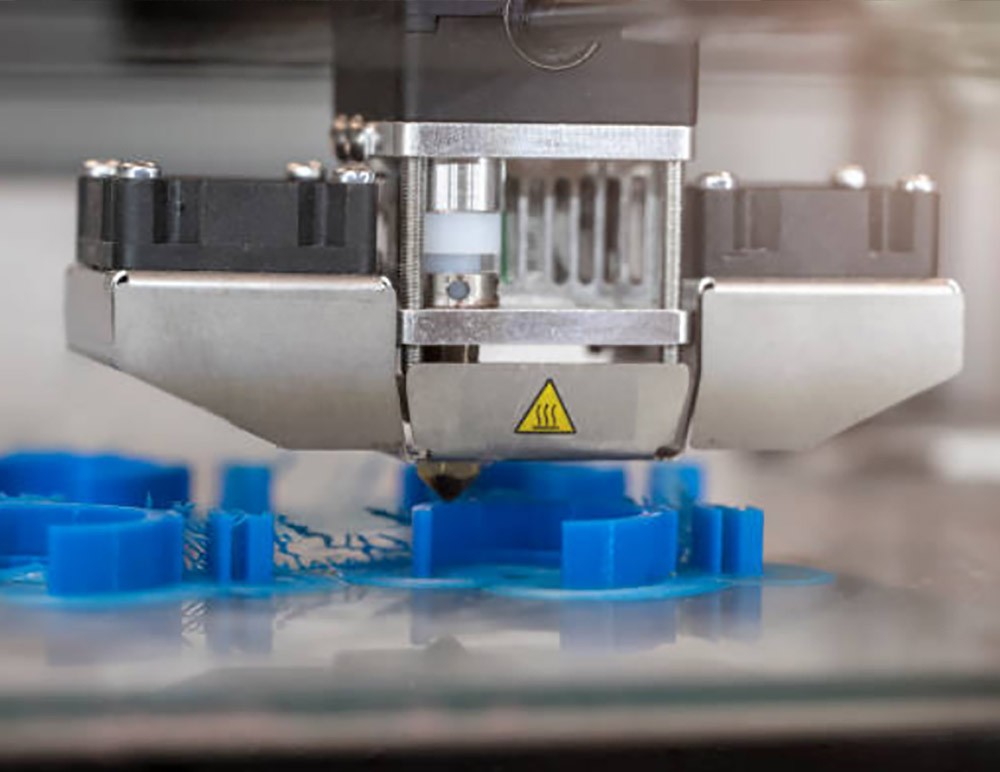

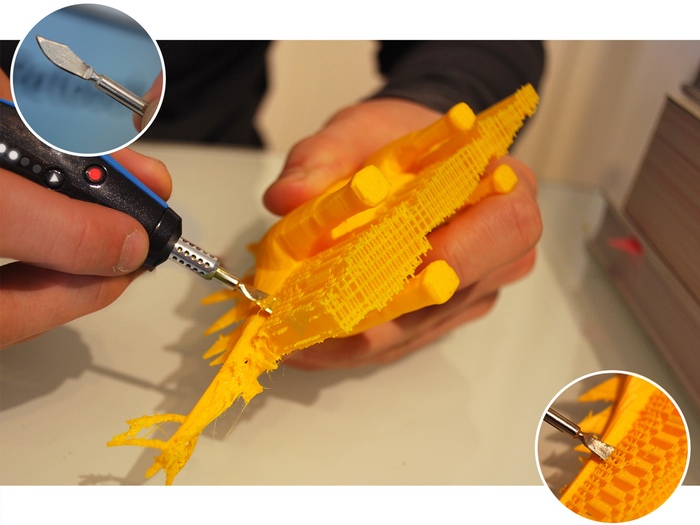

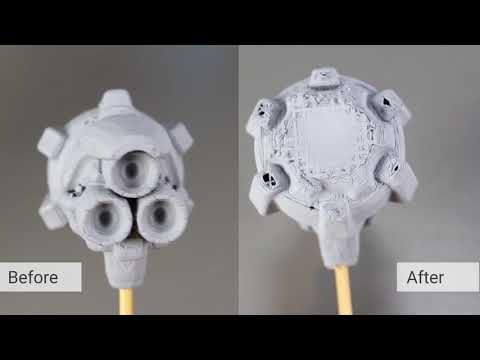

Here an operator holds a nozzle that.

How to smooth out 3d prints. We used a razor blade to scrape excess xtc 3d into the unwanted holes and gaps making sure to avoid any areas we didnt want filled like the letters dim. Once youve finished that the surface should look reasonably shiny. Fill in holes or gaps in your print with a very thin 164 coat. As you sand run your fingers over the print to get a feel for how smooth it is.

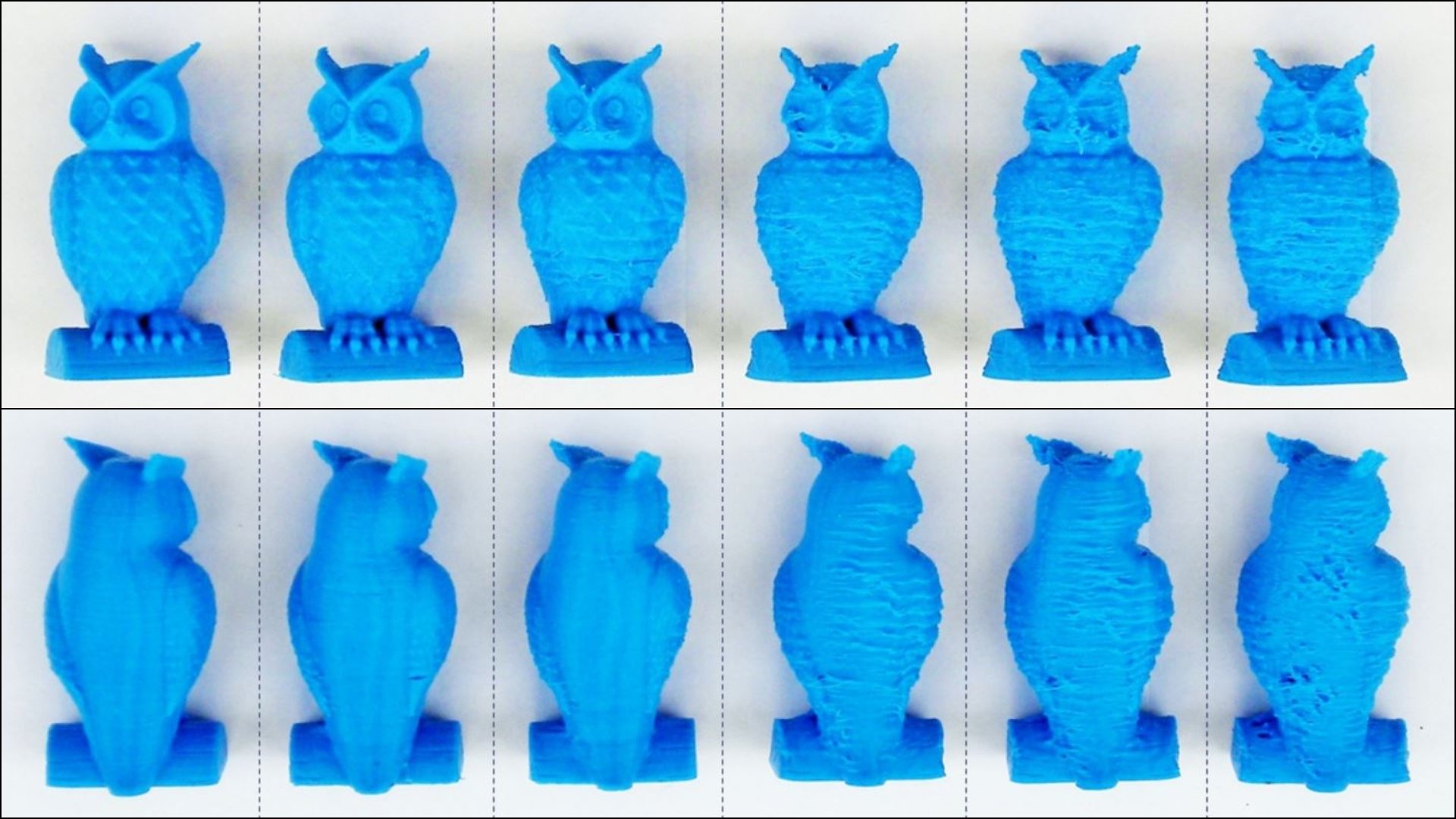

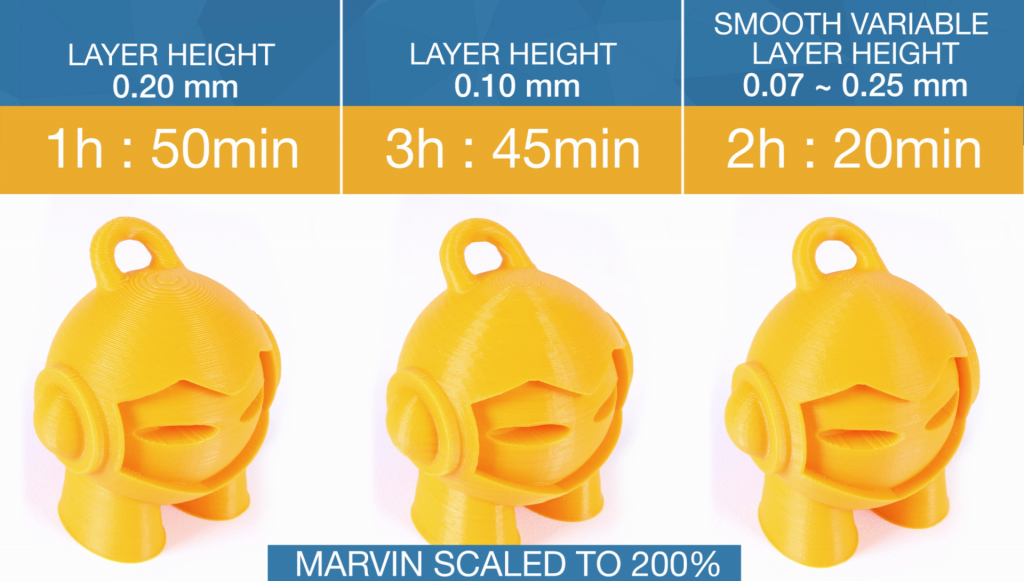

Next carefully place the coated 3d print under a fan to make it dry faster and prevent dripping. Here is what the 3d print looks like after two matte gray coats of paint or two gloss gray coats. When you think its pretty smooth youre ready for paint. Even the best fdm 3d printer produces layer lines.

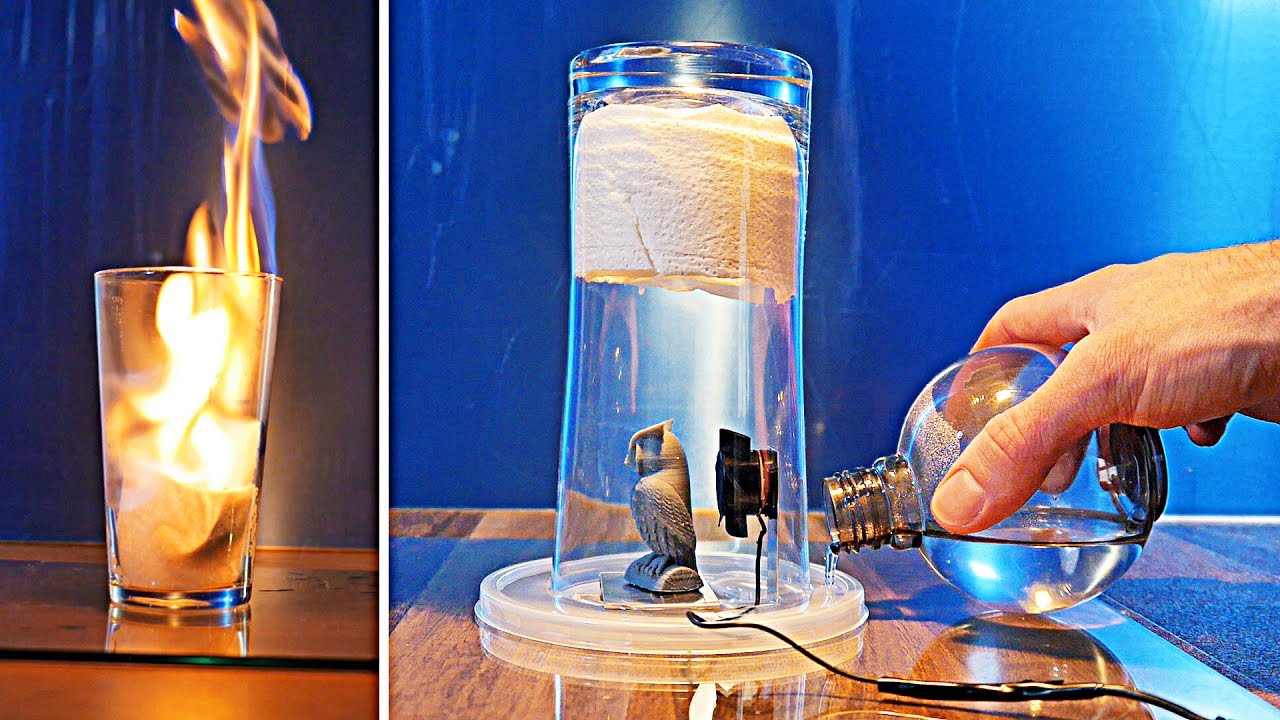

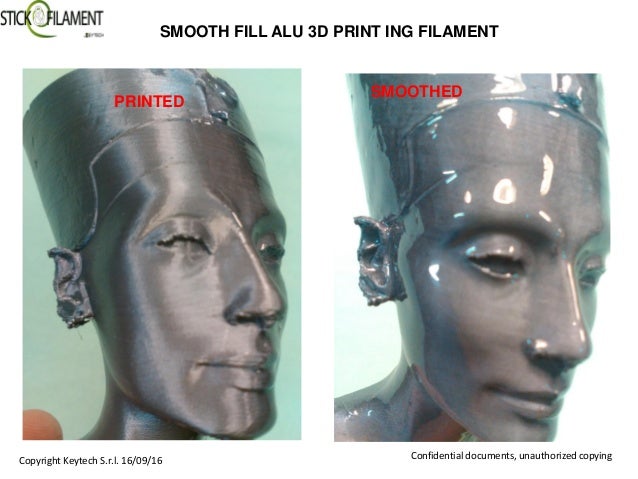

This is simply due to the way the printer works building layer by layer on top of each other. The final stage is to buff up the surface into that mirrored polished shine. The second most commonly used finishing process is bead blasting. Fused deposition modeling fdm may be the easiest and cheapest way to get into 3d printing but it is not without its limitations.

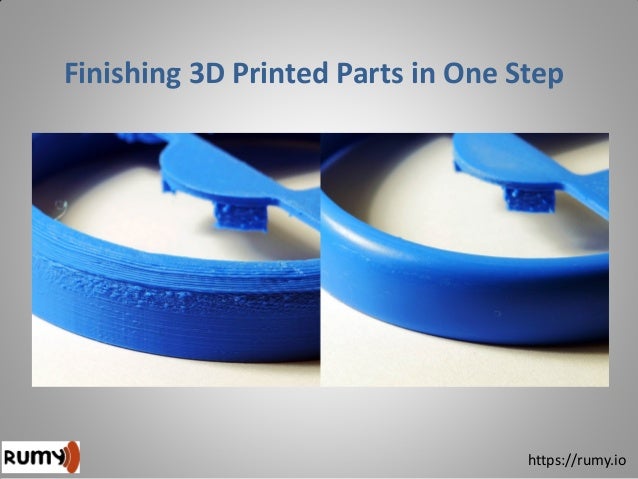

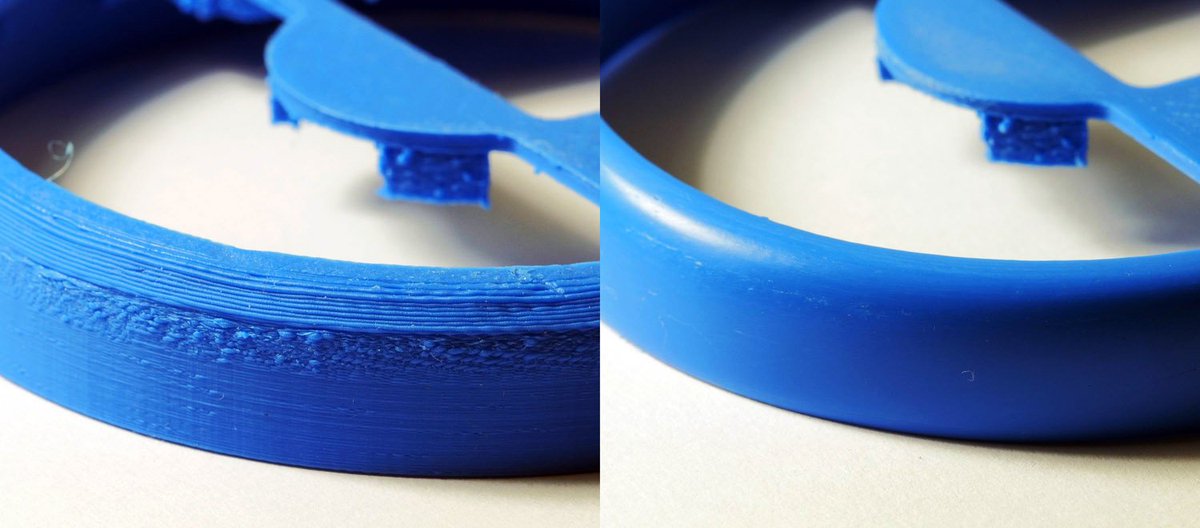

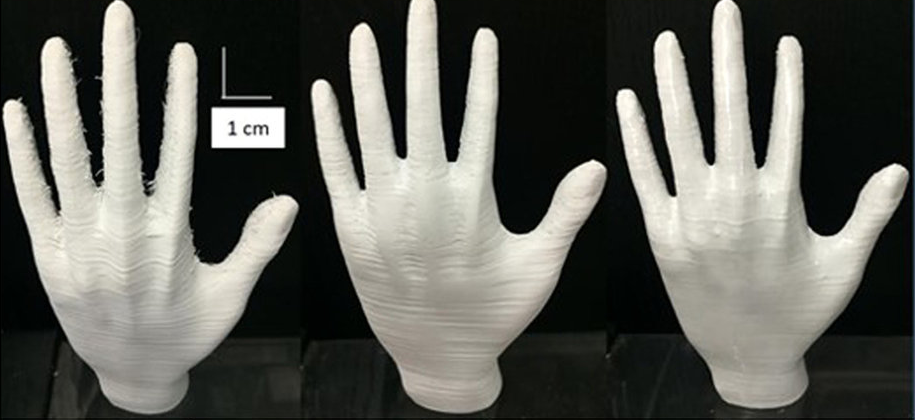

You can see how nice and smooth the pieces can turn out. We all want the end result to be smooth and polished but the surface finish of even the nicest prints are covered in tiny ridges. Though fdm systems are engineered to produce high quality parts right off the machine the layer lines can be. How to smooth 3d printed parts sanding.

Taking the spray paint of your choice coat the 3d print with a layer of paint quickly followed by a layer of the polyurethane. A thin layer of xtc 3d will level itself out. Finishing your 3d prints are just as important as actually printing them out carefully. Check our guide to smoothing 3d prints to learn three methods of pla smoothing for a professional finish.

I cant stress enough how important it is to spray in thin layers. The water helps keep the paper from clogging and gets a much finer finish than dry sanding with the same grit. Get a soft cotton cloth and apply a small amount of liquid polish. The horn was printed with a layer height of 015 mm.

Especially if you mask areas you can use the masking tape to hold the 3d print as shown in the picture on the right. In this video ill be showing you how to treat 3d printed parts with an acetone vapor bath to make make impressive looking injection mold quality prints.

.jpg)