Injection Molding Vs 3d Printing

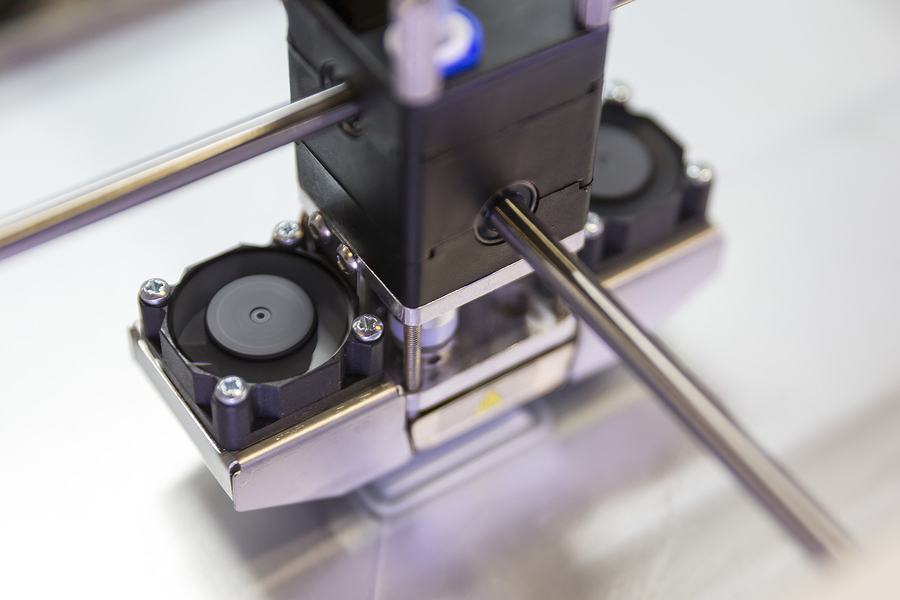

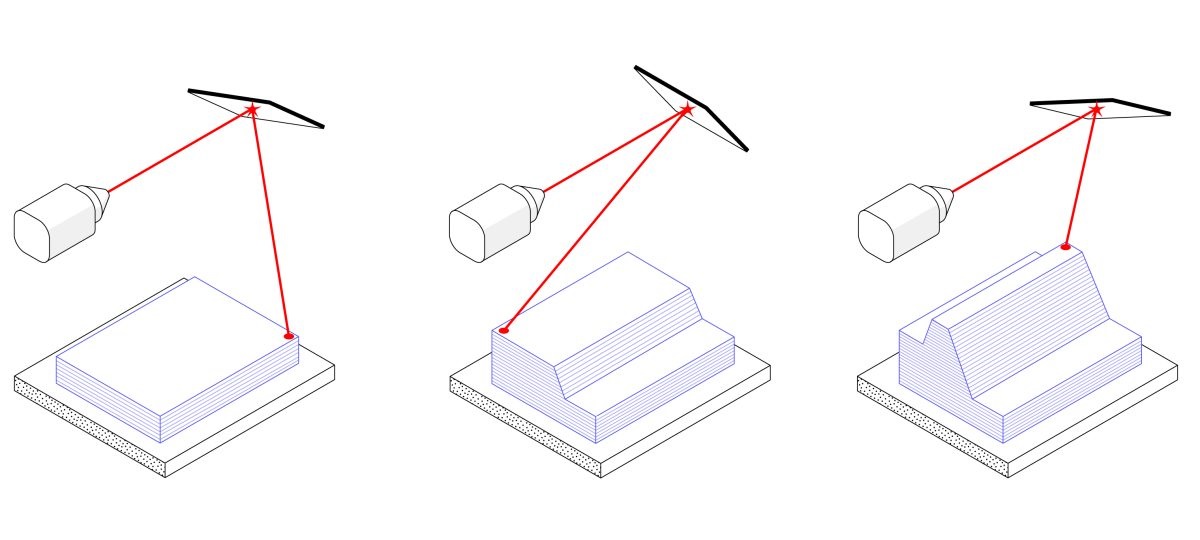

It is taking raw material and printing it layer upon layer until the finished part or component is created.

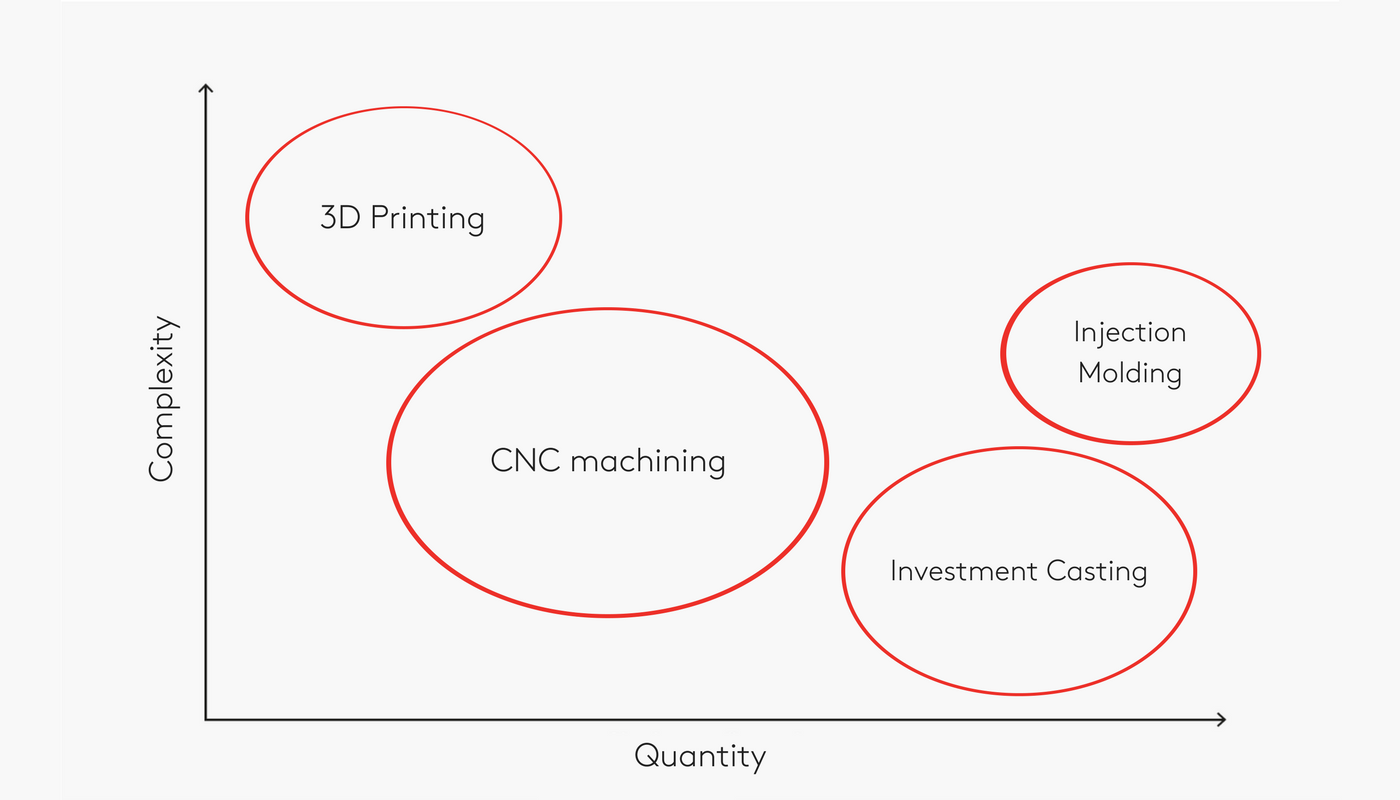

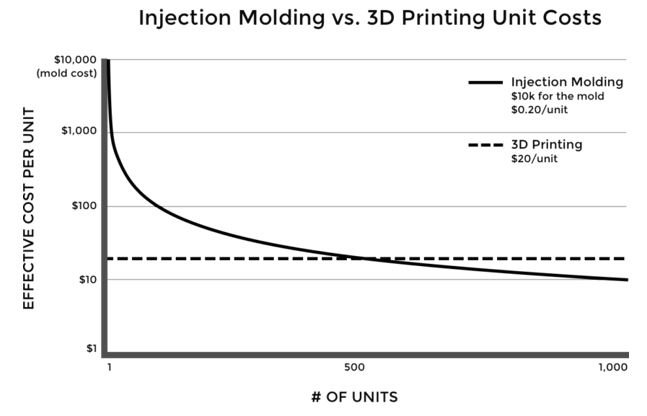

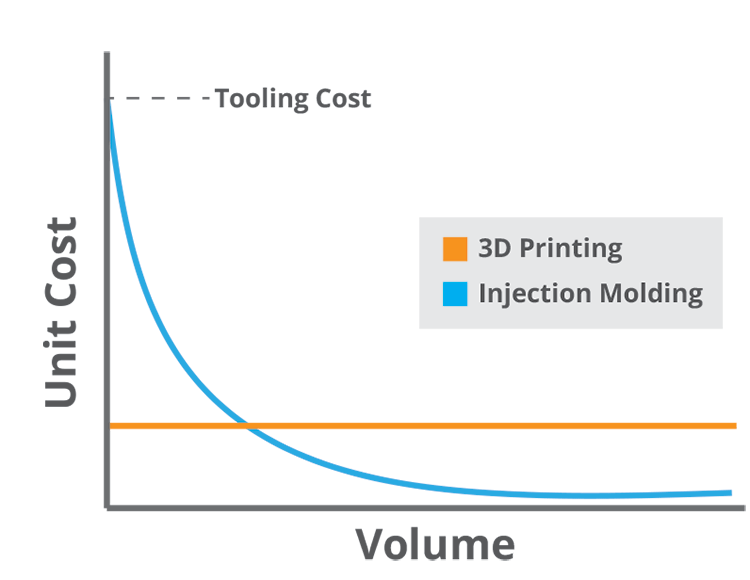

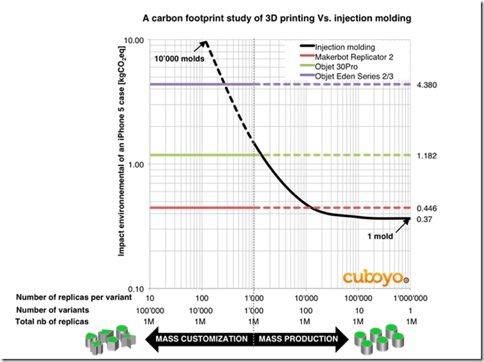

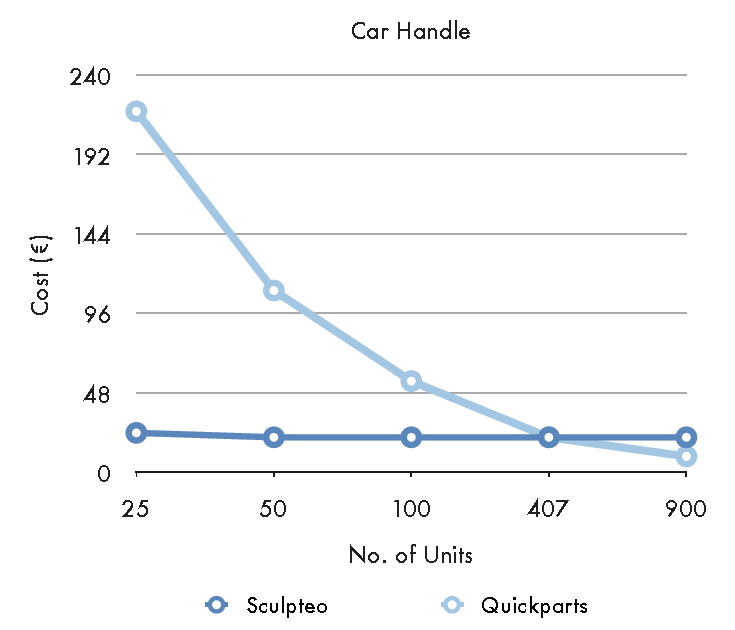

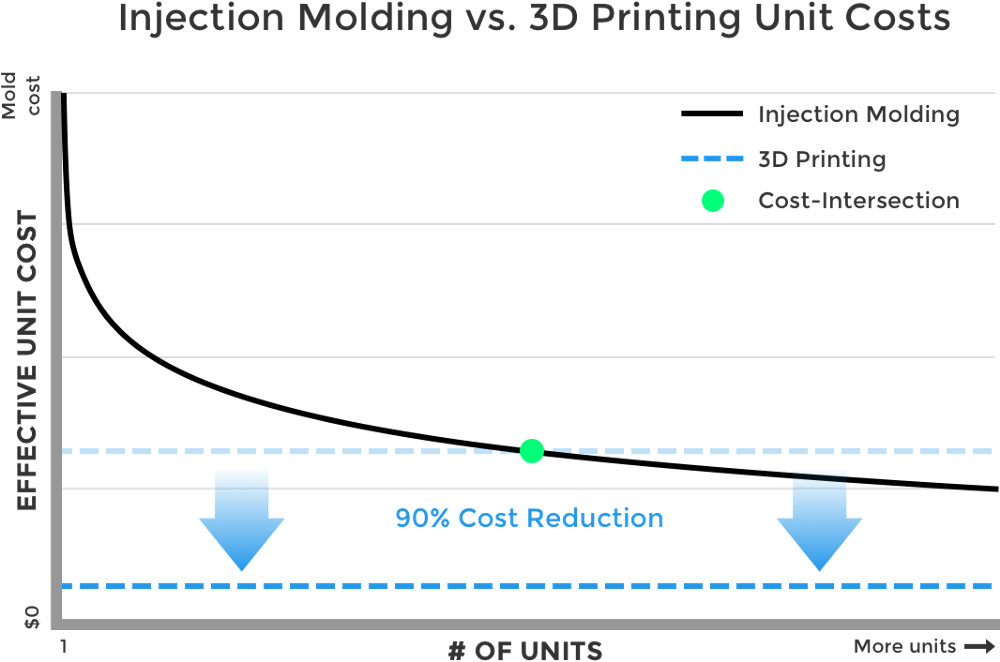

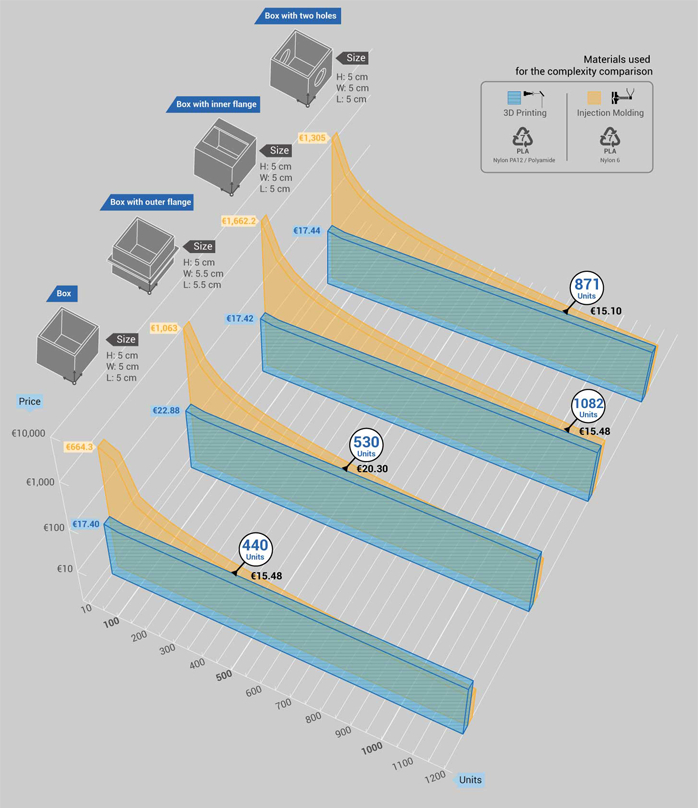

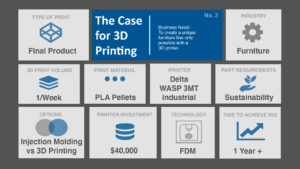

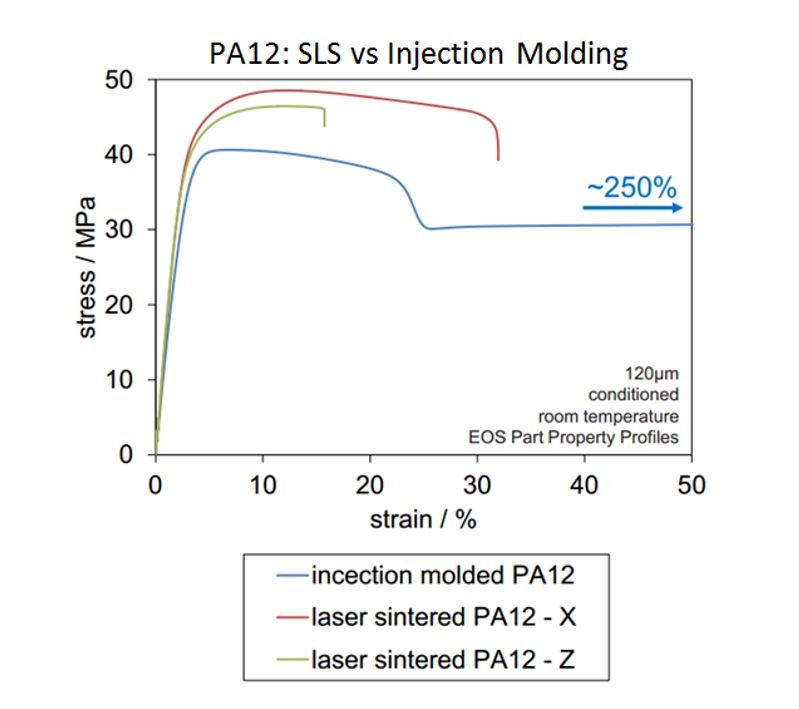

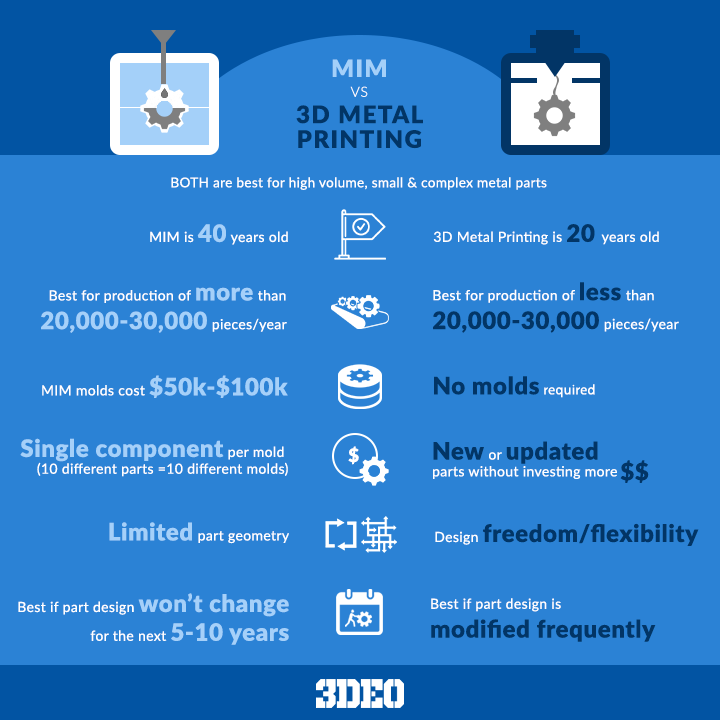

Injection molding vs 3d printing. For example a business may use sls for rapid prototyping and low volume production and then switch to injection molding once the volume of parts is above a certain threshold. The main differences between 3d printing vs injection molding are. Unlike injection molding 3d printing does not require any tooling or additional setup costs. With modern advances it has become an excellent option for many full scale manufacturing projects as well.

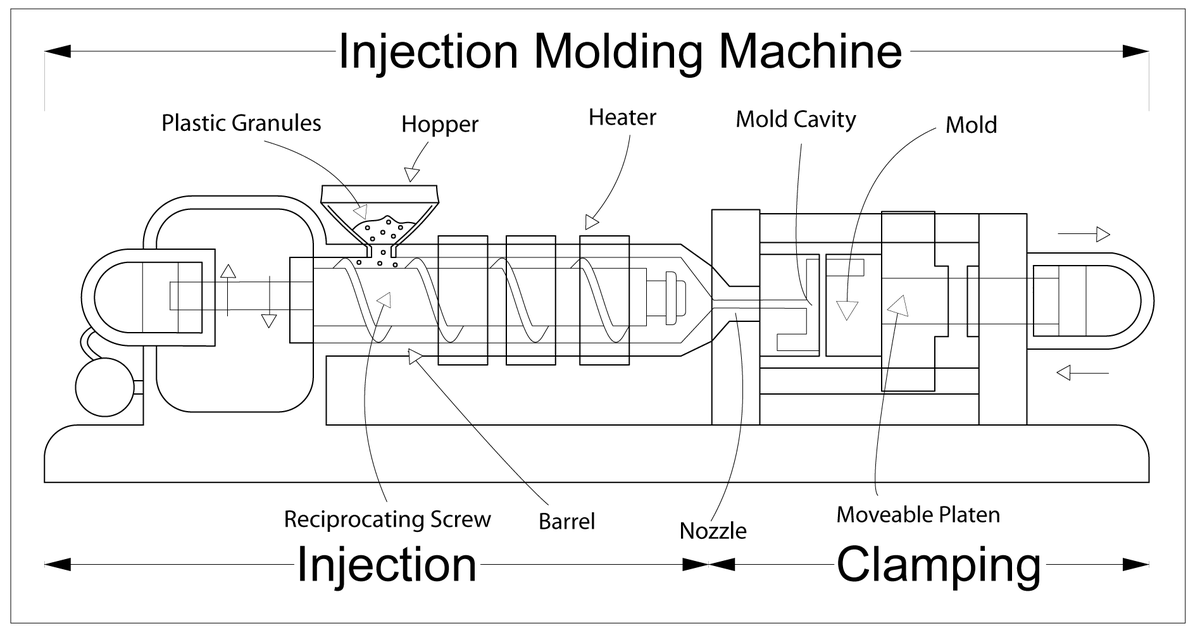

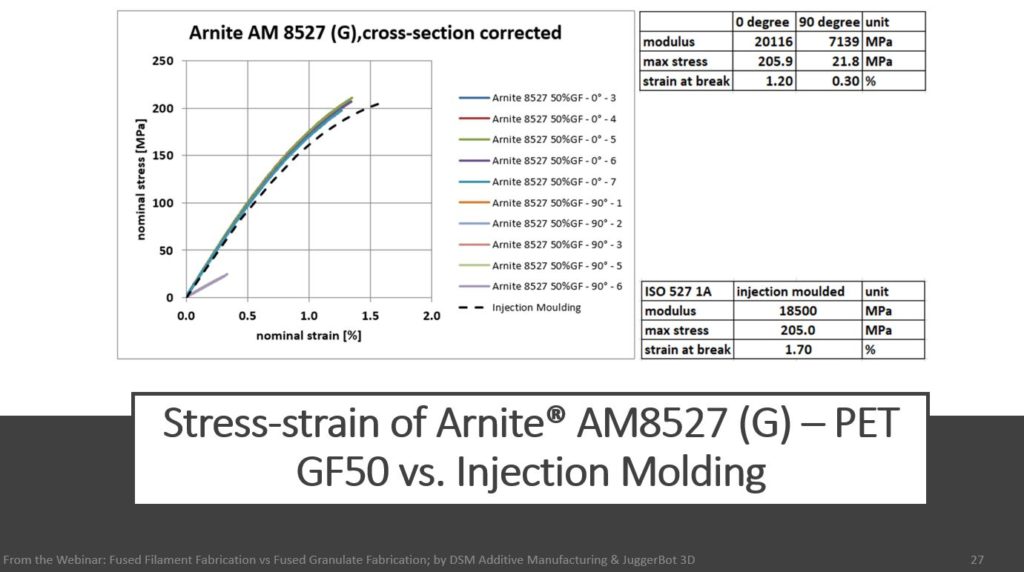

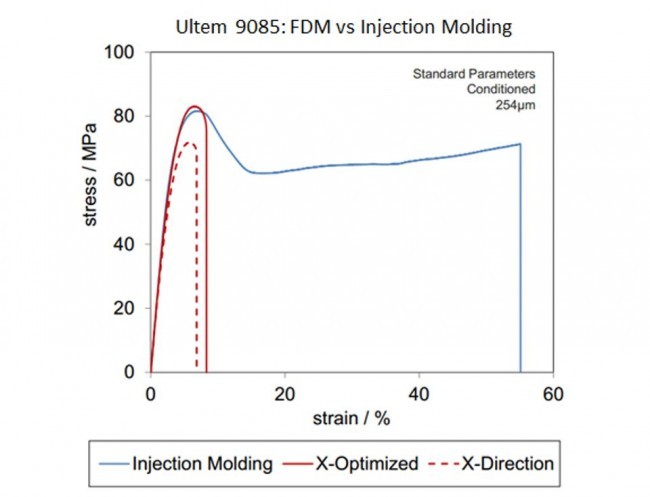

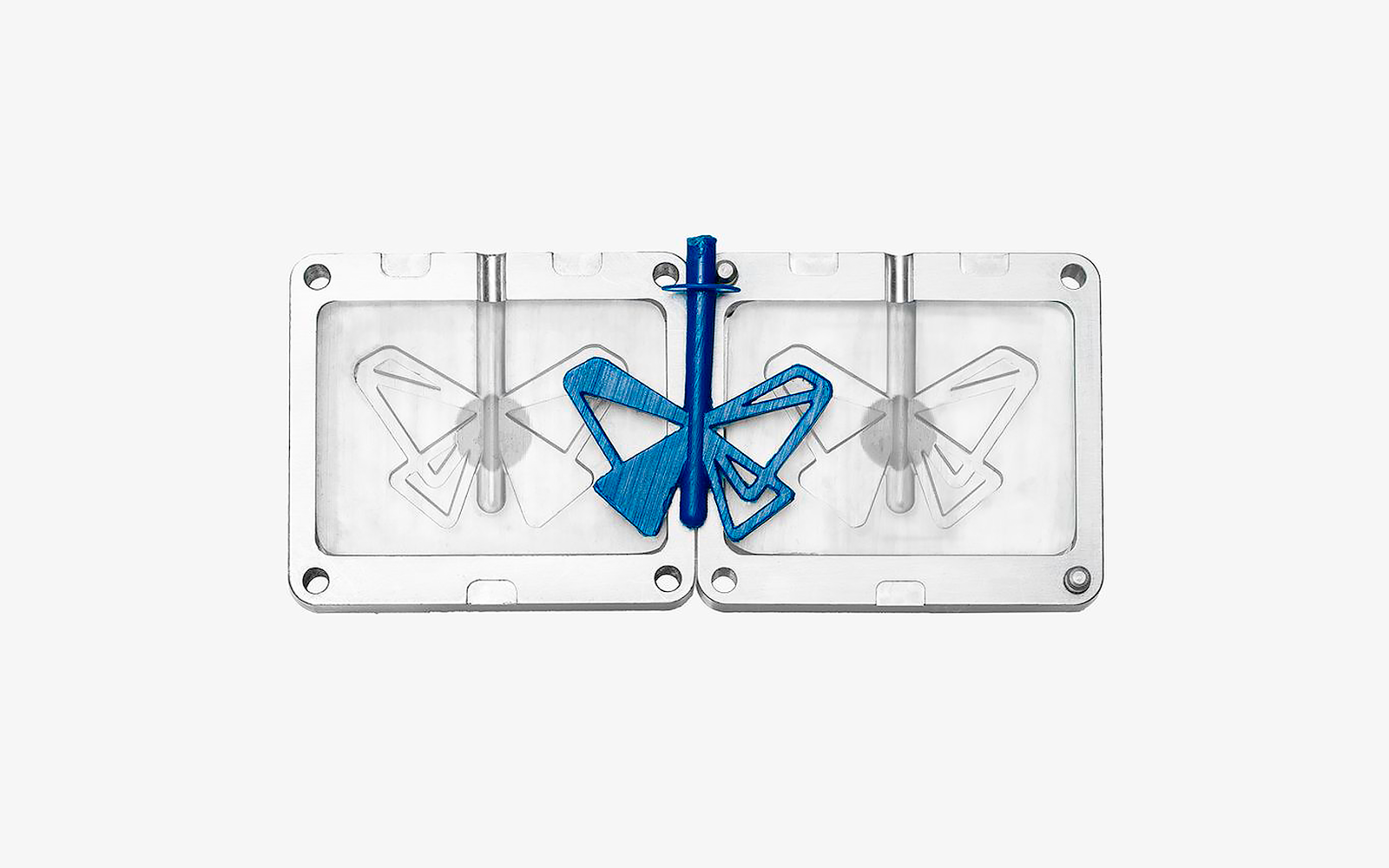

Both can theoretically be used for manufacturing and both can technically be used for rapid prototype generation. Although the trend for additive manufacturing processes different types of 3d printing is growing most serious manufacturing is done with injection molding equipment while in most cases the 3d printer is a much more effective tool for rapid prototype development. 3d printing works differently than injection molding. 3d printing is smaller whereas injection molding machines are quieter and faster.

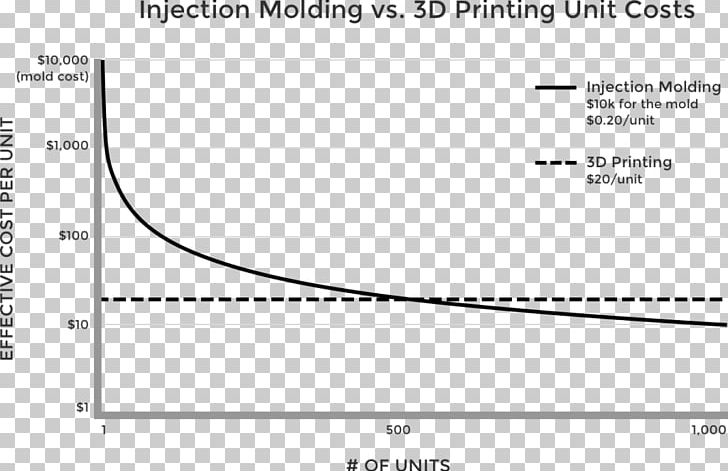

Even if injection molding always seems more professional some things now start to change and 3d printing is becoming a real alternative allowing to create really accurate parts. The dimensions shapes and other physical qualities are loaded into a 3d printing machine through computer aided drafting cad drawing or other files. This is because 3d printing becomes exponentially more expensive as volume increases. 3d printing some might wonder why we cant just 3d print a bunch of plastic parts for a client instead of investing in an injection mold.

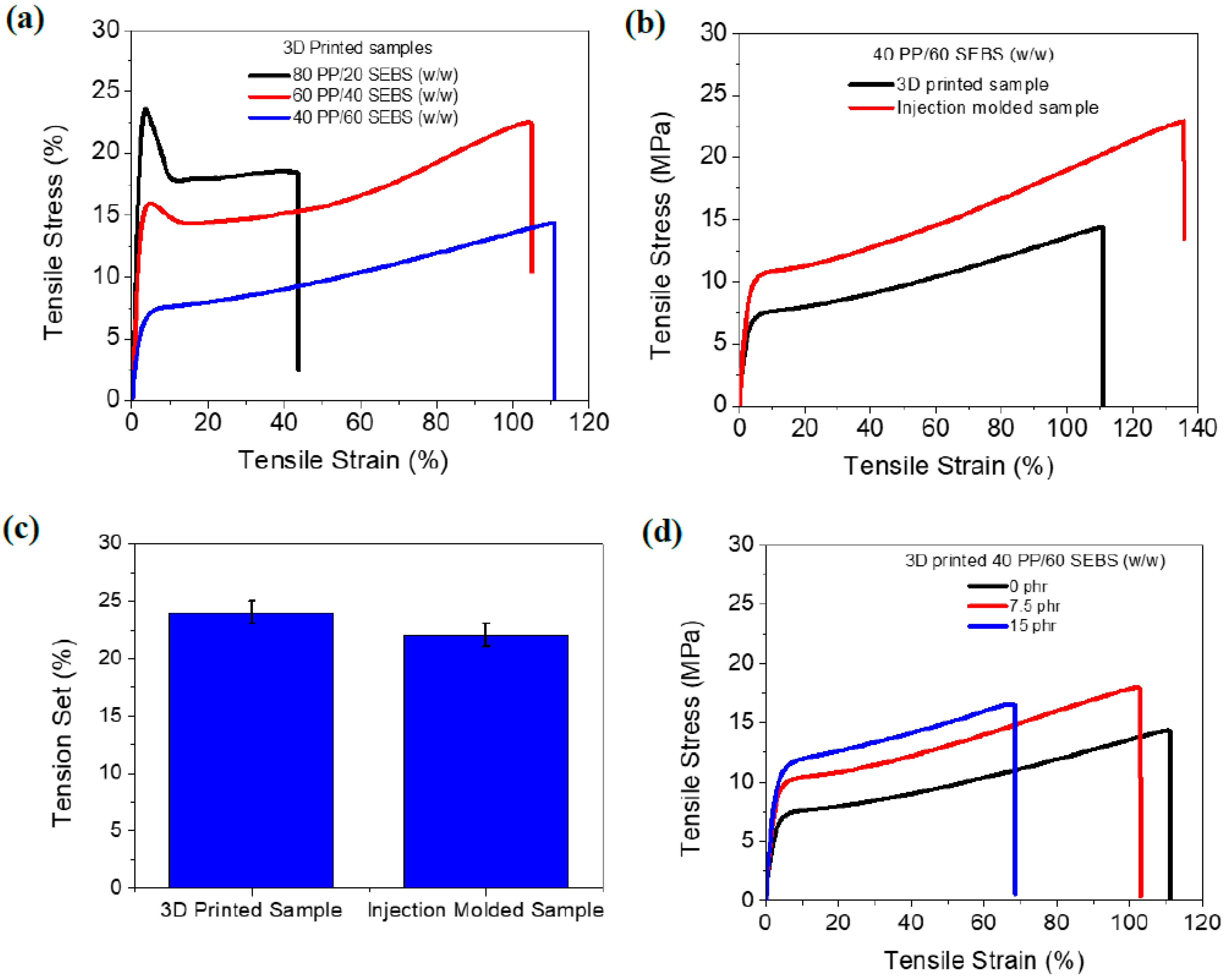

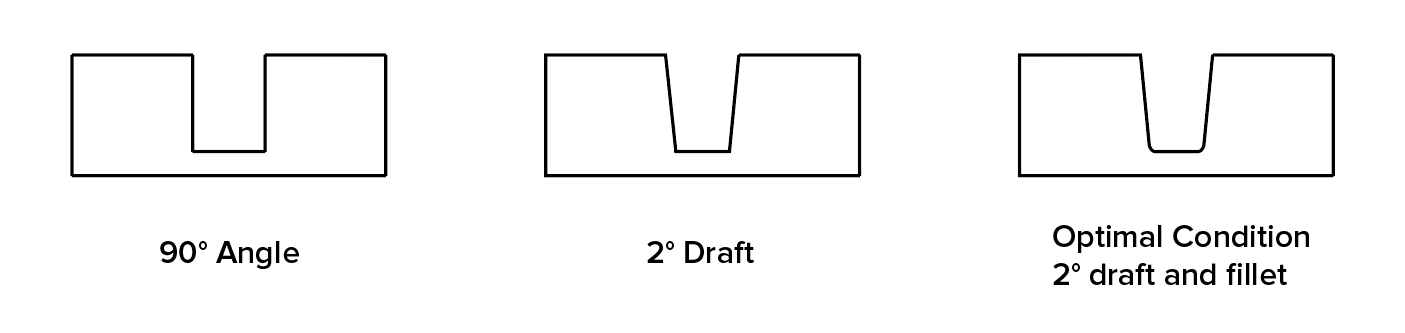

Rather than a preformed mold to shape your part the products dimensions shape and other physical qualities are loaded into a 3d printing machine via cad drawing or other compatible file. Unlike injection molding where liquid plastic is injected into a mold 3d printing heats the material up just enough so that each layer bonds together. 3d printing and injection molding are not competing but rather complementary ways of manufacturing. The 3d printing process works very differently from injection molding.

Even though it has its limits for each pieces size injection molding can work on a bigger scale because of the industrial. 3d printingand injection moldingarent really competing technologies so much as they are complementary. 3d printing allows you to make changes at any stage of the production process whereas with injection molding you cant make changes during the producing process. 3d printing is an additive manufacturing process.

Plastic injection molding can produce bigger parts than 3d printing. 3d printing is more expensive whereas injection molding is a cheaper variant for bigger produce. These two techniques can help you with both your rapid prototyping process and your production.