Metal 3d Printed Jet Engine

There are even some instructables eg.

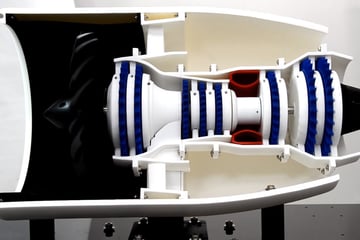

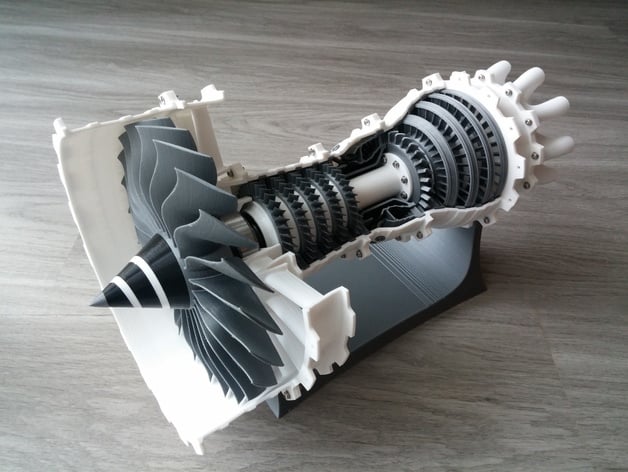

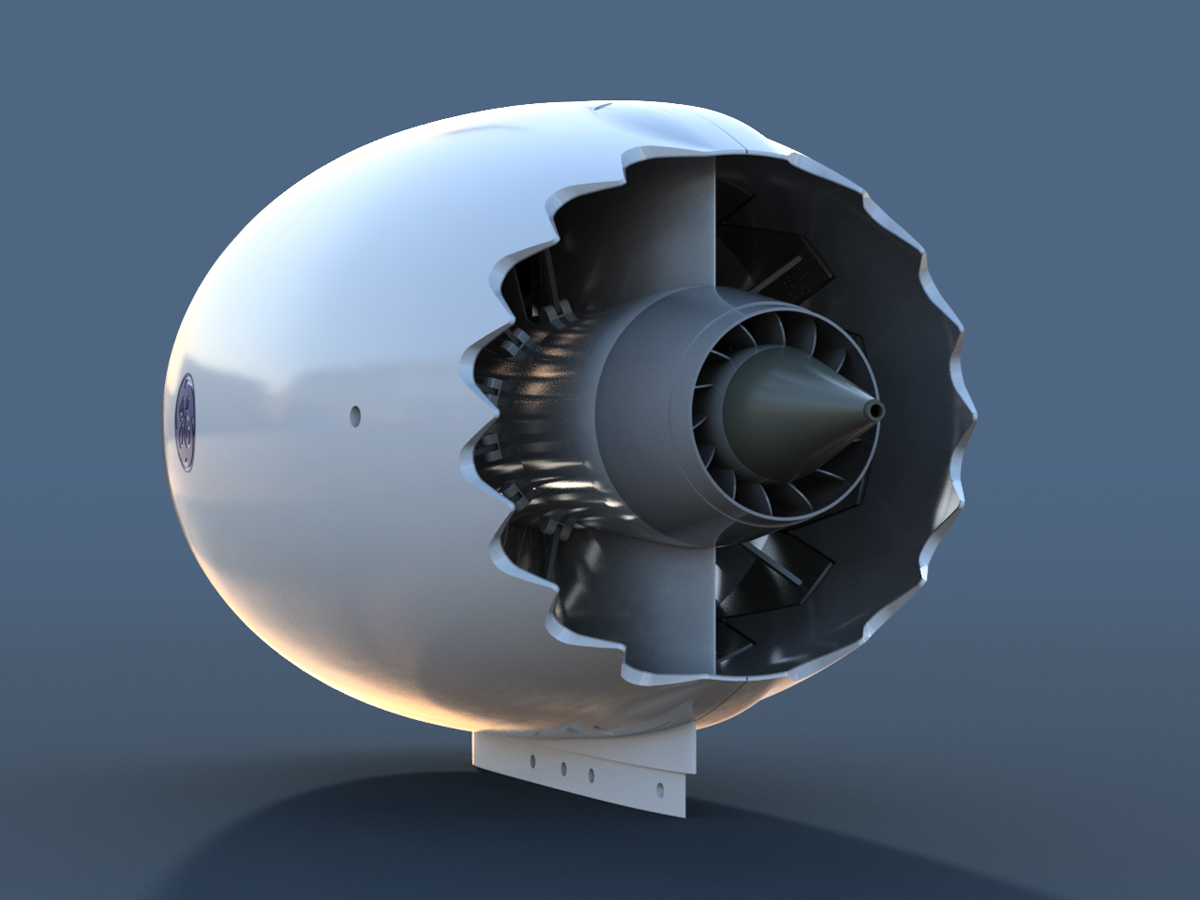

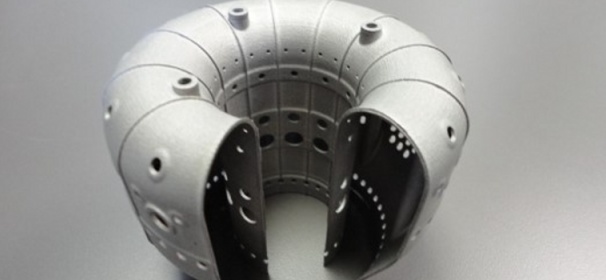

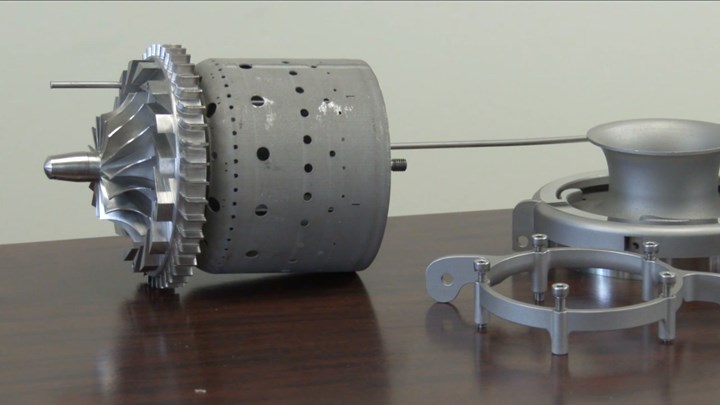

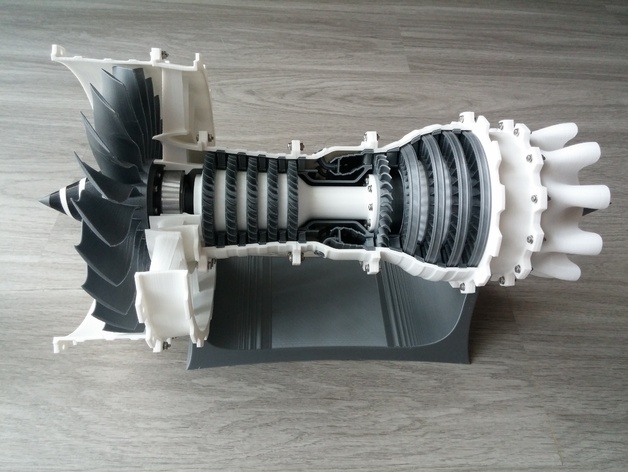

Metal 3d printed jet engine. Air force 3d printed the first metal jet engine part using additive manufacturing technology. These are big blades says giorgio abrate general manager for engineering at avio aero. A model of a 2 spool high bypass turbofan. Homemade tin can turbine with 3d printed compressor.

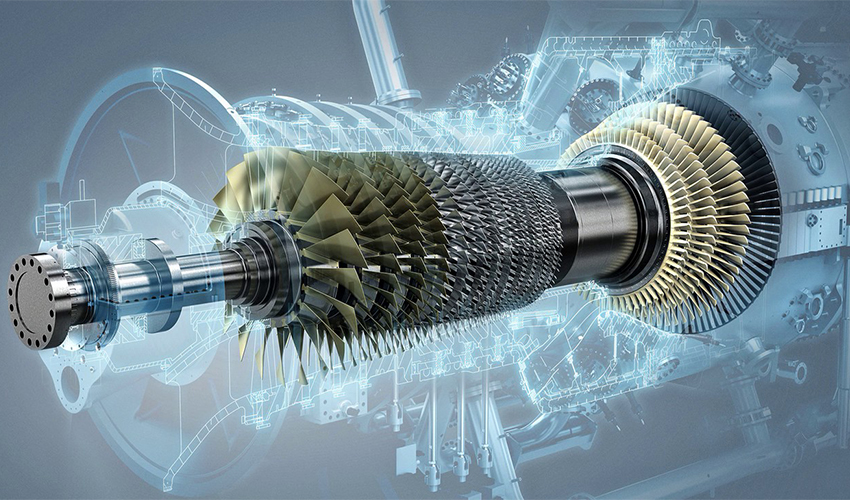

The 3d printed blades spin inside the engine at 2500 times per minute and face searing heat and titanic forces. The nozzles which spray fuel inside the combustion chamber replaced conventional nozzles that had more than a dozen. I designed the whole engine from scratch with visual cues to certain existing engines. As a senior engineer for additive design at ge aviations additive technology center atc in cincinnati in 2016 he helped bring to mass production a 3d printed fuel nozzle that efficiently sprays fuel inside the leap jet engine.

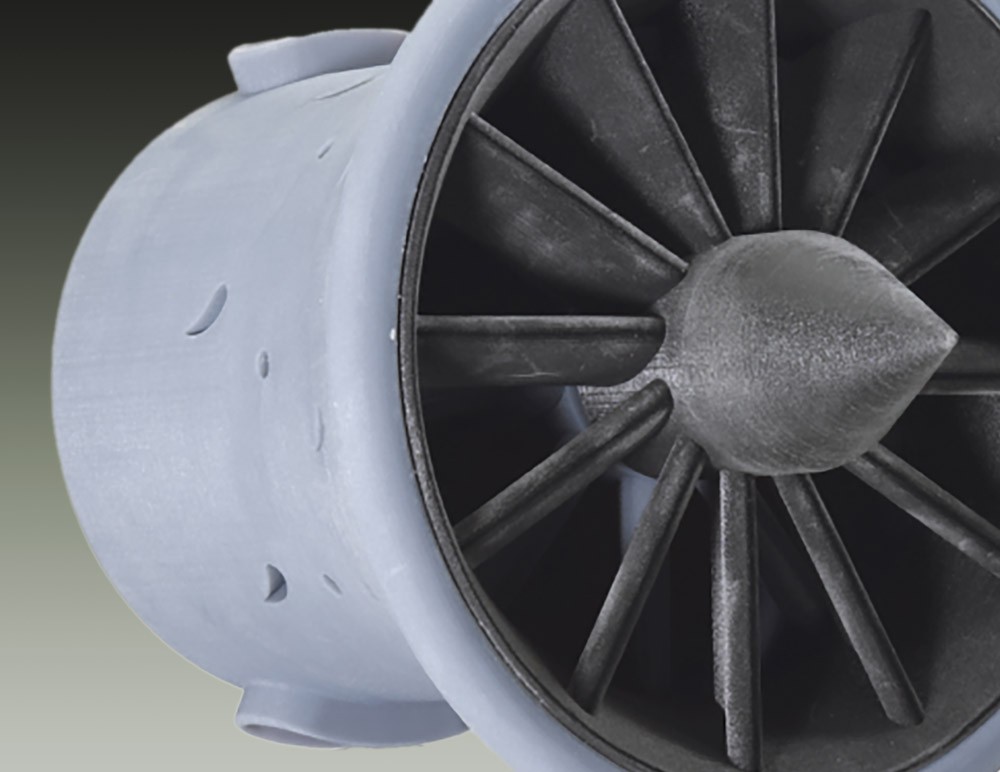

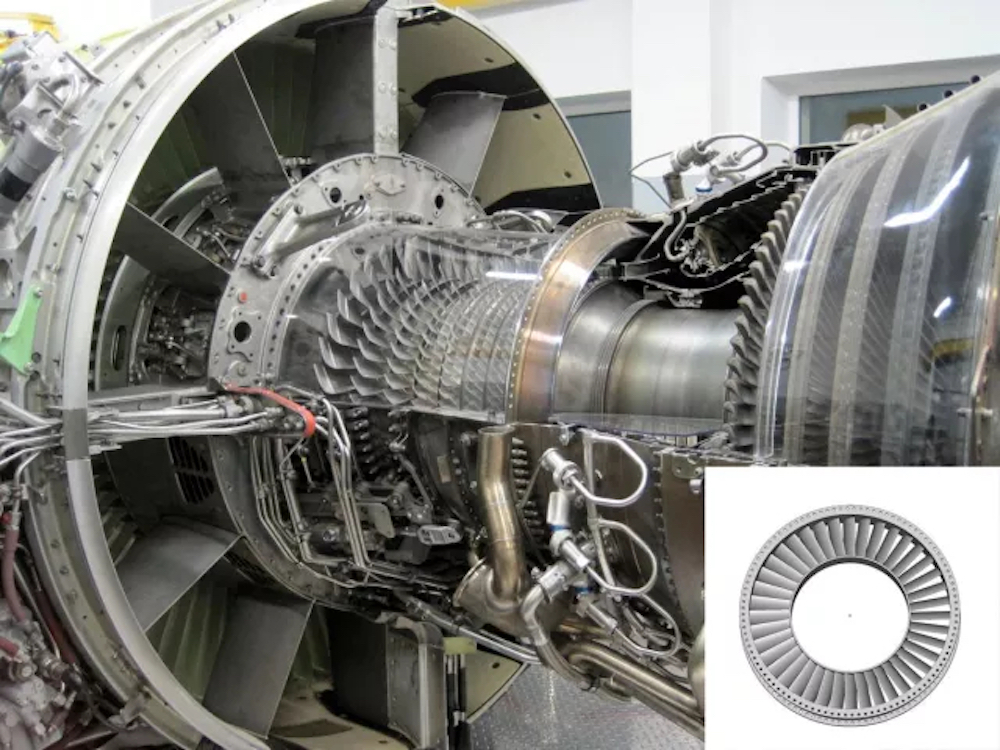

In this instructable we will learn how to make a really working gas turbine engine at home. Each engine has 16 carbon fiber fan blades and 19 3d printed fuel nozzles. I included these supports in the parts as needed and they. Air force aircraft engine a significant milestone for future sustainment efforts of aircraft like the e 3 airborne warning and control system e 8 joint surveillance target attack radar system and the b 52 stratofortress.

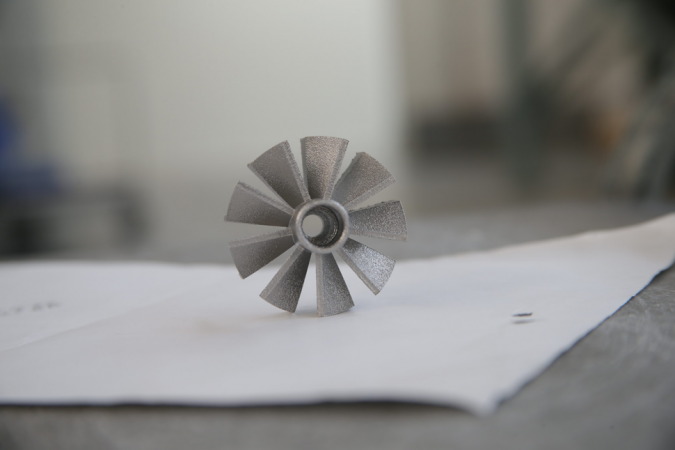

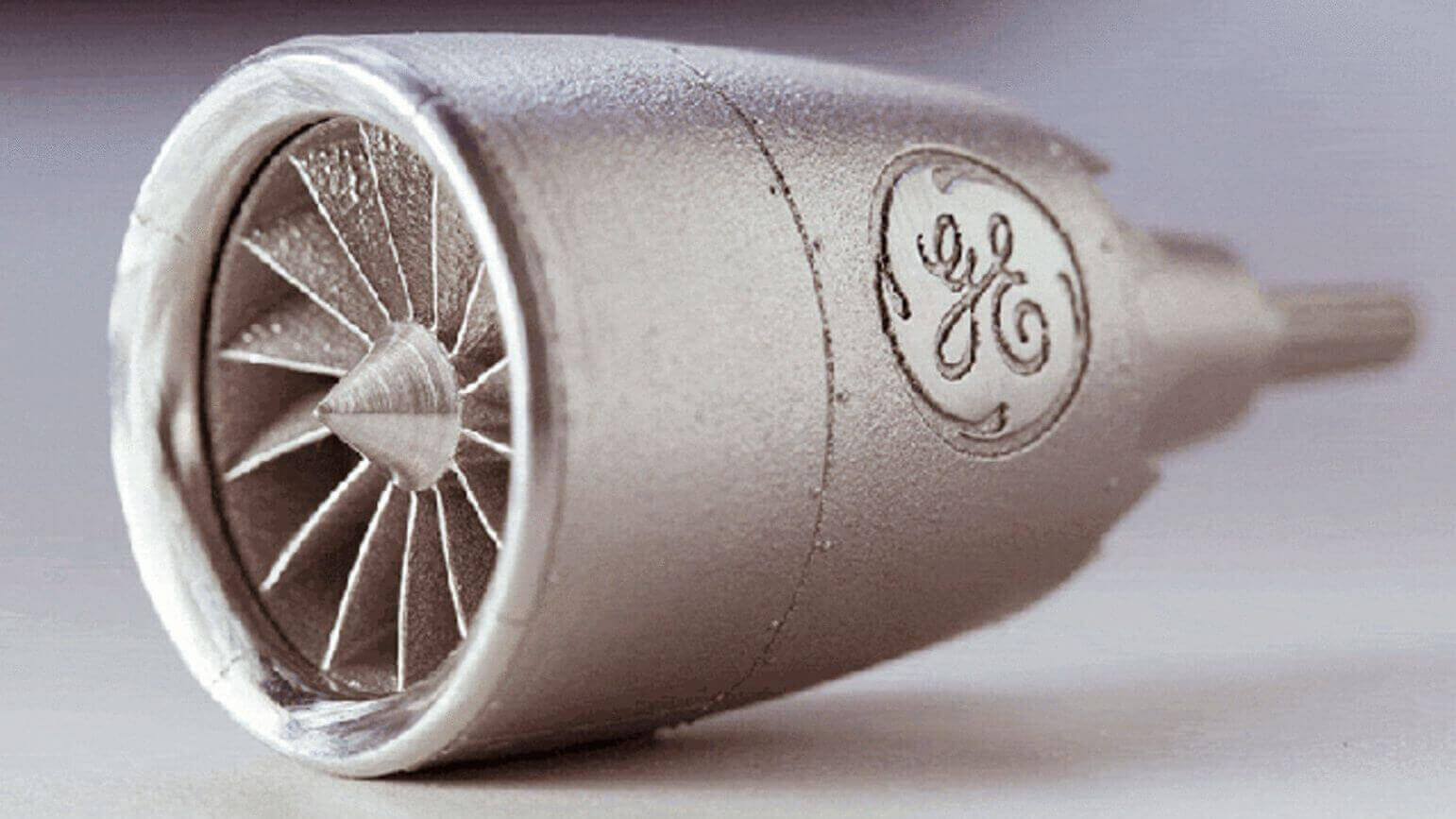

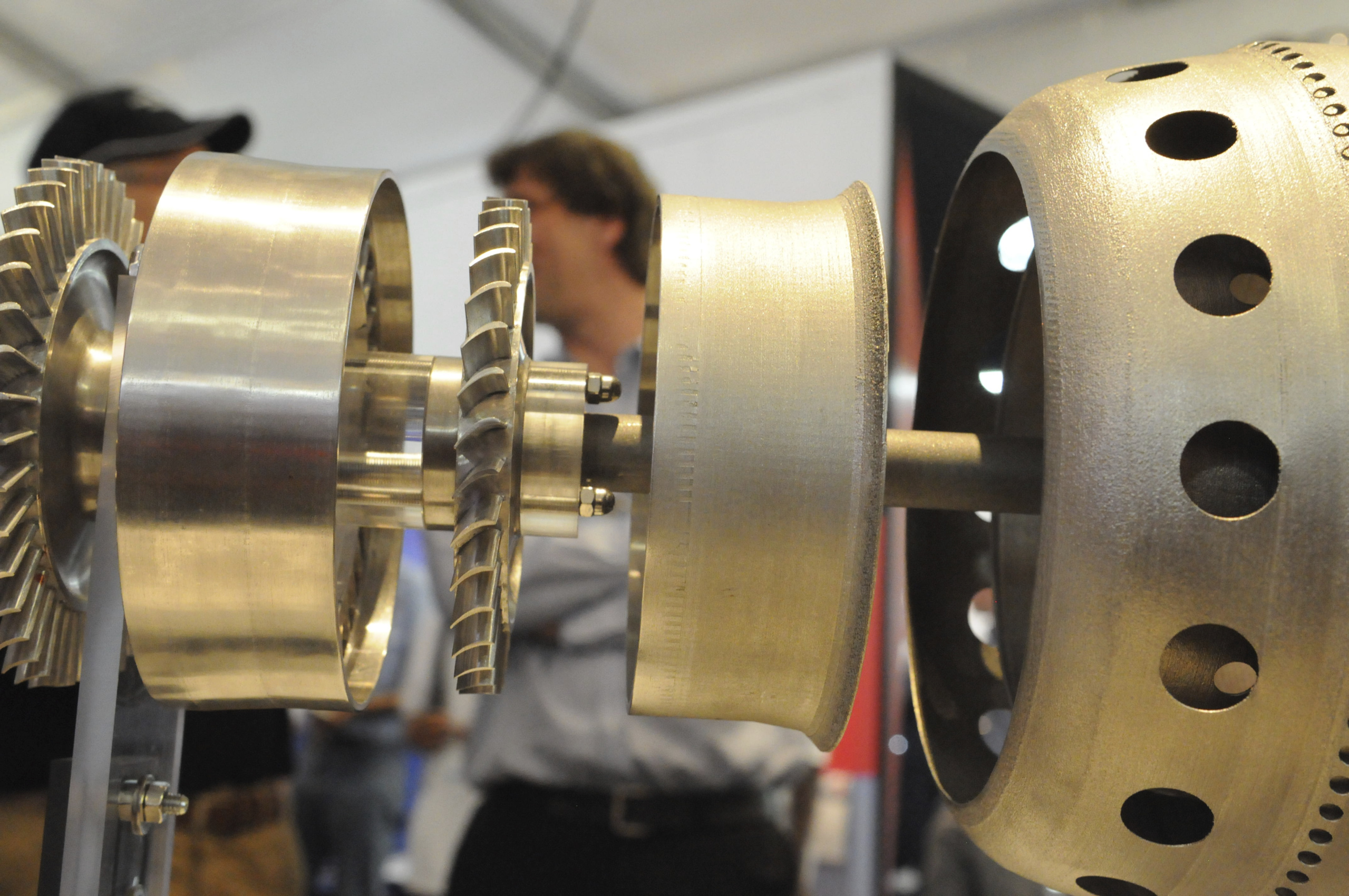

There are many tries to make a homemade gas turbine described over the net. By the way this model was featured on solidsmack. Tinker afb units produce first 3d printed engine component. The size of a walnut this wickedly complex metal part was previously made from 20 components.

Photo courtesy of oklahoma city air logistics. Monash university 3d prints two entire metal jet engines february 25 2015 by whitney hipolite 3d design 3d printing its only a matter of time before we begin seeing just about every man made. For example i think rolls royce makes the best looking fans so theres some resemblance there. A more detailed and narrated version is in the.

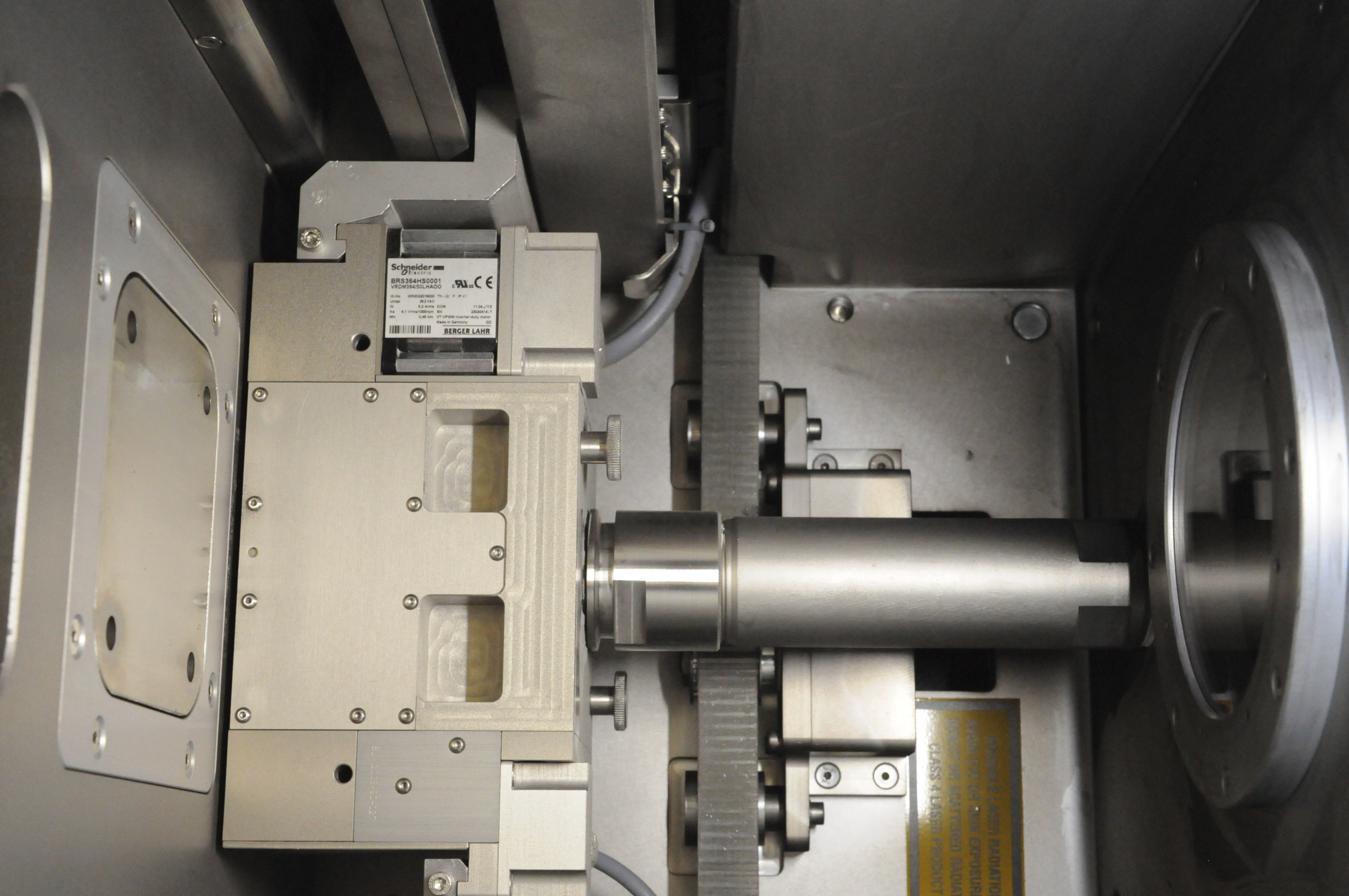

The service cant wait to print parts that are expensive or no longer made by manufacturers. Ge aviation acquired avio aero in 2013 and developed the ge9x engine for boeings next generation 777x jets. Members of the oklahoma city air logistics complex have produced the first additively manufactured metal jet engine part successfully installed and tested on a us.

:format(jpeg)/cdn.vox-cdn.com/assets/2625419/CFM56-leap-engine-press.jpg)