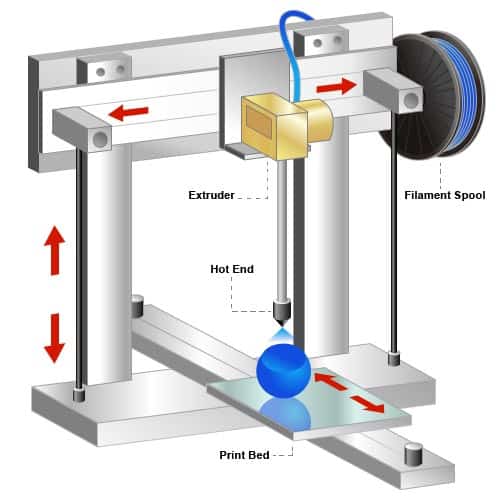

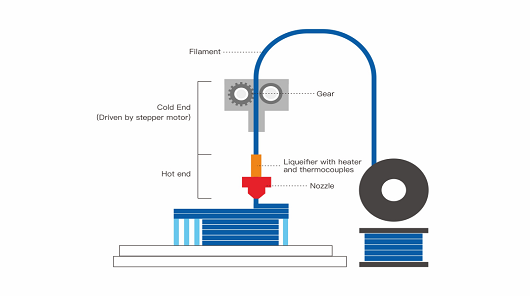

3d Printer Hot End Diagram

News printables buyers guides reviews basics.

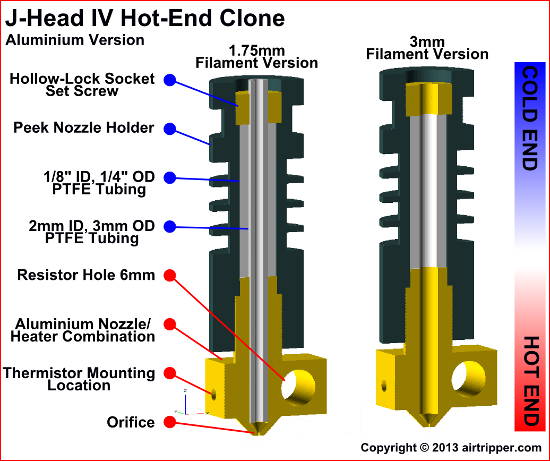

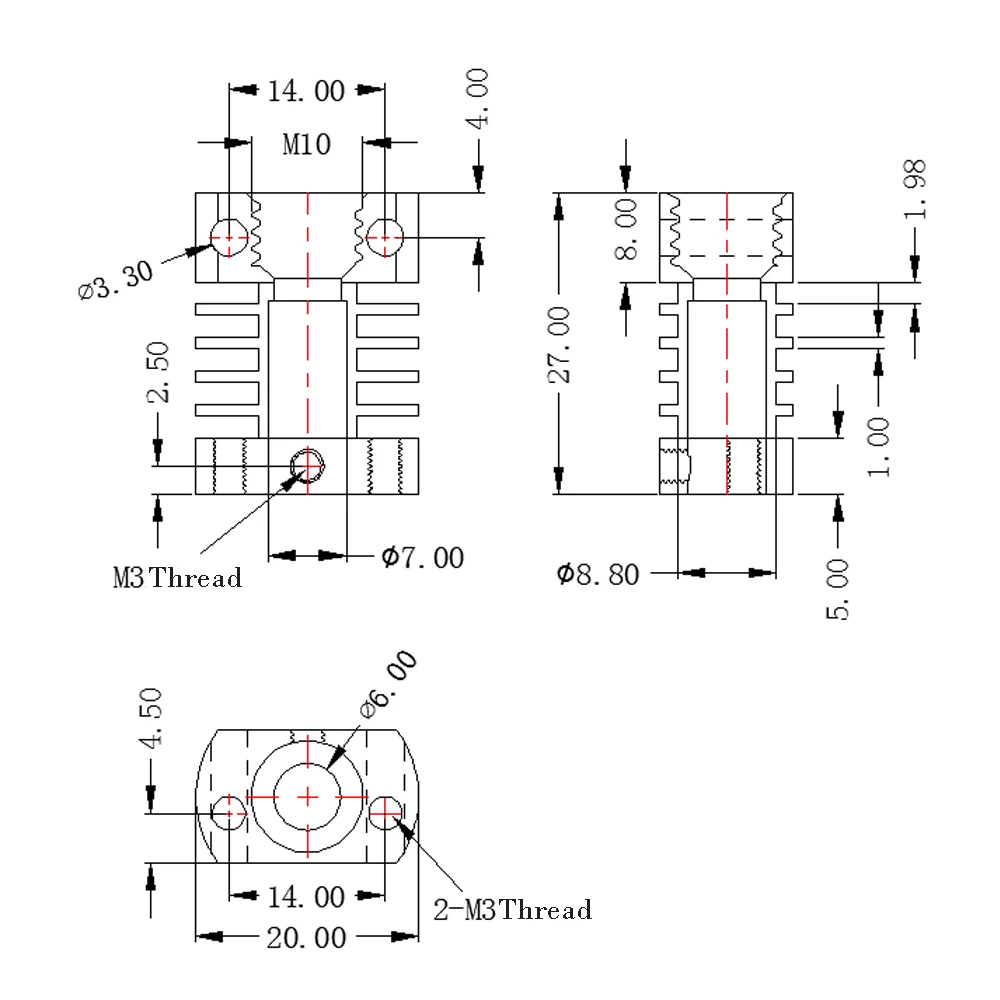

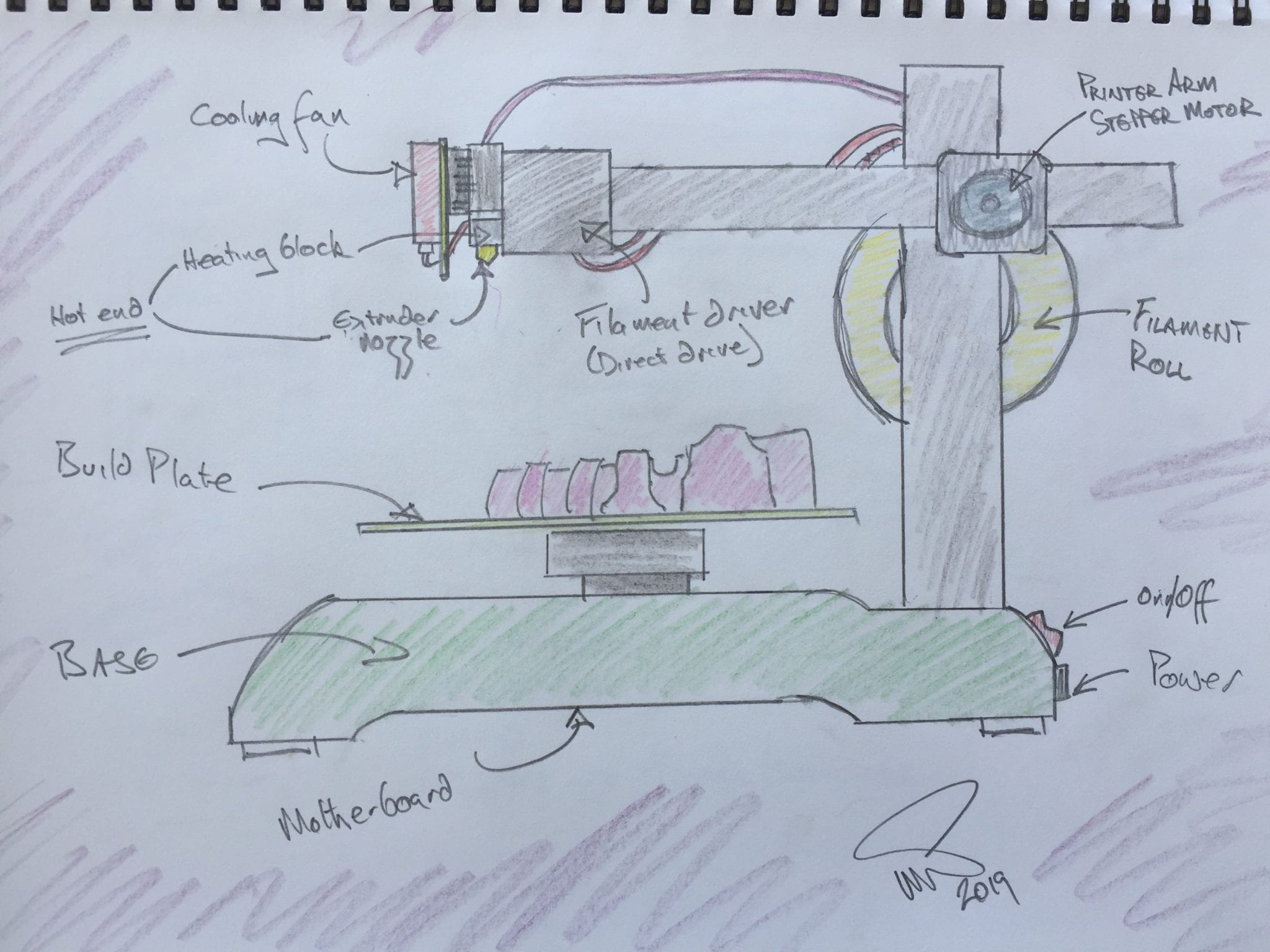

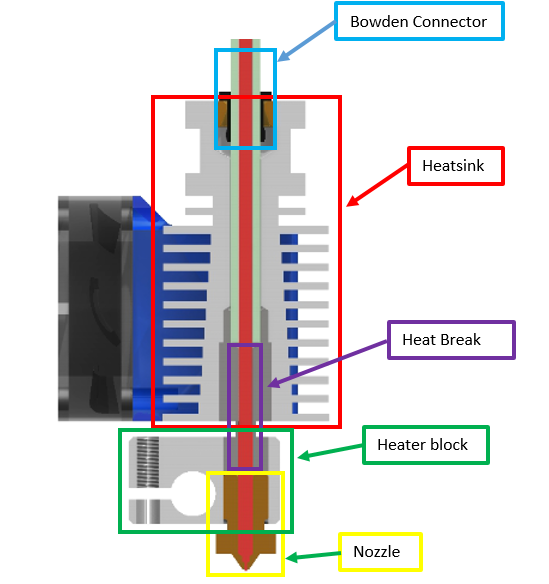

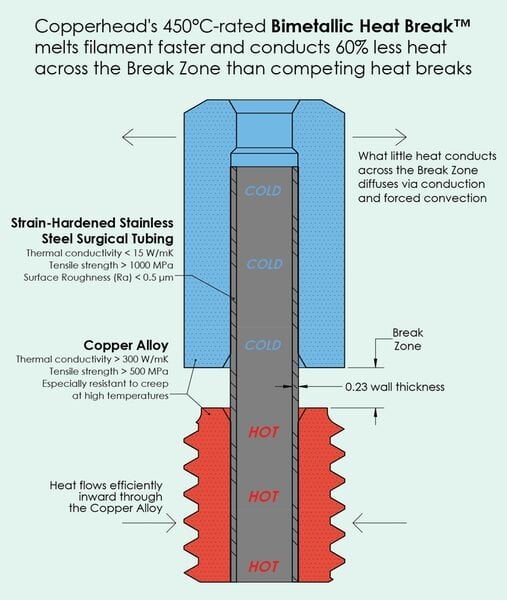

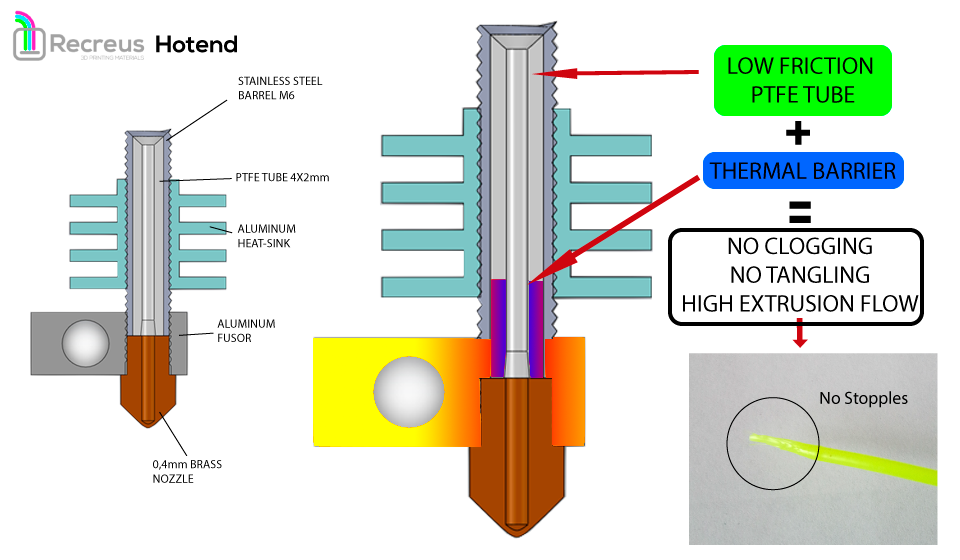

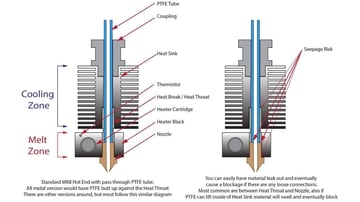

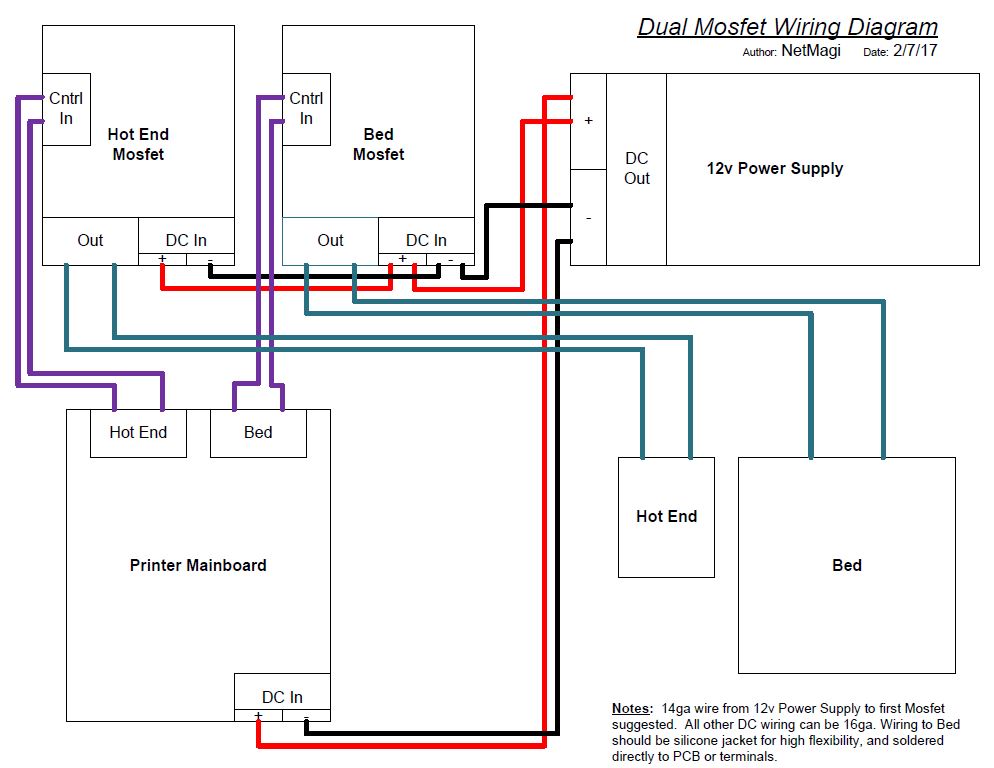

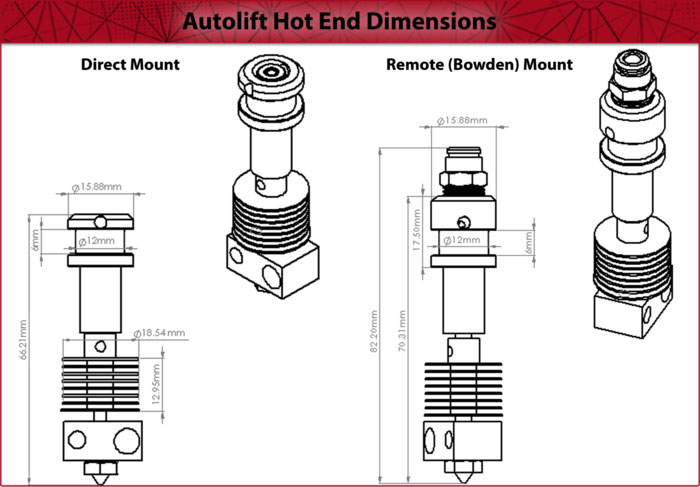

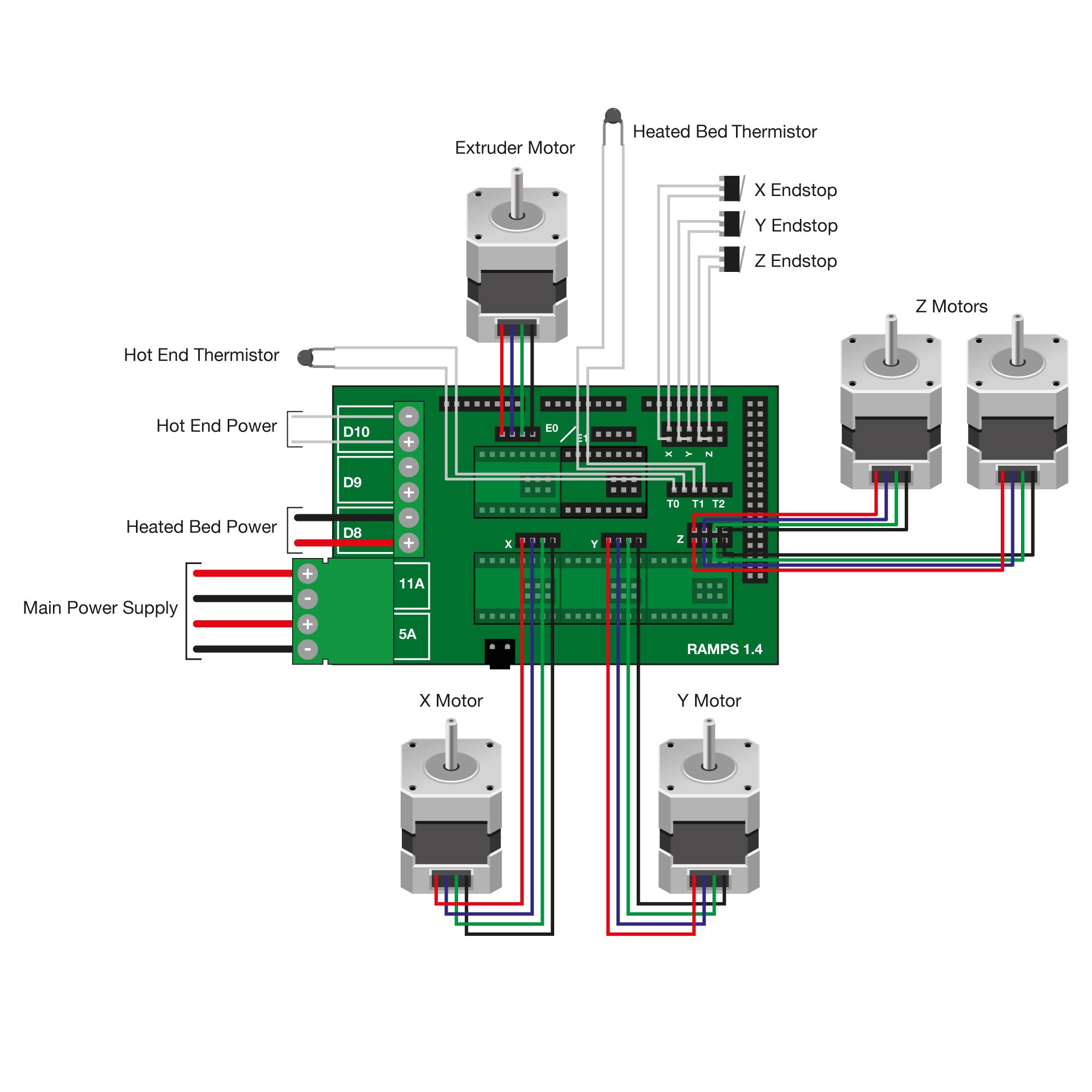

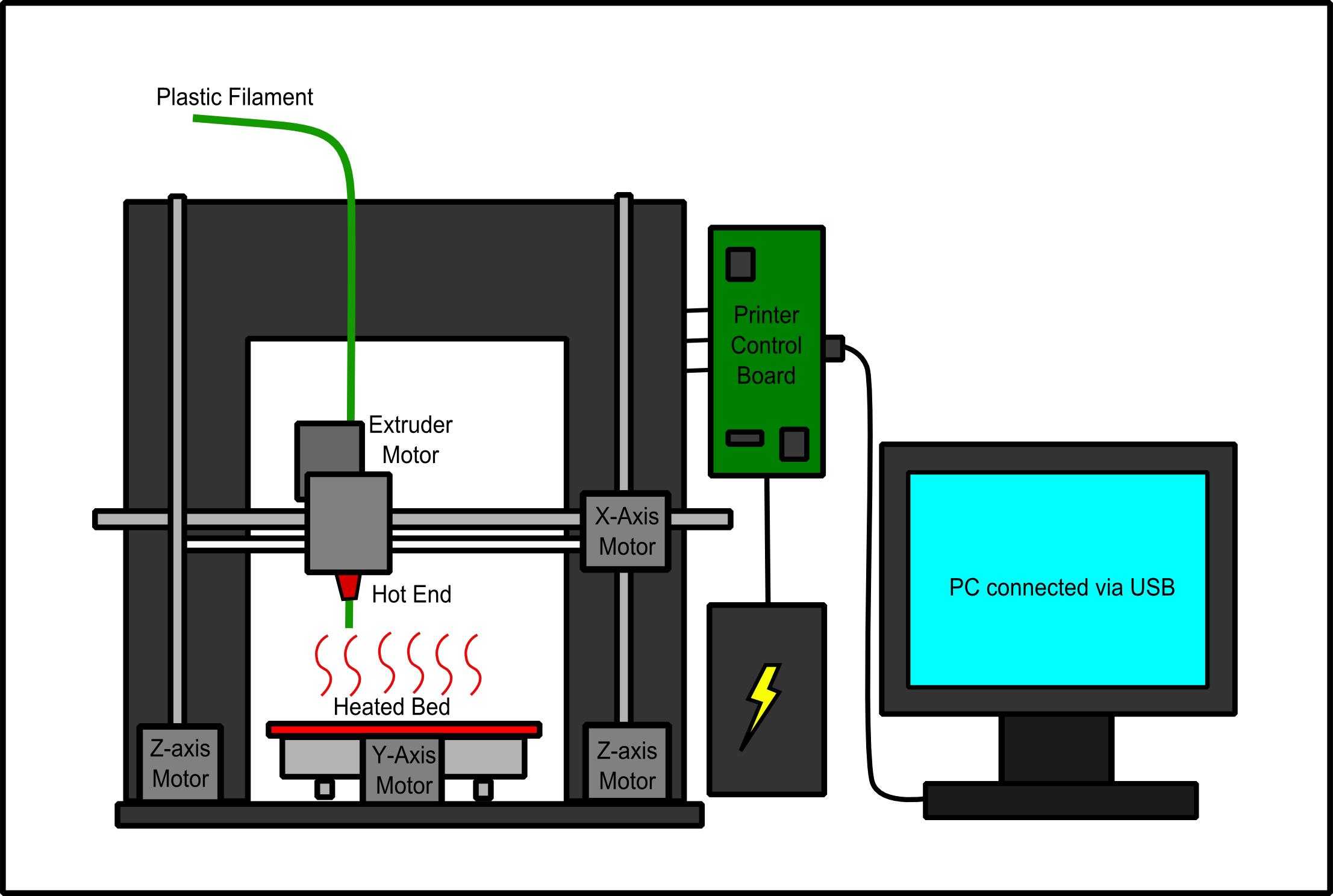

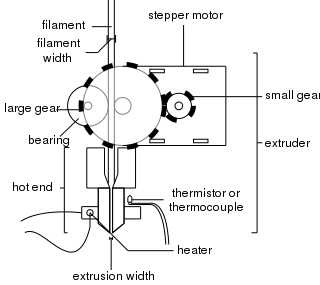

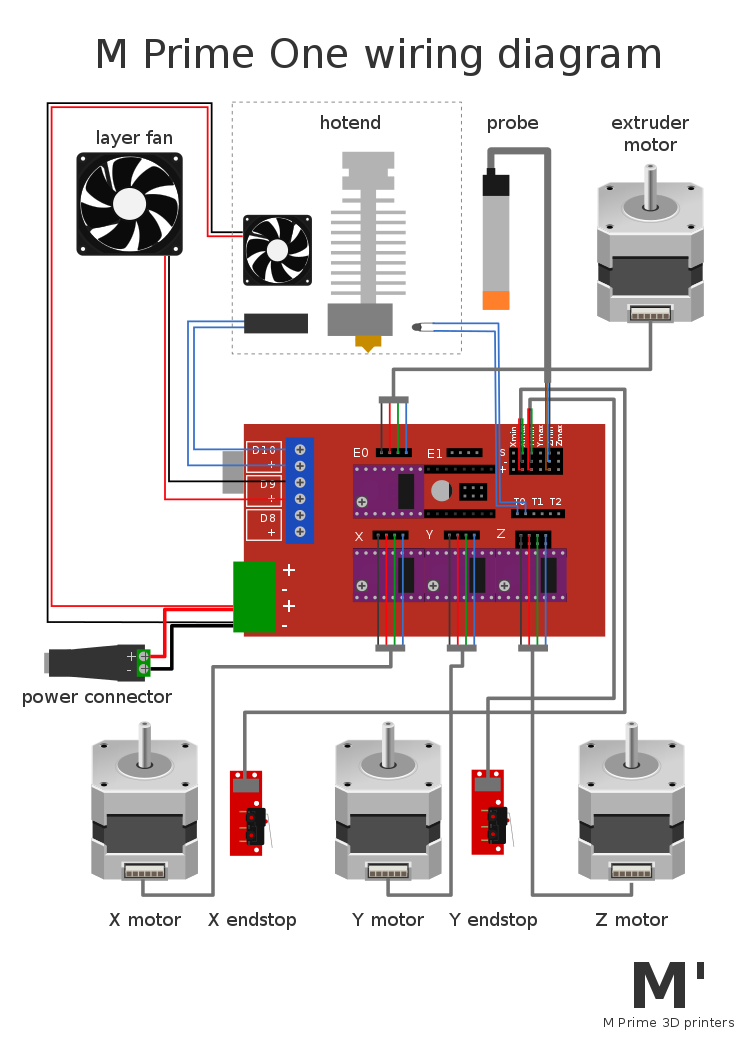

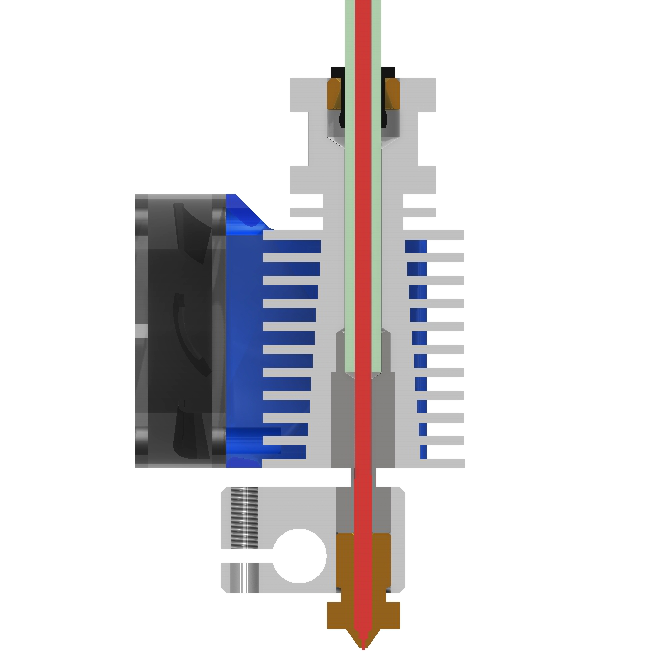

3d printer hot end diagram. 3d printer wiring is one of the most important parts of a 3d printer build. With the ptfe polytetrafluoroethylene tubing your 3d filament is protected from any temperature changes until it comes in contact with the nozzle. The copperhead hot end explanatory diagram of the copperhead hot end source. Select the correct input voltage to match your local mains 230v or 115v because of softwarehardware upgrades and model differences new revisions may not be listed in this guide.

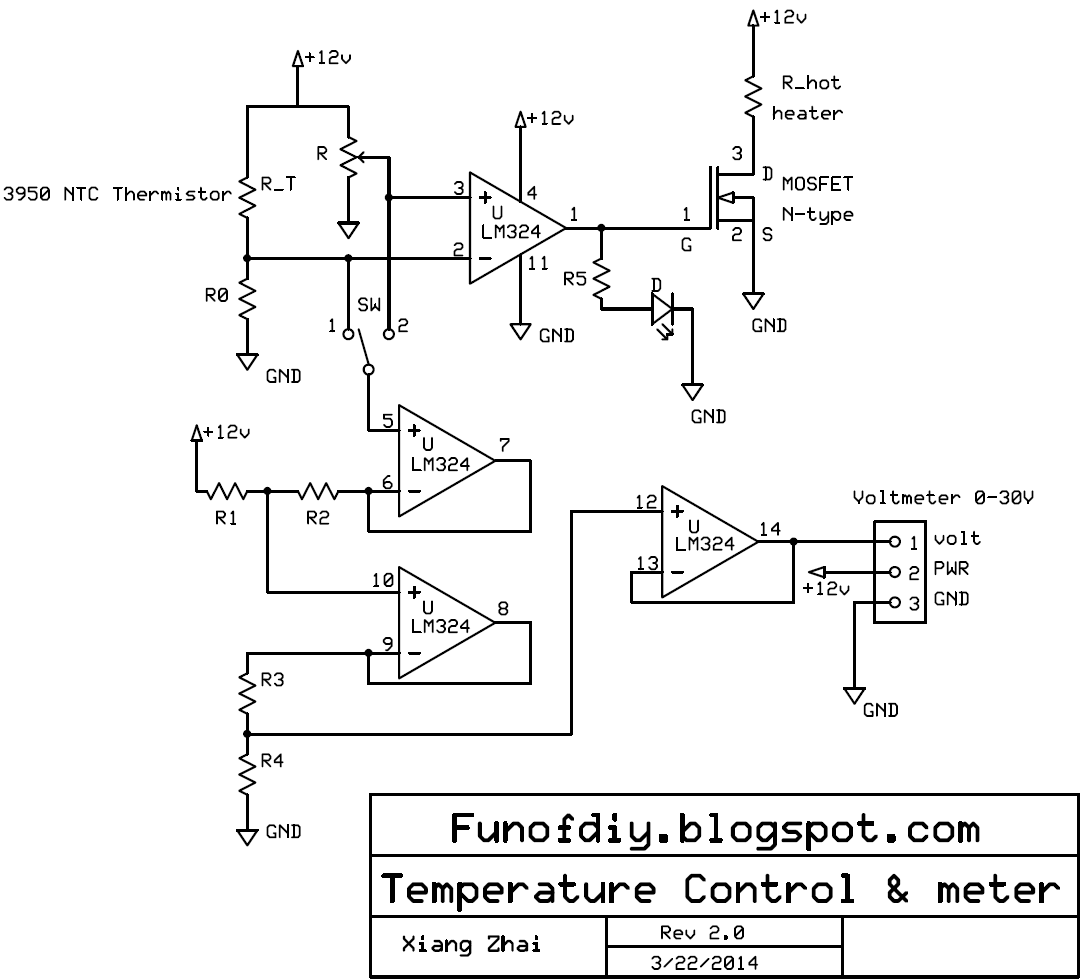

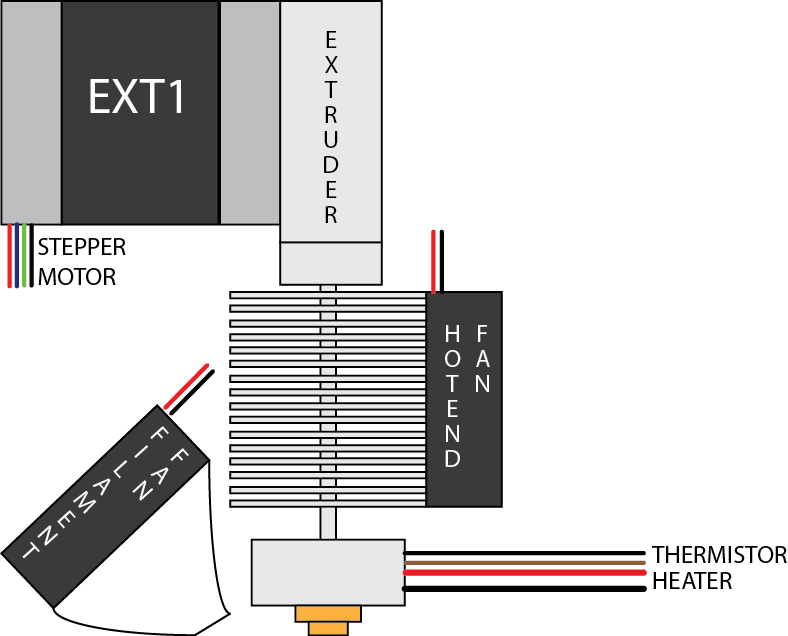

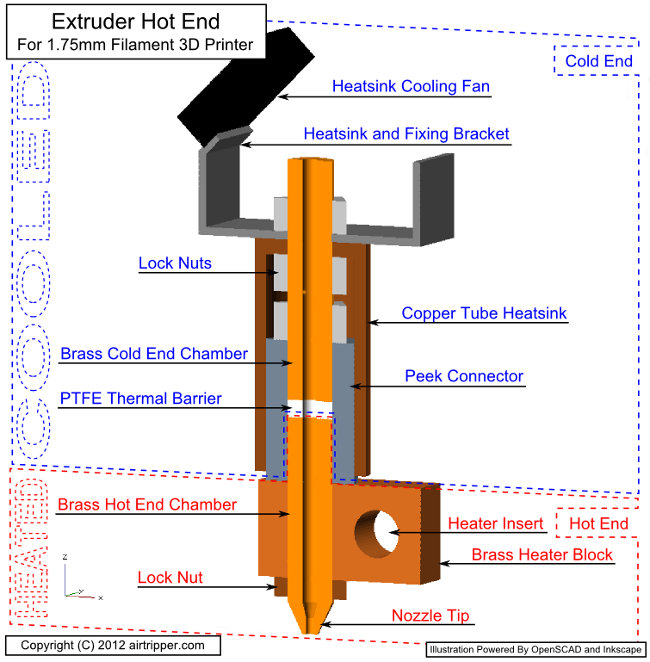

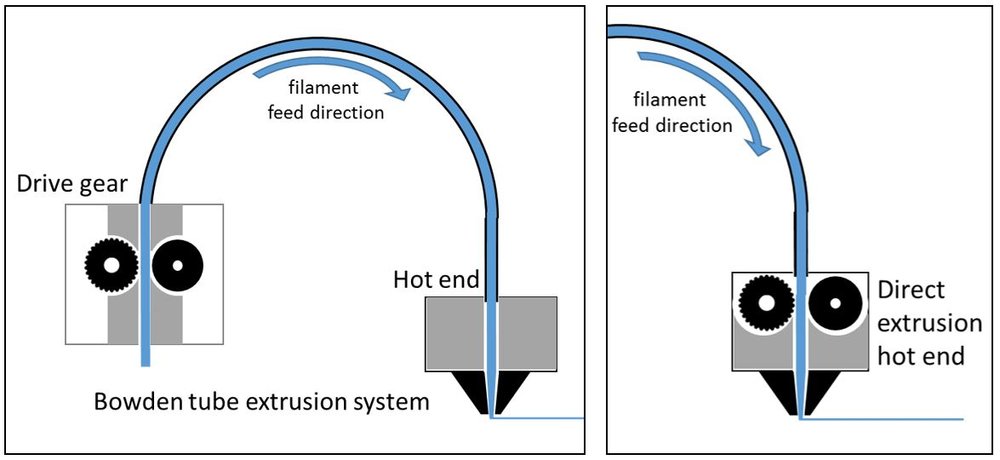

The cold end will be stationary and bolted somewhere onto the printers frame. Figure 11 will show the final connection of all these components. This eliminates meltdowns inside the hotend especially when printing with. That metal has excellent thermal transfer properties and their design seems to leverage that very well.

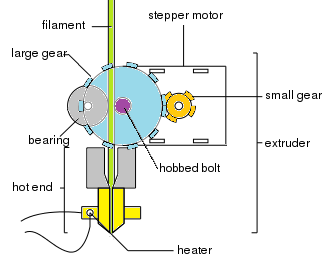

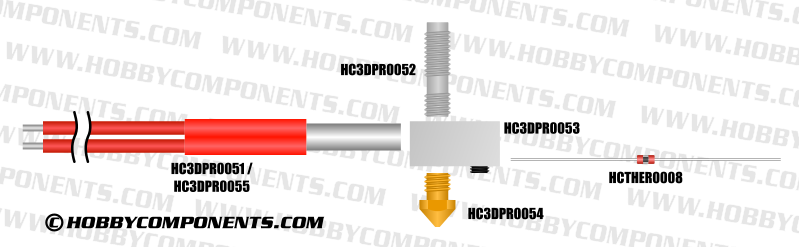

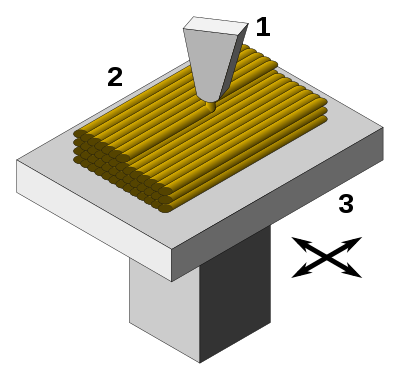

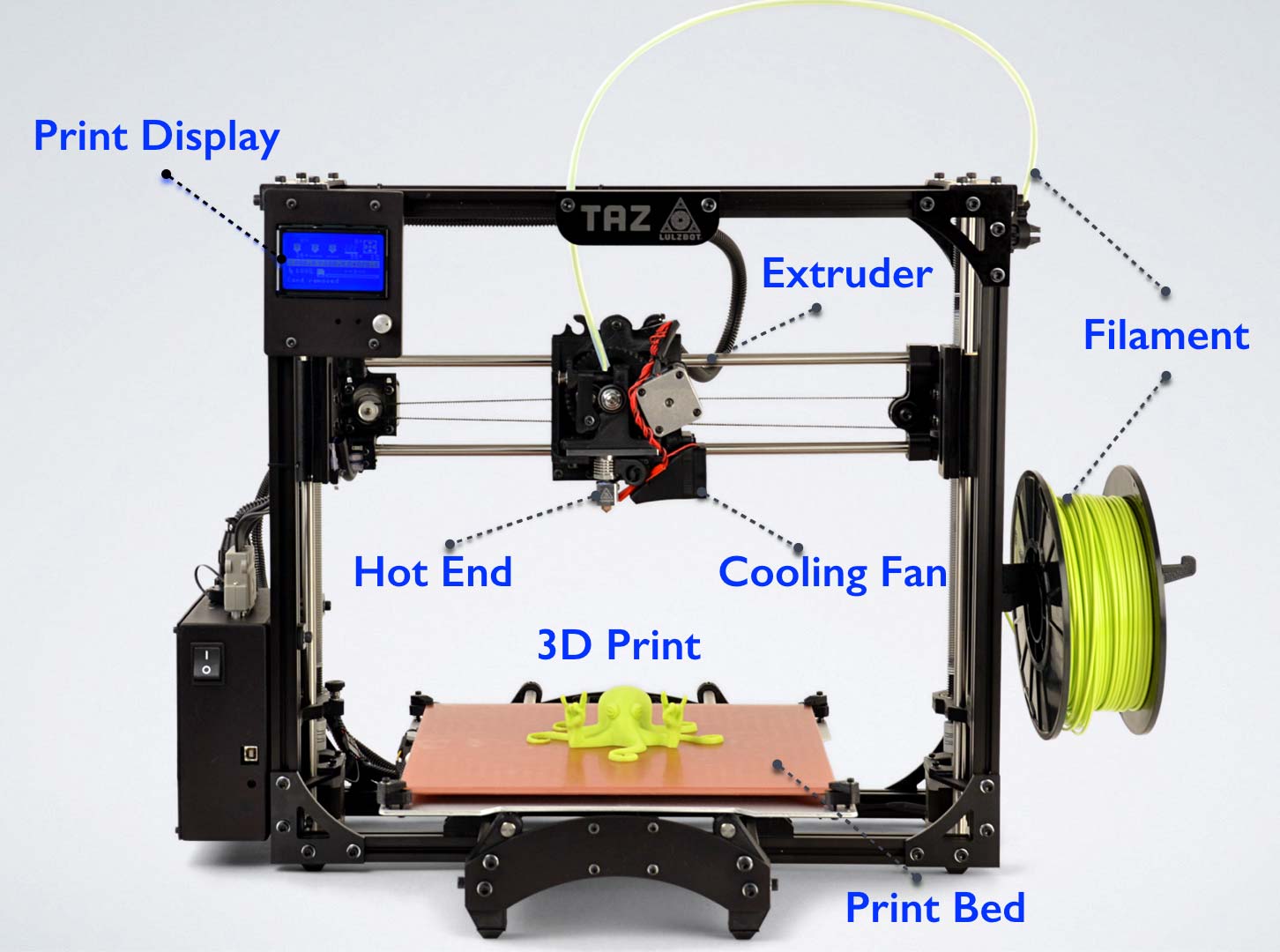

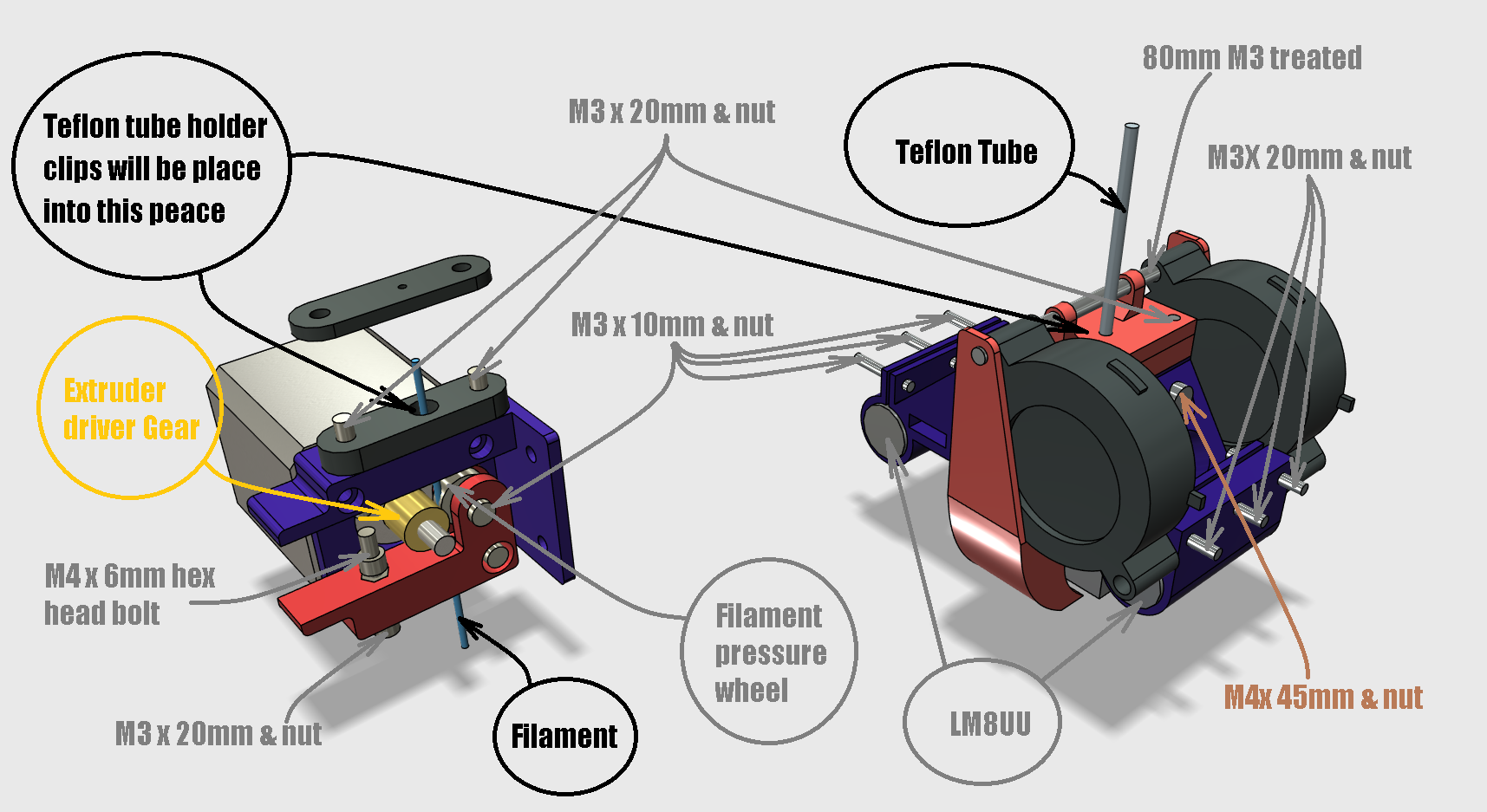

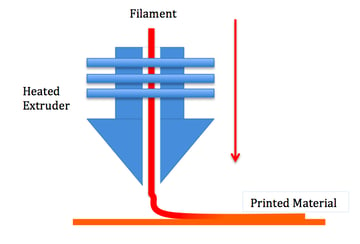

Nozzle assembly the nozzle is where the filament is. Slice engineering enter the copperhead. Assemble the hot end components the hot end melts the filament and extrudes it to build the 3d printed object. The extruder fan the extruder motor the heater and the thermistor.

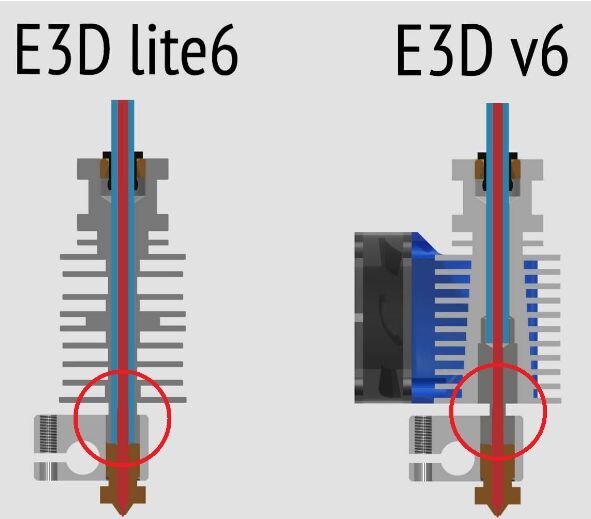

Hot end wiring diagram creprap wiki the hot end and extruder for your printer should have four sets of wires. When shopping for the best hot end for your 3d printer there are some things that you should consider. Check out the best 3d printer extruder hot ends on the market. E3d v6 hotends are designed inside and out for the best performance for any 3d printing application you can imagine.

Goal by the end of this section you will have built the hot end assembled it with the effector and installed it in the printer frame. If your looking to build your own 3d printer youve come to the right place. Building your own 3d printer wiring harnesses can be a challenge for some. I said screw that and instead spent 300 on a new 3d printer to design and print my own.

In this article i will give some examples and explain some of the most common connectors and wire gauges used to build 3d printers. 1 6 this part will clip into my router and will accept a vacuum hose to help remove wood dust and chips. The filament goes straight down through the cold end and into the hot end. It is specifically designed to maintain the two separate thermal zones with the use of copper.

.jpg)