3d Printer Temperature Calibration

The tolerance is also outlined on these spools.

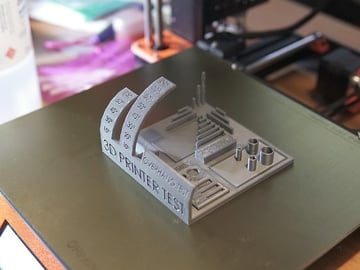

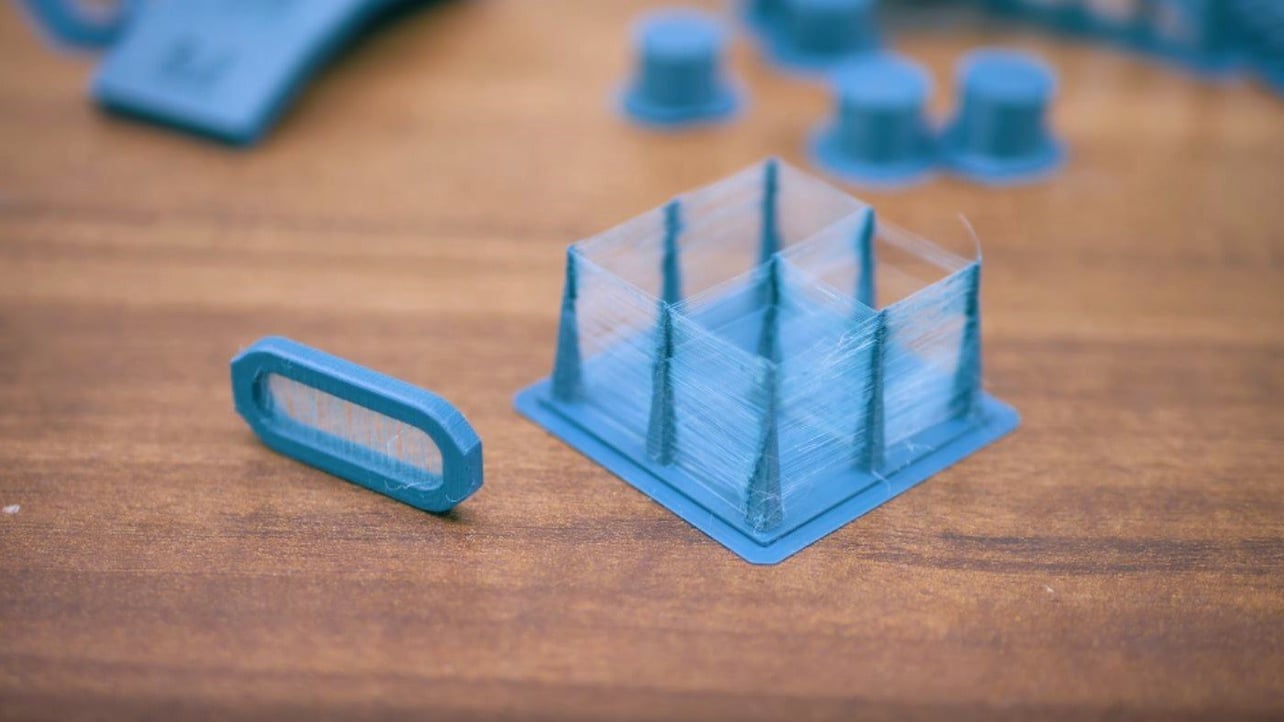

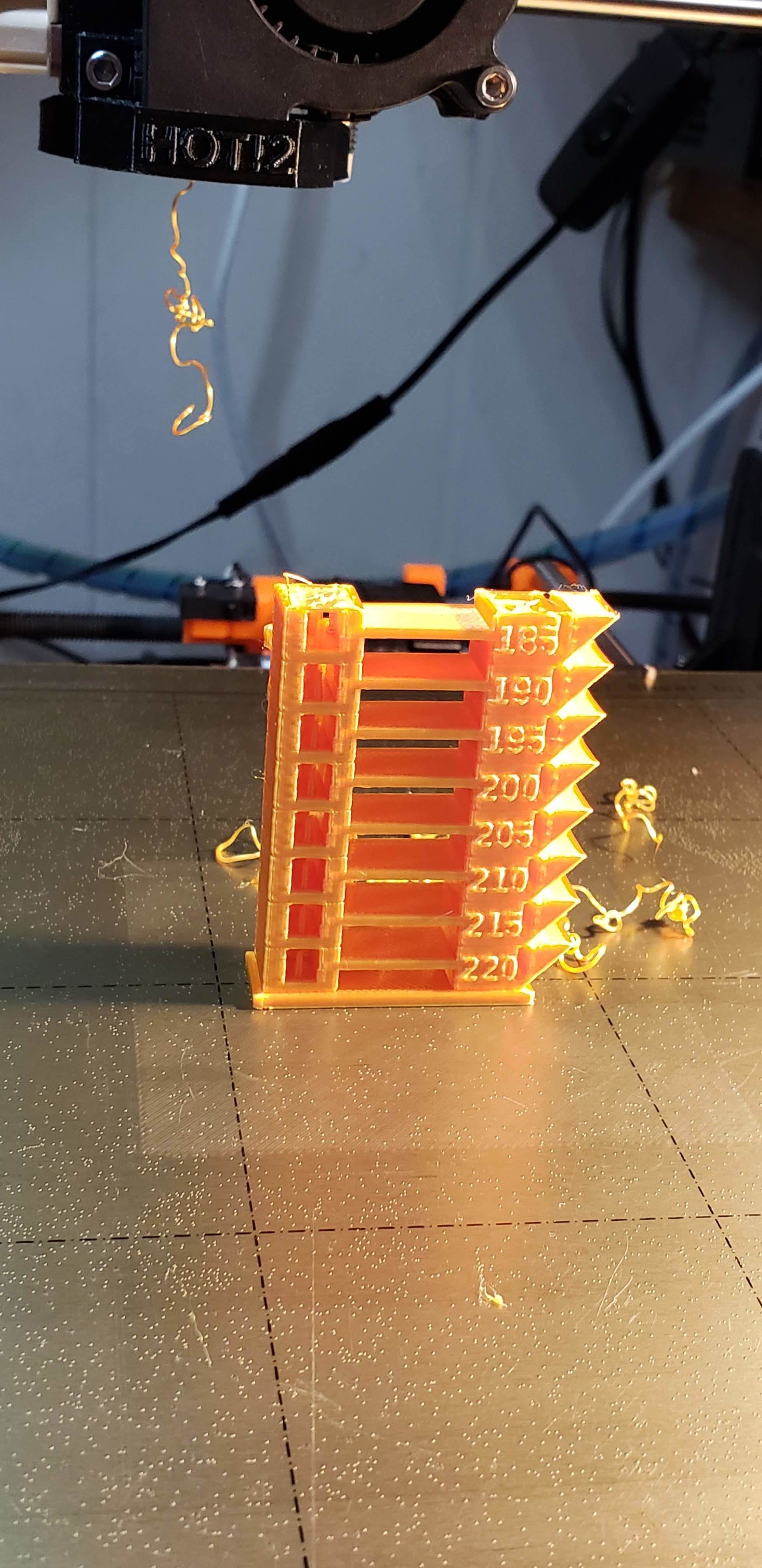

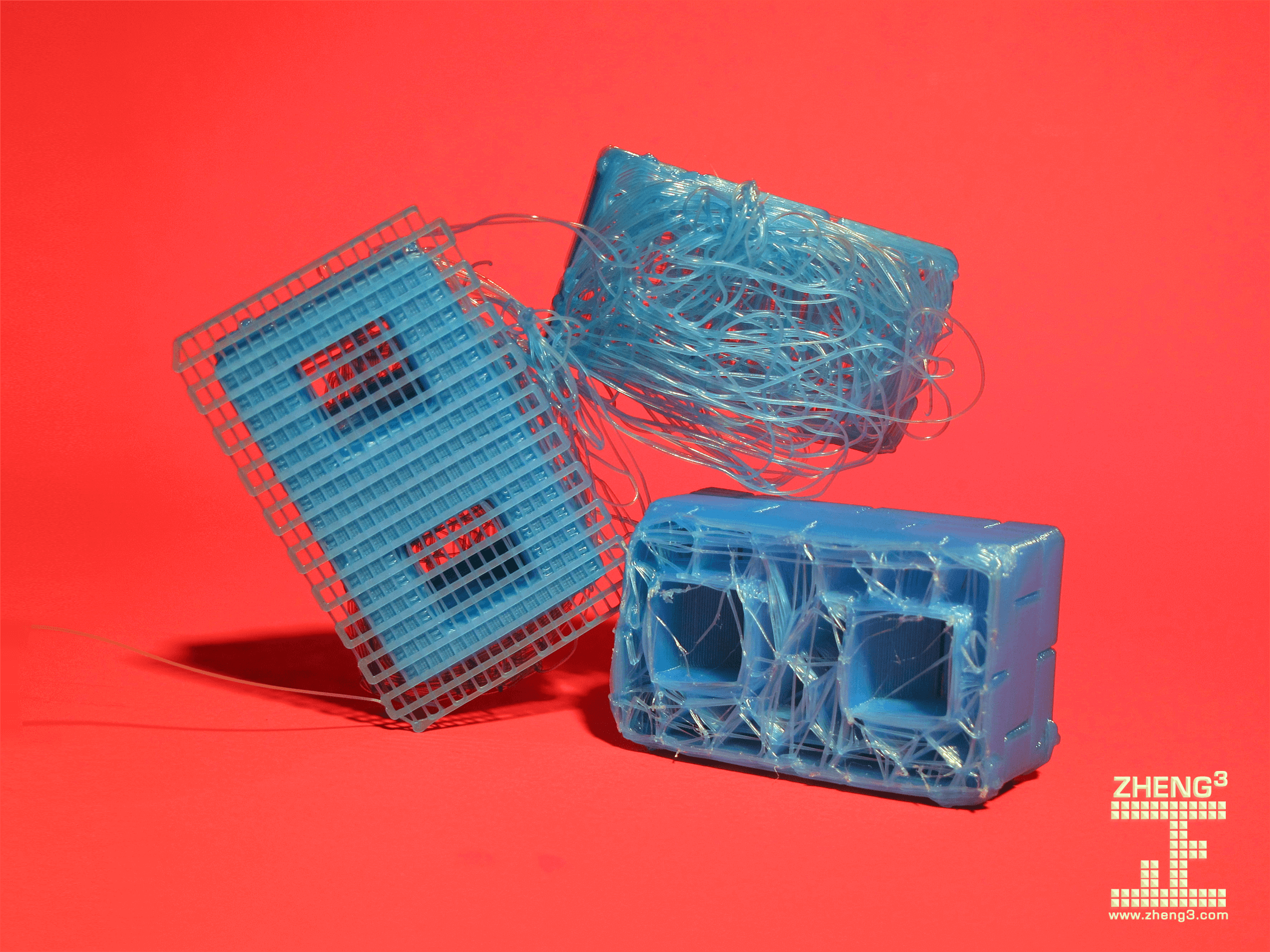

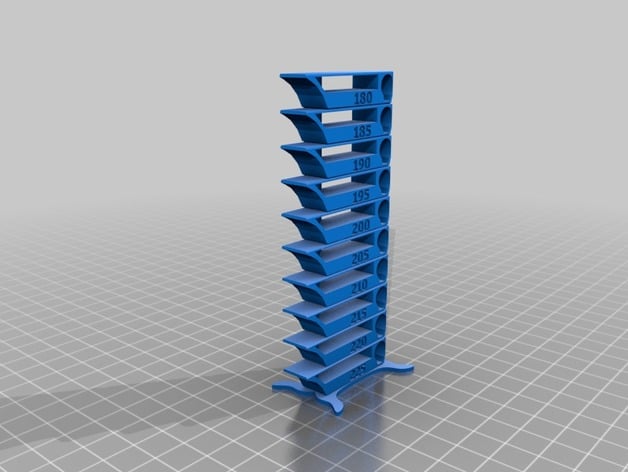

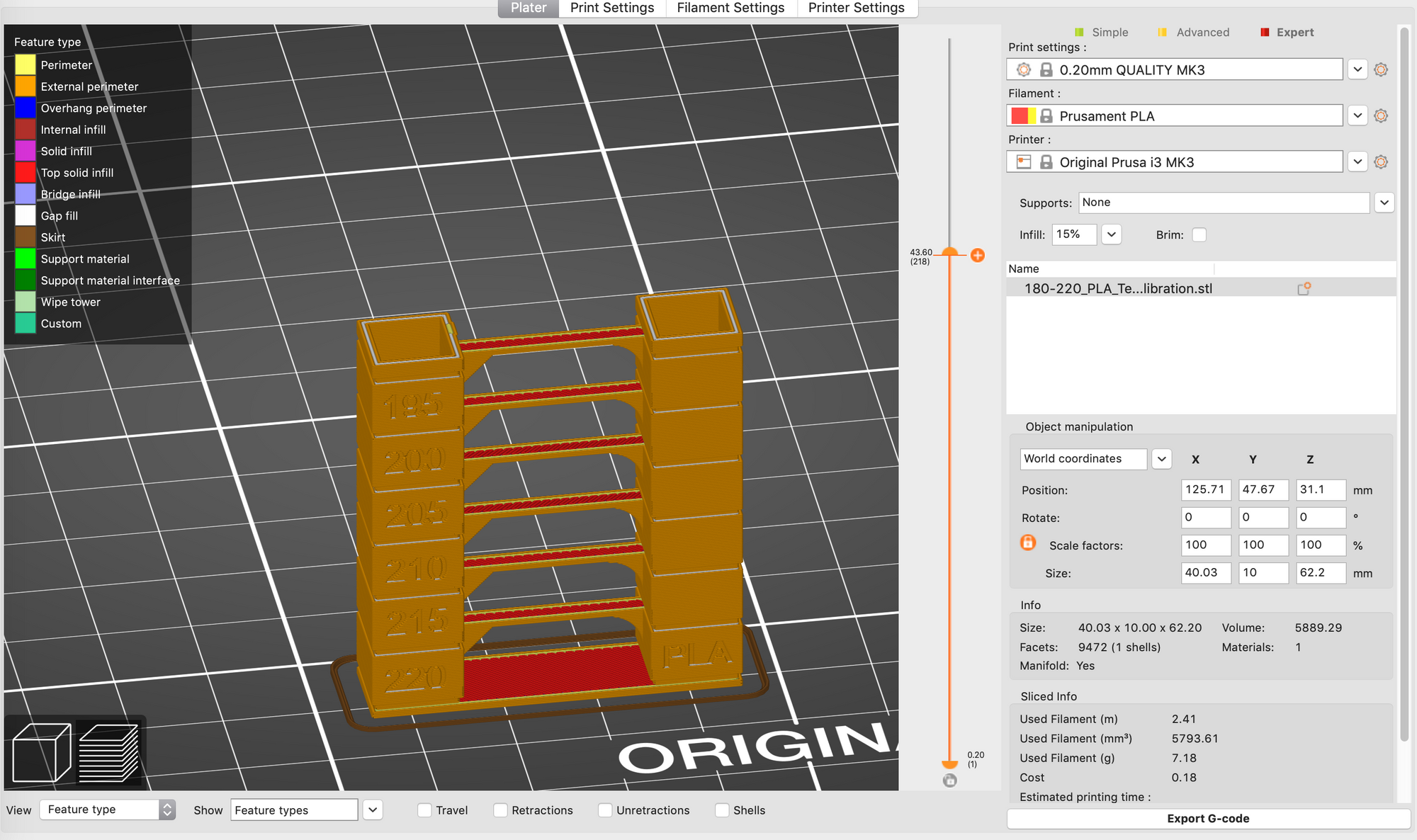

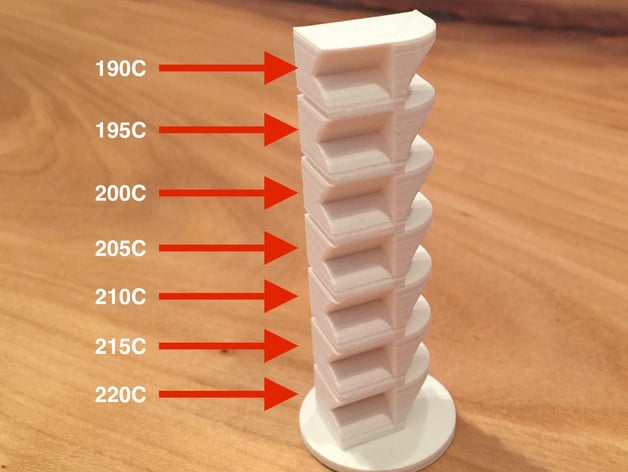

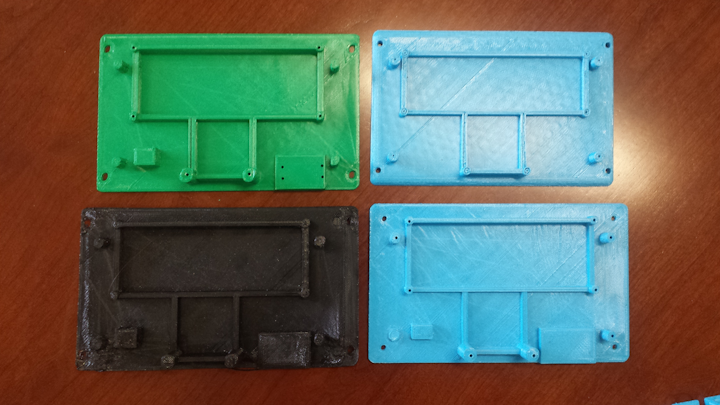

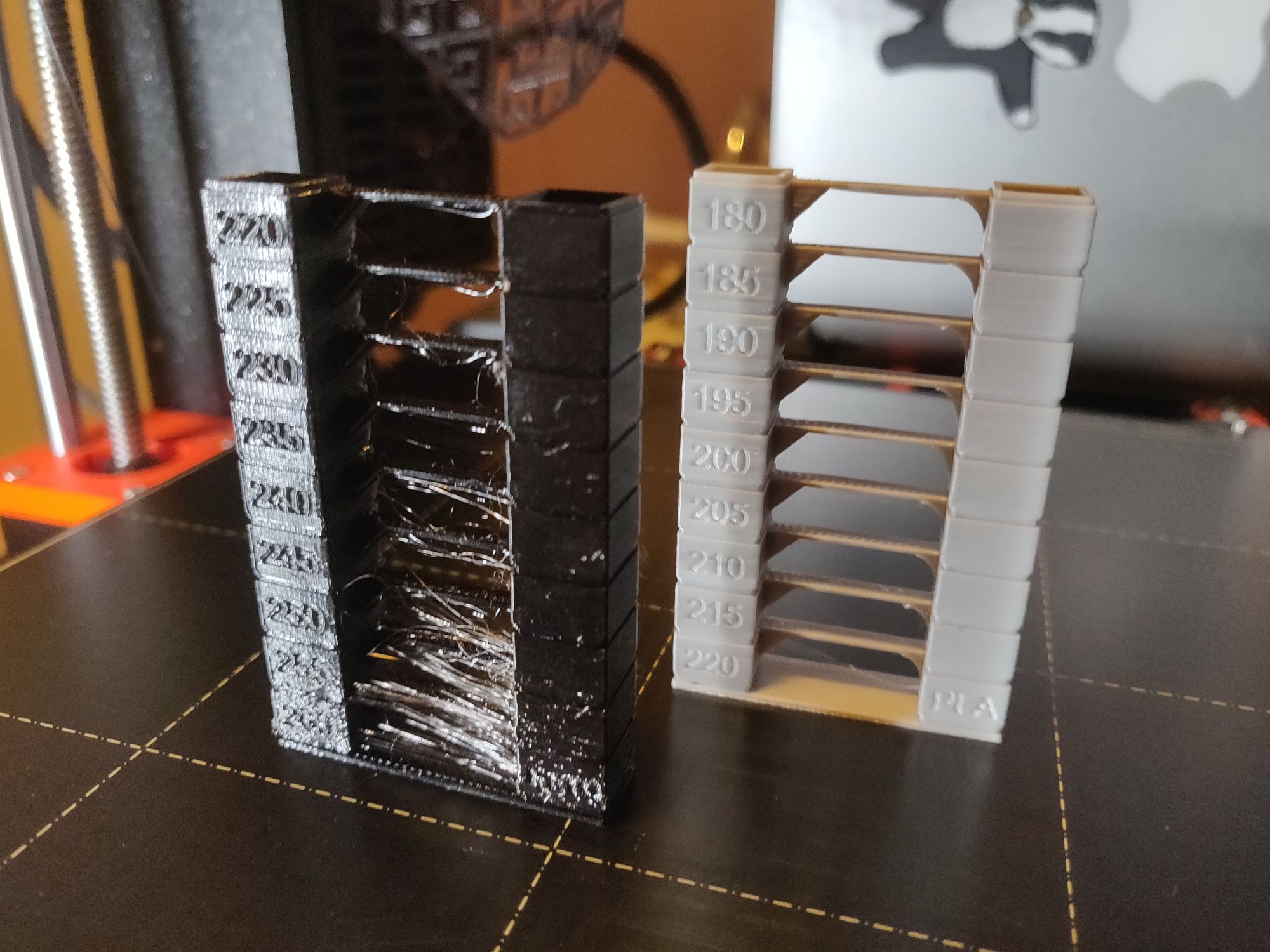

3d printer temperature calibration. Ready to print heat tower as shown in the video. Heres how to slice and print a temp tower. When we test a new printer or material we will usually run them through these set of different calibration prints. Run the m106 s255 command in order to set your cooling fan to 100.

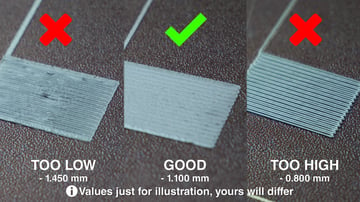

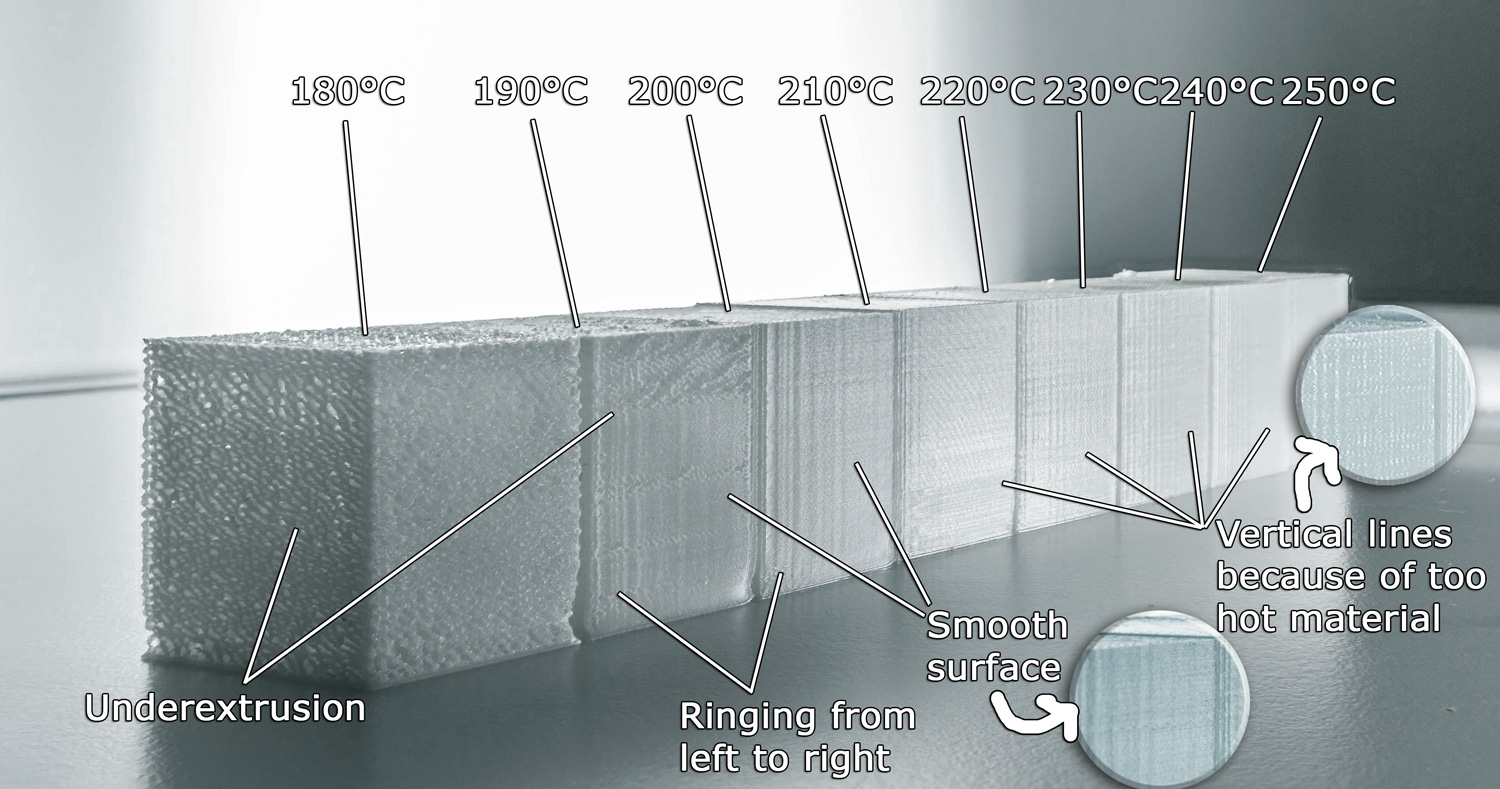

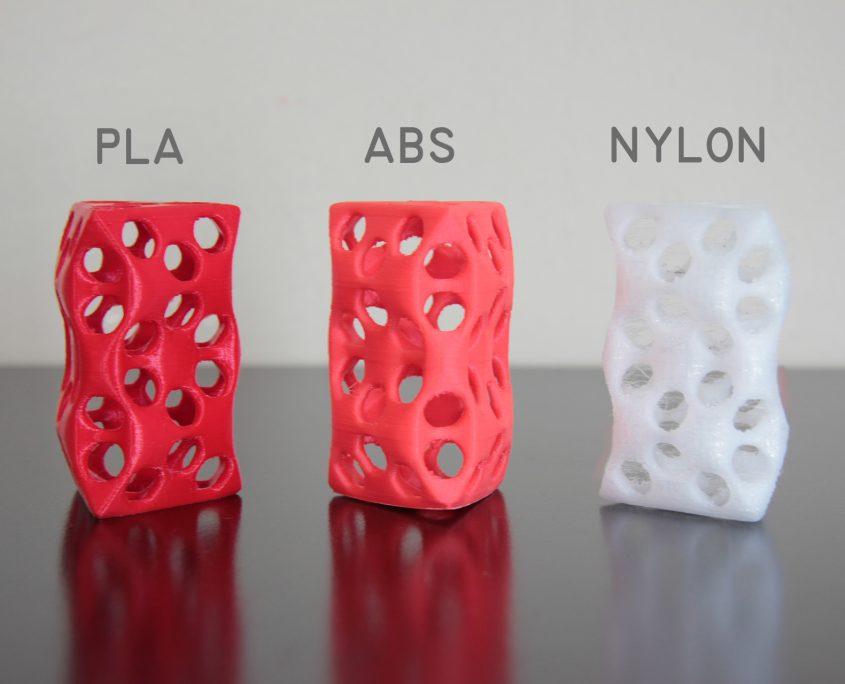

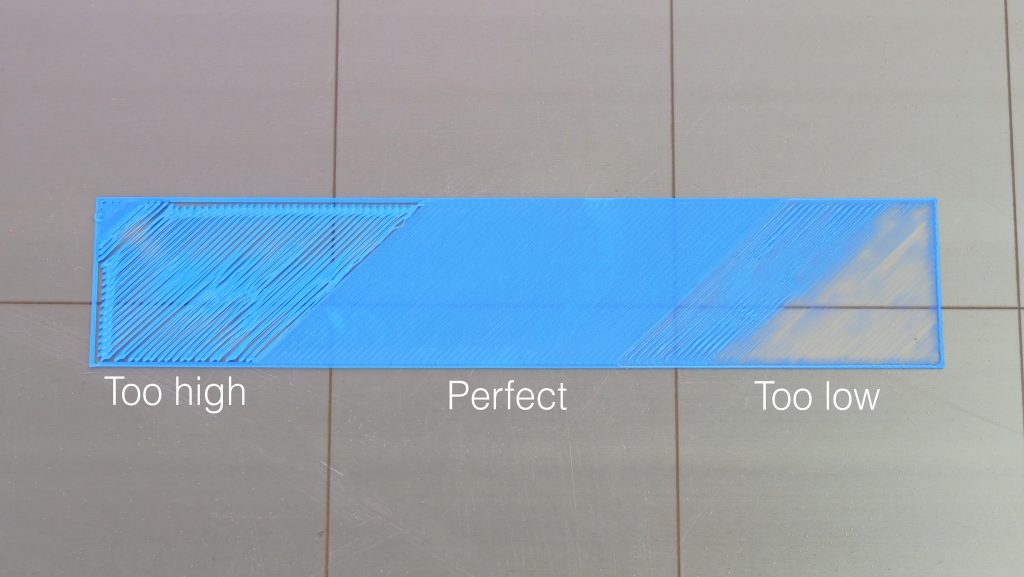

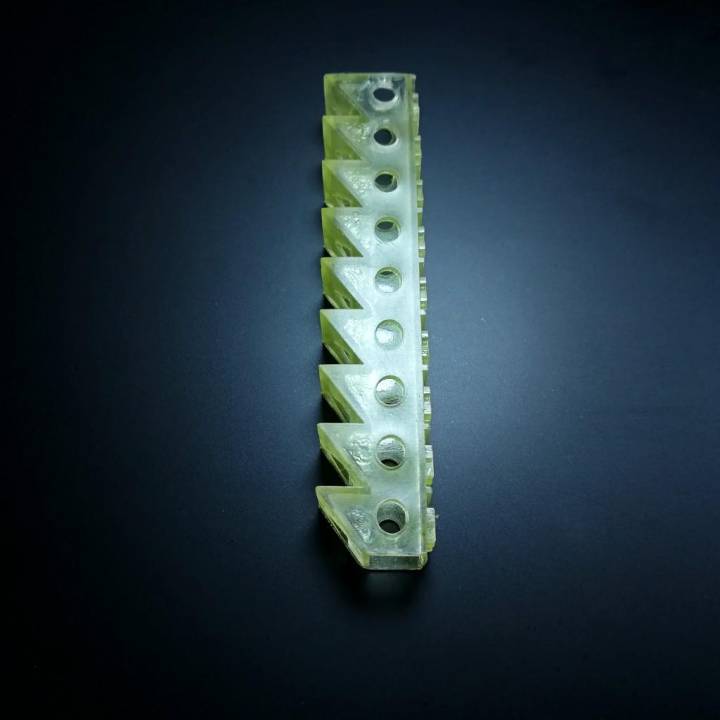

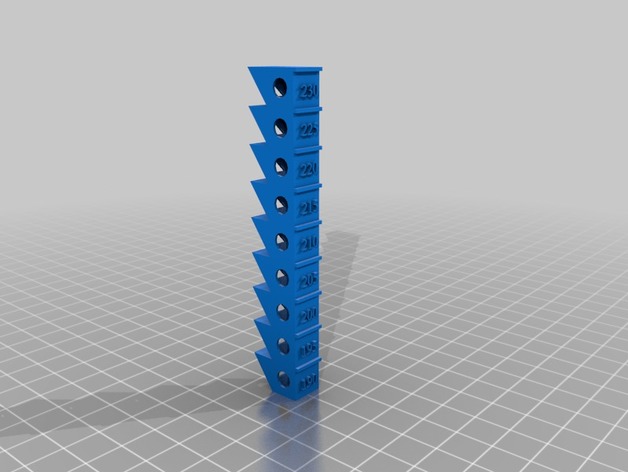

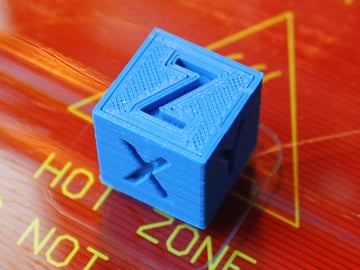

3d printing printing a temp tower to get better quality 3d prints. In previous years make magazine put together a list of fff and sla 3d printers and tested them using a set of 3d models specifically tailored for different geometry conditions. If using petg set a temperature of 225c. The diameter of a roll of.

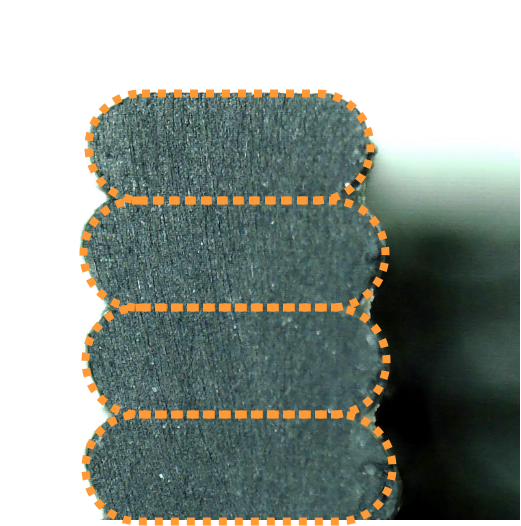

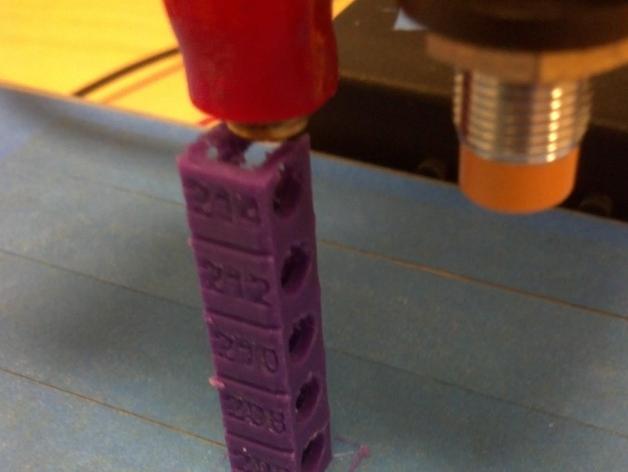

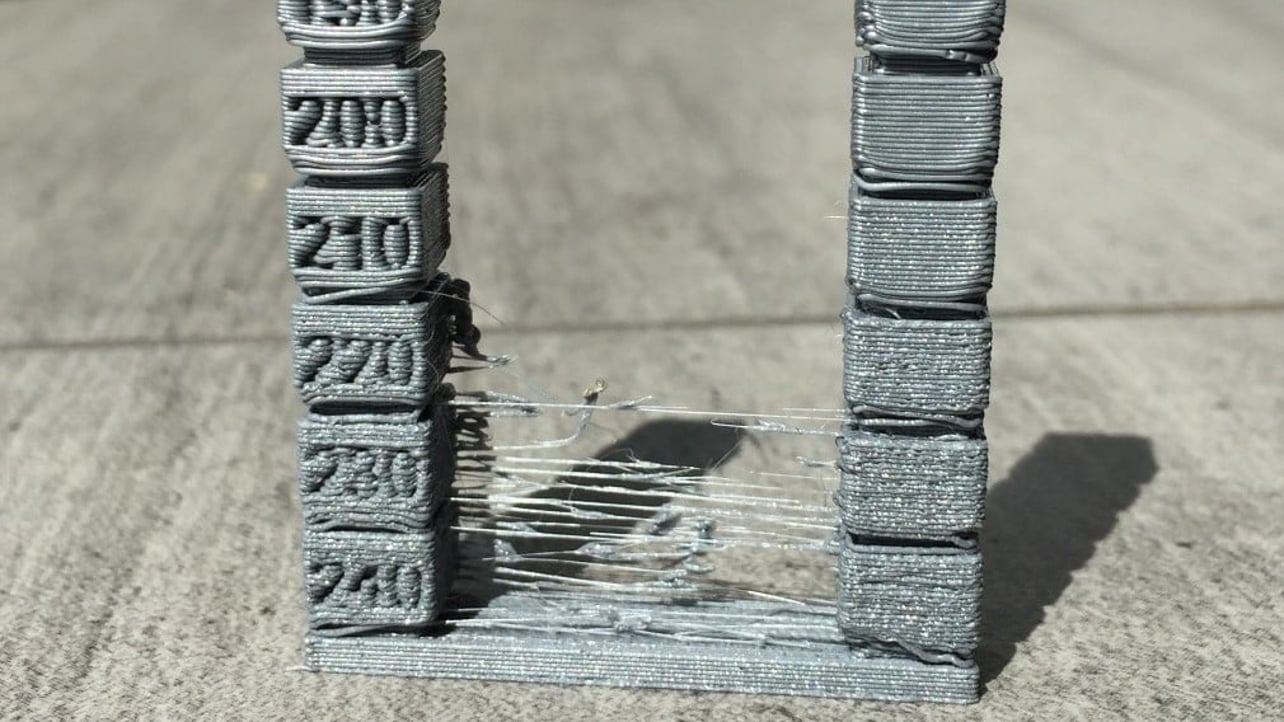

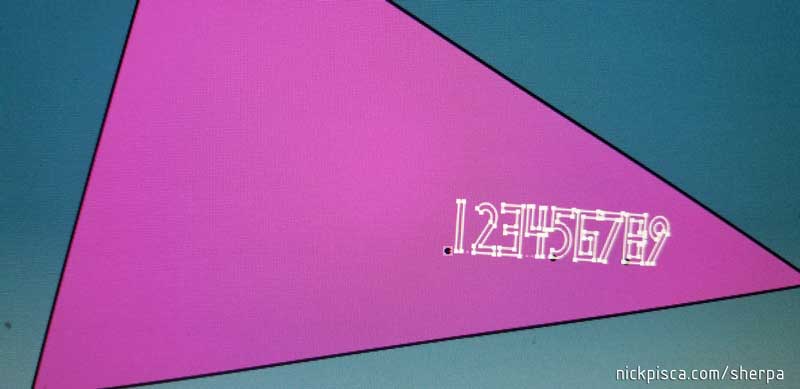

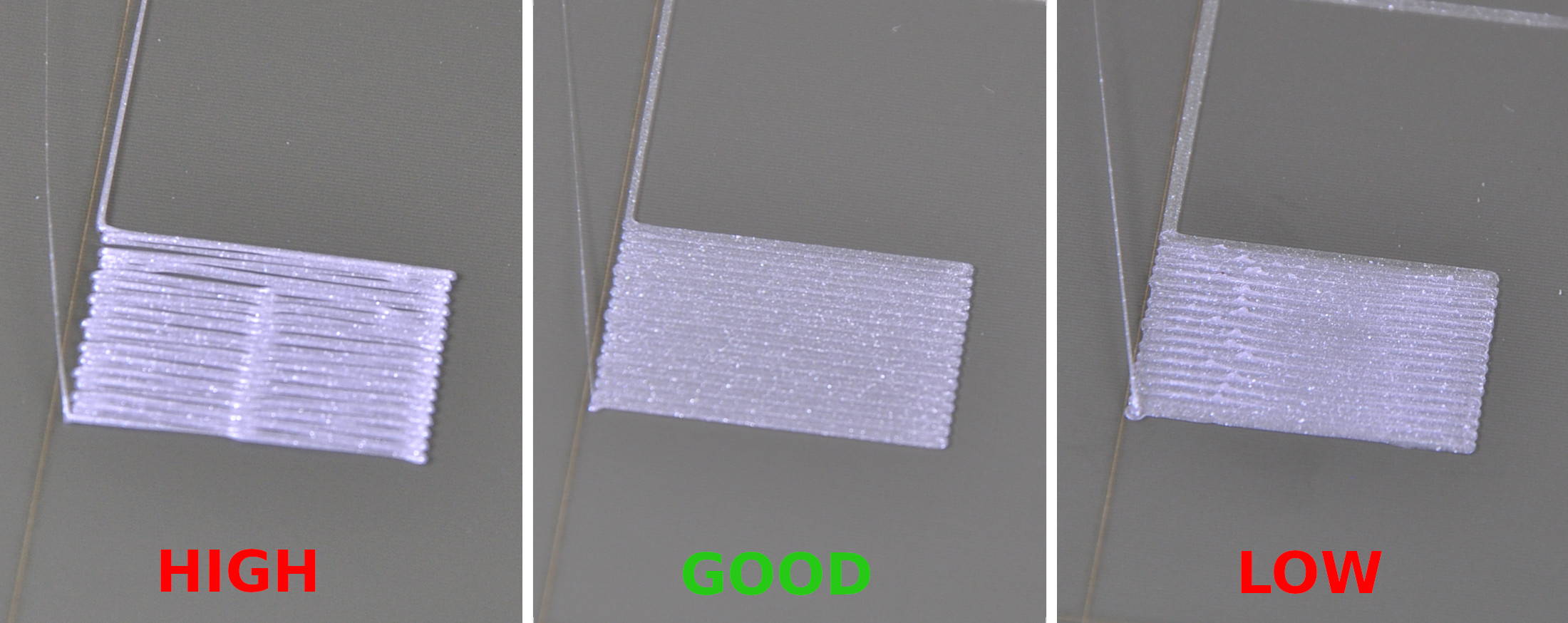

This is only tested on cr 10s. Even just a 5c change can make all the difference to the performance of a filament. 3d printed footwear 2020 2030 an analysis of the market potential of 3d printing in the footwear industry. Measure your filamentuse calipers to measure the true diameter of the filament.

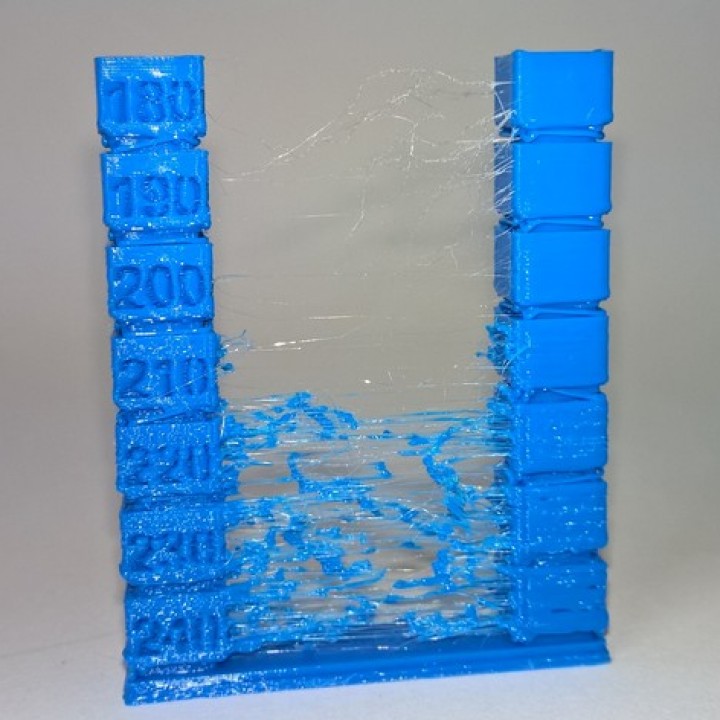

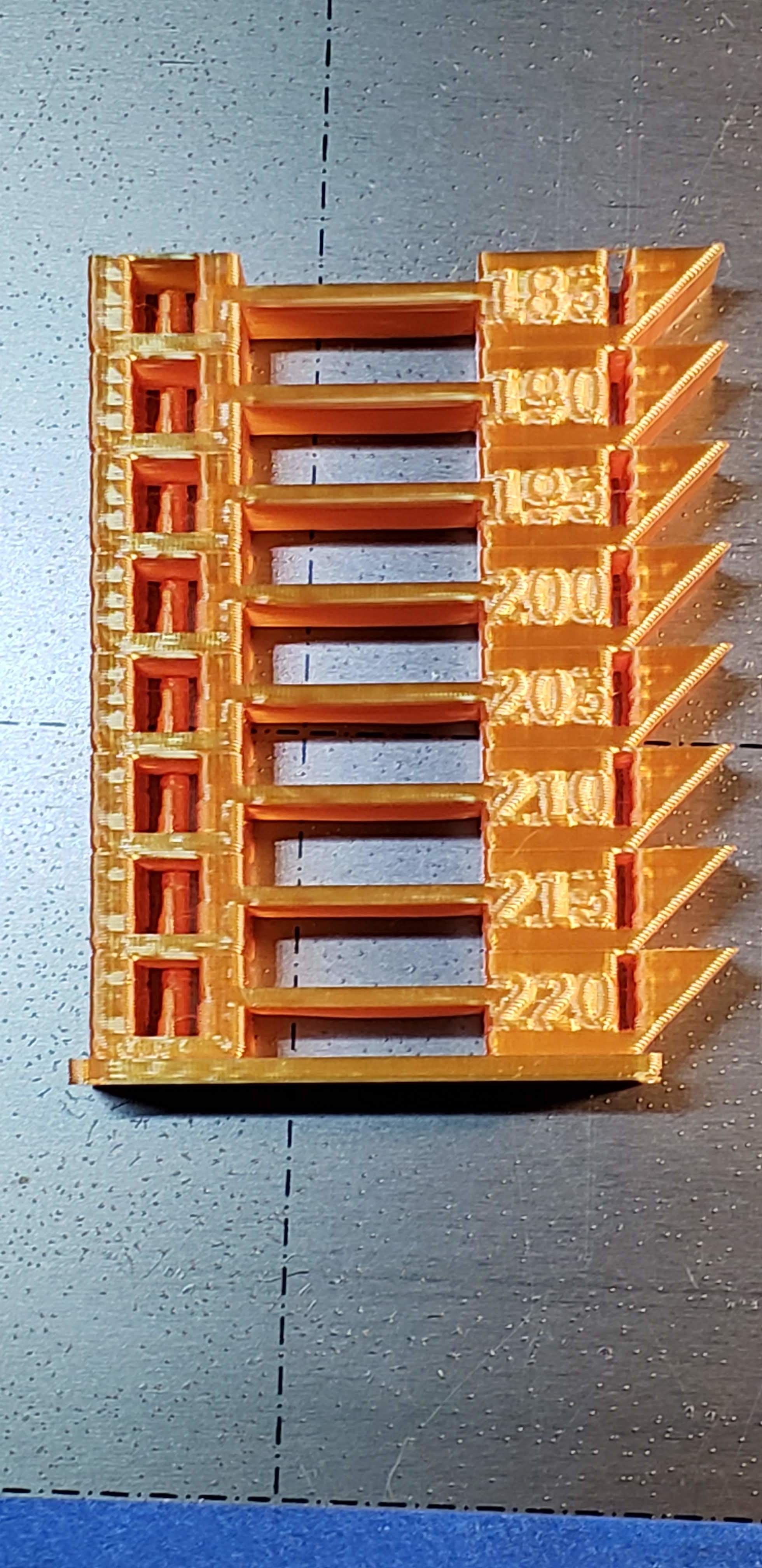

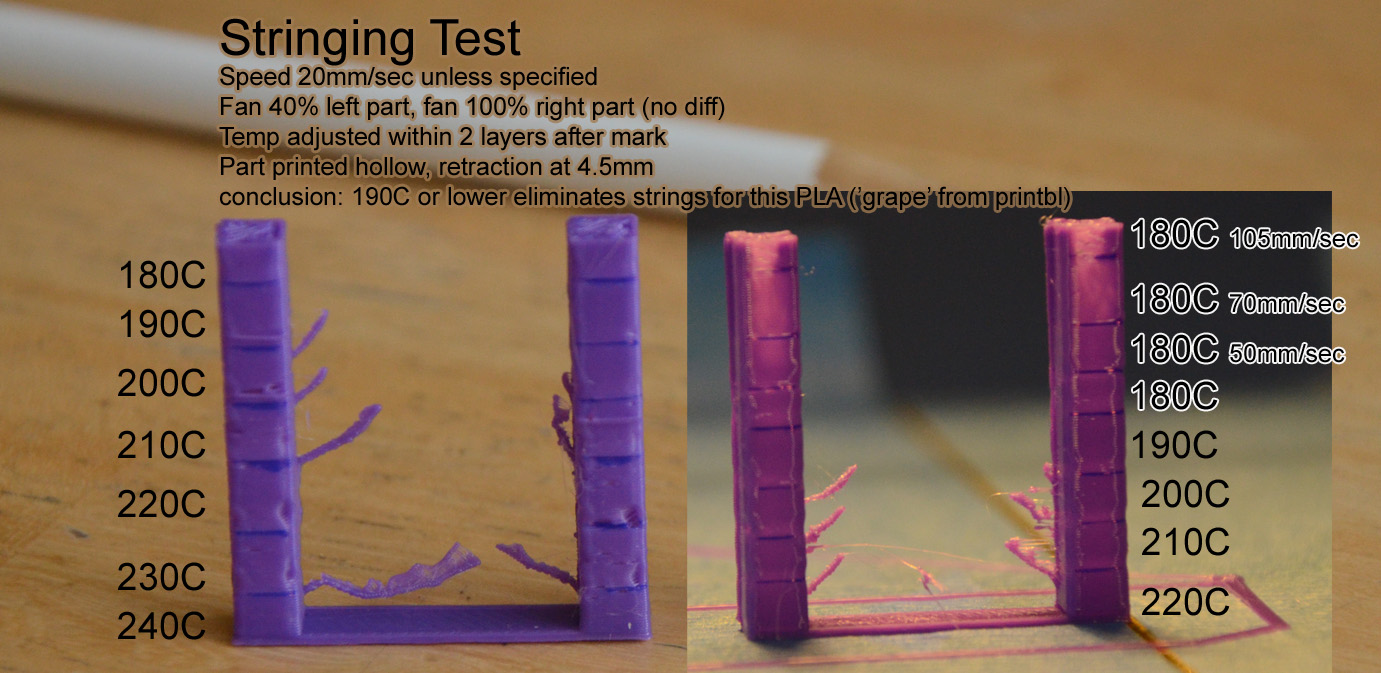

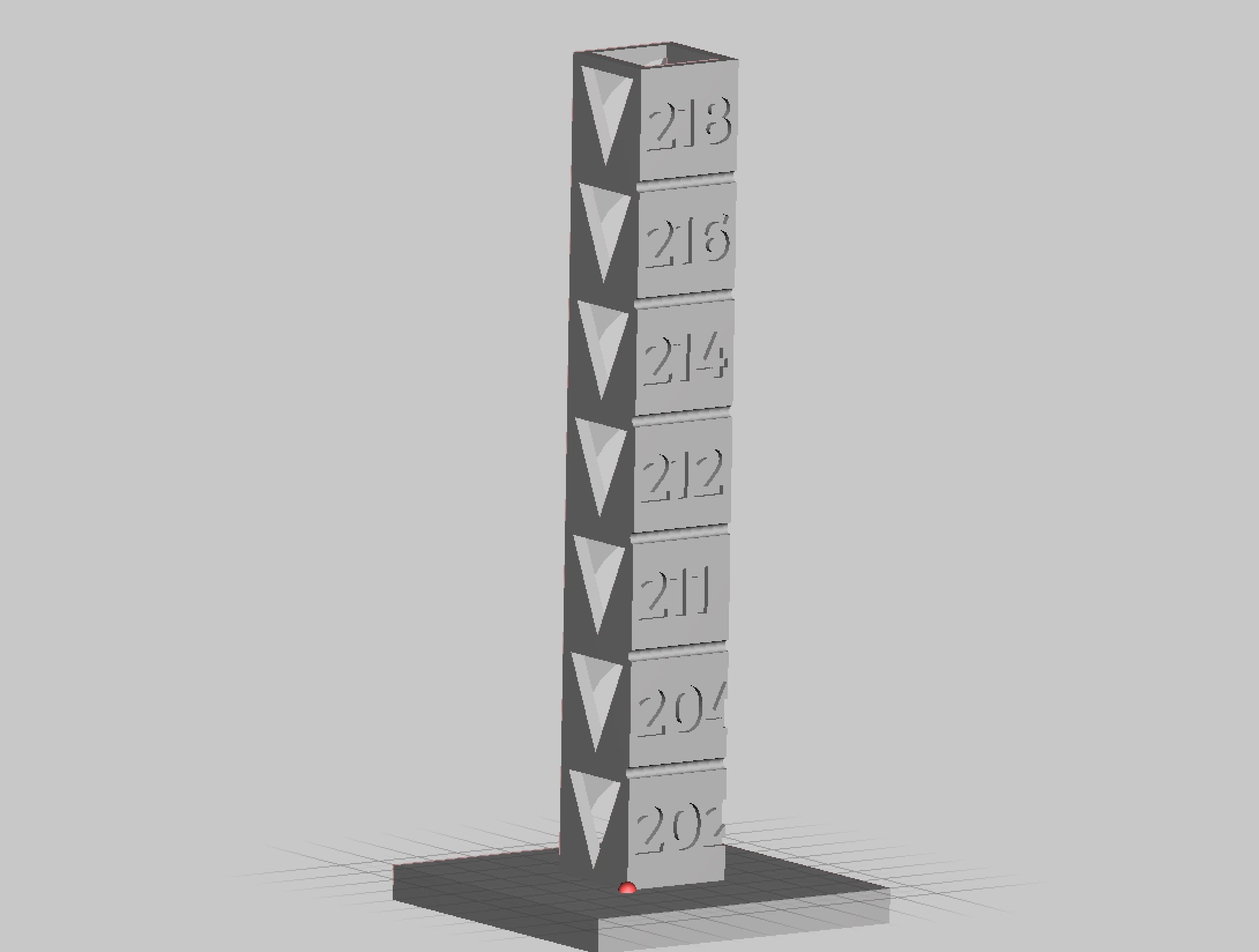

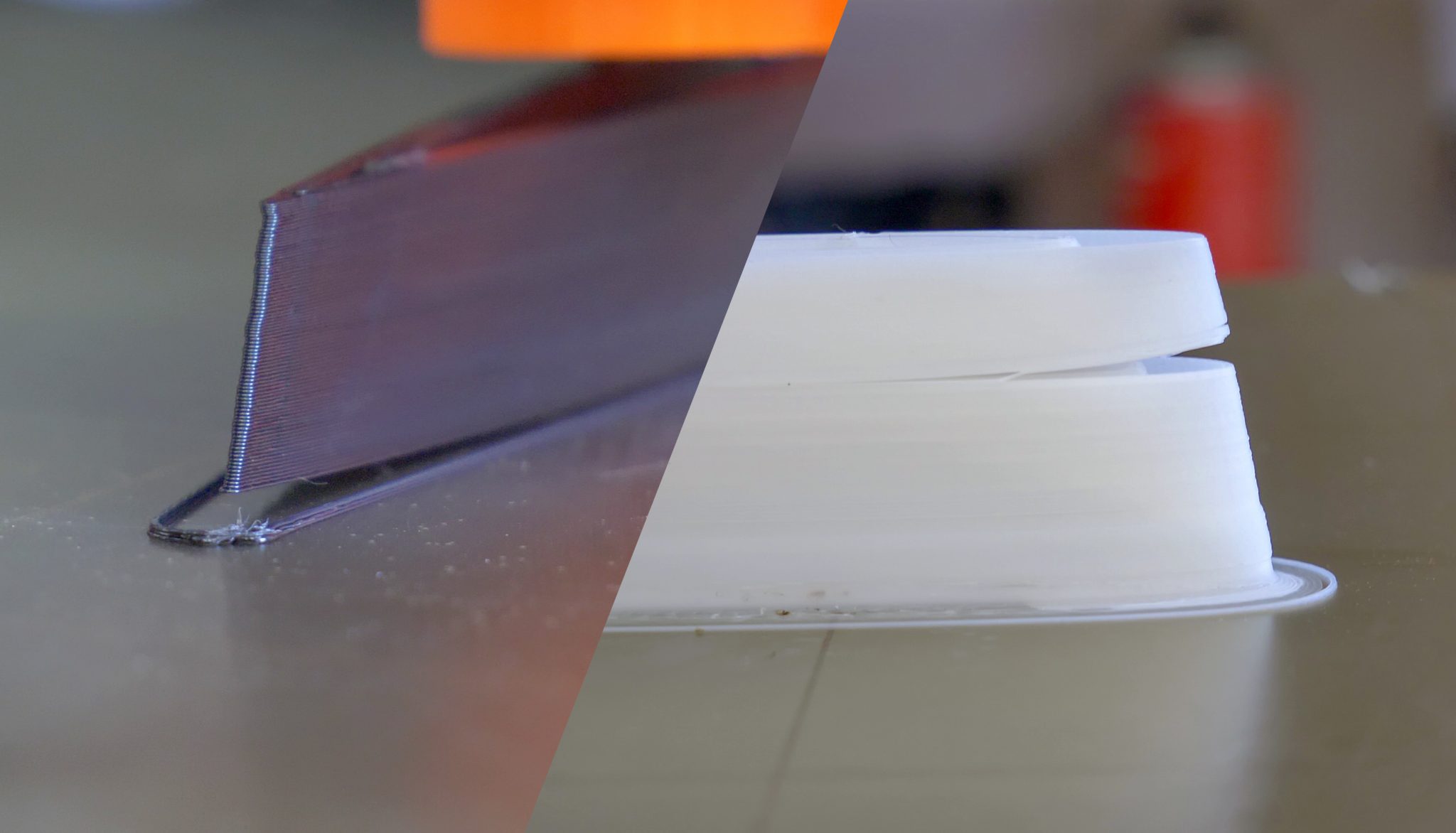

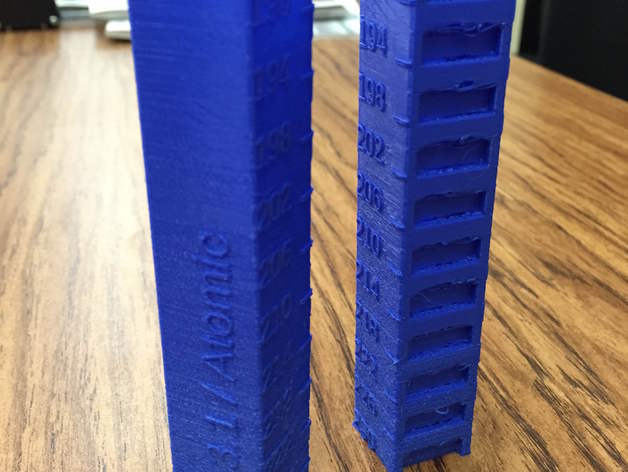

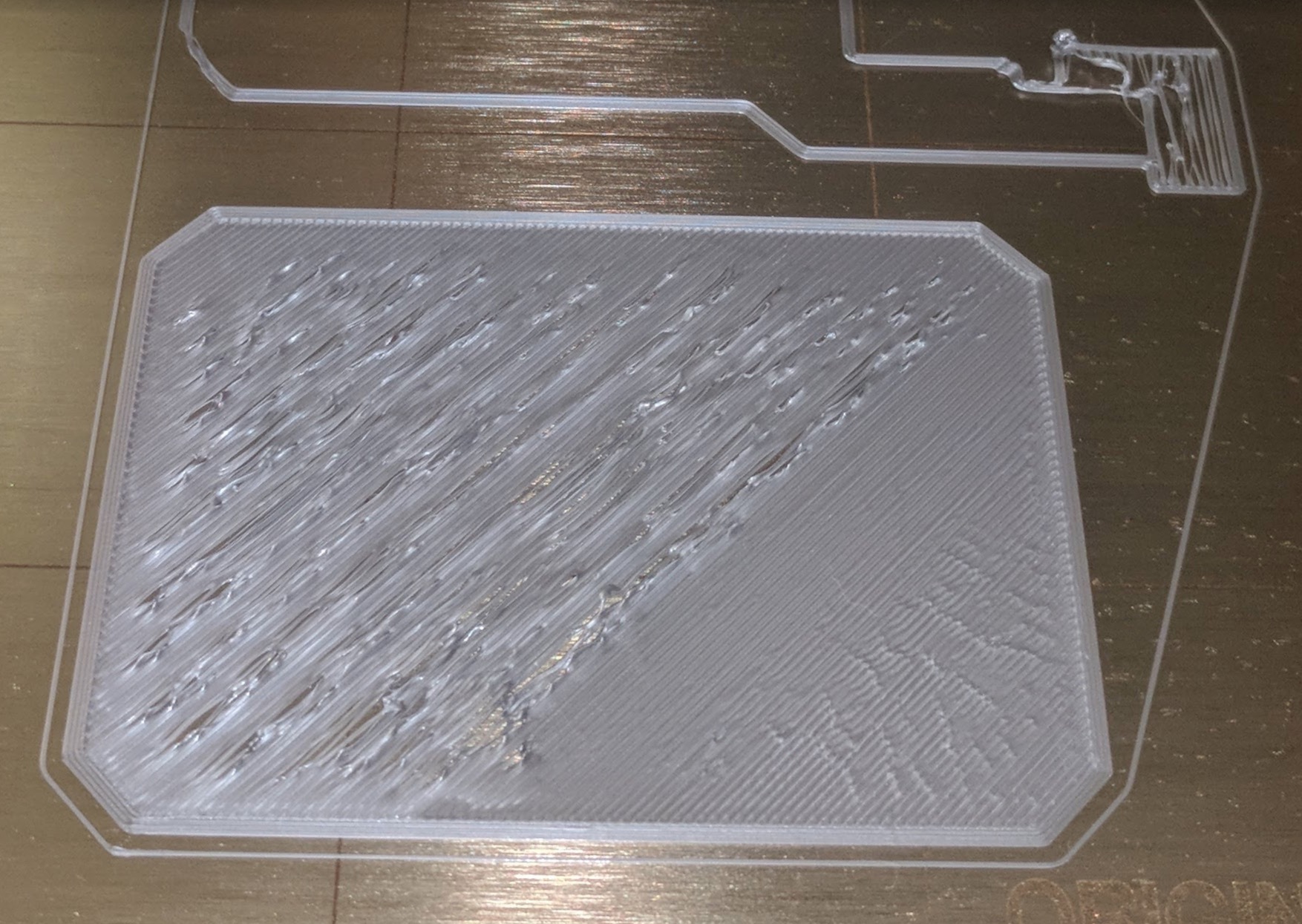

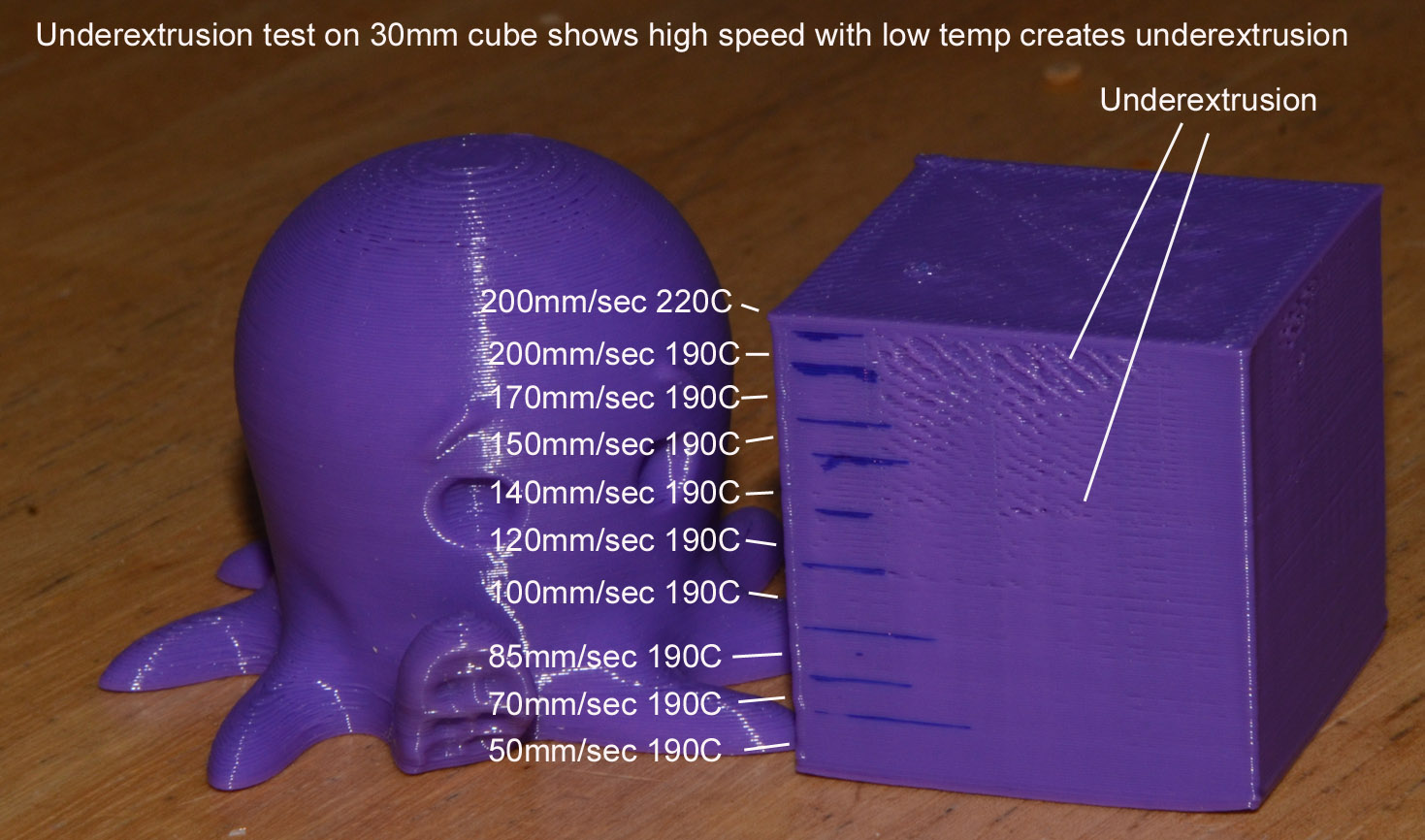

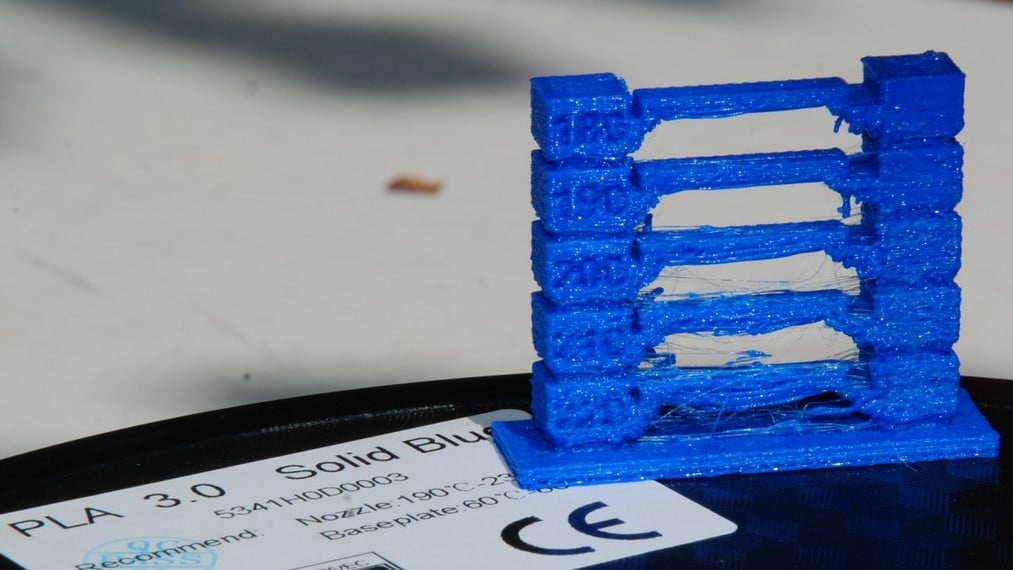

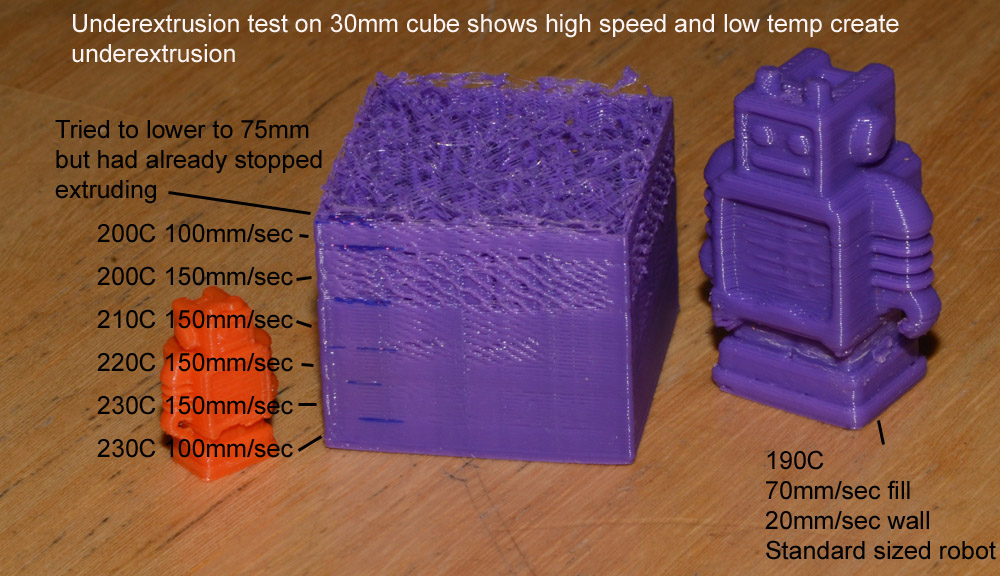

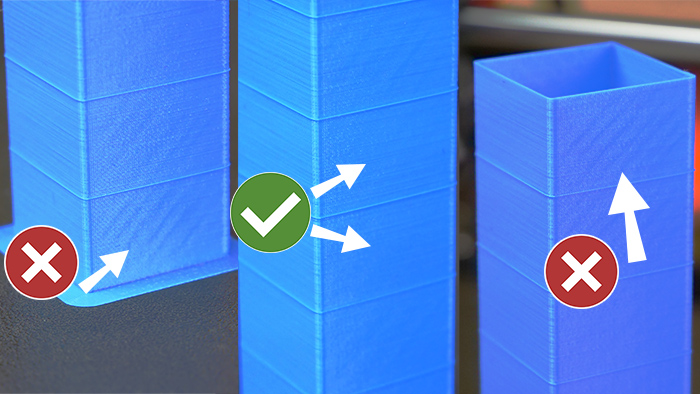

The tower is designed with separate blocks created at different heights. Its important to use a temperature close to what you normally use for printing. The best way to find out the temperature for printing is by 3d printing a temperature tower. For a successful extruder calibration the hotend needs to be set at the correct temperature according to the filament used.

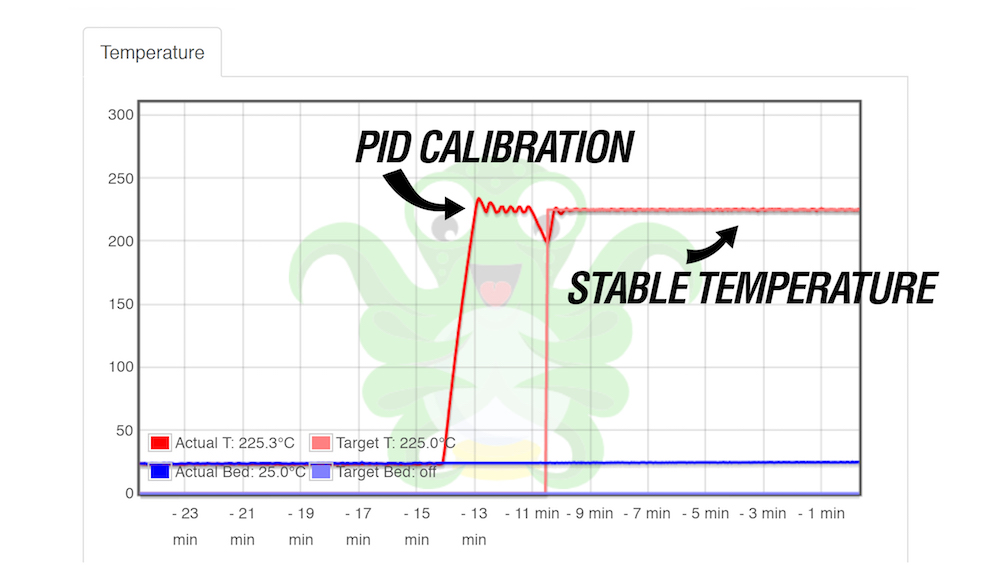

August 18 2020. Run the m303 e0 s215 c8 command and wait for the process to finish. In order to get the best quality prints its important to know the correct temperature to print each filament at. 3d printer temperature calibration.

Now that we have the 3d printer connected to the computer we can start the hotend pid calibration. Get the current pid settings using the m503command. Hence it is a necessary step when setting the filament for printing.