3d Printed Injection Molds Cost

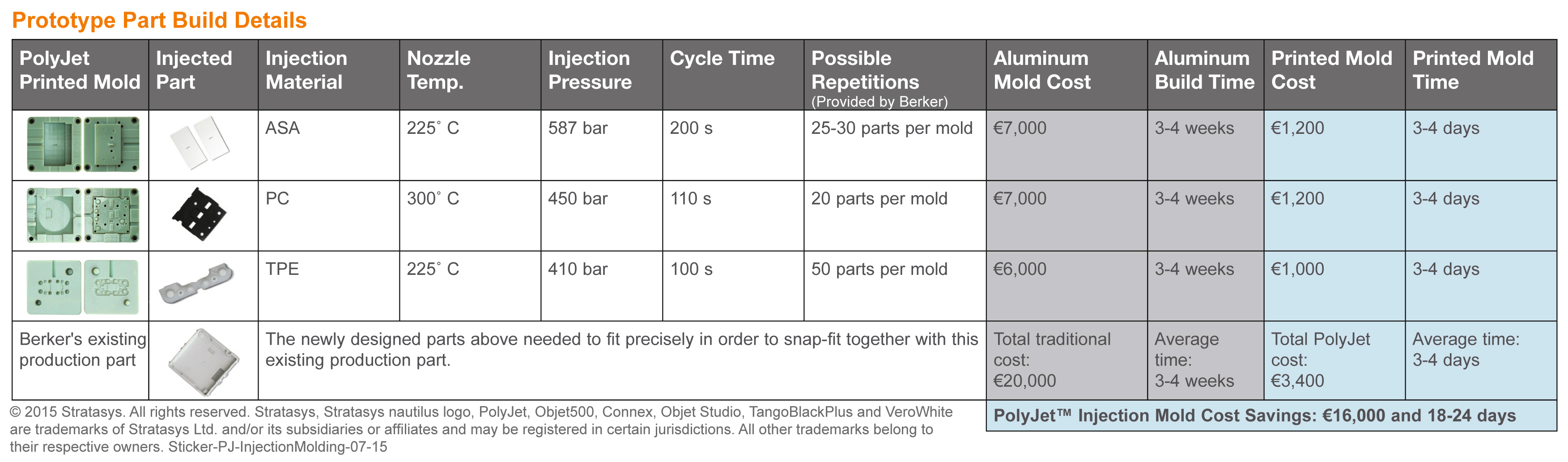

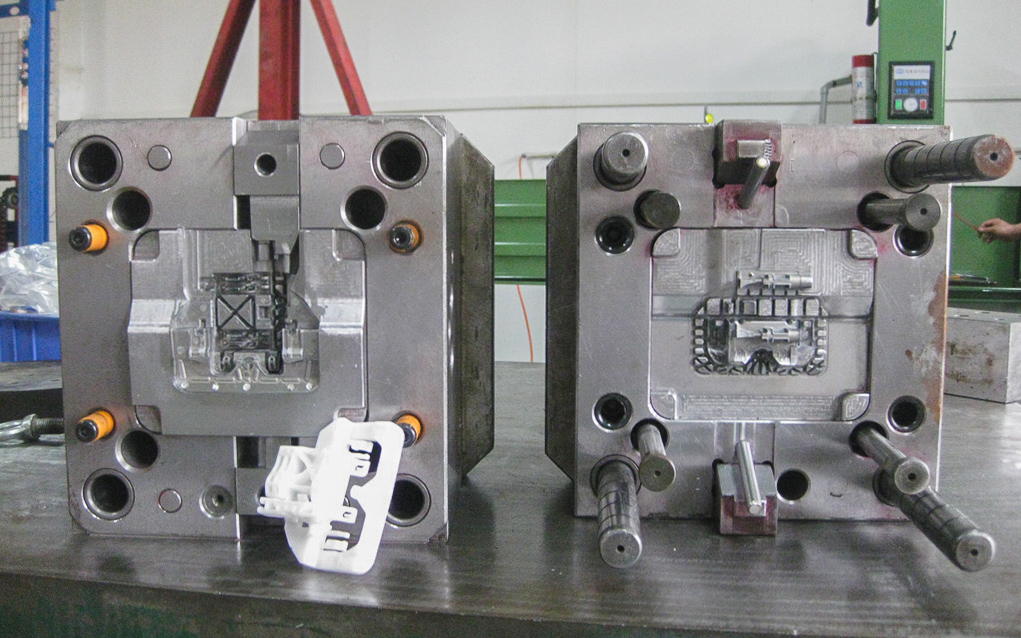

These costs can range between 10000 and 100000 and are associated mainly with the very high requirements in designing engineering and manufacturing the injection molding dies.

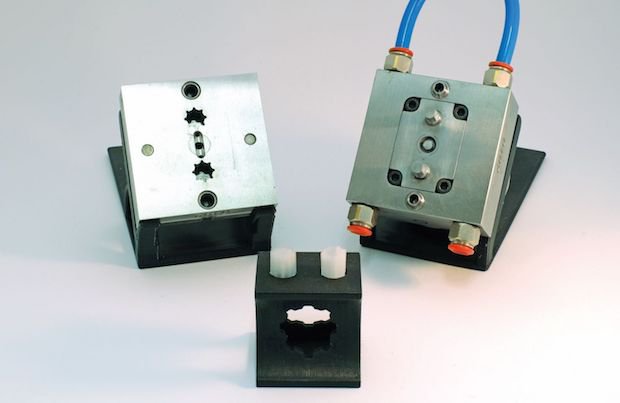

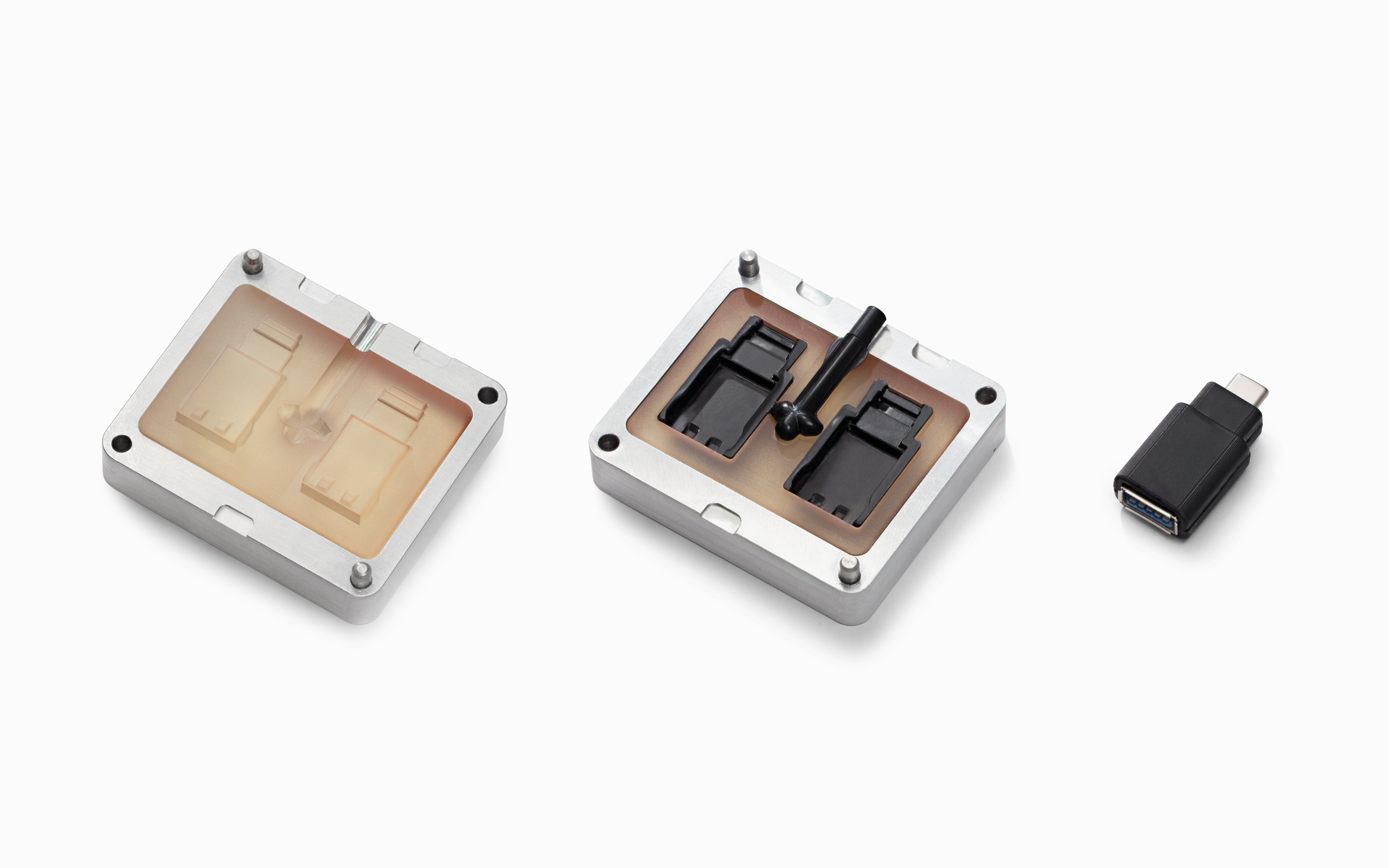

3d printed injection molds cost. Whale cuts lead time by 97 with 3d printed injection molds are reporting. Companies such as seuffer video. However there are upfront costs when generating conformal cooling channels using 3d printing for example access to a 3d. Streamlining injection molding with 3d printed tools milacron video.

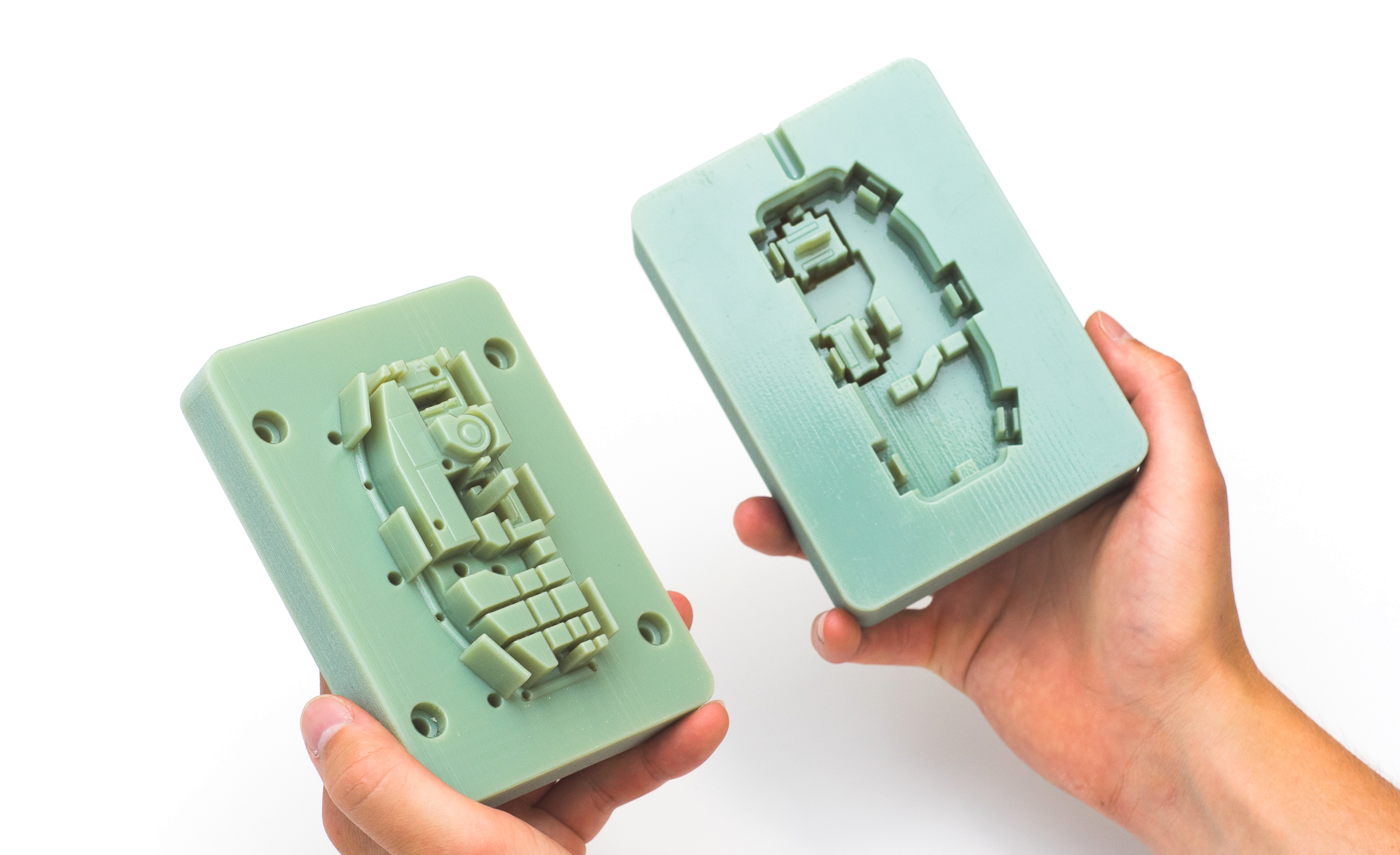

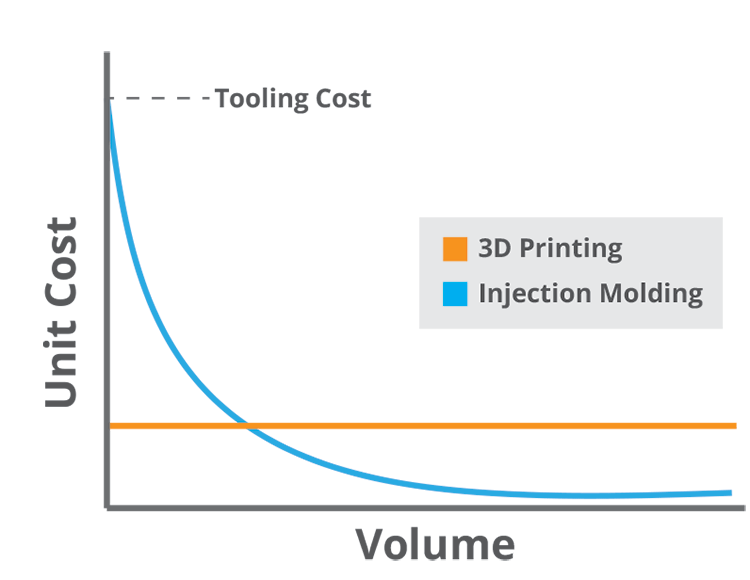

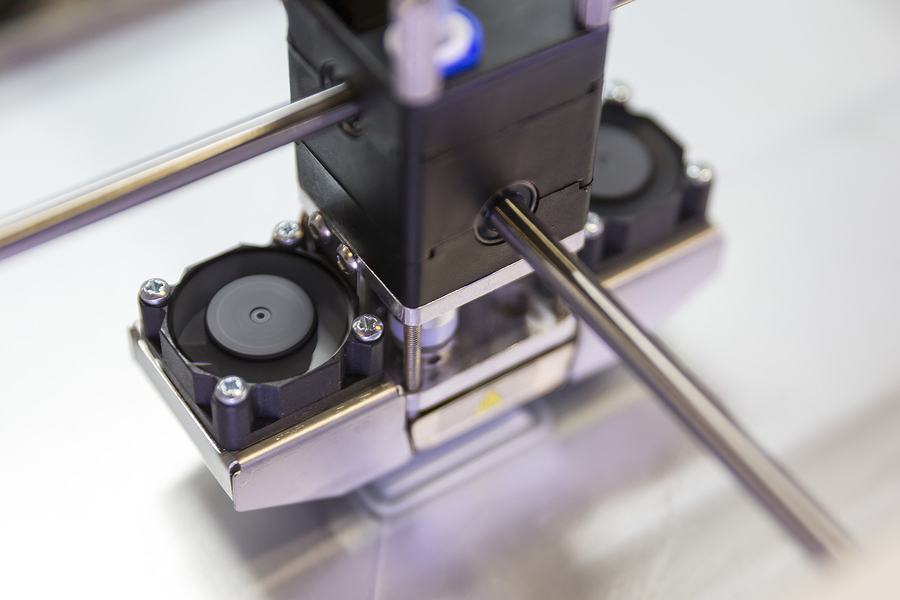

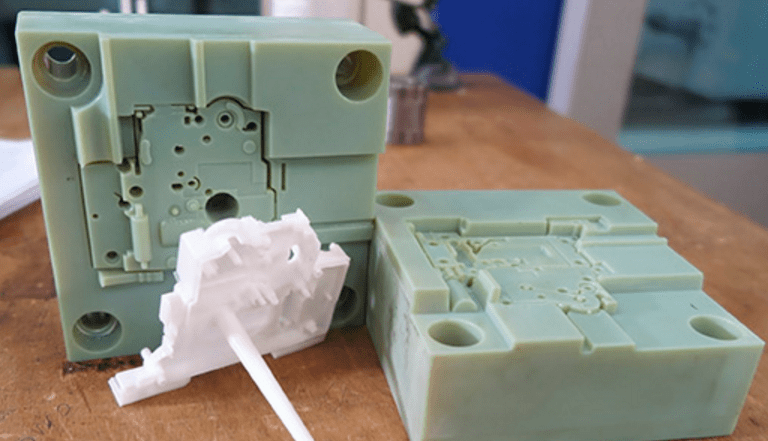

Because of this injection molding is typically only used to produce very high volumes of identical parts at a low cost. This is great as long as you have the 250000 3d printer they used and the injection molding machine. Other reasons 3d printing might be chosen for mold production include the short turnaround time. One of the most dramatic impacts that 3d printing is having on design and manufacturing is in injection molding.

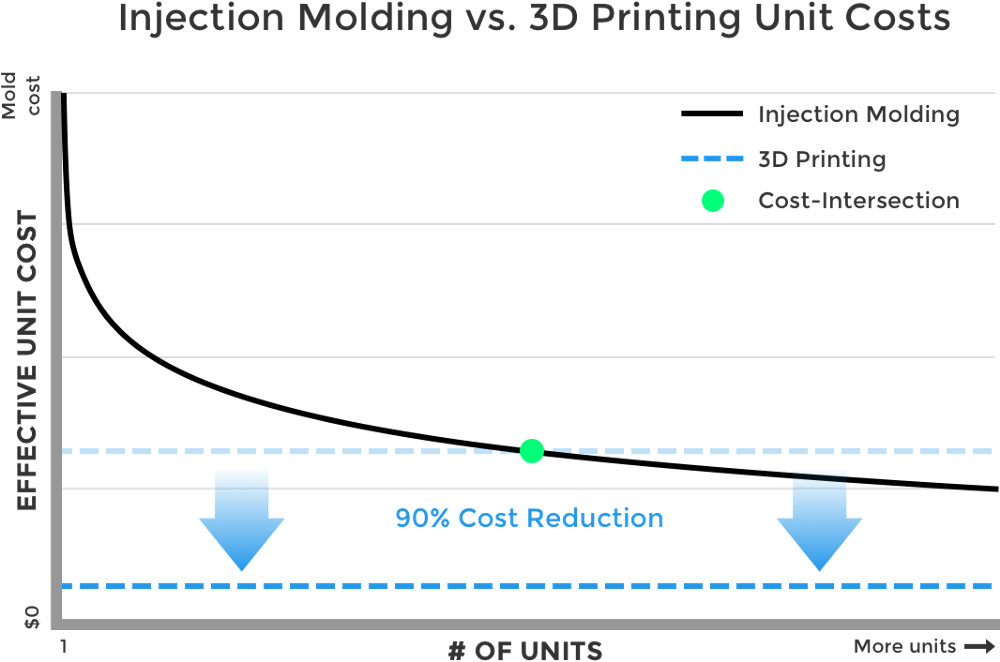

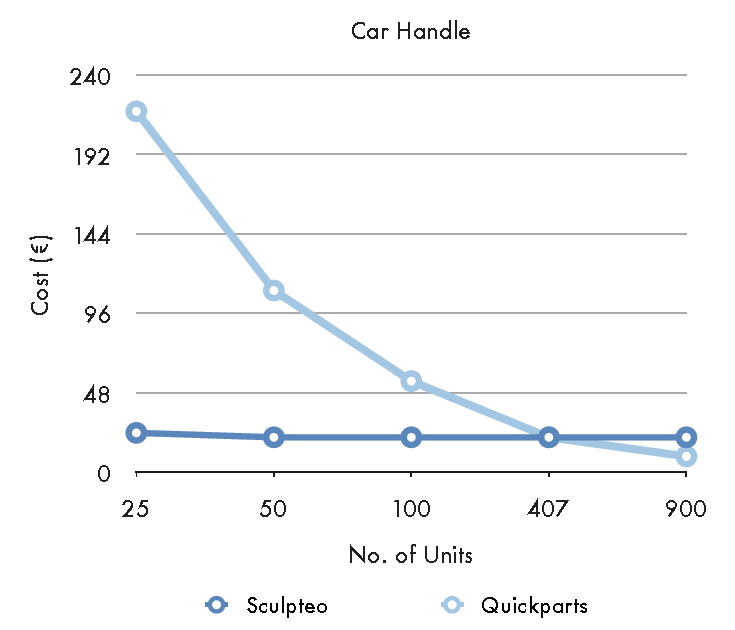

The results are clear at around quantity 250 it makes sense to start considering injection molding for a project with this geometry with scaling that quickly goes to dollars a unit. Aluminum molds at protolabs start around 1500 and are ready to go. With new 3d technology like the formlabs fuse 1 there are a variety of options availible for small batch production needs that help manufacturers save on cost per parthowever in some cases injection molding is still ideal for scaling production needs. The bottom line is the use of proper conformal cooling channels in a steel plastic injection mold will produce better parts faster permitting the molder to be more competitive and make more money if the production run is long enough to recover the upfront costs.

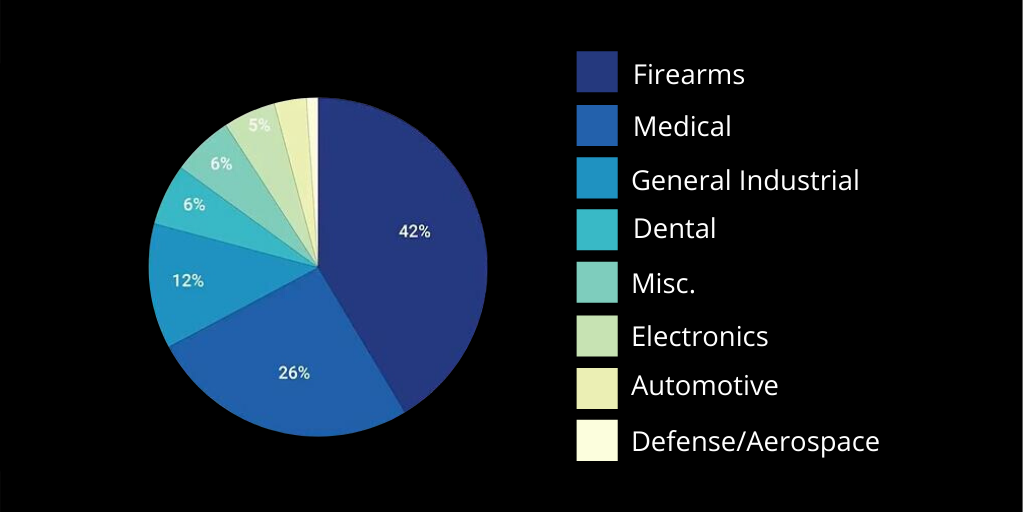

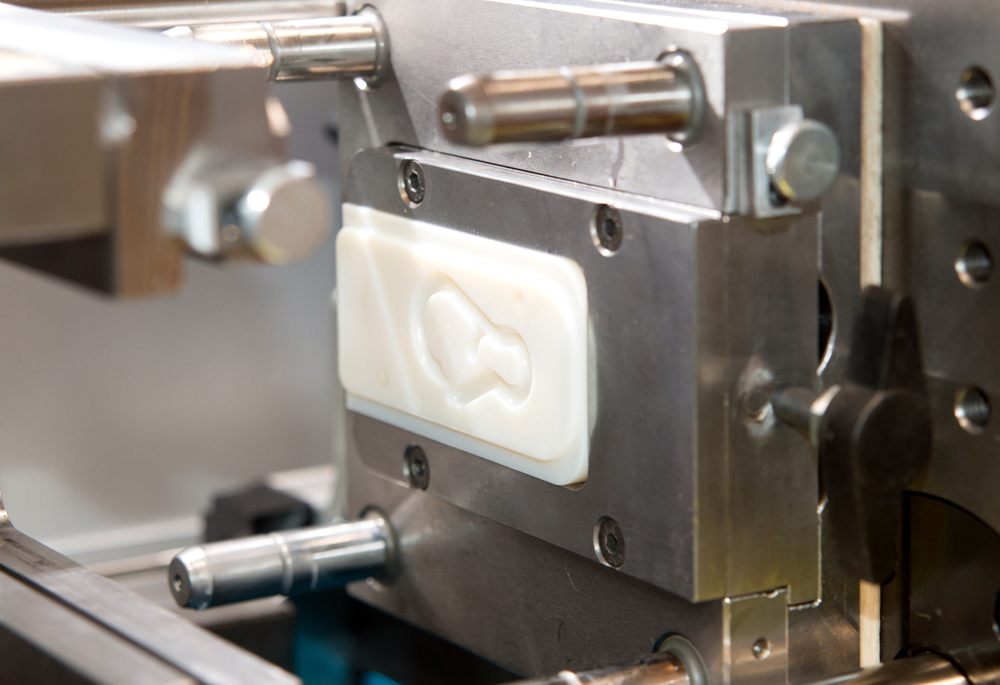

Its no secret that 3d printing is a great tool for affordable production of custom objects. Icomold provides plastic injection molding cnc machining of plastic and metal and urethane casting to customers worldwide in a variety of industries. It takes essentially the same skill to map the part itself in a cad software but 3d printing can print directly from the file and injection molding requires the creation of mold or tooling and then the injection process to create the piece. Any quantities from single prototypes to large on demand production runs.

Also the material used to print the mold is 1200 per 33 kg container. We offer low cost high quality custom plastic parts manufactured to your design with a very fast turnaround. Milacron shifts gears to 3d printed injection molds for rapid part prototyping and whale video. Cost estimates for printed molds are frequently material only and do not include labor for assembly and fitting ejector systems and miscellaneous hardware.