3d Printed Injection Molds

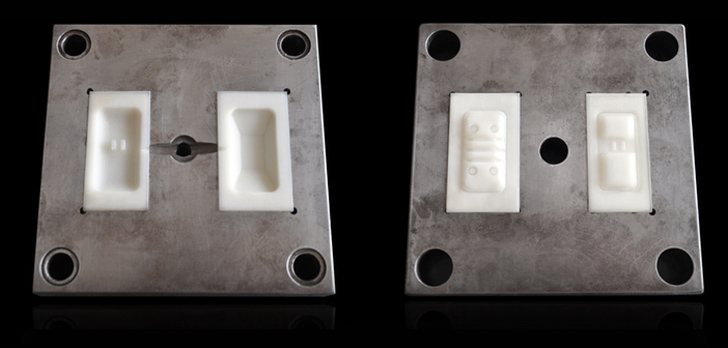

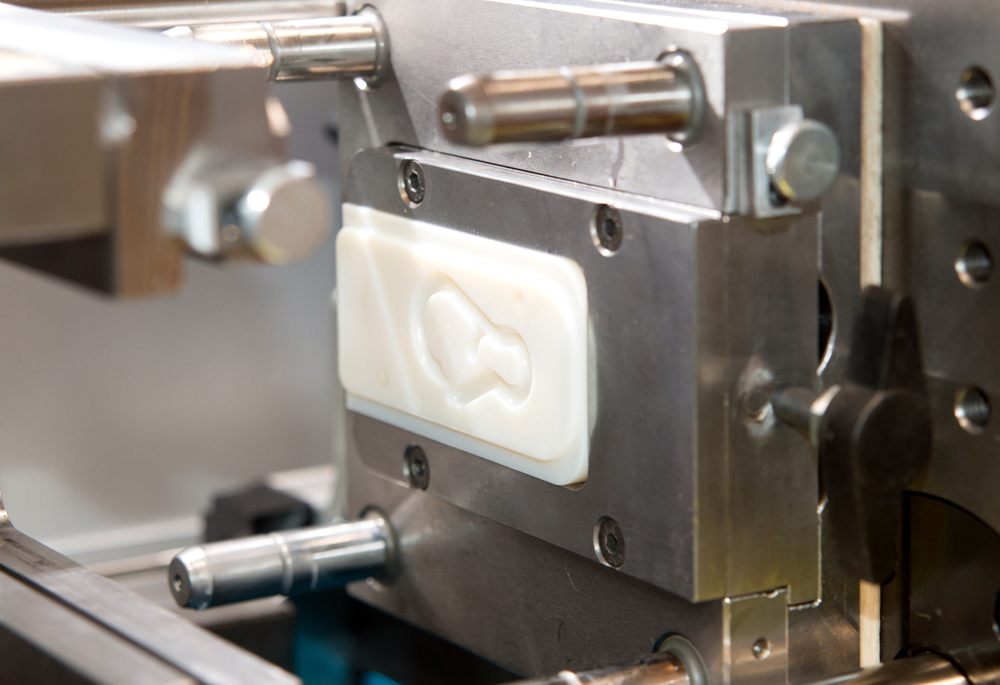

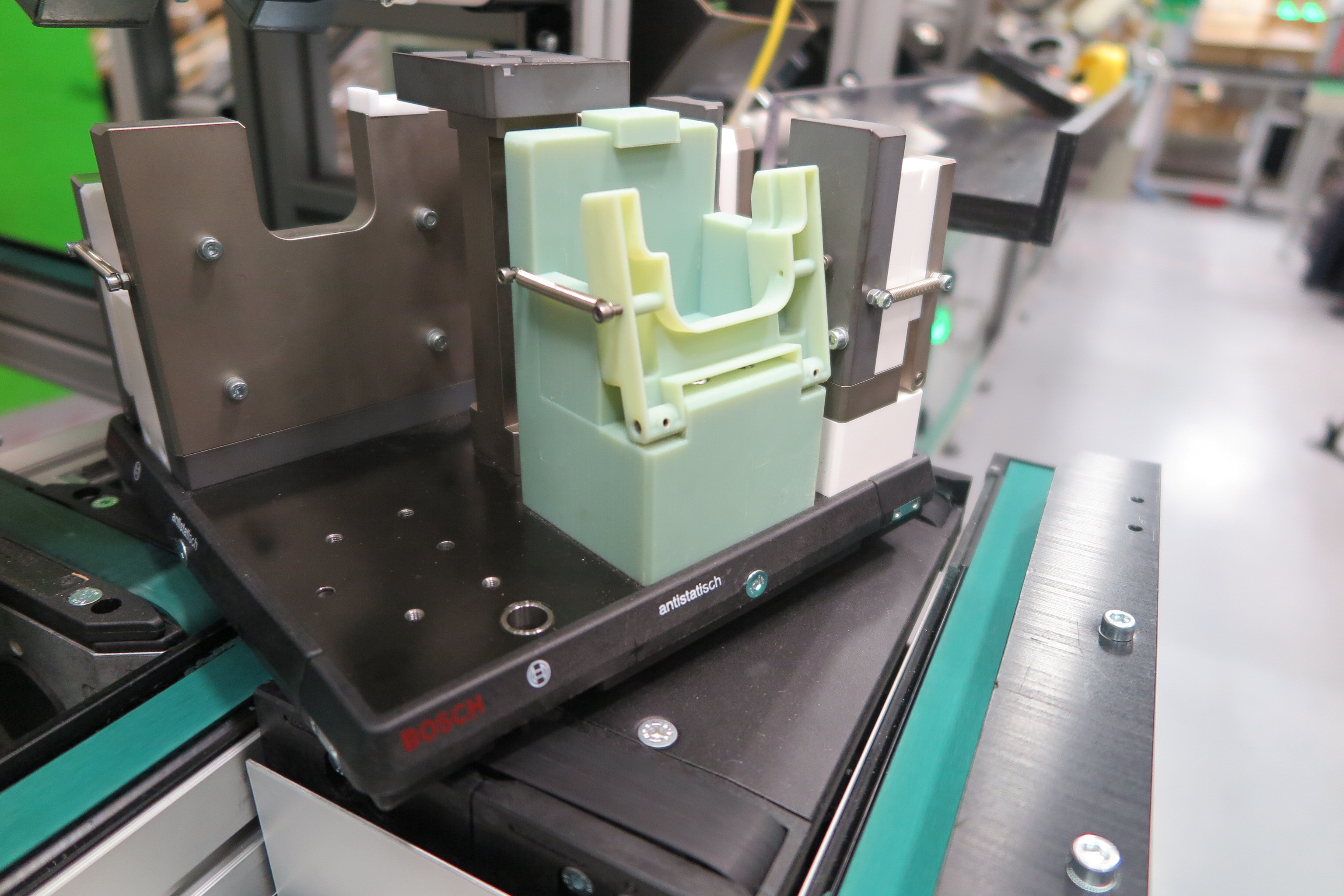

By 3d printing the injection molds with digital abs were able to achieve the high quality associated with traditional manufactured prototypes while ensuring that the high temperatures and pressures of the injection molding process.

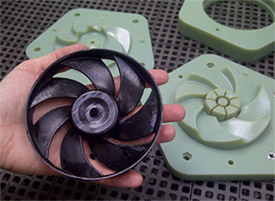

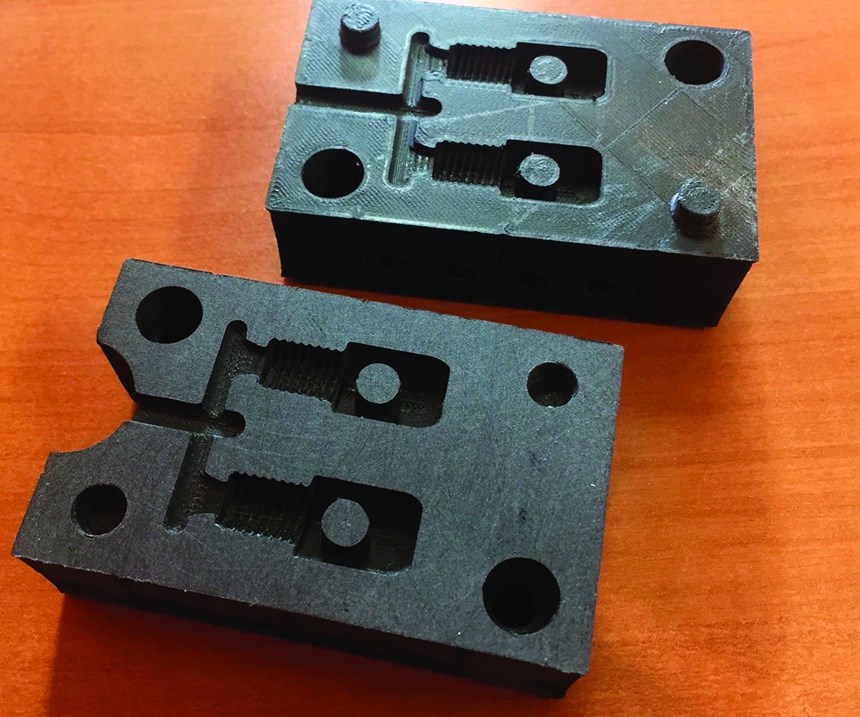

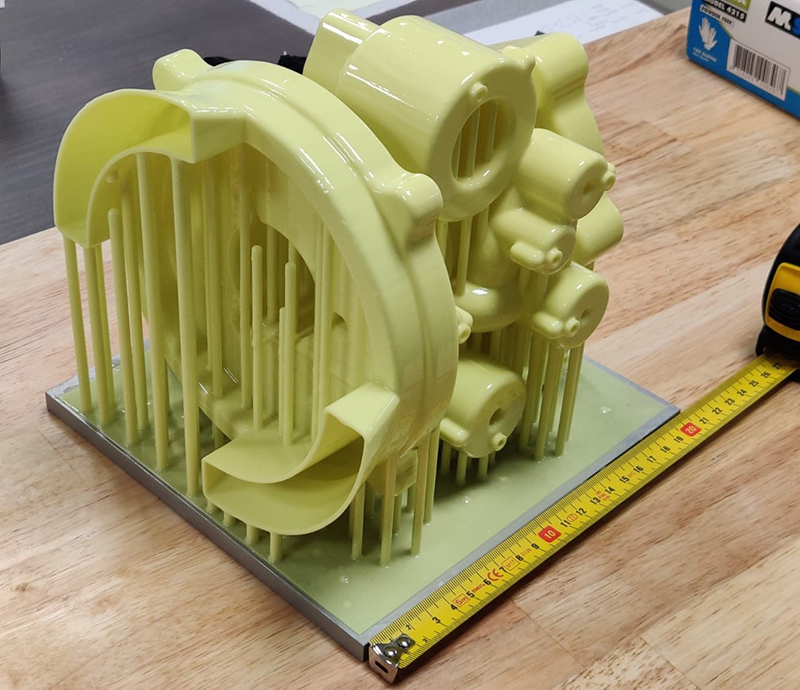

3d printed injection molds. Plastic injection molds cant be made in a minute or even in an hour. Use wide draft angles 2 o degrees or more and a release compound to increase the lifetime of the molds. 3d printing is smaller whereas injection molding machines are quieter and faster. Keep the part volume lower than 165 cm 3.

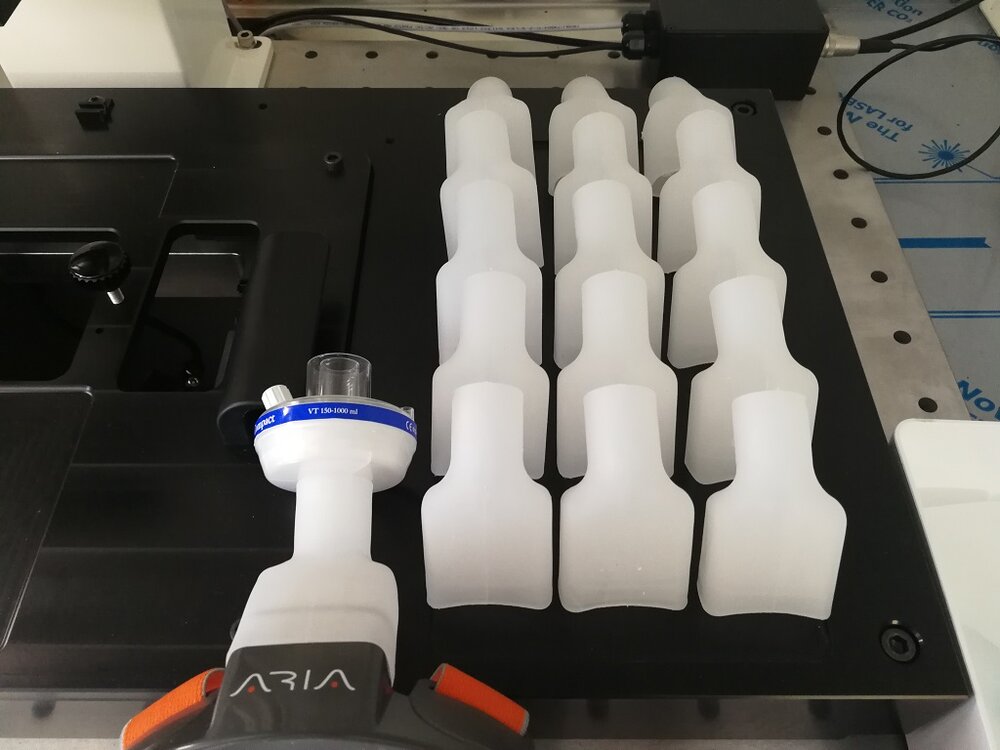

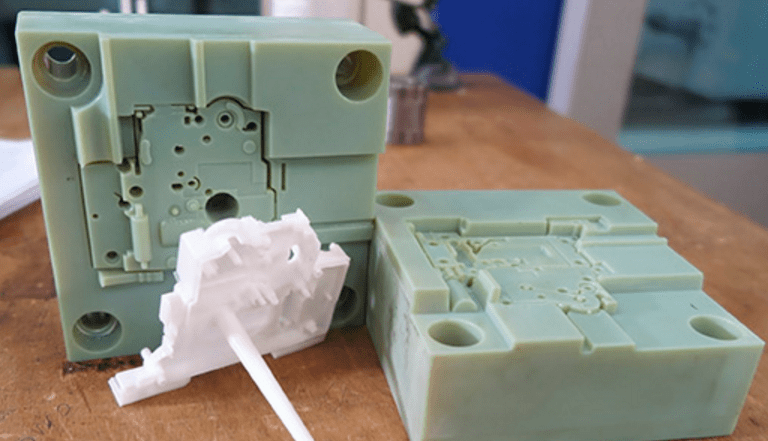

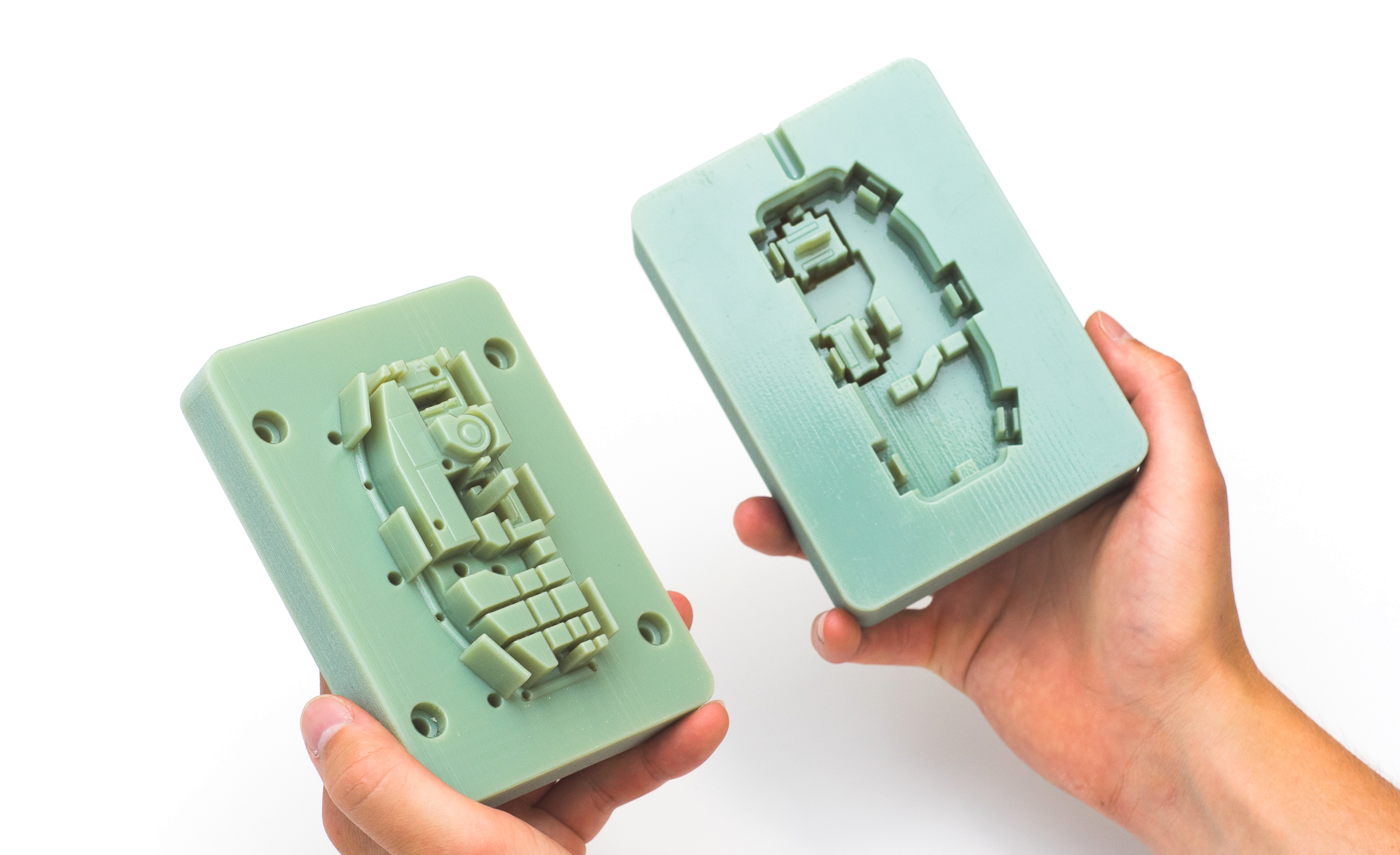

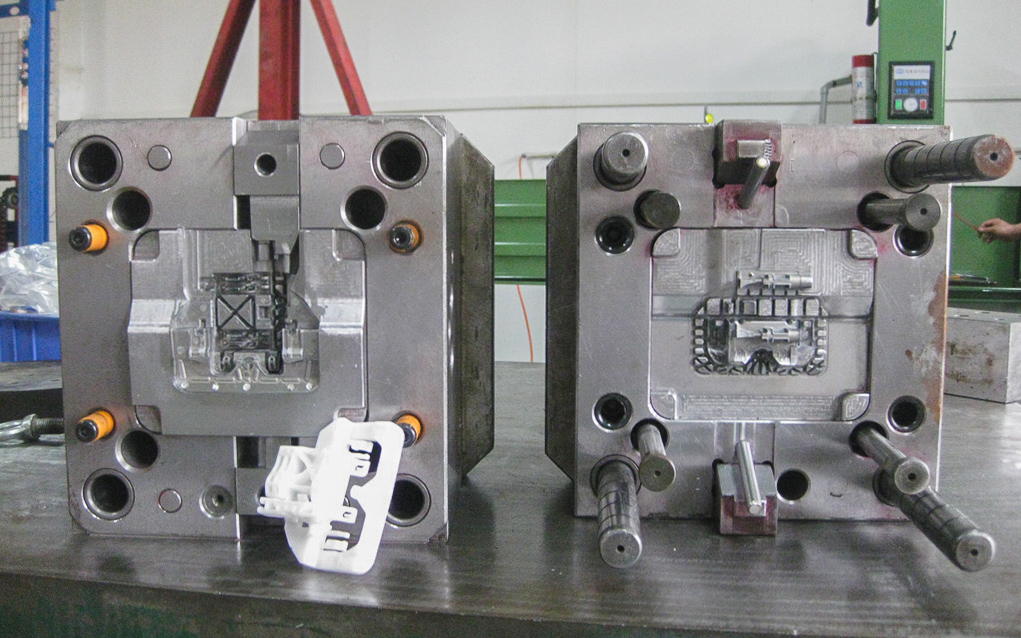

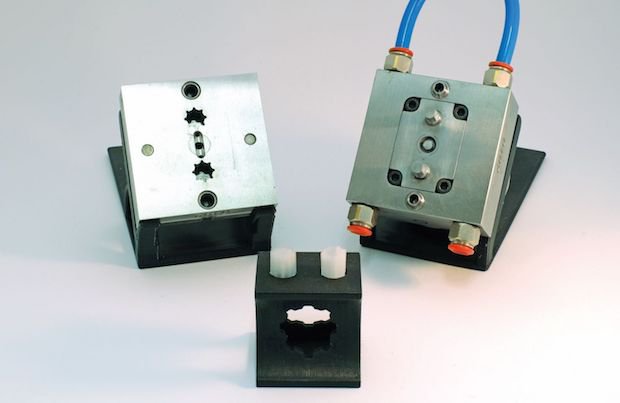

With affordable desktop 3d printers temperature resistant 3d printing materials and injection molding machines it is possible to create 3d printed injection molds in house to produce functional prototypes and small functional parts in production plastics. Formlabs also recently introduced a new 3d printing resinspecifically designed to withstand higher temperatures. 3d printing the injection molds is the most cost effective way for low run injection molding. The main differences between 3d printing vs injection molding are.

Thats great youre thinking but really. 3d printing is more expensive whereas injection molding is a cheaper variant for bigger produce. Injection molding is a highly demanding application for a 3d printed material as the molds have to withstand the processing forces at an elevated temperature and retain their dimensional accuracy over multiple runs. Fast turnaround times 1 2 week opposed to 5 7 weeks.

But they can be 3d printed in a day or so which is far faster than the weeks or even months most in the industry have come to expect. You can download the paper directly from their website here. With new 3d technology like the formlabs fuse 1 there are a variety of options availible for small batch production needs that help manufacturers save on cost per part. This can take the form of surface vents ejector pins and vent holes to name a few.

22 stratasys the 3d printing solutions company arad group 3d printed injection molding process injection process molded parts machine 50t arburg injection temperature 2600 c injection pressure 880 bar shot size 38 cubic cm switch over point 85 cubic cm packing pressure 200 bar. One way to compensate for this is to add in more ventilation than there otherwise would be in a steel tool. We recently collaborated with formlabson a technical paper they published detailing how their 3d printers can be used to make prototype injection molds. Low cost injection molding using 3d printing its no secret that 3d printing is a great tool for affordable production of custom objects.

3d printed molds are unable to withstand the kind of pressures that steel molds can endure.